Abstract

Recent studies on next-generation permanent magnets have focused on filling in the gap between rare-earth magnets and rare-earth-free magnets, taking into account both the cost-effectiveness and magnetic performance of the magnetic materials. As an improved rare-earth-free magnet candidate, here, Ca-substituted M-type Sr-lean hexaferrite particles within a nano- to micro-scale regime, produced using an ultrasonic spray pyrolysis method, are investigated. Theoretically, the maximum coercivity (Hc) can be achieved in submicron Sr-ferrite crystals (i.e., 0.89 μm). The plate-like resultants showed a significant enhancement in Hc, up to a record high of 7880.4 Oe, with no deterioration in magnetization (M: 71–72 emu/g). This resulted in more favorable magnetic properties than those of the traditional Sr–La–Co ferrites. On the basis of microstructural analysis and fitting results based on the law of approach to saturation method, the Ca-substitution effects on the change in size and anisotropic characteristics of the ferrite particles, including pronounced lateral crystal growth and a strong increase in magnetocrystalline anisotropy, are clearly demonstrated. The cost-effective, submicron, and Ca-substituted Sr-ferrite is an excellent potential magnet and moreover may overcome the limitations of traditional hard magnetic materials.

Similar content being viewed by others

Introduction

As the world pursues higher energy efficiency for miniaturized devices such as small motors in hybrid electric vehicles, the demand for ultra-high-performance permanent magnets is rapidly increasing. There are two types of permanent magnets: rare-earth (RE) magnets (e.g., SmCo and NdFeB) with broadly outstanding magnetic characteristics but they have high concentrations scarce RE elements; and the diametrically opposed RE-free magnets (e.g., Sr-ferrite and Ba-ferrite), which possess relatively poor magnetic properties, but are less expensive and have excellent oxidation resistance1. So-called “gap magnets” have been introduced as a compromise to fill the gap between RE magnets and RE-lean magnets, given both their lower material costs and good magnetic performance2,3.

To date, many reports have suggested M-type Sr-hexaferrite (SrFe12O19) with elemental substitutions as a viable candidate for a high-performance magnet, by the substitution of RE ions and other cations such as Sm3+4, Sm3+–Co2+5, La3+–Sm3+6, La3+–Co2+7,8, Nd3+9, Nd3+–Y3+10, and Nd3+–Co2+11. Among these gap magnets, partial La3+–Co2+-substituted Sr-ferrite has received great attention due to the successful enhancement in its intrinsic coercivity (Hc)8,12. Interestingly, upon non-RE substitution, Al3+ for Fe3+ in SrFe12O19, the Hc increased up to tens of kOe, although this came at the expense of the saturation magnetization (Ms), which dropped from ~ 60 emu/g to ~ 10 emu/g. This led to a deterioration in the maximum energy product ((BH)max), which is the most important magnetic parameter13,14.

In this regard, elemental substitution should enhance Hc without sacrificing the M value. We have found that Sr-ferrites with earth-abundant Ca-substitution need further research in terms of their microstructure and magnetic properties. There are a few previous reports on M-type hexaferrites with Ca-substitution using conventional solid-state reaction routes15,16,17,18,19,20; however, the solid-state process does not allow adequate control of the particle size, morphology, or homogeneity, resulting in ambiguities in the relationship between the effect of elemental substitution and the microstructural properties21. Some reports developed an enhancement in Hc upon Ca-substitution; however, the reason has not been fully corroborated. From microstructural, magnetic, and anisotropic points-of-view, we have found that the Ca-substitution effect is still in need of further research.

The goal of this study is to synthesize Ca-substituted Sr-ferrites possessing enhanced Hc without Ms deterioration and to elucidate the Ca-substitution effects on the morphological, crystallographic, and magnetic performance of the ferrite particles. Motivated by the past success of La–Co-substitution in Sr-ferrite, we concurrently searched for the optimal amount of La–Co-substitution. We used salt-assisted ultrasonic spray pyrolysis (SA-USP) to prepare Ca-substituted, M-type Sr-hexaferrites, Sr0.75-xLa0.25CaxFe11.8Co0.2O19 (Ca content x = 0.00, 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.40, and 0.60) in a submicron regime. Recently, the application of spray pyrolysis in a salt matrix for the synthesis of single crystals with exquisitely controlled homogeneity has become an attractive research area22.

