Abstract

cis-Abienol, a natural diterpene-diol isolated from balsam fir (Abies balsamea), can be employed as precursors for the semi-synthesis of amber compounds, which are sustainable replacement for ambergris and widely used in the fragmented industry. This study combinatorially co-expressed geranyl diphosphate synthase, geranylgeranyl diphosphate synthase, Labda-13-en-8-ol diphosphate synthase and diterpene synthase, with the best combination achieving ~ 0.3 mg/L of cis-abienol. An additional enhancement of cis-abienol production (up to 8.6 mg/L) was achieved by introducing an exogenous mevalonate pathway which was divided into the upper pathway containing acetyl-CoA acetyltransferase/HMG-CoA reductase and HMG-CoA synthase and the lower pathway containing mevalonate kinase, phosphomevalonate kinase, pyrophosphate mevalonate decarboxylase and isopentenyl pyrophosphate isomerase. The genetically modified strain carrying chromosomal copy of low genes of the mevalonate with the trc promoter accumulated cis-abienol up to 9.2 mg/L in shake flask. Finally, cis-abienol titers of ~ 220 mg/L could be achieved directly from glucose using this de novo cis-abienol-producing E. coli in high-cell-density fermentation. This study demonstrates a microbial process to apply the E. coli cell factory in the biosynthesis of cis-abienol.

Similar content being viewed by others

Introduction

cis-Abienol, a bicyclic tertiary labdanoid diterpene alcohol found in balsam fir (Abies balsamea) and tobacco, is the fragrance precursor of most oriental tobaccos and part cigars, commonly used in cigarette extract1,2,3. It also plays a key role in the chemical defense against herbivores and pathogens, such as bark beetles and their associated fungi4. Furthermore, cis-abienol and other oxygen-containing diterpenoids of plant origin (e.g., sclareol and manool) can be used as precursors for the semi-synthesis of amber compounds like Ambrox5, which is a sustainable replacement for ambergris and widely used in the fragmented industry because of its high fixative and olfactory qualities6,7. Currently, the cis-abienol was extracted from cis-abienol plants8,9. The primary sources of cis-abienol are balsam fir10, tobacco trichomes (Nicotiana tabacum; family Solanaceae)9,11, or tuberous roots of Bolivian sunroot (Polymnia sonchifolia; family Asteraceae)12. The current isolation method of cis-abienol from the plant is inefficient, requiring substantial expenditure of natural resources and many of environmentally hazardous chemicals. So the problems of the shortage of natural resources and environmental pollution have let us employ microorganisms for the production of cis-abienol, which can utilize renewable glucose derived from lignocellulose.

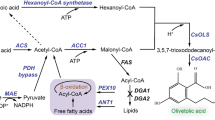

Microorganisms provide a sustainable and environment-friendly alternative for the production of cis-abienol starting from pure carbon sources and frequently show high product specificity13. cis-Abienol is synthesized from the cyclization of the geranylgeranyl diphosphate (GGPP) which is derived from isopentenyl pyrophosphate (IPP) and dimethylallyl pyrophosphate (DMAPP) manufactured through either the methylerythritol 4-phosphate (MEP) pathway in prokaryotes or the mevalonate (MVA) pathway in archaea/eukaryotes14,15,16. IPP is transformed into its isomer DMAPP by isopentenyl pyrophosphate isomerase (IDI). DMAPP and IPP are converted to farnesyl pyrophosphate (FPP) by farnesyl pyrophosphate synthase (ispA/Erg20) and further converted to GGPP by geranylgeranyl pyrophosphate synthase (CrtE) (Fig. 1). Biosynthesis of cis-abienol from GGPP involves two steps. The first is initiated by a carbon–carbon protonation, catalyzed by a class II diterpene synthase (diTPS) and leads to a cyclic diterpene diphosphate intermediate called labda-13-en-ol diphosphate (LDPP). The class II diTPS from S. clare has been cloned and functional characterized in Escherichia. coli for the biosynthesis of sclareol17. The second step of the pathway is catalyzed by cis-abienol synthase (Cas) which pertains to class I diTPS containing several types to produce a specific end product18,19,20. Based on this, the cis-abienol was biosynthesized in Yarrowia lipolytica by overexpressing the class II diPTS and Cas from different species21. Many biotechnological studies have been focused on the efficient production of desirable isoprenoids using E. coli as a host22. In E. coli, the isoprenoid was naturally biosynthesized through the endogenous MEP pathway23. For isoprenoid biosynthesis, a sufficient supply of IPP and DMAPP is essential. This has been often achieved by the expression of the idi and dxs (1-deoxy-d-xylulose 5-phosphate reductoisomerase) gene in the MEP pathway24. However, it has been shown that the introduction of the MVA pathway is more successful than engineering endogenous MEP pathway in E. coli, as it may avoid the natural regulatory mechanisms associated with the MEP pathway25,26. Michel et al. overexpressed the MVA pathway from saccharomyces cerevisiae and the enzymes responsible for the biosynthesis of sclareol to construct the sclareol biosynthetic pathway in genetically engineered E. coli and reached sclareol titers of ~ 1.5 g/L in high-cell-density fermentation17. Therefore, increasing the efficient supply of precursors is important to enhance cis-abienol production.

