Abstract

The purpose of the work is to analyze the structure of the environmental impact of energy willow cultivation (Salix spp.) on plantations of various sizes, divided per materials and processes. The research covered 15 willow plantations, ranging from 0.31 ha to 12 ha, located in southern Poland. It was found, among others, that the so-called processes, i.e. the use of technical means of production, dominate the structure of the environmental impact (EI) related to the cultivation of energy willow, and that the cultivation of energy willow on larger plantations has a much lower environmental impact compared to cultivation on smaller plantations. Also, in the case of the environmental impact of processes, the largest environmental impact was recorded in the human health category, which is mainly associated with the consumption of fuel, i.e. diesel. It was determined, e.g., that the cultivation of energetic willow on larger plantations is characterized by a much lower environmental impact (as per the cultivation area), at approx. 108 Pt, compared to the cultivation on smaller plantations, where the value of the environmental impact is 168 Pt. A decisively dominant position in the structure of the environmental impact (EI), related to the cultivation of energy willow, is held by the so-called processes, i.e. the use of technical means of production. Their share in the total environmental impact decreases from 148.5 Pt in the group of the smallest plantations to 77.9 Pt in the group of the largest plantations.

Similar content being viewed by others

Introduction

Growing concerns about climate change, geopolitical uncertainty associated with continuous energy supply, and increasing costs of fossil fuels motivate the search for clean and renewable conventional fuel substitutes1,2,3. One alternative to fossil fuels is the so-called bioenergy, the interest in which has increased significantly in recent years4. Bioenergy can be obtained from biomass used for the production of fuels, which in turn can be processed to obtain power, heat, and transport fuels5,6. As a source of renewable energy, biomass has enjoyed great interest for some time, also due to the postulates of the so-called sustainable energy management and the reduction of greenhouse gas emissions. The European Union has adopted several goals for the year 2020, e.g.: 20% reduction in greenhouse gas emissions, a 20% increase in energy efficiency, and reaching a 20% share of renewable energy in total energy produced7. Biomass for bioproducts and bioenergy can be obtained from forests, arable crops, various waste, and dedicated wood or herbaceous crops8,9. Work is currently underway on short rotation woody crops (SRWC) to provide a renewable raw material for bioenergy production10. SRWC, such as willow (Salix spp.), and poplar, are an important source of renewable energy and can be converted into electric power and/or heat using conventional or modern biomass processing technologies11.

SRWC is a fast-growing, high-yield energy plant that can not only be burned but also gasified to generate heat and energy11,12. There are about 450 varieties of willow globally13. This perennial energy plant is known for its high biomass yield in a short time and a broad genetic pool14. Moreover, willow shrubs are characterized by easy vegetative reproduction from dormant hardwood cuttings, easy cultivation, and the ability to regenerate after many harvests15,16. Its advantage is also that willow can be grown on arable land17.

According to Heller18, the production of biomass from willow plants requires the use of 0.018 MJ of non-renewable energy to produce 1 MJ of renewable energy in the form of wood fuel. In turn, the production of power from dedicated energy willow crops, 0.092 MJ of non-renewable energy is consumed per 1 MJ of generated power18. Many species of willow are a promising source of woody biomass, which can be very beneficial for the development of rural areas, apart from the environmental aspects19,20. Compared to annual cultivation systems, perennials, including willow are less susceptible to adverse weather conditions or epidemics of pests and diseases when it comes to crop yields21,22. The transformation of land into perennial bioenergy crops promotes the increase of some types of habitats of wild fauna and flora and reduces GHG emissions, depending on the nature and location of the plantation20,23. Moreover, it can contribute to soil organic carbon storage24 and in the short term, alleviate the effects of high CO2 concentrations25. Perennial willow plantations can effectively absorb groundwater and soil pollution and be used in land reclamation26. Agricultural biomass may be of interest for the purposes of energy production, especially in rural areas where end-users are in the vicinity of biomass farms. This would avoid problems with the transport of biomass, which generally has a low bulk density and low energy value in the unconcentrated state27. However, many researchers point out that, unfortunately, large-scale conversion of land to bioenergy production may have serious ecological effects28,29,30,31 because it affects wildlife habitats32 and competes for arable land with food crops33. The use of agricultural land for the production of raw material energy crops can have an indirect negative environmental effect. This is due to a significant intensification or expansion of agricultural production elsewhere to compensate for the lost food production34. Land conversion can also disrupt ecosystem cycles such as the hydrolog35, soil storage of organic carbon36,37,38,39,40, and nutritional cycles41,42. Potentially, changes in land use can also increase GHG emissions43,44,45. Due to some unfavorable aspects of the use of biomass, opinions are also voiced that the production of energy crops should be minimized and the focus should be on the available, yet unused biomass resources46. After all, the use of biomass as an energy source can cause emissions that are harmful to human health and the environment, both on a local and global scale47.

