Abstract

The paper describes a novel technique to harvest 222Rn laden air from soil gas of natural origin as a highly efficient source of 222Rn for calibration applications in a walk-in type 222Rn calibration chamber. The technique makes use of a soil probe of about 1 m to draw soil gas, through a dehumidifier and a delay volume, using an air pump to fill the calibration chamber. 222Rn concentration in the range of a few hundred Bq m−3 to a few tens of kBq m−3 was easily attained in the chamber of volume 22.7 m3 within a short pumping duration of 1 h. A new technique referred to as “semi-dynamic mode of operation” in which soil gas is injected into the calibration chamber at regular intervals to compensate for the loss of 222Rn due to decay and leak is discussed. Harvesting soil gas has many important advantages over the traditional methods of 222Rn generation for calibration experiments using finite sources such as solid flow-through, powdered emanation, and liquid sources. They are: (1) soil gas serves as an instantaneous natural source of 222Rn, very convenient to use unlike the high strength 226Ra sources used in the calibration laboratories, and has no radiation safety issues, (2) does not require licensing from the regulatory authority, and (3) it can be used continuously as a non-depleting reservoir of 222Rn, unlike other finite sources. The newly developed technique would eliminate the need for expensive radioactive sources and thereby offers immense application in a variety of day to day experiments—both in students and research laboratories.

Similar content being viewed by others

Introduction

The worldwide recognition of 222Rn as a health hazard to the population has led to large scale environmental and indoor surveys aimed at evaluating concentration levels and dose assessments. To set-up standard protocols and maintain mutual conformity between the various detectors and instruments used by different laboratories, calibration facilities have been established in different countries1,2,3,4. It is desirable to have a large volume calibration facility for calibrating a large number of detectors simultaneously. Further large calibration chamber is preferred for calibrating 222Rn and 222Rn decay products monitors (and dosimeters) because the decay products tend to attach to walls of the chamber which may cause non-uniformity in the airborne decay products concentration in small chambers. An essential component of the calibration facility pertains to the availability of reliable radioactive source for injecting the 222Rn gas into the calibration chamber. The essential characteristics of such sources should be (1) capability to provide steady concentration for a long period, (2) free of interference from the 220Rn isotopes and decay products, (3) non-dependence of the source on environmental parameters, and (4) ability to deliver a wide range of concentration levels in the chamber. It is always advisable to calibrate the detector in the same measurement range for which it is designed. For example, several types of SSNTD based passive 222Rn dosimeter systems5,6 are being used in different indoor environments where concentration may vary significantly, from few tens to few thousands of Bq m−3, depending upon the 222Rn exhalation potential of soil and the building materials, and the ventilation rate. However, dosimeters used for these measurements are calibrated at a much higher level of concentration due to difficulty in maintaining low 222Rn concentration level in the calibration chamber for an extended period using the standard 222Rn sources.

Similarly, 222Rn measurement system used for high concentration measurements such as soil gas, Uranium tailings pond7 and Uranium mines needs to be calibrated at higher concentration levels. The calibration experiments performed worldwide in a walk-in kind of 222Rn chambers use different types of conventional sources such as solid flow-through type2,4,8, powdered emanation type9,10 and 226Ra solution type11,12 etc. One of the available standard sources often used by investigators is the well-known flow-through type 222Rn source (RN-1025, Pylon Electronics, Ottawa, Canada). This source is capable of meeting most of the requirements mentioned above, but with one limitation—it does not provide a steady 222Rn concentration when drawn for a long time duration. Hence, it is challenging to maintain the stability of concentration in a large calibration chamber. Thus, one looks for an alternate source of 222Rn delivery.

Variety of sampling techniques and measurement instrumentation used for 222Rn measurements require suitable calibration protocol and measurement standards. The measurement standards must be traceable to a reference 222Rn standard developed by the national reference standard generation body13. Establishing a primary 222Rn standard requires precise determination of the source activity and hence Uranium tailings and naturally enriched soils as 222Rn generators are avoided because of the uncertainties in their characterization and origin (NSRB-2018). In a secondary chamber such as the one described here, traceability is established with internal standard methods through the use of instruments which are calibrated in a primary calibration facility. The primary calibration facility is the one which has established traceability to NIST or another official standard laboratory. As a result of being equipped with the secondary measurement systems as a reliable tool, application of soil-gas as a secondary 222Rn standard for calibration experiments in a walk-in kind of calibration chamber is demonstrated in this paper.

The soil gas as a rich source of 222Rn and 220Rn and its use for calibration experiments have been demonstrated earlier by14,15 for small dimension chambers of volume 0.22 m3 and 0.13 m3 respectively. Soil gas was also used as a source of high 222Rn and 220Rn concentrations in studies aimed at developing techniques for mitigation of these gases in workplaces16,17,18. It was also used as a source of 222Rn for studying the 222Rn absorption capacity of edible oils19. But its use as a source for 222Rn in calibration and exposure experiments in walk-in kind of chambers has not been reported earlier, and the present work is first of its kind.