The MEP pathway and MVA pathway for cis-abienol production in E. coli. Genes overexpression are indicated in bold. Construction of the cis-abienol production strains overexpression the MVA pathway and cis-abienol pathway. Genes of MVA pathway are denoted by the blue arrows while the cis-abienol pathway is denoted by the violet red arrows. Enzymes involved in the MVA pathway and MEP pathway: MvaE, acetyl-CoA acetyltransferase/HMG-CoA reductase; MvaS, HMG-CoA synthase; MK, mevalonate kinase; PMK, phosphomevalonate kinase; MVD, mevalonate pyrophosphate decarboxylase; IDI, IPP isomerase; FPPS, farnesyl pyrophosphate synthase; GPPS, geranylgeranyl pyrophosphate synthase; LPPS, Labda-13-en-8-ol diphosphate synthase, CAS, cis-abienol synthase, Dxs, 1-deoxy-d-xylulose-5-phosphate synthase; Dxr, 1-deoxy-d-xylulose 5-phosphate reductoisomerase; IspD, 4-pyrophosphocytidyl-2-C-methyl-d-erythritol synthase; IspE, 4-pyrophosphocytidyl-2-C-methylerythritol kinase; IspF, 2-C-methyl-d-erythritol 2,4-cyclopyrophosphate synthase; IspG, 4-hydroxy-3-methylbut-2-enyl pyrophosphate synthase; IspH, 1-hydroxy-2-methyl-butenyl 4-pyrophosphate reductase. Pathway intermediates: GAP, glyceraldehyde 3-phosphate; PYR, pyruvate; DXP, 1-deoxy-d-xylulose 5-phosphate; MEP, 2C-methyl-d-erythritol 4-phosphate; CDP-ME, 4-diphosphocytidyl-2C-methylD-erythritol; MEcPP, 2C-methyl-d-erythritol 2,4-cyclodiphosphate; HMBPP, 1-hydroxy-2-methyl-2-(E)-butenyl 4-diphosphate; A-CoA, acetyl-CoA; AA-CoA, acetoacetyl-CoA; HMG-CoA, 3-hydroxy-3-methylglutaryl-CoA; Mev-P, mevalonate 5-phosphate; Mev-PP, mevalonate 5-diphosphate; IPP, isopentenyl pyrophosphate; DMAPP, dimethylallyl pyrophosphate; FPP, Farnesyl pyrophosphate; GGPP, geranylgeranyl pyrophosphate; LPP, Labda-13-en-8-ol diphosphate.

In this study, based on our previous work27,28, cis-abienol was produced by assembling a biosynthetic pathway in an engineering E. coli, using the heterologous MVA pathway combined with the additional of CrtE gene, Labda-13-en-8-ol diphosphate synthase (LPPS) gene from Salvia. sclarea and Cas gene from A. balsamea. The cis-abienol production of the final genetically modified strain, CM2/pCLES/pLCEC, was finally investigated under fed-batch fermentation condition. This study has begun the necessary foundations for a more sustainable route of cis-abienol production.

Results

Engineering a pathway for cis-Abienol biosynthesis

GGPP, generated from either MEP or MVA pathway, could be catalyzed by the Lpps and Cas into cis-abienol. In the previous study28, it has proved feasible that overexpressing the Lpps gene and sclareol synthase gene along with the native MEP pathway to produce sclareol in E. coli. In this study, the cis-abienol biosynthesis pathway was constructed by expressing the primary enzymes diphosphate synthase (IspA), CrtE, Lpps, and Cas. The biosynthesis genes (Lpps, Cas, CrtE, IspA) of cis-abienol pathway were cloned into the plasmid pACYDuet-1 one by one to generate combination plasmid pLCCI. Accumulation of cis-abienol was not detected in the recombinant strain BL21 (DE3)/ pLCC for two days shake flask. We postulated that the low level of FPP may restrict the cis-abienol biosynthesis in the strain BL21(DE3)/pLCC. Because FPP pool was required to synthesize trans-octaprenyl diphosphate (ODP) and cis-undecaprenyl trans-undecapreyl diphosphate (UDP) in E. coli, which were the precursors of ubiquinone and peptidoglycan, respectively29,30,31. To improve the accumulation of FPP, the diphosphate synthase (IspA) gene was added to the plasmid to enhance the efficiency of the conversion of IPP and DMAPP to FPP. Thus BL21 (DE3) carrying pLCCI for two days shake flask resulted in one dominant peak in an LC–MS chromatogram (Fig. 2A) with a concentration of 0.32 mg/L of cis-abienol (Fig. 3). Comparison of the retention time and mass-spectrum of this compound with authentic standard confirmed the production of cis-abienol (Fig. 2A-D). The results showed that overexpressing the gene LPPS, Cas, CrtE, IspA together with the native MEP pathway was capable of synthesizing synthesize cis-abienol in E. coli.

Identification of cis-abienol by LC–MS. (A) total ion current chromatogram of the extracts of the fermentation broth from E. coli BL21(DE3) harboring pLCCI after being induced for 48 h. (B) total ion current chromatogram of cis-abienol standard (the peak of cis-abienol was marked with an arrow corresponding to the retention time of 19.8 min). (C) mass spectrum of fermentation production. (D) mass spectrum of cis-abienol standard.

cis-Abienol production by BL21(DE3) harboring respective plasmid. CM1, ERG8, ERG12, ERG19 and IDI1genes were integrated into the E. coli chromosome with trc promoter, CM2, ERG8, ERG12, ERG19 and IDI1genes were integrated into the E. coli chromosome with Gi1.2 promoter, pLCC, pACYDuet-1 derivative carrying genes Lpps, Cas, CrtE, pLCCI, pACYDuet-1 derivative carrying genes Lpps,Cas, CrtE, ispA, pCLES, pCL1920 derivative carrying genes mvaE, mvaS, PYJM14, pTrcHis2B derivative carrying genes ERG8, ERG12, ERG19 and IDI1, nd not detected. Data were obtained after each strain was induced for 48 h in liquid M9 mineral medium supplemented with 1 mM MgSO4 and 20 g/L glucose. Error bars represent the range of three independent fermentations.

cis-Abienol microbial toxicity

Oleoresin components, produced by conifers, most of which are a diverse of diterpenoids like cis-abienol, play a key role in the chemical defense against fungi4. Microbial production of cis-abienol in high titers may be restricted by its potential toxicity to the producing host. The effect of the concentration of cis-abienol on the E. coli strain was analyzed by measuring the OD600 for 36 h in shake flasks containing 20 mL of LB medium, which showed that E. coli strains could grow well at the commercially available cis-abienol titer from 0 g/L to 2 g/L. As shown in Fig. 4, when added exogenously to the growth medium, cis-abienol shows low toxicity to BL21(DE3)/pLCCI, the lack toxicity to the producing host should enable the production of cis-abienol in higher titers.

