Abstract

This work reports on an optimized procedure to synthesize methylammonium bromide perovskite nanoparticles. The ligand-assisted precipitation synthetic pathway for preparing nanoparticles is a cost-effective and promising method due to its ease of scalability, affordable equipment requirements and convenient operational temperatures. Nevertheless, there are several parameters that influence the resulting optical properties of the final nanomaterials. Here, the influence of the choice of solvent system, capping agents, temperature during precipitation and ratios of precursor chemicals is described, among other factors. Moreover, the colloidal stability and stability of the precursor solution is studied. All of the above-mentioned parameters were observed to strongly affect the resulting optical properties of the colloidal solutions. Various solvents, dispersion media, and selection of capping agents affected the formation of the perovskite structure, and thus qualitative and quantitative optimization of the synthetic procedure conditions resulted in nanoparticles of different dimensions and optical properties. The emission maxima of the nanoparticles were in the 508–519 nm range due to quantum confinement, as confirmed by transmission electron microscopy. This detailed study allows the selection of the best optimal conditions when using the ligand-assisted precipitation method as a powerful tool to fine-tune nanostructured perovskite features targeted for specific applications.

Similar content being viewed by others

Introduction

Nanostructured lead halide perovskite materials have gained significant attention in the last few years mainly because of their potential for application in the field of electronics and photonics. There are several available reports demonstrating their implementation into light emitting diodes (LED)1,2,3, solid-state lasers4, solar cells5, photodetectors6 and optical cooling systems7. Especially the photoluminescence quantum yields (PLQY) of up to 100% make these nanostructured perovskite materials very interesting8. In addition, their optical properties can be tailored efficiently by tuning the halide composition and stoichiometry9 and their size due to quantum confinement effects10,11. Depending on the synthetic approach, nanomaterials with defined size and shape can be obtained ranging from nanoplatelets12, nanowires13, nanorods14, nanocubes15 to quantum dots16. The shape and size can be controlled by changing the reaction conditions and the solvent during hot-injection17,18,19 or ligand-assisted precipitation methods, where also the choice of the capping agents plays a crucial role20. Furthermore, perovskite nanoparticles can also be grown within nanopores21, or in templates of diblock copolymer micelles22.

Most synthetic approaches for MAPbBr3 perovskite nanoparticles are based on the room-temperature ligand-assisted precipitation method where the capping agents are used for the formation of nanostructures23. This method is convenient and cost-effective due to its mild equipment requirements and moderate operating temperatures. Another benefit of the ligand-assisted precipitation method is that the product of the reaction is a colloidal dispersion that can be easily processed by spin coating24, centrifugal casting8 or ink-jet printing25. However, there are several important parameters which need to be controlled during this ligand-assisted precipitation technique. Hence, the resulting final properties of the nanomaterials depend on the precipitation temperature26, the choice of solvent system27, the choice of capping agents8,27 and their concentration28 and on the water concentration in the precursor solutions11. However, a detailed understanding of the interplay of all these parameters is currently missing.

Various types of capping agents have been applied recently to stabilize perovskite nanomaterials. Among them, ligands containing primary amine groups along with carboxylic acids are used for stopping the crystal growth, providing higher stability in the colloidal solutions18. Commonly used amines are long-chain primary amines18,23 and zwitterion-based capping agents29. In fact, our group previously demonstrated that the use of bio-inspired capping agents, such as amino acids27 and cyclopeptides30 can also control the nanoparticle growth. Besides, promising stabilizing properties were also found for adamantane-based capping agents8,31, where colloidal solutions exhibit a PLQY up to 100%.

Herein, this manuscript provides a comprehensive study of the parameters that influence nanoparticle formation when applying the ligand-assisted precipitation method. We optimized the properties of adamantane-1-amine (AdNH2) stabilized MAPbBr3 perovskite nanoparticles (PNP) by varying temperature, concentration and solvents. We report the optical and physical properties along with the temporal stability of precursor solutions and colloids.

Results and discussion

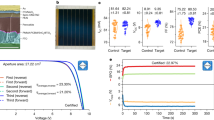

In general, perovskite precursors are soluble in highly polar aprotic solvents such as N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO) and γ-butyrolactone (GBL)32. Encouraged by previous experiments, we tested DMSO30 and DMF27 as solvents for the preparation of precursor solutions. The precursors were soluble in both DMSO and DMF. For both solvents, a transparent clear precursor solution was obtained, see Figure S1. The colloidal solutions prepared from precursors in the DMF and DMSO exhibited green emission under a UV-lamp (Fig. 1). Figure 1a shows the comparison between the absorption and emission spectra of the dispersions prepared in toluene from the DMF and DMSO precursor solutions. The emission maximum of the colloidal solutions prepared from DMF and DMSO precursor solutions was of 522 and 530 nm and the photoluminescence quantum yield (PLQY) was of 43% and 2%, respectively (see Table 1). The red-shifted emission maximum and the decrease of PLQY of the sample from precursor solution prepared in DMSO can be related to the retarded crystallization process during the precipitation. Due to its strong binding to the lead precursor33, the capping agents cannot be involved in the crystal growth control and in the PNP stabilization. The better optical properties of the colloidal solution prepared from the DMF precursor solution led to using DMF as a precursor solvent for the further studies. As a first step, the robustness of the PNP synthesis was tested by preparing DMF-based precursor solutions followed by the precipitation in toluene as described above. Colloidal solutions were obtained with an emission maximum of 521 ± 2 nm, a PLQY of 48 ± 7% and a band gap in the range 2.32–2.34 eV suggesting a good reproducibility of the PNP synthesis procedure.

