Abstract

Hyperthermophilic Thermotoga spp. are excellent candidates for the biosynthesis of cellulosic ethanol producing strains because they can grow optimally at 80 °C with ability to degrade and utilize cellulosic biomass. In T. neapolitana (Tne), a putative iron-containing alcohol dehydrogenase was, for the first time, revealed to be a bifunctional aldehyde/alcohol dehydrogenase (Fe-AAdh) that catalyzed both reactions from acetyl-coenzyme A (ac-CoA) to acetaldehyde (ac-ald), and from ac-ald to ethanol, while the putative aldehyde dehydrogenase (Aldh) exhibited only CoA-independent activity that oxidizes ac-ald to acetic acid. The biochemical properties of Fe-AAdh were characterized, and bioinformatics were analyzed. Fe-AAdh exhibited the highest activities for the reductions of ac-CoA and acetaldehyde at 80–85 °C, pH 7.54, and had a 1-h half-life at about 92 °C. The Fe-AAdh gene is highly conserved in Thermotoga spp., Pyrococcus furiosus and Thermococcus kodakarensis, indicating the existence of a fermentation pathway from ac-CoA to ethanol via acetaldehyde as the intermediate in hyperthermophiles.

Similar content being viewed by others

Introduction

As a leading candidate among alternatives to petroleum-derived transportation fuels, the production of fuel ethanol from cellulosic biomass has received considerable attention and effort over the last two decades1,2. However, the high costs of converting biomass to sugars and distilling ethanol at low concentrations from fermentation products are the primary factors that impede the establishment of a cellulosic biofuels industry1,3. Thermophiles can produce cellulosic ethanol at a high temperature, where ethanol is directly distillated from fermentation, and biodegradation of lignocellulose can be simultaneously achieved when these thermophiles carry and express cellulase and hemi-cellulase genes3,4.

Thermophiles can be categorized into three groups based on their optimal growth temperatures: moderate thermophiles grow optimally between 50 and 64 °C; extreme thermophiles and hyperthermophiles can grow optimally between 65 and 79 °C and above 80 °C, respectively5,6. Thermotoga spp. are cellulolytic and hemicellulolytic hyperthermophiles growing at temperatures up to 90 °C. They are excellent candidates for the construction of a cellulosic ethanol producer. At present, research has been focused on the identification of hyperthermophilic enzymes for an effective ethanol fermentation pathway in hyperthermophiles.

Generally, the final steps of ethanol fermentation in anaerobes are two reversible redox reactions, from ac-CoA to acetaldehyde (ac-ald) catalyzed by the CoA-dependent aldehyde dehydrogenase (Aldh) (enzyme classification number, EC 1.2.1.10), and from ac-ald to ethanol catalyzed by alcohol dehydrogenase (Adh, enzyme classification number, EC 1.1.1.2). Generally, Aldhs could be divided into two types based on their dependence on CoA; the CoA-independent Aldhs (EC 1.2.1.3) and the CoA-dependent Aldhs (EC 1.2.1.10). The CoA-independent Aldhs catalyze the irreversible oxidation of aldehydes to their corresponding acids7. However, CoA-dependent Aldhs catalyze the reversible conversion of acyl-CoA to the corresponding aldehydes8. Among the extremely thermophilic microbes, Thermoanaerobacter ethanolicus (Tet) grows optimally at 69 °C, and produces ethanol as a main fermentation product. The ethanol fermentation pathway of Tet is established by AdhA, AdhB, and AdhE, where AdhB and AdhE are bifunctional aldehyde/alcohol dehydrogenases (AAdh)9,10. However, to our knowledge, CoA-dependent Aldh activity has not yet been reported in any hyperthermophiles such as Thermotoga that grows at temperature up to 90 °C. In Thermotoga maritima (Tma) and Thermotoga hypogea (Thy), the pyruvate ferredoxin oxidoreductase (POR or PFOR) has CoA-dependent pyruvate decarboxylase (PDC) activity11,12. However, the bifunctional POR/PDC exhibited a very low specific activity of PDC, which was less than 2% of that of POR activity11,12. These results revealed that more than 98% of pyruvate would be converted to ac-CoA by POR, and ac-CoA would be further converted to acetic acid in the absence of an enzyme to catalyze the reduction of ac-CoA to produce ac-ald.