Methods

Chemicals

To synthesize a Ca–La–Co-substituted SrFe12O19 submicron powder via SA-USP, we used the following raw materials without further purification: strontium (II) nitrate (Sr(NO3)2, 99.0%; Sigma-Aldrich, USA), lanthanum (III) nitrate hexahydrate (La(NO3)3·6H2O, 99.0% up; Sigma-Aldrich, USA), calcium (II) nitrate tetrahydrate (Ca(NO3)2·4H2O, 99.9%; Merck, Germany), iron (III) nitrate nonahydrate (Fe(NO3)3·9H2O, 98%; Junsei Chemical Co., Ltd., Japan), and cobalt (II) nitrate hydrous (Co(NO3)2·6H2O, 99.9% up; Kojundo Chemical Laboratory Co., Ltd., Japan) as metal precursors, and sodium chloride (NaCl, 99.0%; Daejung Chemical & Metals Co., Ltd., South Korea) as a salt matrix.

Hexaferrite particle synthesis through the SA-USP process

To prepare the precursor solution for Sr-ferrite with various degrees of Ca-substitution, a series of stoichiometric amounts of nitrate sources were dissolved in 300 mL of distilled water according to the formula Sr0.75−xLa0.25CaxFe11.8Co0.2O19 (x = 0.00, 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.40 and 0.60), to give 65 mmol of the all amounts of the cations (i.e., Sr2+, La3+, Ca2+, Fe3+, and Co2+). All precursor solutions contained a fixed concentration of NaCl (0.92 M) to regulate the reaction conditions.

For the USP process, the precursor solution, which was homogeneously stirred for 3 h, was fed into a cylindrical quartz tube with side arms (see the schematic of a laboratory-scale USP setup in Fig. S1a). The precursor solution was first atomized by an ultrasonic mist generator (1.7 MHz of frequency), and the atomized droplets were introduced into a tube furnace by an O2 carrier gas (flow rate of 2 L/min), and then thermally pyrolyzed through the heating stage in O2 currents at 650 °C. A subsequent calcination process of the trapped intermediate particles was performed at 1050 °C (in air, for 1 h) to complete the SrFe12O19 phase formation23. The calcined samples were rinsed with distilled water to remove most of the residual NaCl, and were dried overnight in a vacuum oven. (See the phase and morphology of the synthesized particles in Fig. S1b and c, respectively.) The overall procedure was slightly modified from a previous method that we describe in detail elsewhere7,22.

Characterization

Morphological characterization and particle size measurement of the Ca–La–Co-substituted SrFe12O19 nanoparticles were performed by using field emission scanning electron microscopy (FE-SEM; MIRA-3, Tescan, Czech Republic). X-ray diffractometry (XRD; D/MAX-2500/PC, Rigaku Co., Japan) was employed for a crystal-structural characterization of the magnetic powder. The Rietveld refinements on the XRD patterns were performed by using the JAVA-based refinement program (Materials Analysis Using Diffraction; MAUD). The magnetic performance of the Sr-ferrite powder at room temperature were examined by vibrating sample magnetometry (VSM; VSM7410, Lake Shore Cryotronics, Inc., USA). There was no additional magnetic alignment and sintering processes.

Results and discussion

Morphology of the ferrites with different Ca contents

FE-SEM micrographs of the series of Ca–La–Co-substituted ferrite samples and their size distributions are depicted in Fig. 1a as a function of Ca content (x). Table 1 contains the numerical data, including the mean particle sizes with corresponding standard deviations. As the amount of Ca increased up to 0.40, there was a noticeable change in not only the thickness, but also in the diameter of the Sr-ferrite particles (ranging from the submicron to micro scale), while they became more plate-like in shape with a high aspect ratio, up to 9.31. Thus, it can be inferred that the Ca-substitution affected the anisotropic parameters, inducing the predominantly lateral crystal growth in the hexagonal ferrites24. Even though there was salt (i.e., NaCl) introduced to prepare the resultant particles with precisely controlled homogeneity of the dimension, additional Ca-substitution (x > 0.40) led to abnormal grain growth, resulting in a broad particle diameter distribution that mainly reflected Ostwald ripening25. Figure 1b presents a schematic of the evolving hexagonal crystal structures of the Sr-ferrites, with their preferred orientation of particle-stacking. Even though there was no applied external magnetic field, the pronounced crystal growth perpendicular to the c-axis with a high aspect ratio (i.e., the <00l> direction) coming from the Ca-substitution led to the easy stacking of the plate-like ferrite particles along the c-axis, in good agreement with the experimental data (Fig. 1c).