The growth of strain BL21(DE3)/pLCCI in LB medium with different concentrations of commercially available cis-abienol. The growth (OD600) was monitored for 36 h. cis-Abienol was added to the LB medium as follows: 0 g/L (■), 0.5 g/L (●), 1 g/L (▲), 1.5 g/L (▼) and 2 g/L (◄). Error bars represent the range of three independent experiments.

Increasing the precursor supply for cis-Abienol biosynthesis

The low content of IPP and DMAPP also limits the efficient biosynthesis of terpenoids in E. coli. High-level polyprenyl pyrophosphate production may prove useful in producing a wide variety of compounds such as isoprene, pinene, longifolene, and sclareol17,32,33,34. One of the key strategies for constructing an efficient terpenoid biosynthesis host is to introduce a heterologous mevalonate pathway. Initially, our attempt to synthesize cis-abienol in E. coli by co-expressing genes LPPS, Cas, CrtE and IspA resulted in only a small amount of cis-abienol (~ 0.32 mg/L) in shake flask culture. To further improve production of cis-abienol, a metabolic engineering approach was adopted to increase the supply of precursor via overexpression of a heterologous mevalonate pathway into E. coli. The acetyl-CoA acetyltransferase/HMG-CoA reductase and HMG-CoA synthase from Enterococcus faecalis encoded by mvaE and mvaS were cloned into the low copy plasmid pCL1920 with medium-strength trc promoter to generate the recombinant plasmid pCLES. The plasmid pYJM14 containing the MVA lower pathway genes ERG12, ERG8, ERG19 and IDI1 from S. cerevisiae under the control of trc promoter (pTrcHis2B) has been constructed in the preliminary experiments in our laboratory32. The recombinant strain BL21 (DE3) (pCLES/pYJM14/pLCCI) carrying MVA pathway could accumulate 3.0 mg/L cis-abienol, which is about ten-fold of that (0.32 mg/L) produced by the control strain BL21 (DE3) (pLCCI) without MVA pathway (Fig. 3). According to the data obtained, increasing the supply of precursor of IPP and DMAPP by overexpression of MVA pathway is conducive to the cis-abienol biosynthesis.

In order to investigate the effect of FPP synthase Erg20 of S. cerevisiae and different gene arrangement of Erg20 and CrtE on the synthesis of cis-abienol, the recombinant pLCCE and pLCEC were constructed and transformed into BL21(DE3)/pCLES/pYJM14 competent cells, respectively. The strain carrying FPP synthase of S. cerevisiae produced 6.1 mg/L of cis-abienol, which is twofold to the strain with native FPP synthase. Although prior reports have shown that native FPP synthase is more effective than S. cerevisiae to produce sesquiterpene in E. coli34, we observed that the FPP synthase from S. cerevisiae was advantageous for the synthesis of cis-abienol. The reason may be that a high concentration of FPP was toxic to E. coli cell growth, resulting in a lower level of cis-abienol in BL21(DE3)/pCLES/pYJM14/pLCCI. This result demonstrated that the FPP synthase of S. cerevisiae was more efficient than the native one for FPP supply. We also found that different order for gene Erg20 and CrtE leads to different production of cis-abienol. The strain BL21(DE3)/pCLES/pYJM14/pLCEC accumulated 8.6 mg/L of cis-abienol, and the yields were 1.5 times that of strain BL21(DE3)/pCLES/pYJM14/pLCCE (Fig. 3). It is concluded that the FPP and CrtE genes order in the operon affected relative expression levels and, consequently, the yield of cis-abienol production.

Construction and characterization of chromosomal gene integration strain

Compared with the over-expression of plasmids, the synthesis of desired products by chromosomal integrated metabolic pathways has considerable advantages in industrial production35. The chromosomal integration of low pathway of MVA may improve the stability of exogenous genes in cells and reduce the use of antibiotics. The lower genes of MVA pathway MVK, PMK, MVD, IDI with Gi1.2 constitutive promoter36,37 and trc promoter were integrated into the E. coli chromosome to construct the strain CM1 carrying a chromosomal copy of Gi1.2-low genes and CM2 carrying a chromosomal copy of Trc-low genes, respectively. The integrated strain of CM1/pLCEC/pCLES resulted in a 30% decrease in cis-abienol production compared to the previous strain. In contrast, cis-abienol was accumulated up to 9.2 mg/L in the strain CM2/pLCEC/pCLES in shake flask (Fig. 3). It was 10% higher than the previous strain. The reason may be that CM1 with a synthetic promoter was too weaker to produce supplementary intermediate products IPP and DMAPP. Although a high copy plasmid (pYJM14) which contains the Erg8-ERg12-ERg19-IDI operon can provide a high copy number and stronger promoter, the replication of the plasmid and the expression of the genes may bring a heavy metabolic burden to the host. These indicate that only the suitable gene expression can increase the yield of the desired product. Due to less plasmid burden, the biomass of CM1 and CM2 was significantly higher than others strain.