In our previous work, it has been revealed that the CoA-dependent Aldh activity can be performed by an enzyme that is annotated as alcohol dehydrogenases8,10,13. We think it necessary to characterize all the enzymes encoded by the alcohol dehydrogenase genes in a hyperthermophilic strain to search a CoA-dependent Aldh activity that is possibly occurring in hyperthermophilic species of Thermotoga. In this paper, we report gene cloning and expression, enzyme purification and characterization of a novel bifunctional iron-containing aldehyde/alcohol dehydrogenase (Fe-AAdh) from Thermotoga neapolitana (Tne). Furthermore, the similarity and distribution of Fe-AAdh in other microbes are also discussed basing on the analysis of bioinformatics. Knowledge about Fe-AAdh of Tne will be beneficial for further understanding an ethanol fermentation pathway in hyperthermophiles.

Materials and methods

Bacterial strains and plasmids

Tne strain NS-E (DSM 4359) was purchased from the German Collection of Microorganisms and Cell Cultures (DSMZ). The organism was grown anaerobically in Tma basal medium (TBM) with 0.5% glucose at 80 °C14.

Escherichia coli JM109 (Promega) was used as host for cloning and expression of genes in a pHsh vector (GenBank accession number: FJ571619.1), constructed by Shine E Biotech, Nanjing, China. E. coli cells were routinely grown aerobically in Luria–Bertani (LB) medium at 30 °C, and 100 μg/ml ampicillin was added to the LB medium for selective cultures.

Molecular cloning and sequencing

The expression vector pHsh was linearized by inverse PCR using a pair of primers with sequences: 5´-AGCGATAGCAGTTTTTTTCATGGGTATATCTCCTTCTTGT C-3´ upstream, and 5´-GTATCTAGACACCACCACCACCACCACTAATAA-3´ downstream. The PCR product was digested by restriction enzyme Xba I such that the linear vector had a blunt end upstream of the target gene, and a sticky end of Xba I that was ligated to the 3´-end of a target gene with a fused His-tag.

Genomic DNA was isolated from Tne cells according to the instruction of kit (Takara). According to the annotation of the genomic sequence of Tne (accession No. CP000916.1), the genes CNT_0580, CTN_1655, and CTN_1756 are open reading frames coding for three putative iron-containing Adhs (Fe-Adh), while CTN_0257 and CTN_1548 are genes encoding a zinc-containing Adh (Zn-Adh) and an Aldh, respectively. These genes were amplified by PCR using Pyrobest DNA polymerase (Takara) with the primers listed in Table 1 and synthesized by Sangon Co. (Shanghai, China). PCR products were digested by Xba I and ligated to pHsh vector to yield expression plasmids.

Gene expression and enzyme purification

E. coli JM109 cells were transformed using the expression plasmids containing the Adh or Aldh genes and were grown at 30 °C to an OD600 of 0.6–0.8 before the cultures were transferred to a 42 °C shaking water-bath incubator for heat-shock induction of gene expression. After 6 h of cultivation along with gene expression at 42 °C, cells were harvested and transferred into an anaerobic chamber for the isolation and purification of recombinant enzymes. E. coli cells were re-suspended in degassed 3-(N-morpholino) propanesulfonic acid buffer (MOPSb, 25 mM, pH 6.5), and disrupted by sonication, followed by heat treatment at 75 °C for 30 min.