In this study, we demonstrate that temporal stability of 222Rn concentration in the chamber for detector exposures during calibration or inter-comparison experiments can be efficiently achieved through periodic injections of soil gas in semi-dynamic mode, in which 222Rn laden soil gas is pumped periodically20. Besides, we also demonstrate the application of soil gas for the static mode of operation of calibration chamber (in which the 222Rn concentration in the chamber is raised initially, and the chamber is then sealed, and experiments are conducted in the decay mode) for short term exposure of 222Rn detectors21.

Advantages of soil gas over finite 222Rn source

As mentioned earlier, the application of a typical flow through radioactive sources of 226Ra (emanation type and solution type) for achieving a steady concentration of 222Rn in the calibration chamber has limitations. The operation of such radioactive sources is restricted to either (1) one-shot injection of built-in 222Rn to the chamber, or (2) steady-state mode of operation, in which 222Rn is drawn continuously and filled to the chamber. Finite 226Ra source cannot meet the requirement of supply of a steady 222Rn concentration over a long period since the built-in 222Rn activity is limited in these sources, and its generation rate is very slow. Both these modes of operation drain the 222Rn activity from source volume very rapidly, and its replenishment requires long time duration, a few days to up to a month, depending upon the strength of the source and 222Rn concentration desired for experiments. One can use multiple sources in the calibration facility, but this leads to cost escalation. Other disadvantages pertain to special arrangements required for storing the source (such as safe room and shielding requirements) and need for regulatory requirements from the national regulator to procure and operate the source. All the above problems are conveniently overcome by the use of naturally occurring soil as a steady source of 222Rn. The 222Rn concentration in soil gas of typical background radiation region, with 226Ra activity of 30 Bq kg−1 (worldwide average value), is expected to vary from 20 to 100 kBq m−3 depending upon the emanation factor, porosity and grain density22. In earlier publications, the use of soil gas as a steady source of 222Rn for small chamber experiments for a sufficiently long duration of up to 9 days was successfully demonstrated14. However, its applicability in large chambers and for a long period needs to be examined carefully. The 222Rn concentration in soil gas undergoes diurnal and seasonal variations which can be a limitation in the outset. One can overcome these by suitably regulating the flow rate and well-planned injection protocols. The details of adapting soil gas as a source of 222Rn for standard chamber experiments through improved delivery methods are discussed, and its advantages are delineated in this paper.

Materials and method

222Rn calibration chamber at the Centre for Advanced Research in Environmental Radioactivity (CARER)

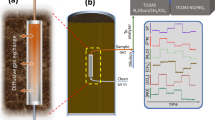

The 222Rn calibration chamber installed at CARER is a walk-in type chamber, and its full exterior and interior views are shown in Fig. 1a, b respectively. The details of the design, construction, characterization and performance evaluation of the facility were published earlier1. Briefly, these aspects may be discussed as follows; the chamber has an internal air space volume of 22.7 m3 and is made of stainless steel with provisions for 222Rn injection, evacuation and sampling ports. Two mixing fans are operated with a combined airflow of 3620 m3 h−1 for homogenizing 222Rn concentration efficiently. Provisions are also available for deploying a large number of passive and several active 222Rn and progeny measuring devices simultaneously. The normal leak rates (mixing fan OFF condition) and the enhanced leak rates (mixing fan ON condition) were well characterized (to be 0.0011 h−1 and 0.0028 h−1 respectively) through a large number of 222Rn decay experiments1. Although in the present paper, we focus on the 222Rn related aspects of the calibration chamber, the chamber has been designed from the perspective of using it for 222Rn progeny monitoring device calibrations as well. The passive progeny detector, such as direct 222Rn progeny sensor (DRPS) and direct 220Rn progeny sensors (DTPS), needs to be calibrated in the environments similar to a typical dwelling. An essential characteristic of a typical dwelling is the surface area to volume ratio (s/v), which is ~ 2 m−1 as per international standard23. Hence, it is desirable that the calibration of the devices is performed in chambers with similar surface area to volume ratio and this forms the rationale for setting up a large chamber of volume 22.7 m3 (s/v ratio = 2.1 m−1) for 222Rn related experiments in the present study.

Soil gas extraction and transport into the chamber

The 222Rn concentration in soil gas increases exponentially with depth and saturates to an equilibrium concentration at a depth of about 0.8–1 m24,25. The extraction was performed using a hand-driven soil gas probe (STITZ, Germany) inserted inside the ground to a depth of about 1 m, as shown in Fig. 2a, b14,16. The extraction was carried out at flow rates ranging from 10 to 80 L min−1, depending upon the experimental requirements. To avoid the possibilities of soil particles choking the inlet of the probes, the total flow was bifurcated into multiple channels, as shown in Fig. 2b. The bifurcation not only reduces the suction velocity at the probe inlet (thereby reducing the possibilities of soil particles blocking the probe inlet) but also reduces the possibility of large area perturbations of 222Rn concentration in the soil matrix. The outlets of multiple soil probes were combined and connected to a progeny filter, dehumidifier, air compressor, and a flow meter with a controller, which in turn was connected to the chamber inlet (Fig. 2b). The 0.052 m3 buffer volume of the air compressor serves as a stock for 222Rn and as a delay volume for mitigating 220Rn.