Bioreactor production of cis-Abienol

In order to investigate the performance of the most efficient strain CM2/pLCEC/pCLES, fed-batch cultivation experiments were performed in a 5-L laboratory-scale bioreactor containing 3L of M9 medium plus 0.5 g/L yeast extract. Glucose was fed at an appropriate rate to maintain it lower than 1 g/L. The biomass, cis-abienol production, and by-product (acetate and mevalonate) during the fermentation process were shown in Fig. 5A,B. After 50 h of fermentation, maximum cell densities reached an OD600 of 120, and cis-abienol titer reached a maximum of 220 ± 2 mg/L (Fig. 5A). The integration of the MVA downstream pathway into the genome may reduce the metabolic burden of the cells, obtaining higher biomass. Due to the low copy number (1 ~ 2) of plasmid (pCLES) in the upstream metabolic pathway of MVA in CM2/pCLES/pCLEC, the accumulation of intermediate metabolite mevalonate in the culture broth was only 357 mg/L (Fig. 5B). We postulated that lower mevalonate supply may affect the biosynthesis of cis-abienol.

Time-course profiles for cell density (OD600), cis-abienol, mevalonate and acetic acid production during fed-batch fermentation of strain CM2/pLCEC/pCLES (A, B) and strain CM2/pLCEC/pETES (C, D). Cultures were performed in a 5 L stirred tank bioreactor. Error bars represent the range of three independent fermentations.

To provide sufficient mevalonate, the CM2/pETES/pCLEC strain containing stronger promoter (T7) and higher copy numbers (~ 50) was constructed to reinforce the upper pathway of MVA. Under the same fermentation conditions as CM2/pCLES/pCLEC, maximum cell densities reached an OD600 of 70, cis-abienol titer reached a maximum of 200 mg/L (Fig. 5C) and the intermediate metabolite mevalonate accumulated in the culture broth and reached a maximum titer of 2200 mg/L (Fig. 5D). Due to the stronger promoter and higher copy numbers plasmid (pETES) in the upstream metabolic pathway of MVA in CM2/pCLES/pCLEC, the intermediate metabolite mevalonate increased in concentration by sixfold. However, cell biomass and the production of cis-abienol were significantly decreased. The excessive production of mevalonate in the upper pathway may exceed the catalytic capacity of the lower pathway, which leads to the accumulation of intermediate products. The metabolic unbalance between the upper and lower pathway resulted in miserable cell growth and decreased the production of cis-abienol. In our work, although CM2/pCLES/pCLEC strain enables the microbial biosynthesis of cis-abienol in high-cell-density fermentation, the cis-abienol production was relatively low. Future work should focus on optimizing expression levels of enzymes of Lpps and Cas to further increase cis-abienol production.

Discussion

Diterpenes have attracted much attention owing to their unique structures and diverse bioactivities in recent years38. As a typical diterpene, the expanding applications and growing demands of cis-abienol, which was raw material for Ambrox synthesis and a spice additive in cigarettes, have led to a widespread search for effective and economical manufacturing methods. Microorganisms provide a sustainable and environment-friendly alternative for the production of terpenoids, starting from simple carbon sources and, frequently, ensuring high product specificity13. Many biotechnological studies have focused on using E. coli as host for efficiently producing desired isoprenoids, in particular, the introduction of heterologous MVA pathway genes into E. coli has been very effective in improving productivity. In this study, E. coli was used as a host to preliminarily verify the feasibility of producing cis-abienol by microorganisms.

The final reaction catalyzed by Cas should be the rate-limiting step in the biosynthesis of cis-abienol. Michel et al. overexpressed the enzymes responsible for the biosynthesis of sclareol and the MVA pathway from S. cerevisiae to construct a sclareol biosynthetic pathway in engineering E. coli, and achieved sclareol titers of about 1.5 g/L in high-cell-density fermentation. Due to the complex carbocation reaction to form bicyclic oxygen-containing diterpenoid, the activity of this enzyme is much lower than any other terpene synthase. However, in recent years, the advancements in comprehending the reaction mechanism of terpene synthase can guide the development of mutant cis-abienol enzymes with improved activity. Screening for effective cis-abienol synthase or using protein engineering strategies to improve its catalytic activity, which is currently being performed in our laboratories, have the potential to increase the productivity of this valuable diterpenes.

The low intracellular IPP and DMAPP content also restrict the efficient biosynthesis of terpenoids in E. coli. High-level yield of polyprenyl pyrophosphate has been demonstrated to be useful in the production of various compounds such as isoprene, pinene, longifolene, sclareol17,32,33. One of the Key strategies for constructing an efficient terpenoids biosynthesis host is introducing a heterologous mevalonate pathway. In this work, A hybrid MVA pathway was expressed in E. coli to promote the accumulation of IPP and DMAPP pools, thereby enhancing cis-abienol production to some extent. In order to improve the stability of foreign genes and reduce the use of the antibiotics, the lower genes of MVA pathway were integrated into the E. coli chromosome, and the production of cis-abienol has been further improved. It shows that further research on balancing the enzymes in MVA pathway will be beneficial for further increasing the production of cis-abienol. In the cis-abienol biosynthesis process, IPP and DMAPP are first condensed to form FPP, by FPP synthase, which is a critical enzyme in the mevalonate pathway, and then FPP condenses with IPP to form GGPP. After comparing two different FPP synthase, we established a complete pathway for the precursor biosynthesis, which further improved the yield of cis-abienol.