(a) FE-SEM micrographs and particle diameter distribution histograms of the samples with different Ca contents (x) in Sr0.75−xLa0.25CaxFe11.8Co0.2O19 (0.00 ≤ x ≤ 0.60); (b) schematic of the hexagonal Sr-ferrite plates with preferred orientation; (c) FE-SEM images of (left) the Sr-ferrite particles with no Ca addition, and (right) partial Ca2+-substituted Sr-ferrite powder with a higher aspect ratio.

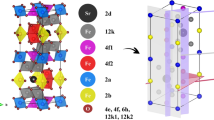

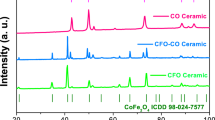

Crystallographic characteristics upon Ca-substitution

Figure 2 shows the normalized X-ray diffraction patterns of the series Sr0.75−xLa0.25CaxFe11.8Co0.2O19 (x = 0.00, 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.40 and 0.60) (see their entire XRD patterns in the 2θ range of 20–80° in Fig. S2). For the samples with Ca content (x) ranging from 0.00 ≤ x ≤ 0.20, the diffraction pattern indicated a pure hexagonal SrFe12O19 phase listed in the JCPDS card, No. 80-1197, suggesting that the Ca2+ ions were all incorporated into the lattice of the Sr-hexaferrite16. At x ≥ 0.30, the pattern was clearly composed of the crystalline SrFe12O19 as well as small amounts of foreign phases, particularly Fe2O3 (No. 89-0596) and CaFe2O4 (No.32-0168). In this regard, Rietveld refinements for the Sr-hexaferrite particles with different Ca contents were conducted and the quantitative results are shown in Fig. S3. The introduction of secondary phases with increasing Ca concentration can be described by the following reactions (Eqs. 1 and 2). For the sake of demystifying the equations, La–Co substitutions are neglected26:

where a, b, c, p, q, and r are constants. Based on the reaction equations and experimental data, we deduced that the maximum amount of Sr2+ substituted by Ca2+ can reach x < 0.30, while surplus Ca2+ cations are prone to induce the formation of spinel Ca-ferrite (CaFe2O4) rather than substitute the Sr2+ site in the ferrites. The x < 0.30 threshold might also be related to the formation of solid solution in the CaO–SrO binary system during thermal pyrolysis (Eq. 1), due to the similar crystal structures, ionic radii, and valences of the two oxides27,28. Besides, this pseudo-binary-phase system has different thermodynamic behavior compared to the single-phase counterparts, thus it is able to induce a difference in the degree of crystal growth during the calcination process. Based on this, Ca-substitution seems to have the effect of accelerating ferrite particle growth to be more platelet-like. When the maximum Ca concentrations were introduced in Sr0.75−xLa0.25CaxFe11.8Co0.2O19, i.e., there is no Sr source (x = 0.75), CaFe2O4 and Fe2O3 X-ray patterns are dominantly observed, while the hexaferrite peaks are relatively weak; this implies that high Ca contents (x > 0.60) weaken the formation of hexaferrite. However, we obtained interesting results from the FE-SEM micrograph showing micro-scale hexagonal plates (composing of a hexaferrite phase) with diameters ranging from 10 to 50 μm, which exceeds the diameter of the ferrites with x = 0.60 (2.5 μm). That is, the Sr-free hexagonal microplates clearly back up the Ca substitution effect on the growth of particles to be more plate-like in shape, with improved crystallinity (see the data in Fig. S4).

The shift in the SrFe12O19 peak position toward a higher angle, which results from a considerable change in the lattice parameters (Figure S5), was observed as the Ca content in Sr0.75−xLa0.25CaxFe11.8Co0.2O19 continuously increased. This could be mainly attributed to the fact that the ionic radius of the Ca2+ ion (0.099 nm) was smaller than that of the Sr2+ ion (0.110 nm), leading to lattice shrinkage during Sr-ferrite phase formation29. Interestingly, the relative intensity ratio of reflections (008) to (110) (= I(008)/I(110)) clearly increased with increasing x from 0.00 to 0.40 (Fig. 2a). It can be inferred that the plate-like Ca-substituted hexaferrites, originating from dominant crystal growth perpendicular to their c-axis, are able to partially and spontaneously orient themselves uniaxially (<00l>), thereby leading to the change in relative intensity ratio of the reflections without an external magnetic field30. When the Ca content increased up to 0.60, the plate-like microparticles were aligned in a haphazard manner, similar to the non-substituted ferrite nanoparticles, due to their broad size distribution and the incorporated byproduct (i.e., Fe2O3 and CaFe2O4). Likewise, the behavior of I(107)/I(114) can be understood in the same way (Fig. 2b).