In recent years, the life cycle assessment (LCA), which is increasingly used to assess the potential environmental impact of production systems48,49,50, including the assessment of the environmental impact of energy crops, has enjoyed considerable interest22,51,52,53. In LCA, the potential environmental impacts associated with the product/service life cycle are assessed based on the life cycle inventory (LCI), which includes the relevant input and output data, as well as emissions included in the system associated with the product/service54. LCA goals can include (1) comparison of alternative products, processes, or services; (2) comparison of alternative life cycles for a specific product or service; (3) identifying parts of the life cycle in which major improvements can be made1. Taking into account the entire life cycle, the life cycle assessment (LCA) reduces the risk of transferring problems from one production phase to another55 and is based on ISO 14,040 and ISO 14,044 standards. Unfortunately, the knowledge of the life cycle of energy willow biomass production is still limited10,56. Literature resources offer studies on the use of the LCA methodology in renewable energy production, but in the case of energy willow, unfortunately, the amount of the studies is relatively small. In many cases, the available research results were published many years ago, which depreciates them due to technological progress. Moreover, there are very few up-to-date results regarding the environmental impact of the very process of willow cultivation, and the published research results very often relate to the processes of converting willow biomass into various forms of energy (power, liquid fuels, heat). Moreover, the methodology used in individual studies of various authors is very different in terms of system boundaries and methods used, which means that they are not always comparable.

Comparing the positive and negative aspects of biomass utilization, there is a need for a comprehensive assessment of the impact of both the technologies related to the energy willow biomass production cycle and those related to processing technology as an energy source.

The purpose of the work was to analyze the structure of the environmental impact of the cultivation of energy willow on plantations of various sizes, divided per production materials and processes (Table 1).

Materials and methods

Research subject

The amounts of materials and energy included in each process have been calculated based on research carried out on energy willow farms. The research consisted of a detailed analysis of technologies related to willow cultivation. The research covered15 energy willow plantations located in southern Poland. The selection of willow plantations was deliberate, i.e. five plantations with a relatively small area (0.48 ha on average) were selected as Group I, five larger, with an average area of 2.08 ha, were included in Group II and five largest (average area—8.06 ha)—in Group III.

General information on energy willow plantations selected for testing is presented in Table 2. The yield of fresh biomass cut after the first year of cultivation ranged from 6.8 t·ha-1 (in Group I) to 9.4 t·ha-1 (in Group II). Energy willow plantations were located relatively close to the farm (from 0.6 km to 1.4 km on average), which impacted the scope of transportation works.

Upon analyzing Fig. 1, it can be observed that willow plantations were located in areas with rather low soil quality. In Group I, 66% of the total plantation area was located on soils of the 4th and 5th class, and in Group III, up to 95%.

System boundaries

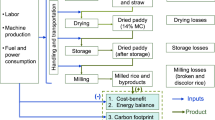

The system boundaries are shown in Fig. 2. The analysis covered only activities related to the establishment of the plantation, its cultivation for one year, as well as the collection and transport of cut biomass. The willow seedlings used were not included in the analysis, due to the lack of such an item in the catalogs of SimaPro software. Post-harvest operations related to the harvested biomass were also omitted. The analysis also excluded the transport of fuels, fertilizers, and pesticides from purchase points to the farm.

Impact assessment methodology

To assess the environmental impact of the cultivation of energy willow, the Life Cycle Assessment (LCA) method was used to determine the environmental relationships of all entrances and exits within the scope of the study, and to estimate the magnitude of their impact on the environment. The LCA method was applied using the SimaPro software, version 8.1.0.60. The detailed environmental impact assessment methods, ReCiPe Endpoint (H) V1.12/Europe ReCiPe H/A and ReCiPe Midpoint (H) V1.12/Europe Recipe H were used in the detailed calculations. The midpoint impact categories, the related indicators, and the key references were presented in Table 3. Endpoint indicators determine the environmental impact at three levels of aggregation, namely: (1) effect on human health (2) biodiversity, ecosystem and (3) resource scarcity. Environmental impact (EI) was calculated in the so-called units of general nuisance (Pt), used quite commonly in the LCA methodology, and related to one ton of fresh biomass yield and the cultivation area. The environmental impact of the use of production materials (materials) and the environmental impact of the use of technical means of production (processes) was estimated separately. The applied LCA methodology is based on the ISO 14,040 standard. The toxicity potential (TP), expressed in kg 1,4-dichlorobenzeneequivalents (1,4DCB-eq), is used as a characterization factor at the midpoint level for human toxicity, freshwater aquatic ecotoxicity, marine ecotoxicity and terrestrial ecotoxicity73.

Life cycle inventory (LCI)

Table 4 summarizes the means of production used in willow cultivation technologies for each of the groups. The amounts of the so-called pure fertilizer component expressed as N, P2O5, and K2, prove that mineral fertilizers were relatively rarely used and only in selected plantations of Groups II and III. In turn, the largest consumption of pesticides (3.42 kg·ha-1 on average) was recorded in the group of the smallest plantations. The used pesticide was mainly the herbicide Roundup, applied before planting to destroy weeds. The willow plantations were not artificially irrigated, and the water consumption presented in Table 4 was only associated with performing chemical plant protection treatments.