(a) Comparison of colloidal solutions in toluene prepared from two different precursor solutions (in DMF and DMSO)—the inset shows photos of colloidal solutions under UV irradiation (excitation wavelength 366 nm); (b) Powder XRD spectra of PNP prepared from DMF precursor solution compared to the spectra of bulk MAPbBr3 single crystal.

The prepared PNP were collected by centrifugation of the colloidal solutions. The resulting material was dried at ambient conditions overnight to ensure the complete evaporation of the solvent traces. Using X-ray powder diffraction (XRD) the perovskite crystalline structure was confirmed by comparing PNP diffractogram with bulk MAPbBr3 diffraction patterns33 (Fig. 1b). Peaks positioned at 14.90°, 21.14°, 26.02°, 30.07°, 33.72°, 37.08°, 43.05°, 45.83° and 48.42° 2θ correspond to the reflections from the planes (001), (011), (111), (002), (021), (211), (220), (300), and (310), respectively34. The broadening of the diffraction peaks observed in the PNP spectrum results from the small crystal volume of the individual nanoparticles27.

Next, the influence of the precursor solution concentration in the resulting colloidal solutions on the PNP formation was studied. For that, samples were prepared by precipitating precursor solution in defined ratios in toluene at 3 °C and their optical properties were determined (see data collected in Table 2). The concentration of PbBr2 was 0.027, 0.054, 0.081, 0.14 and 0.27 mmol L−1 in the resulting toluene dispersion and the concentrations of MABr, AdNH2 and HeA were adjusted accordingly to keep their ratio of 1.1, 0.8 and 9.5 with respect to PbBr2. As a result, the obtained colloidal solutions showed very similar optical properties (Table 2). Therefore, it can be assumed that the ratio between the precursor solution and the precipitation medium has no significant effect on the formation of PNP. Nevertheless, with higher concentration of nanoparticles formed in the precipitation medium, the optical density of the resulting dispersion was observed to increase (Figure S2a). Following, detected optical densities were of 0.15, 0.24, 0.35, 0.56 and 0.52 at the excitation wavelengths of 405 nm in the integrating sphere for colloidal solutions prepared with the concentration of 0.027, 0.054, 0.081, 0.14 and 0.27 mmol L−1 of PbBr2 in the resulting toluene dispersion, respectively. It must be emphasized that at high concentrations, the recorded PLQY values may be inaccurate due to strong self-absorption of the colloidal dispersion35. Consequently, the concentration of 0.054 mmol L−1 of PbBr2 in the precipitation medium was used for further experiments because of the accurate optical density of 0.24 at the excitation wavelength of 405 nm.

As reported previously26, there is a significant effect of the precipitation temperature on the resulting properties of the colloidal solutions. Therefore, in order to evaluate the influence of the temperature during the precipitation on the resulting optical properties of colloidal solutions, temperatures from − 5 to 80 °C were varied by using an ice or an oil bath. In all cases, a colour change was detected during the precipitation and the colloidal solutions were formed, as seen in Figure S3. The temperature changes from − 5 up to 40 °C brought a negligible shift in emission spectra, while the PLQY was affected significantly. The highest PLQY of ca. 48% with the emission maximum of 521 nm was obtained for samples prepared at 3 °C. Interestingly, when the precipitation temperature was 60 and 80 °C, a red-shift of the emission maxima and a strong decrease of PLQY was clearly noticed (Table 3). Along with the emission maximum at ca. 528 nm, the optical properties of the colloidal solution were similar to the optical properties of a polycrystalline MAPbBr3 film where the emission maximum is 530 nm and a line width of 23 nm (FWHM) was reported36. Hence, it could be assumed that increasing the precipitation temperature enhances the tendency to form the perovskite lattice, and in this case, the crystallization could have occurred too promptly to be controlled by the capping agents.

