Abstract

Self compacting concrete (SCC) is special type of concrete which is highly flowable and non-segregated and by its own mass, spreads into the formwork without any external vibrators, even in the presence of thick reinforcement. But SSC is also brittle nature like conventional concrete, which results in abrupt failure without giving any deformation (warning), which is undesirable for any structural member. Thus, self-compacting concrete (SCC) needs some of tensile reinforcement to enhance tensile strength and prevent the unsuitable abrupt failure. But fiber increased tensile strength of concrete more effectively than compressive strength. Hence, it is essential to add pozzolanic materials into fiber reinforced concrete to achieve high strength, durable and ductile concrete. This study is conducted to assess the performance of SCC with substitutions of marble waste (MW) and coconut fiber (CFs) into SCC. MW utilized as cementitious (pozzolanic) materials in percentage of 5.0 to 30% in increment of 5.0% by weight of binder and concrete is reinforced with CFs in proportion of 0.5 to 3.0% in increment of 0.5% by weight of binder. Rheological characteristics were measured through its filling and passing ability by using Slump flow, Slump T50, L-Box, and V-funnel tests while mechanical characteristics were measured through compressive strength, split tensile strength, flexure strength and bond strength (pull out) tests. Experimental investigation show that MW and CFs decrease the passing ability and filling ability of SCC. Additionally, Experimental investigation show that MW up to 20% and CFs addition 2.0% by weight of binder tend to increase the mechanical performance of SCC. Furthermore, statistical analysis (RSM) was used to optimize the combined dose of MW and CFs into SCC to obtain high strength self-compacting concrete.

Similar content being viewed by others

Introduction

In civil engineering, increased in interest in Self compacting concrete (SCC) has been observed. SCC is still developing a wide range of application and properties1. SCC is particular types of concrete which is flowable, non-segregated and by its own mass spread into place and fill the formwork even in the presence of congested reinforcement2. SCC can be defined in terms of four characteristics such as flowability, viscosity, passing ability and segregation resistance. If the concrete possess all the above four characteristics are term as SCC3. Historically, the concept of SSC was first proposed In 19864. But 1988 Japan was first country which was successfully able to develop the prototype of (SCC).

The concept of environmental development believes that environmental reserves must be considered as restricted goods and the wastes must be reasonably controlled. Growing quantities of accumulated garbage, up to 2500 million tons per year over the world which promote the scholar to a built modern technique of dumping5. In the cement production industry, there are several opportunities to utilized waste raw material in concrete6. Waste can be utilized as fine or coarse aggregate or cement in concrete.

For a good quality concrete mix, fine aggregates must be clean, hard, strong, and free of immersed chemicals and more fine materials that may possibly produce the weakening of concrete. Rajan and Singh7 show that, aggregate plays major role on the performance of concrete. Unluckily, the majority of the natural sand used in concrete is either rolled sand, sand of river, dune sand, and sea sand is chosen for the economy and the accessibility8. Properties of sand disturb the strength performance of concrete, as sand is an important ingredient of concrete.

Various productions are the cause of waste which are created as a byproduct during the production procedure. It is recommended that Marble be able to be utilized in the building production to make Cement Concrete9. The aim of this article is to utilized waste marble as a partially substitution of sand which takes from the marble factory. Real estimate about the amount of waste generated in Pakistan from the marble industry are unavailable since it is not analyzed or supervised by the government or any other political party. More references assess that 20 to 25% of the marble delivered in the form of slurry through the cut off procedure10. These marble wastes are present in the environment and cause to pollution.

Subsequently ancient occasions marble has been commonly utilized as a cementitious material in cement concrete. The factories disposing of the marble residue material, which contain of a extremely fine ash, currently comprises one of the ecological problem throughout the world11. Management of the marble powder in various factories regions particularly the paper, agriculture, glass, and building factories would assist to care for the environment12. Through the quarrying procedure and in the cleaning of marble dust, marble powder is seen as a rubbish material13.

Many developed countries have put in motion legal regulations concerning the recovery of structural waste aiming to reduce the amount of waste and to ensure waste recycling14. Let consider the example of Japan in visible of us, a nation that effectively improved the reprocessing rate of concrete waste up to 98% utilizing waste material as aggregate15. It has been identified that the Marble powder delivered through treating corresponds to almost 40 percent of the finishing product from the marble factory16. They also described that workability of concrete reduce with the supplement of marble powder.

Katuwal et al. also suggest that marble as a fine aggregate reduce workability of concrete17. They detected that compressive strength is enhanced up to 50 percent substitute of fine aggregate with marble dust which is almost 12 percent greater than from reference concrete18. Compressive strength and flexural strength of concrete are improved almost 28 percent and 13 percent correspondingly at 50 percent substitution and then steadily decline with the supplement of marble dust19. Resistance to the acid of concrete made with waste marble was slightly low in comparison to that of control concrete20. It has been Indicated that Marble dust can be easily utilized in the cement concrete production9. A study shows that durability aspects of concrete such corrosion and drying shrinkage improved with addition of marble waste21. It has been also reported that marble waste increased mechanical performance concrete due to micro filler22. Although marble increase mechanical performance of concrete considerably, but still concrete has less tensile strength which result brittle failure. Therefore, concrete still some of tensile reinforcement to improve tensile capacity. Fibers is one of the most prevalent method to enhance tensile capacity of concrete.

Through extensive research, it has been determined that the performance of concrete were significantly increased because of the addition of fibers to concrete23,24,25,26. Improving the production technique of SCC is increasing day by day in concrete production27. ACI 544.5R-10 stated that thick fibers are lower efficient in reducing the plastic shrinkage cracks width as compare to thin fibers28. Most thin diameter microfibers are particularly effective in reducing plastic shrinkage cracking of concrete because larger surface area of fibers29. Moreover, the use of fibers helps in reducing the porosity and bleeding of concrete30,31,32,33.