Results and discussion

Energy willow cultivation technologies were quite similar in all area groups. Preparation of the soil consisted of mechanical working, i.e. plowing, cultivating, and harrowing. Sometimes disking or tilling was also performed. The planting of the willow was done manually. Weeding was performed manually, or with tractor hoers. During the harvest, slat mowers were used only sporadically to cut willow, in the group of the larger plantations, while most often the harvesting was done manually, using pruning shears. The means of transport were used only partially during the harvesting as the harvested biomass was immediately loaded on trailers. The use of forestry harvesters could solve the problem to some degree as they could be relatively easily adjusted to biomass harvesting74. Transport of cut biomass and means of production, e.g. fertilizers or seedlings, was carried out using agricultural tractors and trailers. The low level of mechanization of the works resulted mainly from small areas of willow plantations, which is confirmed by research by Kwaśniewski75. He reports that in southern Poland the willow plantations are usually of small acreage, and scattered from each other, which is a certain economic barrier to the use of mechanized technologies.

Table 5 presents the results of the ReCiPe Midpoint analysis in individual area groups. Generally, it can be stated that as the area increased, the unit impact of processes decreased in all the analyzed categories. In the case of materials, in 13 out of 18 categories, an increase in the characterization factors was observed as the plantation area increased.

Table 6 shows the results of the ReCiPe Midpoint analysis of the used production materials, as per crop area. Diesel fuel was consumed in all treatments, while mineral fertilizers, pesticides, and water were additionally used during fertilization and chemical protection treatments. Upon analyzing the environmental impact of the materials used, the decisive share of mineral fertilizers can be observed, although they were not heavily used due to the relatively good quality of the soil. Significant environmental impacts are also associated with the cultivation procedures and transportation. Although the only production material used in soil cultivation and transport was diesel fuel, the relatively high unit fuel consumption (in soil cultivation) and the high yield of willow biomass (in transport) result in a significantly high diesel fuel consumption and thus, a significant environmental impact.

Table 7 shows the results of the ReCiPe Midpoint analysis of the used technical means of production, as per crop area. Among all impact categories, the processes related to the use of transport take by far the dominant position. As already mentioned, this is due to the high yield of energy willow biomass and the applied harvesting technology, which required using means of transport and significantly increased their working time. Murphy7 identifies transport as one of the three key processes in the production chain with the greatest environmental impact of all considered categories. Processes requiring the use of soil cultivation machinery rank second in terms of environmental impact, which results from the significant labor intensity of soil cultivation.

Table 8 shows the results of the Midpoint environmental analysis of the fertilizers and pesticides only, as per crop area. Mineral fertilizer use is dominant in this impact category, although it was used less frequently than the pesticides (mainly herbicides, to control weeds). The highest amount of pesticides as per crop area was used in Group I, while the highest amount of fertilizers was used in Group II (Table 4). The use of fertilizers results in a climate change impact of 36,107 kg CO2-eq, while the use of pesticides results in half the amount of kg CO2-eq. According to Keoleian and Volk14, fertilizer use is responsible for 75% of GHG emissions caused by agricultural inputs associated with energy willow cultivation.

Table 9 and Fig. 3 present the level of CO2 emissions in area groups calculated per the calorific value of fresh weight of the harvested willow. It can be observed that a decisively higher emission level, approx. 221 kg CO2· GJ-1, occurs in the smallest plantations, and in the group of the largest plantations, it decreases to 121 kg CO2· GJ-1. The decisive share in emissions (from 79 to 95%) belongs to processes.

Energy willow cultivation doesn’t produce large CO2 emissions. Compared with the coal system, the combustion of just biomass pellets to generate 8,300 GWh of power can reduce global warming impacts by 7.9 million tons of CO2-eq, which is equivalent to an 85% reduction in GHG emissions, according to Wiloso et al.76. It should also be remembered that energy crops store CO2 in the soil and roots, which according to Yang and Tilman77 is a more important determinant in the climate change mitigation potential of biofuels than the above-ground biomass. According to Heller et al.78, power production from willow biomass is nearly GHG-neutral (40–50 kg CO2 eq./MWh of electric power produced).