Furthermore, the influence of washing PNP with toluene on the optical properties of colloidal solutions was investigated. A colloidal solution was prepared by precipitating precursor solution in toluene in a volume ratio of 0.002 under cold conditions (3–4 °C) in order to keep the optimal ratio of precursor and antisolvent for the optical characterization. The sample was washed up to three times, thus four samples were obtained from one batch in total—crude colloidal solution and then colloidal solutions once, twice and three times washed. The volume of added toluene for the redispersion was always set to keep the original concentration of PNP. Remarkably, no significant changes in emission spectra were detected when washing the colloidal solutions. However, a strong decrease in PLQY was detected after the purification procedure, the PLQY typically dropped to 40–60% of the original value. A typical example is shown in Table 4, where a decrease in PLQY was observed, from 54 to 30%, after the colloidal solution was washed three times. Hence, the influence of the washing procedure on the resulting nanoparticles’ size, shape and possible formation of aggregates was analysed by transmission electron microscopy (TEM). TEM images were taken of crude and thrice-washed samples dropped on a TEM grid for comparison. No significant change was observed between both samples. In fact, in both cases, the nanoparticles formed aggregates, while more individual nanoparticles were visualized from the sample prepared with crude colloidal solution, see Fig. 2. In TEM images it can be seen that individual nanoparticles are covered with an amorphous shell. The shell is most likely formed from the surface ligands that appeared during the nanoparticle formation. However, due to the Van der Waals intermolecular interaction the shell is in equilibrium at a nanoparticle surface, therefore it is not expected to be removed during the washing steps. Apparently, the washing steps did not have any significant effects on the morphology of individual nanoparticles and the spherical shape and highly crystalline structure were not affected, as demonstrated in Figure S3, concluding that repeated washing does not affect the morphology of the PNPs. Even so, unwashed particles showed a typical diameter of 8.5 ± 1.8 nm, whereas a diameter of 9.3 ± 2.0 nm was observed after 3 times of washing with toluene. This could be attributed to the possible removal of the capping agents from the PNP surface37 which could reduce the final colloidal stability of the PNP. Moreover, the thinner organic shell formed around the nanoparticles could increase the probability of non-radiative transitions between them, thus decreasing the PLQY values.

From an application point of view, it is important to test solvent systems suitable for PNP processing, since the possibility of preparing colloidal solutions in different precipitation media may increase the applicability of these materials38. Therefore, different precipitation media were tested during the preparation of the precursor solutions and chlorobenzene, n-hexane, cyclohexane, 1-octadecene, acetonitrile, tetrahydrofuran, diethylether, chloroform, xylene, acetone and toluene were selected. Remarkably, only chlorobenzene, diethylether, chloroform, xylene and toluene supported the formation of a colloidal solution exhibiting green light emission under UV irradiation (Figure S4). These colloidal solutions were further characterized by optical spectroscopy techniques to evaluate the changes in optical properties. In particular, the use of chloroform as an antisolvent resulted in the formation of colloidal solutions with the most blue-shifted emission spectrum with a maximum of 509 nm, in agreement with our previously reported work27. Besides, a strong photoluminescence quenching effect39 was observed in the case of the sample prepared in chloroform where the PLQY was found <1%. On the other hand, the use of toluene resulted in the formation of colloidal solution with the emission maximum of 521 nm with a PLQY of ca. 48%. All recorded optical properties of the samples are summarized in Table 5.

The ratio of the precursor chemicals was also supposed to influence the resulting optical properties28. For that reason, different precursor solutions with varying concentration of MABr, AdNH2 and HeA were prepared while the concentration of PbBr2 was kept constant. The emission maxima shifted to higher wavelengths with increasing MABr concentration in the precursor solution (see Table 6 and Figure S7). As expected, PLQY was affected by the MABr concentration changes and the highest PLQY of 40% was observed for a PbBr2:MABr ratio of 1:1.1. A decrease in PLQY detected with increasing MABr concentration was attributed to replacing AdNH2 by methylammonium ions on the nanoparticles’ surface. Here, the probability of non-radiative transitions between the particles could increase because of thinning the organic shell. Alternatively, increasing the concentration of AdNH2 in the precursor solutions led to blue-shifted emission and to an increase in the PLQY. Also, by keeping the molar ratio of AdNH2 at 0.4 and 2.5 with respect to PbBr2, emission maxima of ca. 523 and 509 nm were detected, respectively, and simultaneously, broadening of the emission spectra was observed (Fig. 3a–b). Here, as expected, the amount of the amino-capping agent had a significant effect on PLQY, which increased with the concentration of AdNH2. The maximum detected PLQY was 70% when 1.6 molar equivalents of AdNH2 were used with respect to PbBr2. A further increase in the concentration of the amino-capping agent to a 2.5 molar ratio with respect to PbBr2 did not lead to a further blue-shift of the photoluminescence, but in a decreased PLQY to about 55%. Regarding to the results, the ratios between precursor chemicals have a crucial effect on the resulting PLQY. Hence, fine tuning of the ratios leads to a significant increase in PLQY. From this point of view, quite big deviations can be explained by this observation—even negligible changes in the precursor chemicals concentration can cause a significant change in PLQY.

Varying concentrations of AdNH2 in precursor solution and the influence on optical properties and the size of nanoparticles: (a) Optical characterization of the colloidal solutions; (b) photo of the colloidal solutions under UV irradiation (excitation wavelength 366 nm); (c–e) TEM images of PNP prepared from precursors with 0.8, 1.0 and 1.6 molar equivalents of AdNH2 with respect to PbBr2, respectively, and zoom to individual nanoparticles with FFT images in the insets.