Reference 222Rn monitors

The reference instruments used for the present study are ionization chamber based monitors (AlphaGuard PQ2000PRO and AlphaGuard Professional, Saphymo, Germany), and scintillation cell-based monitors (Smart RnDuo, AQTEK SYSTEMS, India). A view of these instruments is presented in Figs. 3a, 3b and 3c. The detection range of ionization chamber based reference monitor is 2 Bq m-3 to 2000 kBq m-3, while that of scintillation cell-based monitor is 8 Bq m-3 to 50,000 kBq m-3. The details of these instruments were published earlier1,14,16,17,18,19. The primary calibration of the ionization chamber-based monitors was initially carried out under a Physikalisch Technische Bundesanstalt (PTB) reference atmosphere and that of scintillation cell-based monitors at BARC, Mumbai. In addition to this, both the type of reference monitors used here are periodically calibrated with an interval of a year at BARC, Mumbai using a standard solid flow-through type 226Ra source of activity 110.6 kBq (model RN -1025, Pylon electronics, Ottawa, Canada) with uncertainty < 2%. The readings provided by scintillation cell-based 222Rn monitors (Smart RnDuo) and ionization chamber based monitors (AlphaGuard) were found to match (within ± 1.1%) hence any of these instruments can be used as a reference monitor.

Experiments, results, and discussion

Experiments were carried out to study two different aspects: characterization of soil gas as a source of 222Rn, and its application for generating desired 222Rn concentration in a large volume calibration chamber. The source characterization experiments were aimed to study (1) stability of 222Rn concentration when soil gas was drawn for long time duration and at different flow rates, (2) realizing temporal stability of 222Rn concentration in the chamber using soil gas, and (3) effective removal of 220Rn from the soil gas to ascertain its non-interference in the calibration experiments. Whereas, studies on the application of soil gas to generate desired 222Rn concentration in a large volume calibration chamber included the demonstration of (1) temporal stability in the 222Rn concentration in the chamber, (2) build-up characteristics of 222Rn in the chamber, (3) versatility of soil gas to achieve steady 222Rn concentration in the chamber, and (4) maximum values of 222Rn concentration attained in the chamber. These are discussed in the following sections.

Characterization of the soil gas source

The technique of using soil gas is expected to work for most of the soils. The 222Rn concentration in the soil gas depends upon the 226Ra content of the soil, bulk density, emanation fraction and the moisture content and these parameters are related as given in Eq. (1)22:

where CRnSG—222Rn concentration in soil gas (kBq m−3), CRa—226Ra concentration of the soil (Bq kg−1), f—222Rn emanation fraction, ρs—material density of soil (kg m−3), ε—total porosity of soil including both water and gas phases, m—water-filled fraction of porosity, KT—partition coefficient of 222Rn between water and gas phases.

As explained in the UNSCEAR report22 for a warm, moist soil (T = 25 °C, KT = 0.23, m = 0.95) with typical soil parameters (CRa = 30 Bq kg−1, which is the worldwide average value for normal background radiation regions, f = 0.2, ε = 0.25) will have a concentration of 222Rn in pore air (CRnSG) of 78 kBq m−3, which is 3.7 times higher than the value, for the same soil under cold and dry conditions (T = 0 °C, KT = 0.53, m = 0.05, CRnSG = 21 kBq m−3). Concentrations below ~ 20 kBq m−3 are extremely unlikely in the soil gas, and this concentration would suffice to meet the requirements of the calibration experiments and thereby to make it potentially a credible natural source for any laboratory experiments.

The present study was conducted using the soil gas extracted from the lateritic soil prevailing in the premises of the laboratory at CARER, Mangalore University. The soil was characterized for its physical parameters such as the bulk density, seasonal moisture content, 226Ra and 232Th contents and 222Rn emanation power. Soil samples were collected at the soil gas harvesting location, and the concentrations of 226Ra and 232Th were measured by gamma spectrometry using High Purity Germanium (HPGe) detector (Canberra, USA) of 50% relative efficiency26. The details of the gamma spectrometer system used in the present study and technique for the analysis of radionuclide concentration in soil were published elsewhere26,27,28. Several measurements of surface exhalation rates of 222Rn and 220Rn were also performed for this site by chamber accumulation method29,30. The results of these measurements are presented in Table 1, along with other measured soil parameters. The mean values of surface exhalation rates were 39.0 ± 4.2 mBq m−2 s−1 and 130.0 ± 40.0 mBq m−2 s−1 for 222Rn and 220Rn respectively. These values are in agreement with the previously reported literature values for the location31,32,33. Also, physical properties of soil (such as 222Rn emanation power, the porosity of the soil, moisture content etc.) play an important role in governing the soil gas 222Rn concentration, in contrast, the soil 226Ra content does not explain this to a greater extent33.

From the measured data on 226Ra activity concentration, 222Rn emanation factor, soil grain density and total porosity of the soil (Table 1), the 222Rn concentration in the soil gas was calculated to be 109.0 kBq m−3 [Eq. (1)] for the location from where soil gas was drawn. We have considered a value of 0.95 for the water-filled fraction of porosity and 0.23 for the partition coefficient of 222Rn22. For comparison, the concentration of 222Rn in soil gas was measured in-situ as discussed in “Soil gas extraction and transport into the chamber” section, and the mean value was 99.0 ± 7.0 kBq m−3, which is in good agreement with the calculated value of 109 kBq m−3. This corresponds to an elevated category of classification range (100–250 kBq m−3) as described by34 for a soil gas mapping study in Germany.