In this study, the best-performing strain CM2/pLCEC/pCLES was assessed in a shake flask with the M9 minimal medium and a 3L fed-batch fermentation with M9 fermentation medium. Cell density reached an optical density 2.3 and the cis-abienol concentration reached 9.2 mg/L (Fig. 3) in shake flask with M9 minimal medium, which was lower than 10.1 (cell density) and 41.1 mg/L (cis-abienol) with TB medium39. While the titer of cis-abienol in this study is lower than the previous report, the cell density in this study is much lower than in the last report39. Therefore, increasing cell density through optimization might lead to higher titers of cis-abienol. The maximum production of cis-abienol reached only 220 mg/L under fed-batch fermentation in the growth medium which was lower than 634.7 mg/L reported with two-phase cultivation in a fed-batch bioreactor. It may be that the higher content of cis-abienol in the broth hinders the spread out of the cell, thus exerting a negative feedback inhibition to the biosynthesis of cis-abienol. Therefore, the method of two-phase cultivation will be employed to improve the production of cis-abienol in future work.

In summary, we established a complete pathway to enhance the precursor supply of cis-abienol from simple building blocks. cis-Abienol production was achieved by assembling biosynthetic genes encoding a heterologous MVA pathway, an FPP synthase from S. cerevisiae, a GGPP synthase from P. agglomerans, Lpps and Cas from A. balsamea in an engineered E. coli strain. The yield of cis-abienol was further improved by fed-batch fermentation of the engineered strain. The best-performing strain CM2/pCLES/PLCEC accumulated cis-abienol up to 220 mg/L under fed-batch fermentation conditions. Although the production of cis-abienol in this study was not as high as previously reported, our study still shows a good strategy to use E. coli cell factory as a robust and competitive platform for the synthesis of cis-abienol.

Methods

Strains, media and culture conditions

Strains and plasmids used in this study were listed in Table 1. S. cerevisiae was used for gene cloning. The E. coli DH5α strain was used for the plasmid construction. The E. coli χ7213 was used for the chromosomal integration as the donor strain40, and E. coli BL21(DE3) was used for production of cis-abienol. E. coli DH5α and E. coli BL21(DE3) were cultured in Luria–Bertani (LB) broth with appropriate antibiotics added to the broth when necessary (50 μg/mL for kanamycin, 34 μg/mL for chloramphenicol, 100 μg/mL for ampicillin and 100 μg/mL for spectinomycin). S. cerevisiae was cultured in YPD medium. M9 minimal medium (15.3 g/L NaH2PO4·12H2O, 3 g/L KH2PO4, 1 g/L NH4Cl, 0.5 g/L NaCl) was used for shake flask fermentation. Growth medium (9.8 g/L K2 HPO4·3H2O, 0.5 g/L yeast extract, 2 g/L MgSO4·7H2O, 2.1 g/L citric acid monohydrate and 0.3 g/L ferric ammonium citrate) supplemented with 10 g/L glucose, and 1 mL/L trace elements (3.7 g/L (NH4)6Mo7O24·4H2O, 2.9 g/L ZnSO4·7H2O, 24.7 g/L H3BO3, 2.5 g/L CuSO4·5H2O, 15.8 g/L MnCl2·4H2O) was used for fed-batch fermentation as previously described41.

Plasmid and strain construction

All PCRs were done using PrimerSTAR Max DNA polymerase (TAKARA, Dalian, China). All of the primers used for DNA manipulation were listed in Table 2. The Labda-13-en-8-ol diphosphate synthase (LPPS, GenBank Accession No.: JQ478434.1) from S. sclarea and diterpene synthase TPS4 (Cas, GenBank Accession No.: JN254808.1) from A. balsamea were code optimized and synthesized by BGI. The CrtE gene were obtained from pAC-lyc 42. The geranyl diphosphate/farnesyl pyrophosphate synthase gene ispA and Erg20 was obtained from E. coli and S. cerevisiae, respectively. Four genes of the enzymes LPPS, CAS, CrtE, ispA were amplified and cloned into the plasmid pACYDuet-1. The gene for LPPS was amplified by PCR with primers and cloned into BamHI and SacI sites of vector pACYDuet-1and the resultant plasmid was named pACY-Lpps. The gene for CAS was amplified by PCR with primers and cloned into BamHI and SacI sites of vector pACY-LPPS to generate recombinant plasmid pACY-LPPS-Cas. The gene crtE and ispA were amplified with primers and ligated using overlapping PCR to generate an engineering fragment, which was cloned to the plasmid pACY-LPPS-Cas to generate recombinant plasmid pLCCI. The crtE and Erg20 gene were amplified with primers and ligated using overlapping PCR to generate an engineering fragment, which was cloned to the plasmid pACY-LPPS-Cas to generate recombinant plasmid pLCCE. To construct pLCEC, Erg20 and CrtE were amplified with primers and ligated using overlapping PCR to generate an engineering fragment and cloned into the plasmid pLC at AatII and XhoI. To construct pTES, mvaE-mvaS was amplified from pACY-mvaE-mvaS which was constructed in our previous work and cloned into pTrchis2B at SacI and NcoI. To construct pLCES, trc-mvaE-mvaS was amplified from pTES and cloned into pCL1920 using an In-Fusion HD Cloning Kit (Takara-Clontech, Japan). To construct pETES, mvaE-mvaS was amplified from pACY-mvaE-mvaS and cloned into pET28 at SacI and NcoI.