The blue-shift in emission spectra connected to the increasing the AdNH2 concentration in the precursor solution can be attributed to the formation of smaller nanoparticles. To confirm this assumption, precursor solutions containing 0.8, 1.0 and 1.6 molar equivalents of AdNH2 with respect to PbBr2 were selected to prepare PNPs for the TEM characterization (Fig. 3c–e). In all samples, spherical and highly crystalline nanoparticles were observed, with average sizes of 8.5 ± 1.8 nm, 6.2 ± 0.4 nm and 4.5 ± 0.6 nm, respective to the concentration. For comparison, the Bohr radius calculated for the MAPbBr3 perovskite materials was 4.7 nm40. Interestingly, the concentration of HeA in the precursor solutions did not show any significant influence on the emission maxima, but it had a strong effect on PLQY (Figure S7). Changing the molar ratio of HeA with respect to PbBr2 from 2.4 to 19 resulted in the formation of colloidal solutions with emission maxima between ca. 523 and 521 nm, and PLQYs of ca. 36% and 53%, (see Table 6). This effect may be explained by the possible formation of a stronger organic shell surrounding the individual nanoparticles and a reduction of surface defects leading to a more radiative recombination.

With respect to a previously reported study8, different carboxylic acids were selected to stabilize the PNP and to evaluate whether the optical properties can be further improved. For that, a fixed ratio of precursors was set to 1:1.1:0.9:9.5 for PbBr2:MABr:AdNH2:carboxylic acid. Here, the selected carboxylic acids were acetic acid (AcA), trifluoroacetic acid (TriflacA), propanoic acid (PropA), hexanoic acid (HeA), n-octanoic acid (OctA), oleic acid (OleicA) and adamantanecarboxylic acid (AdA). The optical properties of the corresponding colloidal solutions are summarized in Fig. 4 and Table 7. For comparison, a colloidal solution without addition of carboxylic acid was prepared (called reference sample, ref).

The stability of colloidal solution prepared for precursor solutions with different carboxylic acids was also further tested. Colloidal solutions were prepared after stirring the precursor solutions for one day and the optical properties of the resulting colloidal solutions were studied over a period of 21 days. It was observed that all the samples tended to precipitate within that time, but nevertheless the solid material was easy to redisperse under a sonication bath. As shown in Fig. 5a, a red-shift was observed over time in all samples except for the sample where PNPs were stabilized by AdNH2 and AdA. It must be noted that the precursor solution containing AdA as a carboxylic acid containing a capping agent formed a cloudy solution, while all the other precursor solutions were clear. This behaviour could be related to the low solubility of the precursors in the solution. For the TriflacA-based solution, the photoluminescence was no longer detectable after three days.

The selection of the surfactant was also further investigated, it was observed that if an appropriate surfactant is chosen, the emission maximum is blue-shifted and PLQY can be increased. For example, the choice of PropA leads to the formation of colloidal solution with an emission maximum of 521 nm with a PLQY of ca. 58%, and a band gap of 2.32 eV. Furthermore, the use of the carboxylic acid improved the colloidal stability and the PLQY of the PNP stabilized by HeA was lowered from initial 58% to 49% over the period of 21 days. The use of any carboxylic acid for the stabilization was noticed to decrease the PLQY from 47 to 33% in the same period. As comparison, a colloidal solution with no carboxylic acid as surfactant was prepared and apparently, it was possible to prepare PNP colloidal solutions without any further stabilization by surfactants. The colloidal solution showed an emission maximum at 528 nm, a PLQY of 45% and a band gap of 2.28 eV.

In order to fully characterize the prepared PNP, X-ray photoelectron spectroscopy (XPS) and Fourier transform infrared (FT-IR) spectroscopy were employed to study the ligands (AdNH2 and HeA) binding to the PNP surface and the complex formation in precursor solutions. XPS revealed the binding energies of the core electrons providing an information about the chemical environment of the individual atoms comprising the nanoparticles41. Two symmetric peaks at 138.3 eV and 143.2 eV were detected in the Pb 4f. high resolution XPS spectra pointing out to Pb 4f7/2 and Pb 4f5/2 signals, respectively (see Figure S6) with a characteristic spin–orbit splitting of 4.9 eV42,43. Simultaneously, the presence of Br 3d5/2 and Br 3d3/2 was proved by detecting peaks at 68.2 eV and 69.2 eV in the Br 3d spectrum44. Both Pb and Br XPS spectra confirm the presence of the perovskite-based material in the sample. On the other hand, the N 1s XPS spectrum showed one peak with the centre at 401.8 eV pointing out to the presence of the methylammonium salt. Nevertheless, it can be simultaneously associated with the ammonium salt of AdNH2 proving the charged character of the primary ammonium group in AdNH2 molecules stabilizing the PNP43. Three peaks were deconvoluted in the C 1s XPS spectrum. Peaks with the centres at 285.0, 286.2 and 289.2 eV can be attributed to C–C/C–H bonds of adamantyl-moiety and the HeA side chain, then to the C–N bond of the amino groups43 and finally to the C–O bond of the carboxylic acid group of HeA, respectively45. The latter could support an assumption about the deprotonated nature of the carboxylic group because of exhibiting one signal due to the delocalized character of the negative charge46. This can be also supported by recording only one peak with the maximum at 533.0 eV in the O 1s XPS spectrum. The quantification of the perovskite components showed ratios of 2.7 and 1.2 for Br/Pb and N/Pb, respectively, which is in accordance with previously reported results8.