Stability of 222Rn concentration in soil gas for long term operation

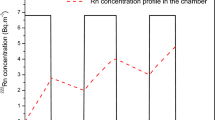

The stability of 222Rn concentration in soil gas was tested by harvesting it continuously during long term operation of over a month. In an earlier publication, we have demonstrated that soil gas technique is capable of providing steady 222Rn concentration when drawn at a flow rate of 10 L min−114,16. We also draw attention to a previous study by one of these authors wherein 222Rn concentration was continuously measured for the duration of 30 days at a flow rate of 15 L min−135. Similarly, monitoring of soil gas 222Rn concentration at the study site was performed at a flow rate of 1 L min−1 using a scintillation cell-based monitor for a year. An average concentration value of 78.0 ± 20.0 kBq m−3 (Fig. 4) was recorded, and the seasonal variation in concentration was within ± 20% of the annual average.

To achieve the concentration of few kBq m−3 in a large calibration chamber in quick time, one needs to pump 222Rn laden air at a much higher flow rate. Therefore, we studied the variation of 222Rn concentration in the soil gas when drawn at a flow rate of 60 L min−1 for 7200 min and the monitoring was done continuously using scintillation cell-based monitors. The results (Fig. 5) confirmed that the concentrations remained steady with a mean value of ~ 99.0 ± 7.0 kBq m−3 for 222Rn and 32.0 ± 2.7 kBq m−3 for 220Rn. This demonstrates the utility of soil gas as a continuous and non-diluted source of 222Rn.

Removal of 220Rn from the soil gas

In the next step, we demonstrate the effective removal of 220Rn from the soil gas so that the air stream entering the calibration chamber is free of it. As discussed in “Soil gas extraction and transport into the chamber” section (Fig. 2), the arrangement for harvesting the soil gas involved transporting it through a progeny filter, transport line of 20 m length, silica gel moisture trap containing ~ 2 kg of silica, air compressor with a delay volume of 0.05 m3, flow meter with the controller, and finally into the chamber inlet port. Experiments were conducted to confirm that during the transport of the soil gas from the soil to the chamber the delay provided by the transport line and the delay volume is adequate for the removal of 220Rn through radioactive decay (T1/2 = 55 s). The absence of 220Rn in the chamber air was confirmed for the highest flow rate of 80 L min−1 of soil gas, employed in the present study. The results of these studies are presented in Fig. 6, which demonstrates that the 220Rn concentration in the chamber is below the detector minimum detection limit (8 Bq m−3).

Demonstration of the application of soil gas as a 222Rn source for calibration chamber

Upon ensuring the potential of the soil gas to serve as a convenient and un-depleted source of 222Rn, experiments were carried to harvest it for achieving desired concentration levels in the calibration chamber. The temporal stability and build-up characteristics of 222Rn concentration in the chamber were also studied, and details are presented in the following sections.

Achieving temporal stability in 222Rn concentration in the chamber

Calibration of measuring devices or any other exposure experiments are generally performed in the chamber under (1) static mode of operation21, or (2) dynamic mode of operation21. The static mode of operation is practically uncomplicated as it requires one-time filling of the chamber with 222Rn laden air to obtain desired concentration, and the experiments are performed during the decay of 222Rn. During the experiments, the 222Rn concentration in the chamber is measured continuously, and the average value is considered for evaluating the response of the detectors which are being examined.

On the other hand, in the dynamic mode of operation, the calibration experiments are performed under a stable 222Rn concentration environment (with deviations lesser than 10% from the reference concentration value) throughout the exposure duration36,37. Here the concentration stability is generally achieved by continuous pumping of 222Rn rich air from the source to the chamber throughout the experimental duration21. Dynamic mode of operation is the preferred method of calibration of devices because of the lower uncertainty associated it. However, this method has a disadvantage: it requires a 226Ra source of very high strength for continuous release of desired 222Rn activity throughout the experiment.

Hence, we demonstrate an innovative technique which we refer to as “semi-dynamic mode” of operation. As mentioned earlier, the decrease in the 222Rn concentration inside the chamber after filling it with the desired level is due to unavoidable processes such as radioactive decay and possible leak, as discussed in the section “222Rn calibration chamber at the Centre for Advanced Research in Environmental Radioactivity (CARER)”. These losses can be offset by a judicious combination of periodic injection of 222Rn laden air for a pre-set duration of pumping. In the new technique, pulsed injection of 222Rn at predetermined intervals was performed to compensate for its loss through decay and leak, as explained below.