Construction of BL21(DE3) strains with chromosomal mutation

The mutant strain was construction using suicide plasmid pRE112 as previously described40. To insert the lower pathway of MVA into E. coli BL21 (DE3) chromosome, a set of suicide plasmid was constructed based on the vector pRE112. For example, the flanking regions of glmS and glmU gene were amplified and linked up with each other by overlap extension PCR, and the restriction sites of NotI and XhoI were introduced at the connection point by primer design. This fragment was cloned into the vector pRE112 to generate pRE112-ΔSU. Then a NotI-KpnI fragment from pYJM14, encoding lower pathway of MVA with Trc promoter or Gi1.2 constitutive promoter, was inserted into the corresponding site of pRE112-ΔSU, and the resulting plasmid was defined as pRE112-ΔSU-Trc-low or pRE112-ΔSU-Gi1.2-low, which was used to mediate the allelic exchange. After two rounds of selection, based on the positive marker chloramphenicol resistance gene cat and negative marker levan-sucrose gene sacB from Bacillus spp.43, we obtained the strain CM1 carrying chromosomal copy of low genes with gi1.2 promoter and the strain CM2 carrying chromosomal copy of low genes with Trc promoter.

Shake flask cultivation

A single clone was inoculated into 3 mL of LB medium containing appropriate antibiotic and cultivated at 37 °C, 180 rpm for about 6 h. Then 1 mL of culture was used to inoculate into 500 mL saline bottle containing 100 mL M9 minimal medium with 2.0% (w/v) glucose as the main carbon source and cultivated at 37 °C, 180 rpm. 0.5 mM of IPTG was added to induce recombinant proteins expression at an OD600 reached about 0.6. Then the temperature was shifted to 30 °C for cis-abienol production. The cell mass and cis-abienol were determined after 48 h culturing.

cis-Abienol microbial toxicity

To investigate the cytotoxicity of cis-abienol to the producing E. coli strain, LB medium was adjusted to the six different cis-abienol concentrations ranging from 0 to 2 g/L by adding various amounts of a highly concentrated cis-abienol micellar solution (50 g/L). Subsequently, the medium (10 mL in 100 mL flask) was inoculated with 5% of preculture grown overnight in LB and incubate at 37 °C under agitation (200 rpm) for 24 h. For each concentration of abieonl, the maximum specific growth rate was determined.

Production of cis-Abienol by fed-batch

A single colony was picked and used to inoculate 3 mL LB medium supplemented with 34 μg/mL of chloramphenicol and 100 μg/mL of spectinomycin and cultivated at 37 °C, 180 rpm for about 6 h. Afterwards, 1 mL of the culture was used to inoculate a 100 mL M9 minimal medium containing appropriate antibiotics in a 500 mL shake flask and cultivated at 37 °C, 180 rpm for about 8 h. The seed culture was used in a ratio of 3% (v/v) to inoculate a 5-L fermenter containing 3L M9 fermentation medium. Sparger aeration was employed using filtered air to maintain the dissolved oxygen (DO) concentration The fermentation process was operated under the following conditions: temperature 32 °C, pH was controlled at 7.0 ± 0.1 by automatic addition of 25% ammonia water, agitation rate at 400 rpm and airflow at 1 vvm. The agitation was associated with DO to maintain a DO concentration above 30% saturation. When the initial glucose was depleted, 60% (v/v) concentrated glucose intermittently fed into the fermenter to maintain the residual glucose below 1 g/L to control the formation of acetic acid. The culture was induced when the OD600 was 12 by the addition of 0.25 mM IPTG unless specified according to different purposes. Samples were collected at certain intervals for cell density, residual glucose, acetic acid, mevalonate and cis-abienol analysis.

Analytical methods

Cell densities of the cultures were determined by measuring optical density at 600 nm using a spectrophotometer (Cary 50 UV–vis, Varian). Cell density samples were diluted as necessary so as to fall within the linear range.

The residual glucose in the culture broth was determined using a Biochemistry Analyzer (YSI 2950D, YSI Life sciences, USA).

The concentration of acetic acid and mevalonate were determined in an Agilent 1200 Infinity series HPLC system (Agilent, Santa Clara, CA), coupled with an Aminex HPX-87H column (Bio-Rad, Hercules, CA) heated at 50 °C and a 1 cm precolumn. The mobile phase of 5 mM H2SO4 was run at 0.5 mL/min. A differential refractive index detector (Agilent, Santa Clara, CA) was used for analyte detection and quantification.

cis-Abienol was determined using an Ultimate 3000 UHPLC (Thermo, USA) quipped with an ultraviolet (UV, 237) detector and a Thermo Acclaim RSLC C18 column (2.1 mm × 100 mm, 2.2 μm) based on a method adapted from Minghong Gao et al.44 Measurement were performed at a column temperature of 30 °C and a flow rate of 0.2 mL/min. A solvent gradient of 0.1% of formic acid in water (A) and ACN (B) with 0.1% formic acid starting at 2% B to 100% B in 15 min and hold for 10 min, returning to 2% B at 25.1 min, holding these conditions at 30 min and stopping the controller. Mass spectrometry (Q-TOF) system (Bruker Daltonics, Billerica, USA) was performed in positive mode measuring ESI ionization, using the following operation parameters: capillary voltage 4500 V, dry temperature 200 °C, nebulizing gas of 1.5 bar, drying gas (N2, purity 99.999%) flowing of 4.5L/min. High resolution MS and MS/MS spectra were acquired in the range 50–1300 m/z. Otof Control software was used to carry out mass spectrometer control and data acquisition and Compass Data Analysis software was applied for data analysis.

References

Severson, R. F. et al. Isolation and characterization of the sucrose esters of the cuticular waxes of green tobacco leaf. J. Agric. Food Chem. 33, 870–875. https://doi.org/10.1021/jf00065a026 (1985).