Additionally, FT-IR spectroscopy was used to detect the presence of the capping ligands AdNH2 and HeA decorating the surface of the PNP precipitated from the precursor solution prepared in DMF (see Fig. 3). The three main characteristic peaks of MABr were easily detected at 3300–2700 cm−1 (broad signal assigned to the Br–H), at 1000 and 912 cm−1 (narrow and medium signals) assigned to C–H rocking bonds 47,48. In the bare solvent, the C = O detected at 1670 cm−1 was shifted in the precursor to a lower wavenumber (1650 cm−1) due to the interaction between PbBr2 and MABr49. Signals at 3300–2990 and 912 cm−1 detected in PNP spectrum could correspond to the vibrations of the methylammonium ions in the surrounding of PbBr3−. Bands at 2900 and 2845 cm−1 related to –CH2 groups from AdNH2 appeared at a higher wavenumber in PNP (2916 and 2857 cm−1, respectively), which was an indication of nanoparticles’ surface passivation. In the precursor, the signals at 2930 and 2855 cm−1 were attributed to the alkyl groups and the signal detected at 1705 cm−1 was assigned to the C = O stretching band from the carboxylic acid group presented in the ligand hexanoic acid, introduced here as a stabilizer. Furthermore, the signal at 1595 cm−1 from the amine of the capping agent AdNH2 was shifted to a lower wavenumber 1579 cm−1 attributed to the possible coordination with the PbBr3− from the amino groups27. The aforesaid is in agreement with preferential stabilization of nanoparticles with the selected ligands (Fig. 6).

Conclusion

In the present work, a complex comparative study of non-template PNP preparation via the ligand-assisted precipitation technique was carried out. Various parameters were controlled during the preparation of PNP stabilized by AdNH2 and their influence on the resulting optical properties was evaluated. It was found that the temperature during the precipitation has a crucial effect on the optical properties, a red-shift in emission spectra and a decrease in PLQY occurs with increasing temperature, which was the result of larger nanoparticles. We assume that at temperatures higher than 40 °C the perovskite lattice forms too fast to be efficiently stabilized by the capping agents. At the same time, the choice of the precipitation medium influences the resulting optical properties. As suitable precipitation media, nonpolar solvents such as chlorobenzene, chloroform, toluene and xylene were evaluated. Also, diethylether as a polar aprotic solvent which is known as an antisolvent for perovskite materials50 was proven to be suitable for PNP preparation. Strong nonpolar aliphatic solvents, such as hexane, cyclohexane and 1-octadecene, and strong polar solvents such as acetonitrile, acetone and tetrahydrofurane were not able to induce perovskite lattice formation. The best precipitation medium was found to be toluene by means of higher PLQY in colloidal solution, but the use of different solvent systems could broaden the applicability of functional devices. In addition, the ratio of precursor chemicals also significantly influenced the optical properties of the nanoparticles due to quantum confinement effects. Especially, increasing the concentration of AdNH2 leads to more efficient control of the crystal growth during the preparation, thus, smaller PNP may be obtained can take place. Moreover, different carboxylic acids were tested as surfactants to evaluate the influence of the length and the bulkiness of their side chain on the resulting optical properties, colloidal stability and on the stability of precursor solution. In agreement with previous reports8, too bulky and long-chain carboxylic acids such as AdA and OleicA were not suitable for surface passivation, probably due to the sterical hindrances. However, high PLQY were detected when short chain carboxylic acids such as PropA and HeA were used as a capping agent together with AdNH2. We strongly believe that this work will help to better understand the preparation of PNP colloidal solutions and thus to effectively tailor not only the optical properties but also the composition (i.e. capping agents, used precipitation medium) for the desired application.

Materials and methods

Chemicals

Lead (II) bromide (PbBr2, 99.999%) and methylammonium bromide (MABr, 98%) were purchased from Sigma Aldrich. Adamantyl-1-amine (AdNH2) and adamantanecarboxylic acid (AdA, 99.6%) were obtained from Provisco CS. Hexanoic acid (HeA, 98%) and n-Octanoic (OctA, > 98%) acid were purchased from TCI. Oleic acid (OleicA, min. 70%) was purchased from Lachner. Glacial acetic acid (AcA, 99–100%) was purchased from J. T. Baker. Trifluoroacetic acid (TriflacA, 99.5 + %) was purchased from Alfa Aesar. Propionic acid (PropA, > 99.5%) and 1-Octadecene (90%) were provided by Sigma Aldrich. N,N-dimethylformamide (DMF), xylene (a mixture of isomers), acetone, diethylether, cyclohexane, chlorobenzene, chloroform and toluene were of reagent grade, n-hexane and acetonitrile (ACN) were of HPLC grade, all provided from VWR. All chemicals were used as received.