After the cell debris and heat denatured protein were removed by centrifugation (14,000×g, 30 min), the supernatants were mixed with the same volume of 2 × binding buffer, and loaded to the Ni-metal affinity column (Novagen) according to the manufacturer’s instructions. Each recombinant enzyme bound to Ni-column was eluted, and collected into a dialysis bag, concentrated by embedding the dialysis bag in polyethylene glycol (PEG) 20,000, and dialyzed against MOPSb with two changes. Purified enzymes were stored in MOPSb with the addition of 10% glycerol, 1 mM dithiothreitol (DTT), 0.02% (w/v) Sodium azide (NaN3), and 1 mM FeCl2 for the Fe-containing enzyme.

Gene expression levels and the purity of recombinant proteins were examined using sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) as described by Laemmli15. Protein concentration was determined by measuring the absorbance at 280 nm and calculating the concentration based on the extinction coefficient for the amino acid sequence of each enzyme.

Enzyme activity assay

Aldh and Adh activities were measured by monitoring the changes in NAD(P)H absorbance at 340 nm. One unit of enzyme activity was defined as the amount of enzyme producing or consuming 1 μmol of NAD(P)H per min. All the activity assays were performed in triplicate, and data reported here are the mean of the three replicates. For standard enzyme activity assays, the reaction mixture consisted of 100 μl of MOPSb containing suitable substrates at concentrations: 1 mM NAD(P)+ or NAD(P)H, 2 mM ac-CoA or CoASH, and 20 mM acetaldehyde (ac-ald) or ethanol, at different pH and temperatures as indicated for each reaction. The CoA-dependent Aldh activity was determined as described by Pei et al.8, and the CoA-independent Aldh activity was measured using 20 mM ac-ald as the substrate and 1 mM NAD(P)+ as the cofactor, in the absence of CoASH, at 85 °C and various pH values. The Km and Vmax of Fe-AAdh on ac-CoA were determined at 80 °C, pH 6.5 with 0.25 mM NADPH as a cofactor. Thermostability of the enzyme encoded by CTN_0580 was analyzed by measuring the residual activity under the optimal assay conditions after pre-incubating aliquots of the purified enzyme for different durations (0 min, 30 min, 60 min, 90 min, 120 min) at 85 °C, 90 °C, and 95 °C.

Analysis of the protein sequence of Fe-AAdh

The multiple sequence alignment (MSA) of Fe-AAdh, AdhB, and AdhE was used the program T-Coffee and ESPript (Easy Sequencing in PostScript, http://espript.ibcp.fr/ESPript/ESPript/index.php)16,17. Similar sequence of Fe-AAdh was also blasted by “Protein BLAST” tool in NCBI (https://blast.ncbi.nlm.nih.gov/Blast.cgi).

Ethical approval

Not applicable, since the work does not involve any study with human participants or animals.

Results

Gene cloning, expression, and enzyme purification

To prepare recombinant enzymes encoded by the Tne genes CTN_0257, CNT_0580, CTN_1548, CTN_1655 and CTN_1756, these genes from Tne genomic DNA were amplified, and successfully cloned into E. coli expression vector pHsh to generate the corresponding plasmids, i.e. pHsh-0257, pHsh-0580, pHsh-1548, pHsh-1655, and pHsh-1756, respectively. The target genes in the expression plasmids were sequenced and it was confirmed that no mutation had occurred in them. The expression plasmids were transformed into E. coli and the target genes were successfully induced to express in the recombinant cells separately (Fig. 1).

Heterologous expression of the genes encoding aldehyde and alcohol dehydrogenases of Thermotoga neapolitana. Lane M, protein markers with molecular masses as indicated; Lane 1, Escherichia coli cell protein as control; Lanes 4–5: Fe-AAdh gene (CTN_0580) expressed in E. coli, and purified Fe-AAdh protein; Lanes 10–11, protein of E. coli cells expressing Aldh gene (CTN_1548), and the purified protein of Aldh; Lanes 2–3, and 6–9: gene expression and purification of the three monofunctional alcohol dehydrogenases (CTN_0257, CTN_1655, CTN_1756).