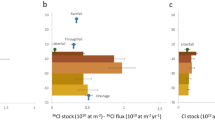

Let us stipulate that it is required to maintain a steady concentration of 6 kBq m−3 with a maximum deviation of 10% (which happens to be the measurement uncertainty of any monitoring devices) for an operational period of 48 h. To accomplish this, the soil gas was pumped into the chamber at a flow rate of 30 L min−1 for 60 min. The concentration in the chamber builds up to a slightly higher value (6.7 ± 0.4 kBq m−3) than the target value (Fig. 7a). Now the pumping was stopped and the periodic injection protocol (pumping for 1 min in a period of 1 h) was adopted. This choice was based on the knowledge of chamber leak rate and 222Rn concentration in soil gas. The experiment was carried out for a duration of 48 h maintaining a relative humidity (RH) of 60% and a temperature (T) of 28 °C inside the chamber. The corresponding temporal variation of 222Rn in the chamber is shown in Fig. 7a and the excursions of the 222Rn profile are well within the previously stipulated bounds of 10%.

Illustration of the useful application of semi-dynamic mode of operation in combination with soil gas to achieve desired and steady-state 222Rn concentration in the chamber. (a) application of semi-dynamic mode of operation in which loss of 222Rn due to decay and leak is compensated with periodic injection, (b) demonstration of the versatility of soil gas harvesting technique to achieve desired steady-state 222Rn concentration levels in the calibration chamber.

In Fig. 7b, we illustrate with more experimental results, the useful application of semi-dynamic mode of operation in combination with soil gas to achieve desired and steady-state 222Rn concentration in the chamber. Both low and high concentration values can be maintained in the chamber using the soil gas, as illustrated in Fig. 7b for 0.51 ± 0.073 kBq m−3, 2.5 ± 0.5 kBq m−3, 5.2 ± 0.5 kBq m−3, 8.9 ± 0.4 kBq m−3 and 15.8 ± 0.7 kBq m−3. It may be remarked that the choice of 1 min pumping in a period of 1 h, discussed just above, is rather empirical and was chosen merely to illustrate the technique. It is possible to arrive at an optimum pumping periodicity by a theoretical analysis of the 222Rn growth and decay equations and then adopt those optimized parameters in the experiments for achieving highly stable concentration value, as desired by the user, for the calibration application. With such a methodology, one can easily overcome the difficulties in maintaining concentration stability in the calibration chamber due to fluctuations of 222Rn concentration in soil gas. This was successfully attempted, and the details are presented in an adjoining publication, as Part-2 of this work38.

The use of soil gas for the static mode of operation of the chamber, discussed above, was also studied. For an illustration, the soil gas was injected at a flow rate of 60 L min−1 for 60 min. Because of this, an initial 222Rn concentration of 12.4 ± 0.9 kBq m−3 in the chamber was attained. The concentration decay pattern was monitored continuously, and the results are shown in Fig. 8. The average value of concentration was observed to be 6.7 ± 0.3 kBq m−3 and, as stated earlier in this section, this value was considered for evaluating the response of the detectors under calibration exercise. It may be noted that this is a purely representative result, and one could start with the desired initial concentration by adequately injecting the soil gas to perform calibration experiments in a static mode of operation.

Build-up characteristics of 222Rn in the chamber

Experiments were conducted by injecting soil gas into the calibration chamber at different flow rates and durations to study the build-up characteristics of 222Rn concentration. Rapid mixing of 222Rn in the chamber was ensured by operating the mixing fans. The variation of 222Rn concentration in the chamber for different injection rates and duration of injection are presented in Figs. 9 and 10. As illustrated, concentration in the chamber reached a steady-state after about 15 min of stopping injection, which can be considered as the response time of the system. Steady-state values remained stable over a considerable length of time (~ 2 h) in the chamber because of low leak rates (mean T1/2 = 69 h). These steady-state values increased linearly with the volume of soil gas injected.

Versatility of soil gas to achieve steady 222Rn concentration in the chamber

Now we demonstrate the versatility of soil gas as a 222Rn source for attaining and sustaining desired 222Rn concentrations in the calibration chamber for the long-time operation. Separate experiments were carried out by pumping soil gas into the chamber at different flow rates of 20 L min−1, 30 L min−1, 40 L min−1, 50 L min−1, 60 L min−1, and 80 L min−1. The build-up of 222Rn inside the chamber was monitored continuously with a scintillation cell-based reference monitor Smart RnDuo. The readings provided by Smart RnDuo were verified by the use of AlphaGuard monitors as well.

As shown in Fig. 9, depending upon the injection rate, the concentration increased linearly with time, and when the injection was stopped, it attained a steady-state. The steady-state concentration value depends on the total volume of the soil gas injected, as shown in Figs. 9 and 10. The correlation plot of steady-state 222Rn concentration attained in the chamber with soil gas pumping rates for a fixed pumping duration of 60 min is presented in Fig. 11. A statistically significant positive correlation with R2 = 0.99 was observed between the two entities. An increase in the flow rate of soil gas by a factor of four induced an eight-fold increase in concentration in the chamber. The negative y-intercept indicates a decrease of 222Rn concentration in soil gas at low flow rates.

In addition to the actual measurements, one can calculate the expected concentration in the chamber with the knowledge of 222Rn concentration in soil gas and volume of soil gas pumped, using Eq. (2).

where Cch—steady-state 222Rn concentration attained in the chamber (kBq m−3), v—volume of 222Rn laden air injected into the chamber (m3), CRnSG—222Rn concentration in soil gas (kBq m−3) at the inlet of the chamber, V—chamber volume (m3).