General methods

Nanoparticle synthesis

Following the previous report by S. González-Carrero et al8. adamantane-1-amine (AdNH2) was used for the stabilization of perovskite nanoparticles (PNP). The synthetic procedure was modified in order to optimize the PNP preparation. Initially, the ratio of precursor chemicals was 1:1.1:0.8:9.5 for PbBr2:MABr:AdNH2:HeA and as a coordinating solvent N,N-dimethylformamide (DMF) was selected. The resulting concentration of precursors was then 0.027, 0.030, 0.022 and 0.26 mol L−1 for PbBr2, MABr, AdNH2, and HeA, respectively. All the precursor solutions were prepared 24 h in advance, in order to favour the complex formation while being stirred. The precipitation of 20 μl of the precursor solution was performed in 10 mL of toluene (precursor solution and toluene were in a volume ratio of 0.002) which acted as a non-coordinating non-polar solvent under cold conditions (ice bath at 3–4 °C), while being stirred. Washing steps were performed by centrifuging the crude colloidal solutions (at 5000 rpm during 10 min) and the resulting solid material was redispersed by sonication in toluene.

General methods

Ultraviolet–visible (UV–Vis) and fluorescence spectroscopy were used to determine the optical properties of the prepared PNP. UV–Vis spectroscopy was carried out with a Lambda 1050 UV/Vis/NIR spectrometer (PerkinElmer). Photoluminescence (PL) spectra were measured on a QuantaMaster 40 from Photon Technology International. The PLQY of colloidal PNP suspensions were measured using a Hamamatsu C9920-03 absolute quantum yield spectrometer. For all PLQY measurements, an excitation wavelength of 405 nm was chosen. Fourier-transform infrared (FTIR) spectra of precursor solutions were recorded on a Perkin-Elmer Spectrum 100. The precursor solutions were measured by using an ATR technique at ambient conditions. Transmission electron microscopy (TEM) images were obtained with a Jeol JEM-2200 microscope using Holey Carbon film 300 Mesh copper grids. All sample grids were previously treated for 5 min in a Jeol EC-52000IC Ion cleaner before the TEM measurement. Powder X-ray diffraction (XRD) measurements were performed on an Empyrean (PANalytical) diffractometer using Cu Kα (1.540598 Å) radiation. The measurement parameters were as follows: tube current 30 mA and voltage 40 kV; scan axis gonio; step size 0.013°2θ; time per step 96 s. Solid samples for powder XRD measurements were prepared by precipitating the precursor solution in toluene in a volume ratio of 0.01 at 3–4 °C. Solid material was collected after the centrifugation (5000 rpm for 10 min) followed by careful washing with toluene (approx. 3 mL). PNP were dried at room temperature for 12 h. X-ray photoelectron spectroscopy (XPS) was employed in order to investigate the binding energy of a core-level electron of an atom in the nanoparticles. The XPS sputter depth profiles were performed using a Thetaprobe XPS system (Thermo Scientific, UK), which was controlled and operated by the Avantage software package from the system manufacturer. The device was equipped with a monochromated Al Kα X-Ray source (hν = 1486.6 eV) and a dual flood gun for neutralizing the surface charges. The X-ray spot on the sample surface exhibited a diameter of 400 µm. The sputtering was performed by using an Ar+ ion gun. The survey spectra were recorded with 200 eV of pass energy and with a binding energy step of 1 eV, while for high-resolution spectra a pass energy of 20 eV and step of 0.05 eV was used. The sample for X-ray photoelectron spectroscopy (XPS) was prepared by centrifugal casting, as reported8. The colloidal solution was prepared by precipitating precursor solution in toluene in a volume ratio of 0.002 at 3–4 °C in a centrifugation tube. A glass substrate (1 × 1 cm) was placed on the bottom of the tube and the sample was centrifuged (at 5000 rpm for 10 min). The supernatant was carefully discharged, and the film formed on the substrate was carefully washed with toluene (approx. 3 mL). The prepared film was dried and stored in a glove box before the measurement.

References

Wei, Z. & Xing, J. The rise of perovskite light-emitting diodes. J. Phys. Chem. Lett. 10, 3035–3042 (2019).

Chen, P. et al. Highly efficient perovsktite light-emitting diodes incorporating full film coverage and bipolar charge injection. J. Phys. Chem. Lett. 8, 1810–1818 (2017).

Ahn, Y. et al. Improving the efficiency of perovskite light emitting diode using polyvinylpyrrolidone as an interlayer. Appl. Surf. Sci. 507, 145071 (2020).

Stylianakis, M. M., Maksudov, T., Panagiotopoulos, A., Kakavelakis, G. & Petridis, K. Inorganic and hybrid perovskite based laser devices: a review. Materials. 12, 859 (2019).

Gao, Y. et al. CsPbBr3 perovskite nanoparticles as additive for environmentally stable perovskite solar cells with 20.46% efficiency. Nano Energy. 59, 517–526 (2019).

Li, J. et al. Stable high-performance flexible photodetector based on upconversion nanoparticles/perovskite microarrays composite. ACS Appl. Mater. Interfaces. 9, 19176–19183 (2017).

Tonkaev, P., Zograf, G. & Makarov, S. Optical cooling of lead halide perovskite nanoparticles enhanced by Mie resonance. Nanoscale. 11, 17800 (2019).

González-Carrero, S., Martinez-Sarti, L., Sessolo, M., Galian, R. E. & Pérez-Prieto, J. Highly photoluminescent, dense solid films from organic-capped CH3NH3PbBr3 perovskite colloids. J. Mater. Chem. C. 6, 6771–6777 (2018).