Table 10 presents the environmental impact of the consumption of production materials used in the cultivation of energy willow as per the plantation area. The environmental impact of production materials was considered on three levels, namely: human health, ecosystems, and resources. In the case of chemical plant protection and mechanical weeding, the environmental impact associated with the use of production materials decreased as the group's area increased. This state of affairs results from a lower intensity of pesticide use per hectare of cultivation, which is confirmed by the data presented in Table 4, as well as from less frequent mechanical weeding operations on larger plantations (lower fuel consumption). Both chemical and mechanical procedures were not compensated in any way by the use of other methods of weed control in larger willow cultivation areas, which is reflected in the decrease in the fresh crop yield (Table 2). The environmental impact (EI) of material consumption is also quite unequivocal in the case of mineral fertilization, yet reversed: as the group area increases so does the EI, which is the result of increasing the unit consumption of fertilizers in the second group. In turn, in the group of the largest plantations, the doses of fertilizers per unit area were slightly lower than in Group II (Table 4), but higher power tractors were used for fertilization, which resulted in significantly higher fuel consumption. Plant life cycle research usually indicates fertilization as a treatment that generates the greatest environmental impact79. Other technological procedures are no longer so unequivocal in terms of environmental impact. The environmental impact associated with transportation is the highest in Group II and the lowest in Group III, which correlates with the transport distances shown in Table 1. In turn, the mechanical harvest was used only in the group of the largest plantations, hence the production materials (fuel) affected the environment in this group. Upon analyzing the structure of the environmental impact on three levels, i.e. human health, ecosystems, and resources (Table 10), it can be observed that for all technological procedures, except mineral fertilization, the structure is dominated by resources, which generally exceeds the value of other streams of environmental impact. Only in the case of mineral fertilization, the dominant impact is human health, which results from the properties of mineral fertilizers used. The level of environmental impact in the resources category ranges from 0.00 Pt for mineral fertilization in Group I and harvest in Groups I and II, to 7.54 Pt for soil preparation activities in Group I. The environmental impact level in terms of human health ranges from 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 5.94 Pt also for mineral fertilization in Group III. In turn, in the category of ecosystems, the magnitude of the environmental impact ranged between 0.00 Pt (mineral fertilization in Group I) to 2.60 Pt, also for activities related to mineral fertilization, but in Group III (Table 10).

Table 11 presents the environmental impact of applying technical means of production (processes) in the cultivation technologies of energy willow, as per the plantation area. The environmental impact of machines and devices was considered on three levels: human health, ecosystems, and resources, similar to the case of production materials. In the case of all technological activities except chemical plant protection, the environmental impact of the use of machines and devices in particular groups is shaped quite clearly. As the plantation area increases in groups, it decreases (soil preparation, mechanical treatment, transportation) or increases (mineral fertilization, harvest). In the case of chemical protection, mechanical cultivation, and transport—the environmental impact resulting from processes per hectare of plantation decreases as the area increases. This is primarily due to the number of procedures performed or the transport distance. In their research,Goglioa80 and Kowalczyk57 indicate the great importance of the distance of biomass transport in the aspect of environmental protection. When analyzing technological procedures related to mineral fertilization and harvesting, the lowest environmental impact of EI processes was recorded in the group of plantations with the smallest acreage, and the highest—in Group III. In Group I, no mineral fertilization was used, and the harvest was done manually, hence the lack of an environmental impact of the use of technical means of production. The lesser environmental impact of chemical plant protection in the largest plantation group, as compared to Group II, is due to the lesser number of chemical sprayings. Upon analyzing the structure of the environmental footprint related to processes (the use of machinery and equipment) on the said three levels, i.e. human health, ecosystems, and resources (Table 11), it can be observed that for all technological procedures, the structure is dominated by the human health category, which generally exceeds significantly the value of the other environmental impact streams. The level of the environmental impact of processes in the human health category ranges between 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 47.76 Pt for transportation in Group I. The impact level in terms of resources ranges from 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 43.93 Pt for transportation in Group I. In turn, the magnitude of environmental impact for the ecosystems category ranged between 0.00 Pt (mineral fertilization category in Group I) and harvest (Groups I and II) to 21.81 Pt for transportation in Group I.

Table 12 presents the environmental impact of the consumption of production materials used in energy willow cultivation technologies, as per fresh biomass yield. As in the previous tables, the analysis of the environmental impact was carried out in three categories: human health, ecosystem, and resources. The environmental impact of material consumption (per biomass yield) for individual technological procedures is almost identical as it is for the crop area unit (Table 4). Only in the case of transportation works, the environmental impact decreases very slightly along with the increase of plantation area in the group. Similarly to Table 11, the structure of the environmental impact was also determined in the following categories: human health, ecosystems, and resources. Due to a different reference unit (fresh willow biomass yield), the level of environmental impact in the resources category ranges from 0.00 Pt for mineral fertilization in Group I and harvest (Groups I and II), to 1.09 Pt for soil preparation activities in Group I. The magnitude of environmental impact in the category of human health ranges from 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 0.82 Pt also for mineral fertilization in Group III. In turn, in the category of ecosystems, the level of environmental impact ranged from 0.00 Pt (mineral fertilization in Group I) to 2.60 Pt, for activities related to mineral fertilization, but in Group III.

The environmental impact of the use of technical means of production (processes) in energy willow cultivation technologies, as per the fresh willow biomass yield, was presented in Table 13. Similarly to production materials, the environmental impact of processes was considered in three categories: human health, ecosystems, and resources. The dependence of the environmental impact on the use of machines and devices in individual plantation groups differs but slightly from the results analyzed in Table 11, the only exception being the chemical plant protection treatments. The structure of the environmental impact associated with processes (the use of machines and devices) on three levels: human health, ecosystems, and resources, is as in Table 11. The level of the environmental impact of processes in the category of human health ranges from 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 7.49 Pt for transportation in Group I. The level of environmental impact in the category of resources ranges from 0.00 Pt for mineral fertilization (Group I) and harvest (Groups I and II), to 6.89 Pt for transportation in Group I. In turn, in the category of ecosystems, the magnitude of the environmental impact ranged between 0.00 Pt (mineral fertilization category in Group I) and harvest (Groups I and II) to 3.42 Pt for transportation in Group I.