The steady-state concentrations, thus calculated for different flow rates, are compared with experimentally measured ones, as shown in Fig. 12. During these experiments, the RH content of the soil gas remained at ~ 90%. Whereas, the RH and T values in the chamber were maintained at 60% and 28 °C respectively. It is important to note that Eq. (2) assumes the ideal condition in which all the injected 222Rn is retained in the chamber. However, during experiments, there is loss due to leak and outflow from the chamber (as described in “222Rn calibration chamber at the Centre for Advanced Research in Environmental Radioactivity (CARER)” section). Because of this, the measured values are always lower than the calculated ones, particularly at higher flow rates.

Maximum values of 222Rn concentration attained in the chamber

The maximum 222Rn concentration that can be attained in the chamber using a single soil gas probe was also measured, and for this soil gas was continuously pumped into the chamber at a flow rate of 60 L min−1 until the steady-state concentration was achieved in the chamber. The time duration to attain this steady-state concentration was found to be ~ 7 h, and further pumping did not increase the concentration. The profile of concentration build-up is shown in Fig. 13. With a single soil gas probe, the highest steady 222Rn concentration that could be attained in the chamber (current chamber volume of 22.7 m3) was 31.4 ± 5.0 kBq m−3 (average value obtained from the readings recorded using three different monitors simultaneously). As pointed out earlier, 222Rn concentration at the outlet of the soil probe had a mean value of 99.0 ± 7.0 kBq m−3 when drawn continuously for 7200 min.

The above discussion makes it abundantly clear that the harvesting of 222Rn from soil gas has several advantages: (1) it is a non-diluting source, thereby providing the benefit of using it continuously for a long time duration, unlike conventional high activity 226Ra sources, (2) does not require elaborate shielding or special arrangements which are necessary for safe handling of conventional sources, and (3) ease in handling, free of cost, and does not require approval from the regulatory agencies.

Comparison with other calibration chambers of the world

A comparison of important specifications and 222Rn sources used in some of the 222Rn calibration chambers available around the world are presented in Table 2. The large volume and small volume chamber facilities are grouped separately in this table. As summarised in Table 2 (column 5), other large volume calibration facilities, except the one described in the present study, make use of different types of 226Ra sources such as Pylon flow-through type, calcined 226Ra ceramic, lantern mantles, solid flow-through type- RF (multiple sources) or a combination of both dry and liquid sources, for 222Rn generation.

As discussed in “Removal of 220Rn from the soil gas” section, in the dynamic mode of operation, 222Rn concentration gradually increases and attains a steady-state after some time. Time to reach steady-state concentration depends upon several factors such as type of source, its 222Rn generation rate, injection flow rate, the volume of chamber and leak rate of the chamber. The comparison highlights the fact that when dynamic method using 226Ra sources are employed, the time required to achieve stable concentration level in the chamber is very long, often higher by a magnitude when compared to that achieved by soil gas technique. It was also observed that irrespective of the mode of chamber operation, the concentration stabilization could be achieved very quickly using soil gas. In the majority of the calibration facilities static mode of operation was adopted5,14,21. However, this results in a short time exposure of the detectors due to the continuous decay of initially injected 222Rn with no scope for maintaining temporal stability.

Conclusion

An innovative technique which uses 222Rn laden air from soil-gas of natural origin as a convenient and effective source of 222Rn for calibration applications in a large walk-in type calibration chamber has been developed and successfully demonstrated. Soil gas is a very stable source and is capable of providing steady non-depleting 222Rn concentration over a long period of operation. The desired 222Rn concentration in the chamber, from < 1.0 kBq m−3 to several tens of kBq m−3, can be attained very quickly and easily. Soil gas source has zero regeneration time and long-term stability when drawn continuously, unlike other radioactive sources of 222Rn. It serves as an instantaneous natural source of 222Rn, very convenient to use unlike the high strength 226Ra sources, has no radiation safety issues, and hence does not require any licensing from the regulatory authority. A semi-dynamic technique has been probed to maintain temporal stability of concentration by periodically pumping 222Rn into the calibration chamber. Approximate values for the injection rate, duration, and period were arrived at to compensate for the decay and leak of 222Rn from the chamber to maintain concentration stability within 10%. This study opens up an avenue for a rigorous theoretical analysis of the 222Rn growth and decay equations to arrive at optimum pumping parameters and adopt those parameters during the experiments for achieving desired and stable concentration in the chamber. This is presented in an adjoining publication, as Part-2 of this study series.

References

Trilochana, S. et al. A walk-in type 222Rn chamber for calibration of radon and progeny measuring devices and inter-comparison measurements. Radiat. Prot. Dosim. 187, 1–16 (2019).

Yamada, Y. et al. Performance of radon/aerosol chamber at NIRS, Japan. Preprint at https://www.ipen.br/biblioteca/cd/irpa/2004/files/6a70.pdf (2001).

Liang, J. C. et al. Development of calibration facility for 222Rn and its progenies at NIM (CHINA). Radiat. Prot. Dosim. 167, 82–86 (2015).

Jong, M. L., Kil, H. A., Ha, S. C. & Tae, S. P. Development of radon calibration chamber at KRISS. Appl. Radiat. Isot. 61, 237–241 (2004).