Xing, J. et al. High-efficiency light-emitting diodes of organometal halide perovskite amorphous nanoparticles. ACS Nano 10, 6623–6630 (2016).

Dong, Y. et al. Precise control of quantum confinement in cesium lead halide perovskite quantum dots via thermodynamic equilibrium. Nano Lett. 18, 3716–3722 (2018).

Jancik Prochazkova, A. et al. Controlling quantum confinement in luminescent perovskite nanoparticles for optoelectronic devices by the addition of water. ACS Appl. Nano Mater. 3, 1242–1249 (2020).

Weidman, M. C., Goodman, A. J. & Tisdale, W. A. Colloidal halide perovskite nanoplatelets: an exciting new class of semiconductor nanomaterials. Chem. Mater. 29, 5019–5030 (2017).

Feng, J. et al. Single crystalline layered metal-halide perovskite nanowires for ultrasensitive photodetectors. Nat. Electron. 1, 404–410 (2018).

Aharon, S. & Etgar, L. Two dimensional organometal halide perovskite nanorods with tunable optical properties. Nano Lett. 16, 3230–3235 (2016).

Paul, T. et al. Fabrication of all-inorganic CsPbBr3 perovskite nanocubes for enhanced green photoluminescence. Mater. Today Proc. 5, 2234–2240 (2018).

Protesescu, L. et al. Nanocrystals of cesium lead halide perovskites (CsPbX3, X = Cl, Br and I): novel optoelectronic materials showing bright emission with wide color Gamut. Nano Lett. 15, 3692–3696 (2015).

Chen, D. & Chen, X. Luminescent perovskite quantum dots: synthesis, microstructures, optical properties and applications. J. Mater. Chem. C. 7, 1413 (2019).

Schmidt, L. C. et al. Nontemplate synthesis of CH3NH3PbBr3 perovskite nanoparticles. J. Am. Chem. Soc. 136, 850–853 (2014).

Pan, A. et al. Insight into the ligand-mediated synthesis of colloidal CsPbBr3 perovskite nanocrystals: the role of organic acid base and cesium precursors. ACS Nano 10, 7943–7954 (2016).

Sun, S., Yuan, D., Xu, Y., Wang, A. & Deng, Z. Ligand-mediated synthesis of shape-controlled cesium lead halide perovskite nanocrystal via reprecipitation process at room temperature. ACS Nano 10, 3648–3657 (2016).

Demchyshyn, S., Roemer, J. M., Groiß, H.; Heilbrunner, H., Ulbricht, C., Apaydin, D., Böhm, A., Rütt, U., Bertram, F., Hesser, G., Scharber, M. C., Sariciftci, N. S., Nickel, B., Bauer, S., Głowacki, E.D., Kaltenbrunner, M. Confining metal-halide perovskites in nano-porous thin films. Sci. Adv. 3, No. e1700738 (2017).

Hui, L. S. et al. Reverse micelle templating route to ordered monodispersed spherical organo-lead halide perovskite nanoparticles for light emission. ACS Appl. Nano Mater. 2, 4121–4132 (2019).

Zhang, F. et al. Brightly luminescent and color-tunable colloidal CH3NH3PbX3 (X = Br, I, Cl) quantum dots: potential alternatives for display technology. ACS Nano 9, 4533–4542 (2015).

Song, J. et al. Quantum dot light-emitting diodes based on inorganic perovskite cesium lead halides (CsPbX3). Adv. Mater. 27, 7162–7167 (2015).

Ilie, C. C., Guzman, F., Swanson, B. L., Evans, I. R., Costa, P. S., Teeter, J. D., Shekhirev, M., Benker, N., Sikich, S., Enders, A., Dowben, P. A., Sinitskii, A., Yost, A. J. Inkjet printable-photoactive all inorganic perovskite films with long effective photo carrier lifetimes. J. Phys.: Condens. Matter. 30, 18LT02 (2018).

Huang, H., Susha, A. S., Kershaw, S. V., Hung, T. F. & Rogach, A. L. Control of emission color of high quantum yield CH3NH3PbBr3 perovskite quantum dots by precipitation temperature. Adv. Sci. 2, 1500194 (2015).

Jancik Prochazkova, A. et al. Proteinogenic amino acid assisted preparation of highly luminescent hybrid perovskite nanoparticles. ACS Appl. Nano Mater. 2, 4267–4274 (2019).

Huang, H. et al. Growth mechanism of strongly emitting CH3NH3PbBr3 perovskite nanocrystals with a tunable bandgap. Nat Commun. 8, 996 (2017).

Krieg, F., Ochsenbein, S. T., Yakunin, S., ten Brinck, S., Aellen, P., Süess, A., Clerc, B., Guggisberg, D., Nazarenko, O., Shynkarenko, Y., Kumar, S., Shih, C.-J., Infante, I., Kovalenko, M. V. ACS Energy Lett. 3, 641–646 (2018).

Jancik Prochazkova, A. et al. Cyclic peptide stabilized lead halide perovskite nanoparticles. Sci. Rep. 9, 12966 (2019).