Various kinds of fibers are utilized to reinforce concrete such organic and inorganic fibers34. The choice of the kind of fibers is depends on different aspects such area, length, tensile strength modulus of elasticity and the material from which it is made. Furthermore the amount to which these fibers effect the performance of concrete35. Mostly fibers are classified into two types, one is metallic and the other one is nonmetallic. Metallic fibers are mainly steel fibers whereas nonmetallic are glass fiber, propylene fiber, carbon fibers36. It has been reported that mechanical performance of foam concrete considerable improved with addition of propylene fibers24. Research shows that, rheological properties (filling and passing ability) of self-compacting decreased with concrete of fibers. Furthermore, mechanical performance of concrete improved considerably up to 2.0% addition of PPFs25. A studies show that, fibers improve mechanical performance in terms of compressive strength, split tensile strength as well as flexure strength of concrete25,34. Steel Fibers improved concrete performance against acid attacks4.

Research significance

In existing literature shows that the fibers increased mechanical performance of concrete particular tensile strength more effectively than compressive strength. Ahmad et37 used steel fiber in concrete and reported steel fiber increased tensile strength more effectively than compressive strength. Further research was recommended37 that pozzolanic materials must be added to fiber reinforced concrete to achieved high strength, durable and ductile concrete. Also reported that steel fibers are too costly as well as easily corroded. Therefore, the primary objective of this research is to utilize marble waste in SCC. Secondary objective of this research is utilizing coconut fibers instead of steel fibers which are costly as well as easily corroded. Third objective of this is research was to optimized substitution ratio of marble waste and coconut fibers with help of statistical analysis (RSM) to achieved high strength self-compacting concrete. Finally experimental results and predicted results from statistical analysis (RSM) will be compared.

Materials

Cement

Normal setting time cement as per according to ASTM C15038, were used as binding material throughout in this study. Furthermore, physical properties and chemical composition of cement used in this study were given Table 1.

Coconut fibers (CFs)

Coconut fibers having 80 to 100 mm long length with a diameter of 0.5 to 1.0 mm were utilize in this study. Its properties are given in Table 2.

Aggregate

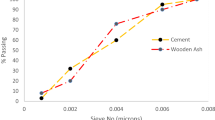

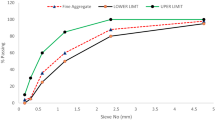

Nearby accessible rive sand in saturated surface dry (SSD) condition were utilized as a fine aggregate throughout in this study. Normal weight limestone crush aggregate in saturated surface dry (SSD) condition were utilized as coarse aggregate in this study. Both (fine and coarse aggregate) were collected from Margallah Taxila Pakistan. Figures 1 and 2 shows gradation curve of fine aggregate and coarse aggregate as per ASTM C3339 respectively. Furthermore, different parameter which influence the performance were evaluated in laboratory and presented in the following Table 3.

Marble waste (Mw)

Marble waste (Mw) were procured from the national marble factory industrial zone Risalpur Pakistan and grinded at Pakistan council of scientific and research lab Peshawar Khyber Pakhtunkhwa, Pakistan. Table 4 depicts different properties (chemical and physical) of marbles waste used in this research study.

High range water reducing admixture (superplasticizer)

Chemrite-530 has been utilized as a super plasticizer since it is a high-range water-reducing mixture that is also considered non-toxic and non-hazardous in compliance with appropriate health and safety regulations. The superplasticizer satisfies the requirements of EN 934–2 T 3.1/340 and ASTM C-494 Type F41 as well as other known practices. Table 5 lists some of the superplasticizer's typical features.

Experimental setup

To attain the project's objective, an experimental study program was created, and it was segregated into two phases. In the first phase, trial mixes were created to meet the technical requirements for SCC2 Six mixes were created by various proportions of marble waste (MW) and coconut fibers (CFs) in the second stage to find out the the impact of marble waste (MW) and coconut fibers (CFs) on self-compacting concrete (SCC), which were developed on the basis of the first stage. Table 6 illustrates typical acceptability requirements for self-compacting concrete as defined by the specific requirements for self-compacting concrete with maximum particle size up to 20 mm.

Testing method

Slump flow, Slump T50, L-Box, and V-funnel tests were used to assess rheological characteristics42. moreover, as per ASTM C39/C39M43, standard-sized cylinders (150 mm in diameter and 300 mm in length) have been used to test the compressive strength at seven, fourteen, and twenty-eight-day intervals. The tensile strength of similar cylinders of standard size (150 × 300 mm) has also determined by casting and testing them in the laboratory. A beam with dimensions of (150 × 150 × 500 mm) would be casted and tested to determine its flexure strength in accordance with ASTM44.Considering ASTM45, a cube of standard dimensions (150mm3) has been used to determine bond strength. For each test, three specimens have been tested at seven, fourteen, and twenty-eight days, and the mean value of the specimens have opted as the strength. Eight different mixtures were created to investigate the impact of marble wastage and coconut fibers on the performance of solidified and fresh concrete. Table 7 presents the details of the mixes.

Results

First stage

In the first phase, eight different mixes have created to obtain the best feasible blend that would meet the requirements of Technical Specification for the product (SCC). As a result of the research, Table 8 exhibits the fresh characteristics of SCC for each trial mix tested using various testing techniques (Slump Flow, Slump T50 Spreads, L-Box, and V-Funnel). Table 8 provides the true picture that Mix 6 will gratify the variety of different tests (Slump flow, Slump T50 Spread time, L-Box, and V-funnel) stated by the specific requirements for self-compacting concrete. Others believe that the mixture does not gratify the range of such testing. Hence, in order to get the good self-compacting concrete mix, Mix 6 is regarded the best mix. It may be used as a reference concrete (control) with varying proportions of MW and CFs for further experimental works.

Second stage

Mix 6 (SCC) was chosen for beyond investigational work according to the results obtain in first stage. Hence, the next stage of the investigational work was performed on Mix 6 (SCC) with differing proportions of Mw and CFs with constant water binder ratio (0.60). Twelve mix were planned at the next phase after attained the requirement of technical guideline for self-compacting concrete (Mix 6). Different proportions of Mw and CFs were incorporated to fresh SCC. The proportions of Mw were from 5.0% to 30% by weight of cement increment in 5.0% and CFs were incorporated from 0.5% to 3.0% by weight of cement in increment of 0.5%. Table 9 indicates self-compacting concrete (SCC) mix with differing proportions of Mw and CFs.