Sahoo, B. K., Sapra, B. K., Kanse, S. D., Gaware, J. J. & Mayya, Y. S. A new pin-hole discriminated 222Rn/220Rn passive measurement device with single entry face. Radiat. Meas. 58, 52–60 (2013).

Tokonami, S. et al. Instrument performance of a radon measuring System with the alpha-track detection technique. Radiat. Prot. Dosim. 103, 69–72 (2003).

Sahoo, B. K. et al. Radon exhalation studies in an Indian Uranium tailings pile. Radiat. Meas. 45, 237–241 (2010).

Dersch, R. Primary and secondary measurements of 222Rn. Appl. Radiat. Isot. 60, 387–390 (2004).

Zareena, H. V. et al. A simple method to irradiate blood cells in vitro with Radon gas. Radiat. Prot. Dosim. 130, 343–350 (2008).

Philippe, S., Youcef, N., Claude, B., Gilles, T. & Francois, B. Absolute activity measurement of radon gas at IRA-METAS. Nucl. Instrum. Methods Phys. Res. A 568, 752–759 (2006).

Dersch, R. & Schoètzig, U. Production and measurement of 222Rn standards. Appl. Radiat. Isot. 49, 9–11 (1998).

Yuu, I. Traceability on radon measurements at the JAEA Ningyo-toge. Health Phys. 42, 247–254 (2007).

Felice, P. D. Primary standards of radon. Metrologia 44, S82–S86 (2007).

Al-Azmi, D. & Karunakara, N. A simple radon chamber for use with soil gas for calibration of radon measuring devices and instruments. Int. J. Low Radiat. 5(6), 429–439 (2011).

Paul, K., Frederick, S. Characterization and use of an accumulating type of radon test chamber. In Proceedings of AARST International Radon Symposium (2012).

Karunakara, N. et al. Evaluation of radon adsorption characteristics of a coconut shell-based activated charcoal system for radon and thoron removal applications. J. Environ. Radioact. 142, 87–95 (2015).

Sudeep, K. K. et al. Thoron mitigation system based on charcoal bed for applications in thorium fuel cycle facilities (part 2): development, characterization, and performance evaluation. J. Environ. Radioact. 172, 249–260 (2017).

Sahoo, B. K. et al. Thoron mitigation system based on charcoal bed for applications in thorium fuel cycle facilities (part 1): development of theoretical models for design considerations. J. Environ. Radioact. 172, 249–260 (2017).

Karunakara, N. & Al-Azmi, D. A study of radon absorption efficiencies of edible oils produced in India. Health Phys. 98, 621–627 (2010).

Trilochana, S. et al. A “semi-dynamic” technique for achieving temporal stability of 222Rn concentration in a walk-in type of calibration chamber. In Proceedings of 21st National symposium on Radiation Protection (NSRP 21) (2017).

Janik, M. Inter comparisons exercises of radon and thoron monitors provided by four laboratories: a review. Health Phys. 52(2), 114–121 (2017).

UNSCEAR-2000. Sources and effects of ionizing radiation: Sources: United Nations, Vienna, Austria, v. I, 649 p. https://www.unscear.org/reports/2000_1.html (2000).

Hong, S. L. & Gon, K. Analysis of energy performance on envelope ratio exposed to the outdoor. Adv. Civ. Eng. https://doi.org/10.1155/2018/7483619 (2018).

Nazaroff, W. W. & Nero, A. V. Jr. Radon and Its Decay Products in Indoor Air, United States of America (Wiley, Hoboken, 1988).

Katalin, Z. S., Gyozo, J., Ákos, H. & Csaba, S. Dynamics of soil gas radon concentration in a highly permeable soil based on a long-term high temporal resolution observation series. J. Environ. Radioact. 124, 74–83 (2013).

Murty, V. R. K. & Karunakara, N. Natural radioactivity in the soil samples of Botswana. Radiat. Meas. 43, 1541–1545 (2008).

Karunakara, N. et al. Soil to rice transfer factors for 226Ra, 228Ra, 210Pb, 40K and 137Cs: a study on rice grown in India. J. Environ. Radioact. 118, 80–92 (2013).

Karunakara, N. et al. Assessment of ambient gamma dose rate around a prospective uranium mining area of South India—a comparative study of dose by direct methods and soil radioactivity measurements. Results Phys. 4, 20–27 (2014).

Raghavayya, M., Khan, A. H., Padmanabhan, N. & Srivastava, G. K. Exhalation of Rn-222 from soil: some aspects of variations. In Special Symposium on Natural Radiation Environment, Bombay, India (eds Vohra, K. G., Mishra, U. C., Pillai, K. C. & Sadasivan, S.) 584–591 (Wiley, New York, NY USA) (1982).

Ishimori, I., Lange, K., Martin, P., Mayya, Y. S. & Phaneuf, M. Measurement and calculation of Radon releases from norm residues. IAEA Technical Report Series, vol. 474 (2013).

Mahesh, H. M. Studies on radioactivity in aquatic and atmospheric environs of coastal Karnataka & Kaiga. Ph.D. Thesis submitted to the Mangalore University, India 82–89 (2002).