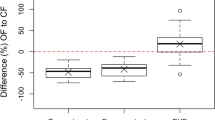

Table 14 and Fig. 4 present the unit total environmental impact (as per plantation area) related to the energy willow cultivation technology, broken down into the impact of materials and processes. The total environmental impact in Groups I and II is very similar and amounts to 168 Pt and 164 Pt. The total environmental impact in the group of the largest plantations is the most favorable and amounts to only 108 Pt. To compare, the environmental impact in potato cultivation, estimated using the same methodology, is approx. 280 Pt48. Upon analyzing the results in Fig. 4, one observes a much greater environmental impact of processes, i.e. the use of machinery and tools, than of production materials. The processes in Group I affect 88% of the total environmental impact; in Group II it is 84%, and in the group of the largest plantations—72%. Materials, in turn, decide on the level of the total environmental impact, from 12% in Group I, to 16% in Group II, to 28% in the group of plantations with the largest area. Thus, a clear tendency of the impact of processes/materials on the overall environmental impact to increase/decrease can be observed along with the increase in the plantation area.

Table 15 and Fig. 5 show the structure of the unit total environmental impact (as per fresh biomass yield) related to the energy willow cultivation technology in individual area groups. This structure, similar to Fig. 4, relates to the interaction of materials and processes. The total environmental impact is at a completely different level than that observed in Fig. 4 (as per plantation area) and is calculated per yield of fresh willow biomass, from 14 Pt in the smallest plantation group to 18 Pt in the middle group and 26 Pt in the largest plantation group. Undoubtedly, the shaping of the above values is affected by biomass yields in individual groups. The results of the Endpoint analysis for particular area groups are consistent with the results of the Midpoint analysis, i.e. a lower environmental impact, both for the growing area and the biomass yield is observed in the cultivation of energy willow on large plantations. This state of affairs results, among other things, from better organization of work, especially related to the use of means of transport, which is evidenced by the results in Tables 14 and 15.

Conclusions and the further research

Based on the conducted research, it was found that:

-

1.

A decisively dominant position in the structure of the environmental impact (EI), related to the cultivation of energy willow, is held by the so-called processes, i.e. the use of technical means of production. Their share in the total environmental impact decreases from 148.5 Pt in the group of the smallest plantations, to 77.9 Pt in the group of the largest plantations. This state of affairs should prompt energy willow biomass producers to simplify the cultivation and reduce the number of technological treatments applied.

-

2.

The cultivation of energetic willow on larger plantations is characterized by a much lower environmental impact (as per the cultivation area), at approx. 108 Pt, compared to the cultivation on smaller plantations, where the value of the environmental impact is 168 Pt. This is due to, e.g. a certain simplification of production technology, as well as a reduction in the use of production materials (fertilizers, pesticides). Unfortunately, these adversely affect the volume of the harvested biomass.

-

3.

In the structure of the environmental impact of production materials used in the cultivation of energy willow, the dominant position (from 57% in Group III to 70% in Group I) is held by the category of resources. Its size depends largely on the level of diesel fuel consumption, i.e. the number of harvest runs and the technical equipment’s level of advancement.

-

4.

In the case of the environmental impact of processes (the use of technical means of production), the largest percentage, approx. 42%, was observed in the human health category, which is also mainly associated with the consumption of fuel, i.e. diesel.

-

5.

The unfavorable impact of production materials applies to the greatest extent to soil preparation and slightly less to mineral fertilization, which once again points to diesel oil as a means of production that is particularly important in the aspect of environmental protection. It is also an argument for the expediency of seeking alternative fuels, the use of which will significantly contribute to environmental protection.

-

6.

Further study of energy willow in subsequent years of cultivation is necessary to better understand its environmental impact and to balance the possible environmental benefits of producing various types of energy and heat from biomass. Further research will include a life cycle analysis on various willow biomass conversion technologies. An economic analysis of biofuel production in terms of the environmental impact of production will also be conducted.

References

Roy, P., Tokuyasu, K., Orikasa, T., Nakamura, N. & Shiixa, T. A Review of life cycle assessment (LCA) of bioethanol from lignocellulosic biomass. JARQ 46, 41–57 (2012).

Palmer, M. M., Forrester, J. A., Rothstein, D. E. & Mladenoff, D. J. Establishment phase greenhouse gas emissions in short rotation woody biomass plantations in the Northern Lake States, USA. Biomass Bioenergy 62, 26–36 (2014).

González-García, S., Iribarren, D., Susmozas, A., Dufour, J. & Murphy, R. J. Life cycle assessment of two alternative bioenergy systems involving Salix spp. biomass: bioethanol production and power generation. Appl. Energy 95, 111–122 (2012).

Mizsey, P. & Racz, P. Cleaner production alternatives: biomass utilisation options. J. Clean. Prod. 18, 767–770 (2010).

Igliński, B., Cichosz, M., Skrzatek, M. & Buczkowski, R. Potencjał energetyczny biomasy na gruntach ugorowanych i nieużytkach w Polsce. Inżynieria i Ochrona Środowiska 21, 79–87 (2018).