Results and discussion (second Stage)

Rheological performance

Slump cone and SLUMPT50

Figures 3 and 4 illustrate the results of the experiments done on slum flow and slump T50, with different proportion of marble wastes and coconut fibers. The highest value sump flow value was achieved by substituting marble waste at a rate of 0 percent (control), while the lowest slump flow value was achieved by substituting 30 percent of marble waste. As the percentage of marble waste increased from 0 to 30% by weight of cement, the time required to spread concrete into a 50 cm diameter (slump T50) increased. The time required to spread concrete into a 50 cm diameter (slump T50) reached its maximum level when the substitution rate of marble waste was 30% by weight of cement into SCC which causes a decrease in flowability. It can be attributed to the particle shape (flat or elongated) and surface texture (rough) of the marble waste, both of which escalates internal friction between the concrete materials. It has been also reported that, marble waste decreased workability of concrete due rough surface texture. A show that marble waste has rough surface texture as compare to cement46. However, all of the SCC mixtures are within the limits defined by the technical standard for SCC and have excellent flowability2.

As for CFs, the Slump flow value decreases as the proportion of CFs in the mixture increases. As indicated in Fig. 3, the maximum slump value was achieved with 0% substitution of coconut fibers (control concrete), while the lowest slump flow was achieved with 3.0% replacement of CFs. The findings of tests show that as the proportion of coconut fibers in SCC increased, Slump flow reduced and Slump T50 value increased, respectively because of decreased workability of SCC. The decrease in workability of concrete mixes when coconut fibers are added may be linked to the increased surface area of coconut fibers (CFs), which necessitated the use of more cement paste to coat them, resulting in less cement paste being available for lubrication. Coconut fibers also increased internal friction between the aggregate and the fibers, requiring additional cement paste to decrease internal friction. However, coconut fibers up to a 2.0% inclusion resulted in Slump flow and Slump T50 values that were within the permissible range specified by the technical standard for SCC and had a good filling capability. But higher dosages of coconut fibers (2.5% and 3.0%) result in Slump flow and Slump T50 values that are outside of the range specified by the technical standard for SCC. Therefore, higher dose of superplasticizer is required for the mix of CFs (2.5% and 3.0%).

L box and V funnel

The ability of self-consolidating concrete to pass the L-Box test was determined using this method. A similar trend to slump flow was observed in the passing ability of concrete, with the proportion of marble waste increasing from the level of 0 to 30% with respect to weight of cement as illustrated in Fig. 5. The passing ability of SCC decreases as the proportion of coconut fibers rises from the range of 0 to 3.0% with respect to the weight of cement, which is parallel to the pattern of slump flow. According to the technical specifications for SSC, the usual permissible range of blocking ratio for excellent passage ability of SSC is in between 0.8 to 1.0. It can be observed from the findings that all of the marble waste mixes have a L box ratio between 0.8 and 1.0, which indicates that these mixes are within the limitations defined by the technical standard for self-compacting concrete and are thus fall acceptable range of SCC2 having good passing ability. Figure 5 demonstrates that mixes containing 0 to up to 2.0% coconut fibers have an L-Box ratio (H2/H1) value ranging between 0.80 and 1. In other words, since the coconut fiber content of these mixtures (0 to up to 2.0 percent coconut fibers) fall within the limit define by the technical specifications for SCC and possess excellent filling and passing abilities. However, at higher dosage of CFs (2.5% and 3.0% coconut fibers), L-Box test ratio (H2/H1) is 0.72 and 0.65 respectively which fall out of the range as specified by technical requirements for SCC, as shown in Fig. 5. Although47 concluded that blocking ratio up to 0.60 possess good passing ability. However, technical specification for SCC states that the SCC has a good passing ability when the blocking ratio value (H2/H1) in the L box test is more than 0.848.

Flowability of self-compacting concrete (SSC) was checked through V-Funnel test. Flow time of V funnel test indicate the flowability of SCC. Increased flowability associates to shorter flow time. Self-compacting concrete flow decreases as percentages of marble waste and coconut fibers increased as illustrated in Fig. 6 . Maximum flowability was found when the substitution of marble waste was set to zero percent, while lowest flowability was found when the substitution of marble waste was set to 30 percent. All marble mix waste streams exhibit flow time ranging from 6 to 12 s, which satisfies the requirements of SSC 2 and have good flowability. As for coconut fibers, maximum flowability was found at 0% substitution of CFs, whereas lowest flowability was found at 3.0% substitution in coconut fiber. Flow time for mix (0 to up to 2.0 percent coconut fibers by weight of cement) is between 6 and 12 s, which is within the permissible range specified by the technical standard for SCC (as shown in Fig. 6). In contrast, at greater dosages of coconut fibers (2.5% and 3.0% coconut fibers), the flow time is 14 s and 17 s, respectively, which is beyond the range specified by technical requirements for SCC. As a result, it is suggested that coconut fibers be used up to 2.0% by weight of cement. It is also advisable to employ the use of coconut fibers up to 3.0%, by weight of cement with the addition of a greater dose of superplasticizer.

Mechanical performance

Compressive strength

Compressive stress is the measure of the concrete's ability to resist the highest compressive load divide by cross sectional area of sample. A cylindrical specimens of standard size 150 mm diameter and 300 mm length were casted and tested for compressive strength under the standard procedure of ASTM C39/C39M43.

Figure 7 illustrates the compressive strength of various marble waste dose levels. The compressive strength rises with the increase of marble waste up to 20%. It has been also reported that marble waste increased the compressive strength43. At a dose of 20% of the marble waste shows maximum compressive strength as compared to the blank or reference concrete. However, beyond 20% of marble waste compressive strength decreased gradually. The positive impact of marble waste on compressive strength is due to pozzolanic reaction in which Sio2 (silica) in marble waste react with CH (calcium hydrate) of cement yields more C-S–H (calcium silicate hydrate) gel which is additional cementitious compounds49. At higher dose of marble waste beyond (20% by weight of cement), strength is reduced owing to dilution effect, resulting in alkali-silica reaction due to the presence of more unreactive silica. Also a higher dosage, compaction becomes more difficult due lack of workability, which results in increased porosity of concrete, leading to porous concrete which ultimate results lower compressive strength50. Based on result, it is suggested that marble waste can be utilized as binding material up to a maximum of 20% by weight replacement.