The recombinant proteins produced from Tne genes CTN_0257, CNT_0580, CTN_1548, CTN_1655, and CTN_1756 were designated as Zn-Adh, Fe-AAdh, Aldh, Fe-Adh1, and Fe-Adh2, respectively, based on their activities and metal ions, and the gene products had subunits similar to their putative molecular masses of 43.3, 42.6, 51.8, 40.6 and 43.6 kD, respectively (Fig. 1). These enzymes were purified to near gel electrophoresis homogeneity after a heat treatment and a metal affinity chromatography by using Ni-column at room temperature (Fig. 1). However, the purified Fe-AAdh became inactivated within about a week after it was stored at − 20 °C, implying that the enzyme was sensitive to O2 in the air and buffer. This problem was resolved by purifying these enzymes in an anaerobic chamber using degassed buffers and keeping the purified enzyme in sealed anaerobic serum tubes. The enzyme concentration is about 1.8 mg/mL after purification.

Dependence of enzyme activity on the temperature and pH conditions

Four possible reactions can occur in the final steps of ethanol formation from ac-CoA. To determine the number of steps each dehydrogenase can catalyze, the biochemical properties of the enzymes were characterized at different reaction pH and temperatures, where substrate(s) and cofactor concentrations were approximately 10 times higher than the Km value of the enzyme. Tne Aldh encoded by gene CTN_1548 catalyzed the oxidation of aldehydes to acetic acid using either NAD+ or NADP+ as coenzyme, while Zn-Adh, Fe-Adh1 and Fe-Adh2 did not show any ac-CoA reduction activity (Data not shown in this paper). Therefore, the main biochemical properties of recombinant enzyme encoded by Tne gene CNT_0580 were further characterized in more detail.

When searching for an enzyme that could reduce ac-CoA to ac-ald, we found that the purified enzyme encoded by CNT_0580 was a bifunctional aldehyde/alcohol dehydrogenase (Fe-AAdh). At temperatures up to 95 °C, Fe-AAdh exhibited significant activities in all the reduction and oxidation reactions in the pathway between ac-CoA and ethanol, including the reactions of ac-CoA → ac-ald, ac-ald → ethanol, ethanol → ac-ald, and ac-ald → ac-CoA (Fig. 2A). Fe-AAdh activities highly depended on the temperature and pH conditions, and the enzyme had different temperature and pH optima when it catalyzed these four reactions (Fig. 2). The enzyme exhibited the highest activity for the reductions of ac-CoA and ac-ald at 85 and 80 °C, pH 7.54 (Fig. 2). However, its temperature and pH optima for the oxidations of ethanol or ac-ald were at 95 °C, pH 8.82, or at 85 °C and pH 9.32, which could be much higher than those for growing conditions of Tne (Fig. 2).

Properties of the bifunctional aldehyde/alcohol dehydrogenase (Fe-AAdh) of Tne. (A) The effects of temperature on the activities of Fe-AAdh. Activity was determined at various temperatures in the standard reaction mixture described in Materials and Methods. (B) The effects of pH on the activities of Fe-AAdh. The buffer composition for these assays was 25 mM each of phthalate, MOPS, Tris, and glycine with pH values calibrated at 80 °C, and the other conditions were the same as those for the standard assays. The highest activity was set as 100%.

Thermostability of Fe-AAdh

Since its gene was cloned from the genomic DNA of Tne, a hyperthermophilic strain of Thermotoga, Fe-AAdh should be a hyperthermophilic enzyme, which was determined by thermostability of the enzyme (Fig. 3). After Fe-AAdh was incubated at 85, 90, or 95 °C for about one hour, it remained about 85%, 70% or 40% activity in comparison with the original activity without preincubation. Therefore, Fe-AAdh had a 1-h half-life at about 92 °C, which is a typical property of hyperthermophilic enzymes, and the highest among CoA-dependent Aldhs (Fig. 3).