Stolarski, M., Szczukowski, S. & Tworkowski, J. Biopaliwa z biomasy wieloletnich roślin energetycznych. Energetyka 1, 77–80 (2008).

Murphy, F., Devlin, G. & McDonnell, K. Energy requirements and environmental impacts associated with the production of short rotation willow (Salix sp.) chip in Ireland. GCB Bioenergy 6, 727–739 (2014).

El Bassam, N. Handboook for Bioenergy Crops. Earthscan, London, 544 (2010).

Eisenbies, M. H., Volk, T. A., Posselius, J., Foster, Ch. & Shi, S. Evaluation of a single-pass, cut and chip harvest system on commercial-scale, short-rotation shrub willow biomass crops. BioEnergy Res. 7(4), 1506–1518 (2014).

Nathan, J., Sleight, N. & Volk, T. A. Recently Bred Willow (Salix spp.) Biomass crops show stable yield trends over three rotations at two sites. BioEnergy Res. 9, 782–797 (2016).

Djomo, S. N., Kasmioui, O. E. & Ceulemans, R. Energy and greenhouse gas balance of bioenergy production from poplar and willow: a review. GCB Bioenergy 3(3), 181–197 (2011).

Hammar, T., Ericsson, N., Sundberg, C. & Hansson, P. A. Climate impact of willow grown for bioenergy in Sweden. BioEnergy Res. 7, 1529–1540 (2014).

Argus, G. W. Infrageneric classification of Salix (Salicaceae) in the new world. Syst. Bot. Monogr. 52, 101–121 (1997).

Keoleian, G. A. & Volk, T. A. Renewable energy from willow biomass crops: life cycle energy, environmental, and economic performance. Crit. Rev. Plant Sci. 24, 385–406 (2005).

Christersson, L., Sennerby-Forsse, L. & Zsuffa, L. The role and significance of woody biomass plantations in Swedish agriculture. For. Chron. 69, 687–693 (1993).

Schroeder, W., Kort, J., Savoie, P. & Preto, F. Biomass harvest from natural willow rings around prairie wetlands. BioEnergy Res. 2, 99–105 (2009).

Abrahamson, L. P., Volk, T. A. & Smart, L. P. Shrub Willow Producers Handbook (SUNY-ESF, Syracuse, 2010).

Heller, M. C., Keoleian, G. A. & Volk, T. A. Life cycle assessment of a willow bioenergy cropping system. Biomass Bioenerg. 25, 147–165 (2003).

Volk, T. A., Verwijst, T., Tharakan, P. J., Abrahamson, L. P. & White, E. H. Growing fuel: a sustainability assessment of willow biomass crops. Front. Ecol. Evol. 2(8), 411–418 (2004).

Rowe, R. L., Street, N. R. & Taylor, G. Identifying potential environmental impacts of large-scale deployment of dedicated bioenergy crops in the UK. Renew. Sustain. Energy Rev. 13, 271–290 (2009).

Lippke, B. et al. Comparing life-cycle carbon and energy impacts for biofuel, wood product, and forest management alternatives. Forest Prod. J. 62, 247–257 (2012).

Caputo, J. et al. Incorporating uncertainty into a life cycle assessment (LCA) model of short-rotation willow biomass (Salix spp) crops. BioEnergy Res. 7(1), 48–59 (2014).

Davis, S. C. et al. Impact of second-generation biofuel agriculture on greenhouse-gas emissions in the corngrowing regions of the US. Front. Ecol. Environ. 10, 69–74 (2012).

Arevalo, C. B. M., Bhatti, J. S., Chang, S. X. & Skidders, D. Land use change effects on ecosystem carbon balance: from agricultural to hybrid poplar plantation. Agric. Ecosyst. Environ. 141, 342–349 (2011).

Pietrzykowski, M. et al. Carbon sink potential and allocation in above-and below-ground biomass in willow coppice. J. For. Res. https://doi.org/10.1007/s11676-019-01089-3 (2020).

Langholtz, M. et al. Economic comparative advantage of willow biomass in the Northeast USA. Biofuels Bioprod. Biorefin. 13(1), 74–85 (2019).

Kimming, M. et al. Biomass from agriculture in small-scale combined heat and power plants. Comp. Life Cycle Assess. Biomass Bioenergy 35, 1572–1581 (2011).

Fargione, J. E., Plevin, R. J. & Hill, J. D. The ecological impact of biofuels. Annu. Rev. Ecol. Evol. 41, 351–377 (2010).

Zhao, F., Wu, J., Wang, L., Liu, S., Wei, X., Xiao, J., Qiu, L., & Sun, P. Multi-environmental impacts of biofuel production in the US Corn Belt: a coupled hydro-biogeochemical modeling approach. J. Clea. Prod. 251, 119561, ISSN 0959-6526 (2020).

Wu, Y., Liu, S. & Li, Z. Identifying potential areas for biofuel production and evaluating the environmental effects: a case study of the James River Basin in the Midwestern United States. Glob. Change Biol. Bioenergy 4, 875–888 (2012).

Wu, Y. et al. Bioenergy production and environmental impacts. Geosci. Lett. 5, 14 (2018).