Mohan, M. P. et al. Influence of rainfall on atmospheric deposition fluxes of 7Be and 210Pb in Mangaluru (Mangalore) at the Southwest Coast of India. Atmos. Environ. 202, 281–295 (2019).

Karunakara, N. Studies on Radionuclide Distribution and Uptake in the Environment of Kaiga. Ph.D. Thesis submitted to the Mangalore University, India (1997).

Winkler, R., Ruckerbauer, F. & Bunzl, K. Radon concentration in soil gas: a comparison of the variability—resulting from different methods, spatial heterogeneity, and seasonal fluctuations. Sci. Total. Environ. 272, 273–282 (2001).

Sudeep, K. K. et al. Activated charcoal adsorber bed as a 222Rn hold up system for application in Uranium Mining Industries. In Proceedings of International Conference on Developments towards Improvements of Radiological Surveillance at Nuclear Facilities and Environment (IARPIC - 2018) (2018).

Picolo, J. L. et al. A radon 222 traceability chain from primary standard to field detectors. Appl. Radiat. Isot. 52, 427–434 (2002).

Guidance on Quality Assurance EPA, National Radon Proficiency Program (NRPP/EPA), 402-R-95-012. https://www.nrsb.org/wp-content/uploads/2019/02/GuidanceOnQA-web2.pdf (2020).

Trilochana, S. et al. A periodic pumping technique of soil gas for 222Rn stabilization in large calibration chambers: part 2—theoretical formulation and experimental validation. Sci. Rep. (Manuscript communication ID:2cb9a292-7a78-4301-b903-b73f5804618d)

Kalina, M. C. et al. Inter-comparison of radon CR-39 detector systems conducted in CLOR’s calibration chamber. Nucleonika 55, 589–593 (2010).

Foerster, E. et al.Messgeräte zur Bestimmung der Radon-222-Aktivitätskonzentration oder der Radon-222-Exposition Vergleichsprüfung 2015 (Instruments to Measure Radon-222 Activity Concentration or Exposure to Radon-222 - Intercomparison 2015). Bundesamt for Strahlenschutz https://doris.bfs.de/jspui/bitstream/urn:nbn:de:0221-2014101611834/3/BfS-SW-16-14.pdf (2015).

Jilek, K. & Timkov, J. ICHLNRRA intercomparison of radon/thoron gas and radon short-lived decay products measuring instruments in the NRPI Prague. Radiat. Prot. Dosim. 164, 556–562 (2015).

Howarth, C. B. Results of the 2004 NRPB Intercomparison of passive radon detectors. Health Protection Agency—Radiation Protection Division -028. ISBN 978-0-85951-598-6. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/340118/HpaRpd028.pdf (2007).

Lopez-Cotoa, I., Bolivara, J. P., Mas, J. L., Garcıa, T. R. & Vargas, A. Development and operational performance of a single calibration chamber for radon detectors. Nucl. Instrum. Methods Phys. Res. 579, 1135–1140 (2007).

Compagno, A., Parlato, A., Rizzo, S. & Tomarchio, E. A chamber to test the response of radon detectors to changing environmental conditions. Radiat. Prot. Dosim. 145, 312–315 (2011).

Tadeusz, A. P. et al. New SRDN-3 probes with a semi-conductor detector for measuring radon activity concentration in underground spaces. J. Radioanal. Nucl. Chem. 285, 599–609 (2010).

Shweikani, R. & Raja, G. Design, construct and test of a calibration radon chamber. Radiat. Meas. 40, 316–319 (2005).

Acknowledgements

Authors would like to thank the Board of Research in Nuclear Science (BRNS), DAE, Govt. of India for funding the research programme (Sanction No.2013/36/22-BRNS/3340 dated 18.03.2014). The authors would also like to thank Shri. H. S. Kushwaha, Former Director, HS&E group, Bhabha Atomic Research Centre (BARC), Mumbai, and Debanik Roy, Chief Program Coordinator, BRNS, for their comments, suggestions, and guidance.

Author information

Authors and Affiliations

Contributions

Prof. N.K.—Developed the idea and concept, contributed to the planning of the whole study, drafting and reviewing the manuscript. Ms. T.S.—performed all the experimental studies and drafted the manuscript. Dr. S.K.—Contributed towards the installation of the instrumentation and experimental work. Dr. B.K. Sahoo and Dr. B.K. Sapra—Contributed towards the calibration of the reference instruments. Prof. Y.S.M.—Contributed towards the planning and review of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karunakara, N., Shetty, T., Sahoo, B.K. et al. An innovative technique of harvesting soil gas as a highly efficient source of 222Rn for calibration applications in a walk-in type chamber: part-1. Sci Rep 10, 16547 (2020). https://doi.org/10.1038/s41598-020-73320-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-73320-9

This article is cited by

-

Baseline study on radiological and mineralogical investigations of heavy mineral depositions on the south–west coast of India

Journal of Radioanalytical and Nuclear Chemistry (2023)

-

Effective dose estimation of radon, thoron and their progeny concentrations in the environs of Himalayan belt, India

International Journal of Environmental Science and Technology (2023)

-

A periodic pumping technique of soil gas for 222Rn stabilization in large calibration chambers: part 2—theoretical formulation and experimental validation

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.