X-ray diffraction (XRD) analyses were conducted at the age of 28 days to investigate the mineralogical composition and to assess the measure calcium silicate hydrate (C-S–H) in control and marble substituted batches. Peaks of C-S–H 27° were selected for analysis. These peaks and their pattern with 10% 20% and 30% substation of marble waste can be observed in Fig. 8. Normal peaks of CSH can be observed in the control samples which shows normal C-S–H amount in concrete without any substitution of marble waste. Similarly, higher and sharp peaks of quartz at 23° can be observed almost in the same pattern in each sample which ensures the presence of crystalline silica in marble waste. This crystalline silica increases with the increasing percentage of marble waste. The C-S–H gel peaks get increased with increasing substitution of marble waste as compared to control sample. The increase in C-S–H gel amount is due to the pozzolanic activity of marble waste through which it utilizes the available CH form during hydration of cement and additional produces CSH gel. It has been also reported that marble waste show pozzolanic activity. A show that marble waste shows pozzolanic activity if the particle size is less than 100 microns. Also reported that pozzolanic reaction of marble waste depends on particle size i-e smaller the particle size, more will be pozzolanic activity51,52,53. Hence X-ray diffraction (XRD) results confirm the performance and strength development of marble waste is due to the pozzolanic reaction which produce secondary C-S–H gel. C-S–H gel possess binding properties which increased the strength of concrete.

As for coconut fiber concern, Compressive strength increased up to 2.0% addition of CFs and then decreased gradually as shown in Fig. 7. It has been observed that the compressive strength enhanced up to 2.0 percent inclusion of fiber54. In comparison with blank or reference concrete, a 2.0 percent dose of Coconut fiber yielded maximum compressive strength at 28 days of curing. The compressive strength, however decreased by further addition of CFs (beyond 2.0%). The confinement of the fiber reinforcement on the specimen results positive influence on compressive strength, Compression causes lateral expansion, which is restricted by the CFs, leading to more compressive strength. The fibers are able to withstand tension and shear because of their strength37. Compaction process become difficult at higher dose (beyond 2.0%), due lack of workability which results lower strength. it has been reported that 1.5% of the fibers increased compressive strength almost 15%, as compare to reference concrete55. Fibers at 1.0% by volume produce a significant increase in the initial as well as the later ages mechanical performance of concrete. The highest improvement in 28-days strength was seen to be 29.15%56. Therefore, there is an optimal limit for Coconut fiber. According to the results of the tests, the optimal dose of Coconut fiber for strength is 2.0% by weight of cement.

Figure 9 shows a relative analysis in which the 28-day compressive strength of the control mix is taken as the reference mix, and from which, various mixes containing increasing percentages of marble waste and coconut fiber are compared. At 20 percent and 2.0 percent replacement of Mw and CFs, compressive strength is around 20% and 18% lower than the control (28 days) at 7 days curing, compared with the control strength (28 days). At 20 percent and 2.0 percent replacement of marble waste Coconut fiber, the compressive strength of concrete is still only 8.0 percent and 5.0 percent lower than that of reference concrete/control (28 days) at 14 days curing, respectively. After 28 days of curing, the compressive strength of concrete is 17 percent and 21 percent greater than that of reference concrete when Mw and CFs is substituted at 20 percent and 2.0 percent, correspondingly, as comparison of reference concrete (28 days control concrete strength).

Response surface technique is a statistical tool whose primary goal is to maximize a response or output that may be affected by a variety of factors or input variables, such as the number of input variables. When there are several responses, it is critical to determine the combined optimal dose of both compounds that does not maximize just one reaction57. In this study dependent variable are dose of Mw and CFs while independent variable is strength.

To investigate the combined effects of Mw and CFs on the compressive strength, a 3D response surface and contour plot were developed in the Minitab software for the Mw and CFs verse compressive strength at the age of 28 days curing. To assess best possible dose MW and CFs in SCC, 3D response surface was transformed into contour plot in which 18% Mw and 1.8% CFs were chosen from contour plot showing compressive strength 23 Mpa as given in Figs. 10 and 11. To justify the computed strength of contour plot for compressive strength of concrete at 28 days curing, the same dose of 18% Mw and 1.8% CFs were cast and tested experimentally in a concrete laboratory. It can be seen that the experimental value was very near to the anticipated value, indicating that the response surface models were correctly computed.

Split tensile strength

Split tensile strength can be defined as the tensile stresses produced as a result of applying tensile force to the concrete sample in such a way that cylindrical sample split at vertical diameter. It is an indirect technique for examining the tensile strength of the concrete. split tests were executed on cylindrical samples of 150 mm diameter and 300 mm height in accordance with ASTM C496-71 58, at the ages of 7, 14 and 28 days of curing.

Figure 12 depicts the split tensile strength of concrete with various doses of the waste marble. As split tensile strength is a function of compressive strength, similar to the compressive strength, split tensile strengths were improved when the proportion of marble waste was increased up to a maximum of 20% replacement, after which they began to decline progressively. Maximum split tensile strength was achieved with a 20% substitution of marble waste, and minimum split tensile strength was achieved with a 0% replacement of marble waste as compared to the results (blank mix). In comparison to natural aggregate, the marble wastage has a greater carbonate content. This increases the connection between the aggregate and the cement paste, which is the cause for the rise in compressive strength of concrete at various curing ages20. The pozzolanic reaction of marble waste, which results in the formation of extra cementitious compounds, is responsible for the beneficial impact on split tensile strength53 According to certain reports, marble waste exhibits pozzolanic characteristics if the particle size that is smaller than that of cement particles, which is 75 microns or less11. It is possible for marble waste concrete to continue to acquire strength over time because of the extra binder generated by the interaction of marble waste with accessible lime. Aside from that, marble waste is the filler material because of its finesse, as it may be used as a micro-filler in cement aggregate matrix to produce dense concrete21,59. Higher dosages (30 percent) make the compaction process more difficult since the material lacks flowability, resulting in porous concrete with reduced strength.