Meehan, T. D., Hurlbert, A. H. & Gratton, C. Bird communities in future bioenergy landscapes of the Upper Midwest. Proc. Natl. Acad. Sci. 107, 18533–18538 (2010).

Murphy, R., Woods, J., Black, M. & McManus, M. Global developments in the competition for land from biofuels. Food Policy 36, 52–61 (2011).

Styles, D., Borjesson, P., d’Hertefeldt, T., Birkhofer, K., Dauber, J., Adams, P., & Vaneeckhaute, C. Climate regulation, energy provisioning and water purification (2019).

Zhang, Y. K. & Schilling, K. E. Increasing streamflow and baseflow in Mississippi River since the 1940s: effect of land use change. J. Hydrol. 324, 412–422 (2006).

Pacaldo, R. S., Volk, T. A. & Briggs, R. D. No significant differences in soil organic carbon contents along a chronosequence of shrub willow biomass crop fields. Biomass Bioenerg. 58, 136–142 (2013).

Guo, L. B. & Gifford, R. M. Soil carbon stocks and land use change: a meta-analysis. Glob. Change Biol. 8, 345–360 (2002).

Gelfand, I., Snapp, S. S. & Robertson, G. P. Energy efficiency of conventional, organic, and alternative cropping systems for food and fuel at a site in the US Midwest. Environ. Sci. Technol. 44, 4006–4011 (2010).

Zenone, T. et al. CO2 fluxes of transitional bioenergy crops: effect of land conversion during the first year of cultivation. Glob. Change Biol. Bioenergy 3, 401–412 (2011).

Henner, D., Smith, P., Davies, C., McNamara, N., Balkovic, J. Sustainable whole system: Miscanthus, Willow and Poplar bioenergy crops for carbon stabilisation and erosion control in agricultural systems. In Geophysical Research Abstracts 21 (2019).

Bouwman, A. F., van Grinsven, J. M. & Eickhout, B. Consequences of the cultivation of energy crops for the global nitrogen cycle. Ecol. Appl. 20, 101–109 (2010).

Galloway, J. N. et al. Transformation of the nitrogen cycle: recent trends, questions, and potential solutions. Science 320, 889–892 (2008).

Fargione, J., Hill, J., Tilman, D., Polasky, S. & Hawthorne, P. Land clearing and the biofuel carbon debt. Science 319, 1235–1238 (2008).

Searchinger, T. et al. Use of US croplands for biofuels increases greenhouse gases through emissions from land use change. Science 319, 1238–1240 (2008).

Sikora, J. et al. The impact of a controlled-release fertilizer on greenhouse gas emissions and the efficiency of the production of Chinese cabbage. Energies 8(13), 2063 (2020).

Tonini, D. & Astrup, T. LCA of biomass-based energy systems: a case 2008 study for Denmark. Appl. Energy 99, 234–246 (2012).

Caserini, S., Livio, S., Giugliano, M., Grosso, M. & Rigamonti, L. LCA of domestic and centralized biomass combustion: the case of Lombardy (Italy). Biomass Bioenerg. 34, 474–482 (2010).

Kowalczyk, Z. Environmental impact of potato cultivation on plantations covering areas of various sizes. In Web of Conferences, E3S Web Conferences, 2019, XXII International Scientific Conference POLSITA, Progress of Mechanical Engineering Supported by Information Technology Vol. 132 (2019).

Kowalczyk, Z. Life cycle assessment (LCA) of potato production. In Web of Conferences, E3S Web Conferences, 2019, XXII International Scientific Conference POLSITA Progress of Mechanical Engineering Supported by Information Technology Vol. 132 (2019).

Roy, P. et al. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 90, 1–10 (2009).

Klein, D., Wolf, Ch., Schulz, Ch. & Weber-Blaschke, G. 20 years of life cycle assessment (LCA) in the forestry sector: state of the art and a methodical proposal for the LCA of forest production. Int. J. Life Cycle Assess. 20, 556–575 (2015).

Cherubini, F. GHG balances of bioenergy systems—overview of key steps in the production chain and methodological concerns. Renew. Energy 35(7), 1565–1573 (2010).

Supasri, T. et al. Life cycle assessment of maize cultivation and biomass utilization in northern Thailand. Sci. Rep. 10, 3516 (2020).

Turconi, R., Boldrin, A. & Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: overview, comparability and limitations. Renew. Sustain. Energy Rev. 28, 555–565 (2013).

Finnveden, G. et al. Recent developments in life cycle assessment. J. Environ. Manage. 91(1), 1–21 (2009).

Guidi Nissim, W., Pitre, F. E., Teodorescu, T. I. & Labrecque, M. Long-term biomass productivity of willow bioenergy plantations maintained in southern Quebec Canada. Biomass Bioenergy 56, 361–369 (2013).

Kowalczyk, Z. & Kwaśniewski, D. Life cycle assessment (LCA) in energy willow cultivation on plantations with varied surface area. Agric. Eng. 23(4), 11–19 (2019).

Huijbregts, M. A. J. et al. ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147 (2017).