Cofactor dependence and kinetics of Fe-AAdh

When Fe-AAdh catalyzes the reduction of ac-CoA or ac-ald, reduced type of cofactors NADH or NADPH are involved in the reactions, and on the other hand, oxidized type of cofactors NAD+ or NADP+ are required for the oxidation of ethanol or ac-ald. The involvements of different cofactors resulted in Fe-AAdh activity changes in each catalytic reaction (Table 2). Fe-AAdh employed NADPH as a sole active cofactor, and no enzyme activity was detected by using NADH in catalyzing ac-CoA reduction (Table 2). The enzyme could use both cofactors in the other three reactions; however, the activities were much higher when using NADPH or NADP+ than using NADH or NAD+ as a cofactor. Therefore, NADPH and NADP+ are preferentially utilized cofactors of Fe-AAdh, and its specific activities for the reductive reactions was significantly higher than those of the oxidative reactions. Although Fe-AAdh showed activity and thermostability at temperatures up to 95 °C, Tne cells grew optimally at 80 °C with an intracellular pH value of about 6.5 as measured upon non-buffered cell-free extracts in this study. Therefore, the kinetics of Fe-AAdh was determined under these conditions in the presence of 0.25 mM NADPH as a cofactor. The apparent Km and Vmax of Fe-AAdh for ac-CoA were 1.75 mM and 0.79 U/mg, respectively.

Bioinformatic analysis of Fe-AAdh protein

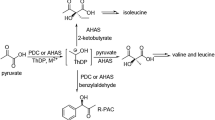

The amino acid sequence of Fe-AAdh was subjected to the multiple sequence alignment (MSA) to compare with the other two bifunctional aldehyde/alcohol dehydrogenases, AdhB (GenBank accession number: DQ323135.1) and AdhE (GenBank accession number: DQ836061.1). Interestingly, AdhE is a large protein with two domains of Fe-ADH (PF00465 family) and an ALDH (ALDH-SF superfamily) while bifunctional enzymes of Fe-AAdh and AdhB are monofunctional ADHs (Fig. 4). Meanwhile, Fe-AAdh and AdhB belong to the iron- and zinc-containing alcohol dehydrogenase families, respectively. These results indicate that these enzymes (Fe-AAdh, AdhE, and AdhB) employ different strategies to achieve CoA-dependent aldehyde dehydrogenase activities.

Surprisingly, some similar enzyme also appeared not only in hyperthermophilic Thermotoga spp., but also in Pyrococcus furiosus (Pfu) and Thermococcus kodakarensis (Tko) (Table 3), which have been just annotated as iron-containing alcohol dehydrogenase (ADH). Thus, basing on these results, the CoA-dependent Aldh activity is probably widespread in hyperthermophilic microbes including bacteria and archaea that grow optimally at temperatures above 80 °C.

Discussion

Thermophilic fermentation at temperatures above the boiling point of ethanol could allow in situ product removal to mitigate ethanol toxicity. Metabolic engineering is an effective approach to construct novel ethanol-producing strains by heterogeneous expression of the genes coding for the enzymes catalyzing reactions involved in ethanol formation18,19. To construct a hyperthermophilic strain for cellulosic ethanol fermentation, researchers have to identify and obtain hyperthermophilic enzymes involved in the ethanol fermentation pathway. The bifunctional POR/PDC has been found in Tma and Thy, as well as in the hyperthermophilic archaeon Pfu. However, POR/PDC can use about 2% and 98% pyruvate to produce ac-ald and ac-CoA, respectively11,12. Thus, more than 98% of pyruvate is probably converted to ac-CoA by POR, and ac-CoA is further converted to acetic acid in the absence of an enzyme that converts ac-CoA to ac-ald and further to ethanol.

Basing on the previous studies on the ethanol fermentation pathway of anaerobic thermophiles, the CoA-dependent Aldh activity is usually performed by the enzymes annotated as alcohol dehydrogenases such as AdhB and AdhE10,20. There is a gene in Tne genome annotated as Aldh, but it was confirmed in this work that the gene product was a CoA-independent Aldh (Data not shown). Therefore, it is necessary to characterize all the enzymes encoded by the Adh genes in a hyperthermophilic microbe.