As for coconut fibers (CFs), similar to the compressive strength split, tensile strength was also enhanced as the proportion of CFs rose up to 2.0 percent and subsequently decreased, as shown in Fig. 12. When comparing the split tensile strength of 2.0 percent CFs to blank or reference concrete after 28 days of curing, the greatest split tensile was achieved at 2.0 percent CFs dose. It has also been observed that the addition of 2.0 percent fibers by volume may increase the tensile strength of concrete by around 40%60. The strength, however, was decreased when the 2.0 percent dose was exceeded. In concrete, fibers are used to improve the flexibility of the concrete by delaying the appearance of tension fractures or avoiding the formation of cracks in such a way that the tensile strength of (SFRC) steel fiber reinforced concrete is greater to that of ordinary concrete. Fibers have a crack-stopping effect rather than a crack-prevention effect. It is important to note that CFs have a greater impact on tensile strength than they do on compressive strength when compared to other materials. Several studies have shown that fibers increase the tensile capacity of post-cracking behavior61. Fibers have been found to have more substantial impacts on flexural tensile strength at volume fractions ranging from 0.5 to 2.0 percent, which were involved in this study62.

As previously stated, split tensile strength exhibits the same pattern as compressive strength in a split configuration. As a result, there was a significant correlation between compressive and split strength. A regression model with an R2 higher than 90 percent, as illustrated in Fig. 13.

As illustrated in Fig. 14 , a relative analysis is also performed in which the 28-day split tensile strength of the control mix is taken into account as the reference mix, and from there, various mixes with varied percentages of marble waste and coconut fiber are compared. At 20 percent and 2.0 percent replacement of marble waste and Coconut fiber, split tensile strength is about 32 percent and 28 percent lower than when compared to the control (28 days) at 7 days curing, correspondingly, with the comparison of control. At 14 days curing, the split tensile strength of concrete is only 19 percent and 24 percent lower than that of reference concrete/control (28 days) when marble waste and coconut fiber is substituted at 20 percent and 2.0 percent of the total mix, respectively. When using 20 percent and 2.0 percent replacement of marble waste and coconut fiber, respectively, the split tensile strength of the concrete is 17 percent and 21 percent greater than the reference concrete after 28 days of curing, respectively.

The optimal dosage of marble waste (MW) and coconut fibers (CFs) for split tensile strength in SCC is determined by selecting 18 percent marble waste (MW) and 1.8 percent coconut fibers (CFs) from the contour plot that gives split tensile strength of 10 Mpa, as displayed in Figs. 15 and 16. As part of the validation process for the estimated value of statistical models regarding split tensile strength of concrete, a comparable dose of 18 percent (MW) and 1.8 percent (CFs) of the concrete is cast and experimentally tested in the laboratory on about the similar days. It may be observed that the experimental value was very near to the anticipated value, indicating that the response surface models were correctly computed.

Flexure strength

Flexural strength, also known as bend strength or modulus of rupture, is a material property that may be specified as the stress in a material immediately before it fails in a flexure test63. Flexure tests were performed on beam specimens with dimensions of 150 × 150 × 500 mm at 7, 14 and 28 days curing.

Figure 17 depicts the flexural strength of marble waste and coconut fibers at various doses. Flexure strength rise in a similar way to compressive strength as the proportion of marble waste climbed up to 20 percent replacement and then dropped progressively, similar to compressive strength. The greatest Flexure strength was achieved with a 20 percent substitution of marble waste, and the lowest Flexure strength was achieved with a 0 percent replacement of marble waste, as compared to reference concrete (blank mix). It has also been observed that the inclusion of marble powder increases the flexure strength of the concrete11. It is due to pozzolanic reaction of marble waste. The pozzolanic reaction of Sio2 in marble waste with CH of cement results in the formation of extra cementitious compounds (C-S–H), which has a beneficial impact on flexure strength49.Increased dosages of marble waste (more than 20 percent by weight of cement) result in a reduction in strength owing to dilution effect, which cause to an alkali-silica reaction due to a greater amount of unreactive silica accessible due to the increased quantity of marble waste used in the mix. A greater dose also makes the curing process more problematic owing to a lack of workability, which results in porous concrete with a lower strength50.

Considering Coconut fiber (CFs), flexure strength rises as the proportion of Coconut fiber grew up to 2.0 percent and subsequently dropped, as shown in Fig. 17. It has been claimed that the flexure strength may be enhanced by as much as up to 2.0 percent fiber is added54. When flexure strength was measured after 28 days of curing, the greatest value was achieved with a 2.0 percent dose of Coconut fiber when compared to blank or reference concrete. The strength, however, was decreased when the CFs exceed 2.0 percent dose. The confinement of the fiber reinforcement on the specimen has a beneficial impact on flexure strength. Compression causes lateral expansion, which results in tension and shear as a result of the expansion. The fibers are able to withstand tension and shear due to their strength. This confinement has the potential to decrease the specimen's transverse deformation while simultaneously increasing its flexural strength. When the percentage of coconut fiber is increased, particularly at a greater dose, the process of compaction becomes more difficult, resulting in porous concrete and a reduction in flexural strength, as previously stated. It has been observed that increasing the flexure strength by up to 1.5 percent of the total volume of fibers increases it from 20 to 25 percent55. Steel fibers, at a concentration of 1.0 percent by volume, produce a significant increase in both the early and long-term strength of concrete. The highest increase in 28-day strength was found to be 29.15 percent with the maximum increase being 29.15 percent56.

Figure 18 depicts the relationship between compressive strength and flexural strength when waste marble and coconut fiber is included into the concrete. This study found a significant co-relation between compressive and flexural strength, with an R2 of more than 90 percent.

Additionally, a comparison (relative analysis) is carried out, in which the 28-day flexure strength of control mix is taken into consideration as the reference mix, from which various mixes with varied percentages of marble waste and Coconut fiber are compare, as shown in Fig. 19. At 20 percent and 2.0 percent replacement of marble waste and Coconut fiber, flexure strength is about 20 percent and 15 percent less than the control (28 days) at 7 days curing, respectively. Concrete flexure strength is only 8.0 percent and 4.0 percent greater than reference concrete/control (28 days) at 20 percent and 2.0 percent, respectively, after 14 days of curing. Concrete flexure strength is only 19 percent and 22 percent greater than reference concrete/control (28 days) at 20 percent and 2.0 percent, respectively, after 28 days of curing.