IPCC Climate change 2013: the physical science basis. In: Stocker TF, QinD, PlattnerGK, TignorM, Allen SK, Boschung J, Nauels A, Xia Y, Bex V, Midgley PM (eds) Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge, Cambridge University Press, 1535 (2013).

Joos, F. et al. Carbon dioxide and climate impulse response functions for the computation of greenhouse gas metrics: a multi-model analysis. Atmos. Chem. Phys. 13, 2793–2825 (2013).

WMO Scientific assessment of ozone depletion. 2010, Global Ozone Research and Monitoring Project-Report 52 (World Meteorological Organization, Geneva, 2011).

Frischknecht, R., Braunschweig, A., Hofstetter, P. & Suter, P. Human health damages due to ionising radiation in life cycle impact assessment. Environ. Impact Asses Rev. 20, 159–189 (2000).

Van Zelm, R., Preiss, P., Van Goethem, T., Van Dingenen, R. & Huijbregts, M. A. J. Regionalized life cycle impact assessment of air pollution on the global scale: damage to human health and vegetation. Atmos. Environ. 134, 129–137 (2016).

Roy, P. O. et al. Characterization factors for terrestrial acidification at the global scale: a systematic analysis of spatial variability and uncertainty. Sci. Total Environ. 500, 270–276 (2014).

Helmes, R. J. K., Huijbregts, M. A. J., Henderson, A. D. & Jolliet, O. Spatially explicit fate factors of phosphorous emissions to freshwater at the global scale. Int. J. Life Cycle Assess. 17, 646–654 (2012).

VanZelm, R., Huijbregts, M. A. J. & VandeMeent, D. USES-LCA 2.0: aglobal nested multi-media fate, exposure and effects model. Int. J. Life Cycle Assess. 14(30), 282–284 (2009).

De Baan, L., Alkemade, R. & Köllner, T. Land use impacts on biodiversity in LCA: a global approach. Int. J. Life Cycle Assess. 18, 1216–1230 (2013).

Curran, M., Hellweg, S. & Beck, J. Is there any empirical support for biodiversity offset policy?. Ecol. Appl. 24, 617–632 (2014).

Döll, P. & Siebert, S. Global modelling of irrigation water requirements. Water Resour. Res. 38, 1037 (2002).

Hoekstra, A. Y. & Mekonnen, M. M. The water footprint of humanity. PNAS 109, 3232–3237 (2012).

Vieira, M. D. M., Ponsioen, T. C., Goedkoop, M. & Huijbregts, M. A. J. Surplus ore potential as a scarcity indicator for resource extraction. J. Indus. Ecol. 21(2), 381–390 (2016).

Jungbluth, N., & Frischknecht, R. Cumulative energy demand. In Hischier, R., Weidema, B. (Eds) Implementation of Life Cycle Impact Assessment Methods, St Gallen Ecoinvent Centre, pp. 33–40.

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F. et al. ReCiPe 2016: a harmonized life cycle impact assessment method at midpoint and endpoint level report I. Charact. RIVM Rep. 2016–0104 (2016).

Spinelli, R., Schweier, J. & De Francesco, F. Harvesting techniques for non-industrial biomass plantations. Biosyst. Eng. 113, 319–324 (2012).

Kwaśniewski, D., Mudryk, K. & Wróbel, M. Zbiór wierzby energetycznej z użyciem piły łańcuchowej. Inżynieria Rolnicza 13, 271–277 (2006).

Wiloso, E. I. et al. Production of sorghum pellets for electricity generation in Indonesia: a life cycle assessment. Biofuel Res. J. 27, 1178–1194 (2020).

Yang, Y. & Tilman, D. Soil and root carbon storage is key to climate benefits of bioenergy crops. Biofuel Res. J. 26, 1143–1148 (2020).

Heller, M. C., Keoleian, G. A., Mann, M. K. & Volk, T. A. Life cycle energy and environmental benefits of generating electricity from willow biomass. Renew. Energy 29(7), 1023–1042 (2004).

Fernandez-Tirado, F. & Parra-Lo´pez C, Calatrava-Requena JA, ,. methodological proposal for life cycle inventory of fertilization in energy crops: the case of Argentinean soybean and Spanish rapeseed. Biomass Bioenergy 58, 104–116 (2013).

Goglioa, P. & Owende, P. M. O. A screening LCA of short rotation coppice willow (Salix sp.) feedstock production system for small-scale electricity generation. Biosyst. Eng. 103, 389–394 (2009).

Acknowledgements

Publication was supported with a grant from the Ministry for Higher Education for statutory activities.

Author information

Authors and Affiliations

Contributions

Conceptualization, Z.K., and D.K.; methodology, Z.K., and D.K.; validation, Z.K., and D.K.; formal analysis, Z.K., and D.K.; investigation, Z.K., and D.K.; resources, Z.K., and D.K.; writing—original draft preparation, Z.K.; writing—review and editing, Z.K.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kowalczyk, Z., Kwaśniewski, D. Environmental impact of the cultivation of energy willow in Poland. Sci Rep 11, 4571 (2021). https://doi.org/10.1038/s41598-021-84120-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-84120-0

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.