In the work reported here, a bifunctional aldehyde/alcohol dehydrogenase Fe-AAdh encoded by CTN_0580 was discovered, which could catalyze four redox reactions involved in ethanol formation (Fig. 2A,B). In comparison, Fe-AAdh displayed properties different from those of the other bifunctional ethanol fermentation enzymes, AdhE has very high ac-CoA reduction activity, however, it loses more than 50% activity after an incubation of 30 min at 70 °C and pH 6.58. AdhB from Tet is a thermostable enzyme that has a 1-h half-life at 85 °C, however, its specific activity for ac-CoA reduction is below 0.1 U/mg under cell growth conditions. In comparison, Fe-AAdh from Tne exhibited the high thermostability of a hyperthermophilic enzyme with 1-h half-life at about 92 °C (Fig. 3). Although the activity of Fe-AAdh in Tne in the reduction of ac-CoA is much lower than that of AdhE in Tet, Fe-AAdh can be a basic framework for in vitro synthesis of a highly active hyperthermophilic CoA-dependent aldehyde dehydrogenase. This can be achieved by site-directed mutagenesis, motif re-assembly between Fe-AAdh and AdhE, or by directed gene evolution in large scales21. Additionally, Fe-AAdh exhibited significant activities to catalyze all four reactions at the optimal reaction conditions (Fig. 5), while AdhE and Adh B can catalyze three reactions for ethanol fermentation8.

Many similar genes were also discovered in other hyperthermophiles (Table 3). A gene (PF_0075) encoding an enzyme with 94% similarity to Fe-AAdh from Tne was blasted from the genome database of hyperthermophilic archaeon Pfu. Previously, a higher amount of ethanol was produced in Pfu by co-expression with AdhA or AdhE, which were probably resulted from the synergy between Adh and Fe-AAdh encoded by PF_007522,23.

In conclusion, hyperthermophilic Thermotoga spp. are excellent candidates for cellulosic ethanol fermentation. A hyperthermophilic Fe-AAdh was, for the first time, revealed to catalyze ac-CoA reduction to form ethanol via an acetaldehyde intermediate. The Fe-AAdh gene is highly conserved in Thermotoga spp. Pfu, and Tko, indicating the existence of a hyperthermophilic fermentation pathway from ac-CoA to ethanol via ac-ald. These findings offer a basic knowledge for the construction of an ethanol fermentation strain from hyperthermophiles, which is a key element for the approach to the consolidated processes of cellulosic ethanol production.

References

Shaw, A. J. et al. Metabolic engineering of a thermophilic bacterium to produce ethanol at high yield. Proc. Natl. Acad. Sci. U. S. A. 105, 13769–13774 (2008).

Taylor, M. P. et al. Thermophilic ethanologenesis: Future prospects for second-generation bioethanol production. Trends Biotechnol. 27, 398–405 (2009).

Le, Y. & Shao, W. Advances in and challenges for thermophilic fermentation of cellulosic ethanol. Chin. J. Biotechnol. 29, 274–284 (2013).

Wiegel, J., Ljungdahl, L. G. & Demain, A. L. The importance of thermophilic bacteria in biotechnology. Crit. Rev. Biotechnol. 3, 39–108 (1985).

Stetter, K. O. History of discovery of the first hyperthermophiles. Extremophiles 10, 357–362 (2006).

Wagner, I. D. & Wiegel, J. Diversity of thermophilic anaerobes. Ann. N. Y. Acad. Sci. 1125, 1–43 (2008).

Perozich, J. et al. Relationships within the aldehyde dehydrogenase extended family. Protein Sci. 8, 137–146 (1999).

Pei, J. et al. Thermoanaerobacter spp. control ethanol pathway via transcriptional regulation and versatility of key enzymes. Metab. Eng. 12, 420–428 (2010).

Burdette, D. & Zeikus, J. G. Purification of acetaldehyde dehydrogenase and alcohol dehydrogenases from Thermoanaerobacter ethanolicus 39E and characterization of the secondary-alcohol dehydrogenase (2 degrees Adh) as a bifunctional alcohol dehydrogenase–acetyl-CoA reductive thioesterase. Biochem. J. 302(Pt 1), 163–170 (1994).