Leffingwell, J. BA basic chemical constituents of tobacco leaf and differences among tobacco types. Reprinted from Tobacco: Production, Chemistry, and Technology (1999).

Sallaud, C. et al. Characterization of two genes for the biosynthesis of the labdane diterpene Z-abienol in tobacco (Nicotiana tabacum) glandular trichomes. Plant J. 72, 1–17. https://doi.org/10.1111/j.1365-313X.2012.05068.x (2012).

Zerbe, P. et al. Bifunctional cis-abienol synthase from Abies balsamea discovered by transcriptome sequencing and its implications for diterpenoid fragrance production. J. Biol. Chem. 287, 12121–12131. https://doi.org/10.1074/jbc.M111.317669 (2012).

Schmiderer, C., Grassi, P., Novak, J., Weber, M. & Franz, C. Diversity of essential oil glands of clary sage (Salvia sclarea L., Lamiaceae). Plant Biol. (Stuttg) 10, 433–440. https://doi.org/10.1111/j.1438-8677.2008.00053.x (2008).

Barrero, A. F., Alvarez-Manzaneda, E. J., Altarejos, J., Salido, S. & Ramos, J. M. Synthesis of Ambrox® from (−)-sclareol and (+)-cis-abienol. Tetrahedron 49, 10405–10412 (1993).

Fahlbusch, K., Hammerschmidt, F., Panten, J., Pickenhagen, W., Schatkowski, D., Bauer, K., Garbe, D. & Surburg, H. In Ullmann's Encyclopedia of Industrial Chemistry (2003).

Vogel, B. S., Wildung, M. R., Vogel, G. & Croteau, R. Abietadiene synthase from grand fir (Abies grandis). cDNA isolation, characterization, and bacterial expression of a bifunctional diterpene cyclase involved in resin acid biosynthesis. J. Biol. Chem. 271, 23262–23268. https://doi.org/10.1074/jbc.271.38.23262 (1996).

Guo, Z. H., Severson, R. F. & Wagner, G. J. Biosynthesis of the diterpene cis-abienol in cell-free extracts of tobacco trichomes. Arch. Biochem. Biophys. 308, 103–108. https://doi.org/10.1006/abbi.1994.1015 (1994).

Gray, P. S., & Mills, J. S. The isolation of abienol from Canada Balsam, the oleoresin of Abies balsamea (L.). J. Chem. Soc. 5822–5825 (1964).

Guo, Z. & Wagner, G. J. Biosynthesis of labdenediol and sclareol in cell-free extracts from trichomes of Nicotiana glutinosa. Planta 197, 627–632. https://doi.org/10.1007/bf00191570 (1995).

Miyazawa, M. & Tamura, N. Characteristic odor components in the essential oil from yacón tubers (Polymnia sonchifolia Poepp. et Endl.). J. Essent. Oil Res. 20, 12–14. https://doi.org/10.1080/10412905.2008.9699409 (2008).

Moser, S. & Pichler, H. Identifying and engineering the ideal microbial terpenoid production host. Appl. Microbiol. Biotechnol. 103, 5501–5516. https://doi.org/10.1007/s00253-019-09892-y (2019).

Goldstein, J. L. & Brown, M. S. Regulation of the mevalonate pathway. Nature 343, 425–430. https://doi.org/10.1038/343425a0 (1990).

Rohmer, M. The discovery of a mevalonate-independent pathway for isoprenoid biosynthesis in bacteria, algae and higher plants. Nat. Prod. Rep. 16, 565–574. https://doi.org/10.1039/a709175c (1999).

Dewick, P. M. The biosynthesis of C5–C25 terpenoid compounds. Nat. Prod. Rep. 19, 181–222 (2002).

Schalk, M. et al. Toward a biosynthetic route to sclareol and amber odorants. J. Am. Chem. Soc. 134, 18900–18903. https://doi.org/10.1021/ja307404u (2012).

Xu, M. et al. Functional characterization of the rice kaurene synthase-like gene family. Phytochemistry 68, 312–326. https://doi.org/10.1016/j.phytochem.2006.10.016 (2007).

Gao, W. et al. A functional genomics approach to tanshinone biosynthesis provides stereochemical insights. Org. Lett. 11, 5170–5173. https://doi.org/10.1021/ol902051v (2009).

Falara, V., Pichersky, E. & Kanellis, A. K. A copal-8-ol diphosphate synthase from the angiosperm Cistus creticus subsp. creticus is a putative key enzyme for the formation of pharmacologically active, oxygen-containing labdane-type diterpenes. Plant Physiol. 154, 301–310. https://doi.org/10.1104/pp.110.159566 (2010).

John, R. Methods for producing abienol. WO2016094178 (A1) (2016).

Harada, H. et al. Efficient synthesis of functional isoprenoids from acetoacetate through metabolic pathway-engineered Escherichia coli. Appl. Microbiol. Biotechnol. 81, 915–925. https://doi.org/10.1007/s00253-008-1724-7 (2009).

Rohmer, M., Knani, M., Simonin, P., Sutter, B. & Sahm, H. Isoprenoid biosynthesis in bacteria: a novel pathway for the early steps leading to isopentenyl diphosphate. Biochem. J. 295(Pt 2), 517–524. https://doi.org/10.1042/bj2950517 (1993).

Choi, H. S., Lee, S. Y., Kim, T. Y. & Woo, H. M. In silico identification of gene amplification targets for improvement of lycopene production. Appl. Environ. Microbiol. 76, 3097–3105. https://doi.org/10.1128/AEM.00115-10 (2010).

Vincent JJ Martin1, 3, Douglas J Pitera1,3, Sydnor T Withers1, Jack D Newman1 & Jay D Keasling. Engineering a mevalonate pathway in Escherichia coli for production of terpenoids. Nat. Biotechnol. (2003).