Magnetic performance as a function of Ca content

Magnetic measurements of the Sr-hexaferrite particles with different Ca contents were conducted at room temperature (Fig. 3a). Regardless of the quantity of Ca-substitution in the Sr-ferrite, all hysteresis loops showed single-phased ferromagnetic behavior without kinks, even though a small amount of the antiferromagnetic Fe2O3 phase was incorporated in the samples with x ≥ 0.3031. Fig. 3b illustrates the dependence of the maximum magnetization at 25 kOe (M25kOe) and the intrinsic coercivity (Hc) of each hexaferrite sample on the amount of Ca. Table 2 provides the numerical data, including M25kOe, remanence (Mr), Hc, and squareness. Clearly, from x = 0.00 to 0.30, the M25kOe values did not degrade, whereas the maximum value of Hc peaked at (~ 7880.4 Oe) at x = 0.20 and then decreased, but remained above the value of the non-substituted ferrites. Generally speaking, the inherent magnetic parameter M can fall from the theoretical value (e.g., ~ 72 emu/g for pristine Sr-ferrites32) mainly due to a decrease in either phase purity or in the crystallinity of the magnetic particles. The saturation magnetization (Ms) of nano-scaled Fe2O3 as reported in a previous study is only ~ 10 emu/g33. Furthermore, the extrinsic factor, Hc, can vary according to a complex set of variables such as the grain size, particle shape, degree of particle orientation, and the particle density19,34; due to the increase of the demagnetization factor, Hc can decrease a fair amount when the magnetic particles become more plate-like18. Accordingly, with cationic substitution, the value of M continued to deteriorate from the theoretical M, even when Hc was maintained or slightly increased to a value more than that of the pristine powder, as has been well documented in many previous studies11,13,14,15,16.

From this viewpoint, the plate-like, Ca-substituted ferrite shows intriguing results. As a measure of crystallinity, the apparent full width at half maximum intensity (FWHM) of the (107) peak and the calculated crystallite size were determined from the XRD data, as shown in Fig. S6. The decrease in FWHM with increasing Ca2+ content resulted in an increasing crystallinity of the Ca-substituted Sr-ferrite particles, maintaining the level of M in spite of the foreign Ca introduction. The onset of a decline in M from x = 0.30 is attributed to the presence of byproducts, which in good agreement with the XRD data.

The Ca-substitution also induced a change in the microstructural characteristics, specifically from a spherical particle shape to a flat hexagonal plate, and this could have led to a strong decrease of Hc. Nevertheless, up to x = 0.60, Hc remained at a high level, increasing up to 12% for x = 0.20 without a significant deterioration of M. Thus, the Hc tendency was not greatly influenced by the change in particle diameter and aspect ratio, implying that there must be another predominant factor having the greatest effect on Hc.

To confirm the effect of Ca-substitution on the magnetocrystalline anisotropy, which can determine the highest achievable Hc, we determined the first anisotropy constant through the law of approach to saturation (LAS) method.

Causality between Ca-substitution and coercivity enhancement

The LAS theory is a popular method for determining the local crystalline anisotropy of magnetic materials, describing the empirical H dependency on M, in the form Eq. 3:

where A/H is the inhomogeneity of the materials, χpH is the field-induced forced magnetization term, and B/H2 is a term associated with the magnetocrystalline anisotropy parameter13.

Through Eq. 3, a typical curve fitting of experimental data with the output statistical parameter R2 (representing the goodness of the curve fit) is shown in Fig. 4. The results fit the curve with high reliability, with an R2 coefficient of determination values above 0.999. This indicates that all of the hexaferrite particles possess a good relationship between M and H and the M does not depend on any one specific term (see the data fitting to the LAS in different equation forms in Fig. S7 and Table S1).

Along with the R2, the fitted parameters also provide important information associated with the magnetic properties (Table 3): the drastic increase in the inhomogeneity parameter A for x > 0.30 can be understood, as the increase in structural defects and nonmagnetic ion inclusions resulted in a secondary phase formation35. For the hexagonal crystal structure, the anisotropy factor B can be expressed as:

where HA is the anisotropy field, and K1 is the magnetocrystalline anisotropy constant. On the basis of the fitting results, K1 and HA were calculated by using Eqs. 4 and 5:

Up to x = 0.20, the K1 and HA first gradually increased with increasing Ca content (x): from 289.55 to 318.81 kJ/m3, and from 15.311 to 16.560 kOe, respectively, which was similar to the behavior of Hc (i.e., from 7035.1 to 7880.4 Oe) in Sr0.75−xLa0.25CaxFe11.8Co0.2O19. While M was steadily maintained (71–72 emu/g), the increases in K1 and HA can be attributed to both the predominant lateral growth in the hexagonal unit cells, and plate-stacking of the ferrite particles along the easy-axial orientation. For x > 0.20, the K1 and HA values decreased, possibly due to the deteriorated M and purity of the ferrite particles and a decreased amount of stacked particles. In terms of the anisotropy factors, Hc can be expressed as follows36:

where α is the shape constant and Nd and Hd are the terms related to the demagnetizing coefficient.