Figures 20 and 21 illustrates the selection of 18 percent marble waste and 1.8 percent Coconut fiber from the contour plot, which results in a flexure strength of 6.5 Mpa (at 28 days), and is utilized to determine the optimal dose of marble waste and Coconut fiber for flexure strength in SCC. To validate the calculated value of statistical models for flexure strength of concrete, a similar dosage of 18% (MW) and 1.8% (CFs) are cast and experimentally tested in the laboratory on the same days. It can be observed that that the experimental value closely agreed with the predicted value, which validates the calculated response surface models.

Pull out/bond strength

Pull out the test was carried out on a cube of size 150 mm to determine bond strength between concrete with reinforcing bar and could be performed according to ASTM C-23445. For this test, the #4 bar is kept 100 mm from the top as shown in Fig. 22, of the mold before filling the concrete in the mold.

Bond strength with varying dosages of marble waste was presented in Fig. 23. Bond strength is opposition offers by the surrounding concrete to pull out reinforced from the concrete cube into a certain depth. Like compressive strength, Bond strength is also increased as the percentage of marble waste increased up to 20% in substitution and then decreased gradually. According to test observation, maximum Bond strength was obtained with 20% substitution of marble waste, and Bond strength was obtained with 0% substitution of marble waste (blank mix). It is due to the pozzolanic activity of marble64 which gives dense mass, and the bond between reinforcement bar and surrounding concrete improved due to the confinement effect. Also, due to its finesse, marble waste acts as a micro-filler in cement aggregate matrix which dense concrete leading to more force is required to pull out reinforcement of concrete59. It has been also reported that bond strength mainly depends on the strength of surrounding concrete i-e before pulling reinforcement concrete laterally expands65. By using marble waste, more force is required to expand concrete laterally which results in more bond strength. However, at a higher dosage of marble waste (beyond 20% by weight of cement) strength reduces due to dilution effect which leads to alkali-silica reaction due to higher quantity of unreactive silica available due to high quantity of marble waste. Also, at a higher dosage, the compaction process become more difficult due to lack of workability which results in porous concrete, leading to lower strength50.

As for Coconut fiber concerns, bond strength improved as the percentage of Coconut fiber (CFs) enhance up to 2.0 percent and then decreased as displayed in Fig. 23. After 28 days of curing, the maximum bond strength was achieved at 2.0 percent dosage of Coconut fiber as in comparison to the control concrete. However, beyond the 2.0 percent dosage, the strength was gradually decreased. The improvement in bond strength is because to the confinement of the coconut fiber around the cylindrical sample. This confinement of CFs can reduce transversal deformation of the specimen. Bond strength mainly depends on the strength of surrounding concrete i-e before pulling reinforcement concrete laterally expands65. By using fibers, more force is required to expand concrete laterally as fiber prevents propagation of cracks which results in more bond strength. However, at a higher dosage, the compaction process becomes more difficult due to lack of workability which results in porous concrete, leading to lower concrete strength leading to less force is required to pull out reinforcement from concrete.

The correlation between compressive strength and bond strength with the incorporation of waste marble is shown in Fig. 24. It can be observed from the regression model that a strong co-relation was existing in between compressive and bond strength having R2 greater than 90%.

A relative analysis is also performed in which the 28-day bond strength of the control mix is taken into account as the reference mix as shown in Fig. 25, and various mixes with varied percentages of marble waste and coconut fiber are compared. At 20 percent and 2.0 percent replacement of marble waste and Coconut fiber, bond strength is about 29 percent and 24 percent lower than when compared to the control (28 days) at 7 days curing, correspondingly, with the comparison of control. At 14 days curing, the bond strength of concrete is only 15 percent and 12 percent lower than that of reference concrete/control (28 days) when marble waste and coconut fiber is substituted at 20 percent and 2.0 percent of the total mix, respectively. At 20 percent and 2.0 percent replacement of marble waste and coconut fiber, the bond strength of the concrete is 20 percent and 22 percent greater than the reference concrete after 28 days of curing, respectively.

To evaluate optimum dosage marble waste and Coconut fiber for bond strength in SCC, 18% marble waste and 1.8% Coconut fiber are selected from the contour plot giving flexure strength 5.0 Mpa (at 28 days) as shown in Figs. 26 and 27. To validate the calculated value of statistical models for bond strength of concrete, a similar dosage of 18% (MW) and 1.8% (CFs) are cast and experimentally tested in the laboratory on the same days. It can be observed that that the experimental value comparable with the predicted value, which validates the calculated response surface models.

Conclusion

In this study, a step towards utilization of marble waste (from 0 to 30% by weight of cement) and coconut fibers (from 0 to 3.0% by weight of cement) has been made in the manufacturing of sustainable self-fiber compacting concrete. The following conclusion has been drawn based on experimental work:

-

When the proportion of marble waste (Mw) and coconut fibers (CFs) is raised, the flowability and passing ability of the concrete decreased. However, all the mixes, except for the 2.5 percent and 3.0 percent CFs, demonstrate excellent filling and passing capabilities within the limits specified by the practical requirement for SCC.

-

Mechanical performance improved as the proportion of Mw was increase up to 20 percent addition and then reduce as compared to the reference concrete. It is because of micro-filling voids in concrete ingredients as well as pozzolanic reaction of Mw.

-

Coconut fibers (CFs) improved mechanical performance up to 2.0 percent addition by weight of cement and then declines gradually as compared to the reference concrete. The positive influence on mechanical performance is because of confinement coconut fibers (CFs) around the sample. However, at higher dosage (beyond 2.0% substitution), the compaction of concrete become more difficult due lack flowability, resulting pore in harden concrete which decreased mechanical performance od SCC.

-

Based on work results, the predicted value from statistical analysis and the experimental value were comparable.

-

The maximum mechanical performance was achieved at the substitution ratio of 18 percent Mw and 1.8 percent CFs respectively, having a maximum compressive strength of 23 Mpa which was almost 37 percent greater than from control mix. Hence 18 percent marble waste (Mw) and 1.8 percent coconut fibers (CFs) were optimal dosage for combined substitution.

Finally, the current research indicates that marble wastes and coconut fibers (CFs) are excellent, abundant, local eco-materials that are low-cost and may be utilized for SCC production from the point of view economic and environmental limitations. SCC has several advantages in terms of production, placement and compaction as compared to conventional concrete namely, removal of external or internal vibration for compaction, better flowability, passing ability and pumpability, as well as increased bonding with congested reinforcement. Moreover, the placement of SCC is faster and requires less labor. The surface finish, mechanical performance and durability aspects of SCC can be considerably better than traditional concrete.