Gonzalez-Carrero, S. et al. The luminescence of CH3NH3PbBr3 perovskite nanoparticles crests the summint and their photostability under wet conditions is enhanced. Small. 12, 5245–5250 (2016).

Shi, L. et al. Solvent engineering for intermediates phase, all-ambient-air-processed in organic-inorganic hybrid perovskite solar cells. Nanomaterials. 9, 915 (2019).

Wu, Y. et al. Retarding the crystallization of PbI2 for highly reproducible planar-structured perovskite solar cells via sequential deposition. Energy Environ. Sci. 7, 2934–2938 (2014).

Kovalenko, A.; Pospisil, J.; Zmeskal, O.; Krajcovic, J.; Weiter, M. Ionic origin of a negative capacitance in lead halide perovskites. Phys. Status Solidi RRL. 11 (2017).

Lewandowska-Andralojc, A. & Marciniak, B. Five major sins in fluorescence spectroscopy of light-harvesting hybrid materials. ACS Energy Lett. 4, 1898–1901 (2019).

Zhang, Z.-Y. et al. The role of trap-assisted recombination in luminescent properties of organometal halide CH3NH3PbBr3 perovskite films and quantum dots. Sci. Rep. 6, 27286 (2016).

Zheng, W. et al. Stabilizing perovskite nanocrystals by controlling protective surface ligands density. Nano Res. 12, 1461–1465 (2019).

Masi, S. et al. Growing perovskite into polymers for easy-processable optoelectronic devices. Sci. Rep. 5, 7725 (2015).

Saperstein, D. & Levin, E. Fluorescence quenching of ultraviolet excited aromatic solutions by chloroform and several related chlorinated methanes. J. Chem. Phys. 62, 3560 (1975).

Wang, Q., Liu, X.-D., Qiu, Y.-H., Chen, K., Zhou, L., Wang, Q.-Q. Quantum confinement effect and exciton binding energy of layered perovskite nanoplatelets. AIP Adv. 8, 025108 (2018).

Greczynski, G. & Hultman, L. X-ray photoelectron spectroscopy: towards reliable binding energy referencing. Prof. Mater. Sci. 107, 100591 (2020).

Acik, M., Park, I. K., Koritala, R. E., Lee, G. & Rosenberg, R. A. Oxygen-induced defects at the lead halide perovskite/graphene oxide interfaces. J. Mater. Chem. A. 6, 1423–1442 (2018).

González-Carrero, S., Galian, R. E. & Peréz-Prieto, J. Maximizing the emissive properties of CH3NH3PbBr3 perovskite nanoparticles. J. Mater. Chem. A. 3, 9187–9193 (2015).

Yi, N. et al. Tailoring the performances of lead halide perovskite devices with electron-beam irradiaton. Adv. Mater. 29, 1701636 (2017).

Lashkor, M., Rawson, F. J., Preece, J. A. & Mendes, P. M. Switching specific biomolecular interactions on surfaces under complex biological conditions. Analyst. 139, 5400–5408 (2014).

Wang, Y. et al. Missing-node directed synthesis of hierarchical pores on a zirconium metal-organic framework with tunable porosity and enhanced surface acidity via a microdroplet flow reaction. J. Mater. Chem. A. 5, 22372–22379 (2017).

Sun, H. et al. Chemically addressable perovskite nanocrystals for light-emitting applications. Adv. Mater. 29, 1701153 (2017).

Théorêt, A. & Sandorfy, C. The infrared spectra of solid methylammonium halides—II. Spectrochim. Acta Part A 23, 519–542 (1967).

Guo, X. et al. Identification and characterization of the intermediate phase in hybrid organic-inorganic MAPbI3 perovskite. Dalton Trans. 45, 3806–3813 (2016).

Wang, H., Zeng, W. & Xia, R. Antisolvent diethyl ether as additive to enhance the performance of perovskite solar cells. Thin Solid Films 663, 9–13 (2018).

Acknowledgement

The authors acknowledge support from Czech Science Foundation project number 19-23718S and from the Ministry of Industry and Trade TRIO (Project FV20022). A. J. P. and J. J. acknowledge project No. FCH-S-20-6340. We gratefully acknowledge the financial support of the Austrian Foundation for Advancement of Science (FWF Z222-N19) within the Wittgenstein Prize for Prof. Sariciftci.

Author information

Authors and Affiliations

Contributions

A.J.P. and Y.S conceived of the presented idea. A.J.P carried out all the PNP preparations and performed the optical characterization and wrote the manuscript with the participation of J.J. M.C.S arranged and optimized the PL and PLQY measurement set up. A.K. developed the theory. M.C.S and C.Y. verified the analytical methods. Y.S. assisted TEM measurements and contributed to characterizations such as FT-IR, size distribution analysis. J.M. contributed to powder XRD characterization. N.S.S., J.K., M.W., and O.B. supervised the findings of this work. All authors provided critical feedback and helped shape the research, analysis and manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jancik Prochazkova, A., Scharber, M.C., Yumusak, C. et al. Synthesis conditions influencing formation of MAPbBr3 perovskite nanoparticles prepared by the ligand-assisted precipitation method. Sci Rep 10, 15720 (2020). https://doi.org/10.1038/s41598-020-72826-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-72826-6

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.