Since Hc is proportional to K1/Ms and HA on the basis of Eq. 6, Hc improved remarkably, up to 7880.4 Oe (about > 800 Oe) alongside K1, in the optimized Sr-lean composition. Consequently, the combination of high M and large Hc results in a calculated maximum energy product ((BH)max) enhancement of 2.01 MG·Oe, over 120% of the value of Sr-ferrites with no Ca-substitution (1.65 MG·Oe). Figure 5 summarizes this empirical dependency.

Conclusion

In summary, Ca-substituted Sr-hexaferrite plates possessing partial La3+–Co2+-substituents (Sr0.75−xLa0.25CaxFe11.8Co0.2O19; 0.00 ≤ x ≤ 0.60) were successfully synthesized via the ultrasonic spray pyrolysis process. Interestingly, simultaneous enhancements in the intrinsic coercivity (Hc), without sacrificing magnetization (M), were achieved by Ca-substitution: 20 at.% of Ca-substitution for Sr exhibited the largest Hc of 7880.4 Oe with a Ms of about 72.6 emu/g and thereby an enhancement in a maximum energy product ((BH)max) of 2.01 MG·Oe, compared to Sr-hexaferrite with x = 0.00 (Hc of ~ 7035.1 Oe; Ms of ~ 71.4 emu/g; (BH)max of 1.65 MG·Oe). Through microstructural and magnetic studies, we found that the additional Ca-substitution led to dramatic changes in the anisotropic characteristics of the Ca-substituted Sr-ferrite, specifically, more plate-like-shaped particles ascribed to pronounced lateral growth, and a strong increase in its magnetocrystalline anisotropy, K1, far beyond the optimized La–Co-substituted Sr-ferrite. As a result, the optimal composition contained earth-abundant Ca, to the benefit of both enhanced magnetic performance and lower composition costs as compared to the current commercial ferrite magnets.

We expect that this new Sr-lean composition, possessing enhanced magnetic properties, will find applications far beyond the limitations of traditional Sr-ferrite-based magnetic materials, and we envision that it can be widely used in new types of affordable magnets.

References

Coey, J. M. D. Hard magnetic materials: a perspective. IEEE Trans. Magn. 47, 4671–4681. https://doi.org/10.1109/TMAG.2011.2166975 (2011).

Trager, R. Chemistry World (Royal Society of Chemistry, Cambridge, 2019).

Cui, J. et al. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 158, 118–137. https://doi.org/10.1016/j.actamat.2018.07.049 (2018).

Yasmin, N. et al. Influence of samarium substitution on the structural and magnetic properties of M-type hexagonal ferrites. J. Magn. Magn. Mater. 446, 276–281. https://doi.org/10.1016/j.jmmm.2017.09.005 (2018).

Xie, T. et al. Preparation and magnetic properties of Sm–Co doped strontium ferrite. Mater. Technol. 33, 467–473. https://doi.org/10.1080/10667857.2018.1465746 (2018).

Shekhawat, D., Singh, A. K. & Roy, P. K. Structural and electro-magnetic properties of high (BH)(max) La–Sm substituted Sr-hexaferrite for brushless DC electric motors application. J. Mol. Struct. 1179, 787–794. https://doi.org/10.1016/j.molstruc.2018.11.083 (2019).

Hwang, T.-Y. et al. Synthesis and magnetic properties of La3+–Co2+ substituted strontium ferrite particles using modified spray pyrolysis–calcination method. Ceram. Int. 43, 3879–3884. https://doi.org/10.1016/j.ceramint.2016.12.051 (2017).

Peng, L., Li, L., Wang, R., Hu, Y. & Tu, X. Effect of La–Co substitution on the crystal structure and magnetic properties of hot press sintered Sr1−xLaxFe12−xCoxO19 (x=0−0.5) ferrites for use in LTCC technology. J. Magn. Magn. Mater. 391, 136–139. https://doi.org/10.1016/j.jmmm.2015.05.007 (2015).