Change history

01 August 2023

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1038/s41598-023-39394-x

References

Ostrowski, K. et al. The effect of the morphology of coarse aggregate on the properties of self-compacting high-performance fibre-reinforced concrete. Materials (Basel) 11, 1372 (2018).

EFNARC S. Guidelines for Self-Compacting Concrete (UK Assoc House, 2002).

Grdic, Z. J., Toplicic-Curcic, G. A., Despotovic, I. M. & Ristic, N. S. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate. Constr. Build. Mater. 24, 1129–1133 (2010).

Okamura, H. Self-compacting high-performance concrete. Concr Int 19, 50–54 (1997).

Agrawal, D., Hinge, P., Waghe, U. P. & Raut, S. P. Utilization of industrial waste in construction material–A review. Int. J. Innov. Res. Sci. Eng. Technol. 3, 8390–8397 (2014).

Saikia, N. & de Brito, J. Use of industrial waste and municipality solid waste as aggregate, filler or fiber in cement mortar and concrete. Adv. Mater. Sci. Res. 3, 65–116 (2009).

Rajan, B. & Singh, D. Understanding influence of crushers on shape characteristics of fine aggregates based on digital image and conventional techniques. Constr. Build. Mater. 150, 833–843 (2017).

Bederina, M. et al. Effect of partial and total replacement of siliceous river sand with limestone crushed sand on the durability of mortars exposed to chemical solutions. Constr. Build. Mater. 47, 146–158 (2013).

Singh, R. E. P., Kuswah, P. & (Dr.) Ishwar Chand Sharma and Prof (Dr.) PBL Chaurasia,. Utilization of marble slurry in cement concrete replacing fine aggregate. Am. J. Eng. Res. 4, 55–58 (2015).

El Haggar, S. Sustainable Industrial Design and Waste Management: Cradle-To-Cradle for Sustainable Development (Academic Press, 2010).

Corinaldesi, V., Moriconi, G. & Naik, T. R. Characterization of marble powder for its use in mortar and concrete. Constr. Build. Mater. 24, 113–117 (2010).

Karaşahin, M. & Terzi, S. Evaluation of marble waste dust in the mixture of asphaltic concrete. Constr. Build. Mater. 21, 616–620 (2007).

Hebhoub, H. et al. Use of waste marble aggregates in concrete. Constr. Build. Mater. 25, 1167–1171 (2011).

Ismail, S. & Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 44, 464–476 (2013).

Dosho, Y. Development of a sustainable concrete waste recycling system. J. Adv. Concr. Technol. 5, 27–42 (2007).

Shirulea, P. A., Ataur, R. & Guptac, R. D. Partial replacement of cement with marble dust powder. Int. J. Adv. Eng. Res. Stud. 2249, 8974 (2012).

Katuwal, K., Duarah, A., Sarma, M.K., et al. Comparative study of M35 concrete using marble dust as partial replacement of cement and fine aggregate

Latha, G., Reddy, A. S. & Mounika, K. Experimental investigation on strength characteristics of concrete using waste marble powder as cementitious material. Growth 4, 2 (2015).

Vigneshpandian, G.V., Shruthi, E.A., Venkatasubramanian, C., Muthu. D. Utilisation of Waste Marble Dust as Fine Aggregate in Concrete. In: IOP Conference Series: Earth and Environmental Science. IOP Publishing, p 12007 (2017).

Kore, S. D. & Vyas, A. K. Impact of marble waste as coarse aggregate on properties of lean cement concrete. Case Stud. Constr. Mater. 4, 85–92 (2016).

Choudhary, R. et al. Permeation, corrosion, and drying shrinkage assessment of self-compacting high strength concrete comprising waste marble slurry and fly ash, with silica fume. In Structures 971–985 (Elsevier, 2021).

Choudhary, R., Gupta, R., Nagar, R. & Jain, A. Mechanical and abrasion resistance performance of silica fume, marble slurry powder, and fly ash amalgamated high strength self-consolidating concrete. Constr. Build. Mater. 269, 121282 (2021).

Kumar, P. Self-compacting concrete: Methods of testing and design. J. Inst. Eng. India Civ. Eng. Div. 86, 145–150 (2006).

Ahmadi, M. A., Alidoust, O., Sadrinejad, I. & Nayeri, M. Development of mechanical properties of self compacting concrete contain rice husk ash. Int. J. Comput. Inf. Syst. Sci. Eng. 1, 259–262 (2007).

Şahmaran, M., Christianto, H. A. & Yaman, İÖ. The effect of chemical admixtures and mineral additives on the properties of self-compacting mortars. Cem. Concr. Compos. 28, 432–440 (2006).

Coppola L, Cerulli T, Salvioni D (2004) Sustainable development and durability of self-compacting concretes. In: 8th CANMET/ACI Int. Conf. on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete. pp 29–50

Felekoğlu, B., Türkel, S. & Baradan, B. Effect of water/cement ratio on the fresh and hardened properties of self-compacting concrete. Build. Environ. 42, 1795–1802 (2007).

Banthia, N. Report on the physical properties and durability of fiber-reinforced concrete (2010).

Vandewalle, L. et al. RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete’-sigma-epsilon-design method-Final Recommendation. Mater. Struct. 36, 560–567 (2003).

Khaleel, O. R., Al-Mishhadani, S. A. & Razak, H. A. The effect of coarse aggregate on fresh and hardened properties of self-compacting concrete (SCC). Proc. Eng. 14, 805–813 (2011).

Zhu, W. Permeation properties of self-compaction concrete. In Self-Compacting Concrete: Materials Properties and Applications 117–130 (Elsevier, 2020).

Pereira, E.N.B., Barros, J.A.O., Ribeiro, A.F., Camões, A. Post-cracking behaviour of selfcompacting steel fibre reinforced concrete (2004).

Islam, G. M. S. & Das, G. S. Evaluating plastic shrinkage and permeability of polypropylene fiber reinforced concrete. Int. J. Sustain. Built. Environ. 5, 345–354 (2016).