Peng, H., Wu, G. & Shao, W. The aldehyde/alcohol dehydrogenase (AdhE) in relation to the ethanol formation in Thermoanaerobacter ethanolicus JW200. Anaerobe 14, 125–127 (2008).

Eram, M. S. et al. Molecular and biochemical characterization of bifunctional pyruvate decarboxylases and pyruvate ferredoxin oxidoreductases from Thermotoga maritima and Thermotoga hypogea. J. Biochem. 158, 459–466 (2015).

Eram, M. S. & Ma, K. Pyruvate decarboxylase activity of the acetohydroxyacid synthase of Thermotoga maritima. Biochem. Biophys. Rep. 7, 394–399 (2016).

Pei, J. et al. The mechanism for regulating ethanol fermentation by redox levels in Thermoanaerobacter ethanolicus. Metab. Eng. 13, 186–193 (2011).

Jiang, Y. et al. A highly efficient method for liquid and solid cultivation of the anaerobic hyperthermophilic eubacterium Thermotoga maritima. FEMS Microbiol. Lett. 259, 254–259 (2006).

Laemmli, U. K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227, 680–685 (1970).

Notredame, C., Desmond, H. G. & Heringa, J. T-Coffee: A novel method for multiple sequence alignments. J. Mol. Biol. 302, 205–217 (2000).

Robert, X. & Gouet, P. Deciphering key features in protein structures with the new ENDscript server. Nucleic Acids Res. 42, W320–W324 (2014).

Basen, M. et al. Single gene insertion drives bioalcohol production by a thermophilic archaeon. Proc. Natl. Acad. Sci. U. S. A. 111, 17618–17623 (2014).

Chung, D. et al. Cellulosic ethanol production via consolidated bioprocessing at 75 °C by engineered Caldicellulosiruptor bescii. Biotechnol. Biofuels 8, 163–163 (2015).

Burdette, D. S., Vieille, C. & Zeikus, J. G. Cloning and expression of the gene encoding the Thermoanaerobacter ethanolicus 39E secondary-alcohol dehydrogenase and biochemical characterization of the enzyme. Biochem. J. 316(Pt 1), 115–122 (1996).

Shao, W. et al. Development and use of a novel random mutagenesis method: in situ error-prone PCR (is-epPCR). Methods Mol. Biol. 1498, 497–506 (2017).

Keller, M. W. et al. Ethanol production by the hyperthermophilic archaeon Pyrococcus furiosus by expression of bacterial bifunctional alcohol dehydrogenases. Microb. Biotechnol. 10, 1535–1545 (2017).

Straub, C. T. et al. Modification of the glycolytic pathway in Pyrococcus furiosus and the implications for metabolic engineering. Extremophiles 24, 511–518 (2020).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Grant no. 31770089), Natural Science Foundation of Jiangsu Province (Youth Fund No. BK20170541), and Advanced Talents Foundation of Jiangsu University (No. 16JDG031).

Author information

Authors and Affiliations

Contributions

W.S. conceived the project and designed the tests. Q.W., C.S. and H.W. performed the tests and analyzed the data. C.S., W.S., A.A., K.M. and J.W. wrote and revised the manuscript. W.S. and A.A. submitted the paper to the journal.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Q., Sha, C., Wang, H. et al. A novel bifunctional aldehyde/alcohol dehydrogenase catalyzing reduction of acetyl-CoA to ethanol at temperatures up to 95 °C. Sci Rep 11, 1050 (2021). https://doi.org/10.1038/s41598-020-80159-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-80159-7

This article is cited by

-

Astrobiological implications of the organic and inorganic cyanide utilization by a novel Antarctic hyperthermophilic Pyrococcus strain

Extremophiles (2024)

-

Biochemical and Functional Characterization of an Iron-Containing Alcohol Dehydrogenase from Thermococcus barophilus Ch5

Applied Biochemistry and Biotechnology (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.