Zurbriggen, A., Kirst, H. & Melis, A. Isoprene production via the mevalonic acid pathway in Escherichia coli (Bacteria). BioEnergy Res. https://doi.org/10.1007/s12155-012-9192-4 (2012).

Yang, J. et al. Enhancing production of bio-isoprene using hybrid MVA pathway and isoprene synthase in E. coli. PLoS ONE 7, e33509. https://doi.org/10.1371/journal.pone.0033509 (2012).

Cheng, T. et al. Enzymatic process optimization for the in vitro production of isoprene from mevalonate. Microb. Cell Factories 16, 8. https://doi.org/10.1186/s12934-016-0622-4 (2017).

Asai, K. et al. The identification of Escherichia coli Ispb (Cel) gene encoding the octaprenyl diphosphate synthase. Biochem. Biophys. Res. Co. 202, 340–345. https://doi.org/10.1006/bbrc.1994.1933 (1994).

Okada, K. et al. The ispB gene encoding octaprenyl diphosphate synthase is essential for growth of Escherichia coli. J. Bacteriol. 179, 3058–3060. https://doi.org/10.1128/jb.179.9.3058-3060.1997 (1997).

Bouhss, A., Trunkfield, A. E., Bugg, T. D. H. & Mengin-Lecreulx, D. The biosynthesis of peptidoglycan lipid-linked intermediates. Fems Microb. Rev. 32, 208–233. https://doi.org/10.1111/j.1574-6976.2007.00089.x (2008).

Yang, J. et al. Metabolic engineering of Escherichia coli for the biosynthesis of alpha-pinene. Biotechnol. Biofuels 6, 60. https://doi.org/10.1186/1754-6834-6-60 (2013).

Yang, C. et al. Synergy between methylerythritol phosphate pathway and mevalonate pathway for isoprene production in Escherichia coli. Metab. Eng. 37, 79–91. https://doi.org/10.1016/j.ymben.2016.05.003 (2016).

Cao, Y. J. et al. Manipulation of the precursor supply for high-level production of longifolene by metabolically engineered Escherichia coli. Sci. Rep. UK https://doi.org/10.1038/s41598-018-36495-w (2019).

Li, M. J. et al. A strategy of gene overexpression based on tandem repetitive promoters in Escherichia coli. Microb. Cell Factories. https://doi.org/10.1186/1475-2859-11-19 (2012).

Payne, M. S. et al. Promoter and plasmid system for genetic engineering. United States patent (2006).

Soucaille, P.Process for the biological production of 1, 3-propanediol from glycerol with high yieldUnited States patent (2012).

Yang, Y. L. et al. Discovery and characterization of a new family of diterpene cyclases in bacteria and fungi. Angew. Chem. Int. Ed. Engl. 56, 4749–4752. https://doi.org/10.1002/anie.201700565 (2017).

Li, L. et al. Combinatorial engineering of mevalonate pathway and diterpenoid synthases in Escherichia coli for cis-Abienol production. J. Agric. Food Chem. 67, 6523–6531. https://doi.org/10.1021/acs.jafc.9b02156 (2019).

Edwards, R. A., Keller, L. H. & Schifferli, D. M. Improved allelic exchange vectors and their use to analyze 987P fimbria gene expression. Gene 207, 149–157. https://doi.org/10.1016/S0378-1119(97)00619-7 (1998).

Liu, H. et al. High titer mevalonate fermentation and its feeding as a building block for isoprenoids (isoprene and sabinene) production in engineered Escherichia coli. Process Biochem. 62, 1–9. https://doi.org/10.1016/j.procbio.2017.07.021 (2017).

Cunningham, F. X. Jr., Sun, Z., Chamovitz, D., Hirschberg, J. & Gantt, E. Molecular structure and enzymatic function of lycopene cyclase from the cyanobacterium Synechococcus sp strain PCC7942. Plant Cell 6, 1107–1121. https://doi.org/10.1105/tpc.6.8.1107 (1994).

Gay, P., Lecoq, D., Steinmetz, M., Ferrari, E. & Hoch, J. A. Cloning structural gene sacb, which codes for exoenzyme levansucrase of Bacillus subtilis - expression of the gene in Escherichia coli. J. Bacteriol. 153, 1424–1431. https://doi.org/10.1128/Jb.153.3.1424-1431.1983 (1983).

Gao, M. H. et al. A natural in situ fabrication method of functional bacterial cellulose using a microorganism. Nat. Commun. https://doi.org/10.1038/s41467-018-07879-3 (2019).

Acknowledgements

The present study was supported by National Natural Science Foundation (21878320, 31670493).

Author information

Authors and Affiliations

Contributions

T.C. conceived of the study, participated in its design, carried out the process control studies and drafted the manuscript. C.X., M.X. and G.Z. conceived of the study, and participated in its design and coordination and helped to draft the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, T., Zhao, G., Xian, M. et al. Improved cis-Abienol production through increasing precursor supply in Escherichia coli. Sci Rep 10, 16791 (2020). https://doi.org/10.1038/s41598-020-73934-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-73934-z

This article is cited by

-

Highly efficient biosynthesis of β-caryophyllene with a new sesquiterpene synthase from tobacco

Biotechnology for Biofuels and Bioproducts (2022)

-

Optimizing the downstream MVA pathway using a combination optimization strategy to increase lycopene yield in Escherichia coli

Microbial Cell Factories (2022)

-

Co-biosynthesis of germacrene A, a precursor of β-elemene, and lycopene in engineered Escherichia coli

Applied Microbiology and Biotechnology (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.