Bentur, A. Role of interfaces in controlling durability of fiber-reinforced cements. J. Mater. Civ. Eng. 12, 2–7 (2000).

Hossain, M.A., Rahman, M.M., Morshed, A.Z., Haque, S.K.M. Investigation of the effect of nylon fiber in concrete rehabilitation

Singh, A. P. Strength and permeability characteristics of steel fibre reinforced concrete. Int. J. Civil, Arch. Sci. Eng 7, 211–216 (2013).

Ahmad, J., Manan, A., Ali, A., et al. A study on mechanical and durability aspects of concrete modified with steel fibers (SFs)

Cement AP ASTM C150 of the following type: 1. Concr which will be contact with Sew Type II, Moderate Sulfate Resist 2:

ASTM C 33/C33M,(2008). Stand Specif Concr aggregates Annu B ASTM Stand 4:498–505

EN TS (2009) 934–2 “Admixtures For Concrete, Mortar and Grout-Part 2: Concrete Admixtures; Definitions, Requirements, Conformity, Marking and Labelling.” Br Stand Inst

High-Range W-RA, Admixture R ASTM C 494/C 494M. Type F

Grout F ASTM C 476, except with a maximum slump of 4 inches, as measured according to ASTM C 143. C 143M

C39/C39M A (2003) Standard test method for compressive strength of cylindrical concrete specimens. Annu B ASTM Stand

Standard A (2010) C78. 2010. Stand Test Method Flexural Strength Concr (Using Simple Beam with Third-Point Load (ASTM C78–10) West Conshohocken, PA ASTM Int

Shannag, M. J., Brincker, R. & Hansen, W. Pullout behavior of steel fibers from cement-based composites. Cem. Concr. Res. 27, 925–936 (1997).

Ahmad, J. et al. Mechanical properties of sustainable concrete modified by adding marble slurry as cement substitution. AIMS Mater. Sci. 8, 343–358 (2021).

Hamzah, A. F. et al. Fresh characteristic and mechanical compressive strength development of self-compacting concrete integrating coal bottom ash as partial fine aggregates replacement. Int. J. Mech. Mechatron. Eng. 15, 61–67 (2015).

Iqbal, S. et al. Effect of fly ash on properties of self-compacting high strength lightweight concrete. Period Polytech. Civ. Eng. 61, 81–87 (2017).

Baboo, R. et al. Influence of Marble powder/granules in Concrete mix. Int. J. Civ. Struct. Eng. 1, 827–834 (2011).

Al-Akhras, N. M. & Abu-Alfoul, B. A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 32, 859–863 (2002).

Munir, M. J., Kazmi, S. M. S. & Wu, Y.-F. Efficiency of waste marble powder in controlling alkali–silica reaction of concrete: A sustainable approach. Constr. Build. Mater. 154, 590–599 (2017).

Li, L. G. et al. Recycling of marble dust as paste replacement for improving strength, microstructure and eco-friendliness of mortar. J. Clean Prod. 210, 55–65 (2019).

Toubal Seghir, N. et al. The utilization of waste marble dust as a cement replacement in air-cured mortar. Sustainability 11, 2215 (2019).

Kikuchi, T., Shintani, Y., Hirashima, T. & Kohno, M. Mechanical properties of steel fiber reinforced concrete at high temperature. J. Struct. Constr. Eng. 85, 169–176 (2020).

Tadepalli, P. R., Mo, Y. L. & Hsu, T. T. C. Mechanical properties of steel fibre concrete. Mag. Concr. Res. 65, 462–474 (2013).

Usman, M., Farooq, S. H., Umair, M. & Hanif, A. Axial compressive behavior of confined steel fiber reinforced high strength concrete. Constr. Build. Mater. 230, 117043 (2020).

Oehlert, G.W. (2000) Design and analysis of experiments: Response surface design. New York

Designation, A. (1976) C496‐71. Stand Method Test Split Tensile Strength Cylind Concr Specimens

Amin, S. K., Allam, M. E., Garas, G. L. & Ezz, H. A study of the chemical effect of marble and granite slurry on green mortar compressive strength. Bull. Natl. Res. Cent. 44, 19 (2020).

Williamson, G. R. The effect of steel fibers on the compressive strength of concrete. Spec. Publ. 44, 195–208 (1974).

Lim, J. C. & Ozbakkaloglu, T. Confinement model for FRP-confined high-strength concrete. J. Compos. Constr. 18, 4013058 (2014).

Deluce, J. R. & Vecchio, F. J. Cracking Behavior of Steel Fiber-Reinforced Concrete Members Containing Conventional Reinforcement. ACI Struct J 110, 2 (2013).

Ashby, M.F. Materials selection in mechanical design (Burlington, MA (2011)

Belachia, M., Aoun, H. & Hebhoub, H. Marble wastes as a substitute in hydraulic concrete. Solid Waste Technol. Manag. 2, 456–463 (2006).

Ahmad, J. et al. Evaluating the effects of flexure cracking behaviour of beam reinforced with steel fibres from environment affect. J. Green Eng. 10, 4998–5016 (2020).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through group research program under grant number RGP. 2/71/42.

Author information

Authors and Affiliations

Contributions

Conceptualization, F.A., J.A.; methodology, F.A.; software, M.H.E.O; validation, F.A and J.A.; formal analysis, J.A.; investigation, F.A. writing—F.A.; writing—J.A.; visualization, F.A.; supervision, M.H.E.O; project administration, K.M.K; funding acquisition, R.M.G; Revision and improving technically Paper, K.M.K; Grammatically improvements. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail:https://doi.org/10.1038/s41598-023-39394-x

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ahmad, J., Aslam, F., Martinez-Garcia, R. et al. RETRACTED ARTICLE: Performance of sustainable self-compacting fiber reinforced concrete with substitution of marble waste (MW) and coconut fibers (CFs). Sci Rep 11, 23184 (2021). https://doi.org/10.1038/s41598-021-01931-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-01931-x

This article is cited by

-

Self-Compacting Concrete with Partially Substitution of Waste Marble: A Review

International Journal of Concrete Structures and Materials (2023)

-

Strength and Durability Properties of Waste Glass Based Self Compacting Concrete: A Review

Silicon (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.