Unal, B. et al. The conductivity and dielectric properties of neobium substituted Sr-hexaferrites. Nanomaterials (Basel) https://doi.org/10.3390/nano9081168 (2019).

Güner, S., Almessiere, M. A., Slimani, Y., Baykal, A. & Ercan, I. Microstructure, magnetic and optical properties of Nb3+ and Y3+ ions co-substituted Sr hexaferrites. Ceram. Int. 46, 4610–4618. https://doi.org/10.1016/j.ceramint.2019.10.191 (2020).

Chen, W. et al. Structural and magnetic properties evolution of Co–Nd substituted M-type hexagonal strontium ferrites synthesized by ball-milling-assisted ceramic process. J. Electron. Mater. 47, 2110–2119. https://doi.org/10.1007/s11664-017-6021-8 (2018).

Kang, Y.-M. High saturation magnetization in La–Ce–Zn–doped M-type Sr-hexaferrites. Ceram. Int. 41, 4354–4359. https://doi.org/10.1016/j.ceramint.2014.11.125 (2015).

Du, Y., Liu, Y., Lian, L. & Du, J. Structural and magnetic properties of Sr0.8La0.2Co0.2Fe11.8−AlO19 hexaferrite particles prepared via sol–gel auto-combustion method. J. Magn. Magn. Mater. 469, 189–195. https://doi.org/10.1016/j.jmmm.2018.08.043 (2019).

Trusov, L. A. et al. Ca–Al double-substituted strontium hexaferrites with giant coercivity. Chem. Commun. 54, 479–482. https://doi.org/10.1039/C7CC08675J (2018).

Moon, K. S., Lim, E. S. & Kang, Y. M. Effect of Ca and La substitution on the structure and magnetic properties of M-type Sr-hexaferrites. J. Alloys Compd. 771, 350–355. https://doi.org/10.1016/j.jallcom.2018.08.306 (2019).

Yang, Y., Wang, F., Liu, X., Shao, J. & Huang, D. Magnetic and microstructural properties of Al substituted M-type Ca–Sr hexaferrites. J. Magn. Magn. Mater. 421, 349–354. https://doi.org/10.1016/j.jmmm.2016.08.034 (2017).

Huang, X. et al. Microstructure and magnetic properties of Ca-substituted M-type SrLaCo hexagonal ferrites. J. Magn. Magn. Mater. 378, 424–428. https://doi.org/10.1016/j.jmmm.2014.09.049 (2015).

Yang, Y., Liu, X., Jin, D. & Ma, Y. Structural and magnetic properties of La–Co substituted Sr–Ca hexaferrites synthesized by the solid state reaction method. Mater. Res. Bull. 59, 37–41. https://doi.org/10.1016/j.materresbull.2014.06.003 (2014).

Li, X., Yang, W., Bao, D., Meng, X. & Lou, B. Influence of Ca substitution on the microstructure and magnetic properties of SrLaCo ferrite. J. Magn. Magn. Mater. 329, 1–5. https://doi.org/10.1016/j.jmmm.2012.10.004 (2013).

Javed Iqbal, M., Naeem Ashiq, M. & Hussain Gul, I. Physical, electrical and dielectric properties of Ca-substituted strontium hexaferrite (SrFe12O19) nanoparticles synthesized by co-precipitation method. J. Magn. Magn. Mater. 322, 1720–1726. https://doi.org/10.1016/j.jmmm.2009.12.013 (2010).

Rösler, S., Wartewig, P. & Langbein, H. Synthesis and characterization of hexagonal ferrites BaFe12-2xZnxTixO19 (0 ≤ x ≤ 2) by thermal decomposition of freeze-dried precursors. Cryst. Res. Technol. 38, 927–934. https://doi.org/10.1002/crat.200310115 (2003).

An, G.-H. et al. Barium hexaferrite nanoparticles with high magnetic properties by salt-assisted ultrasonic spray pyrolysis. J. Alloys Compd. 583, 145–150. https://doi.org/10.1016/j.jallcom.2013.08.105 (2014).

Sivakumar, M. et al. Nanophase formation of strontium hexaferrite fine powder by the sonochemical method using Fe(CO)5. J. Magn. Magn. Mater. 268, 95–104. https://doi.org/10.1016/S0304-8853(03)00479-7 (2004).

Kools, F., Morel, A., Grössinger, R., Le Breton, J. M. & Tenaud, P. LaCo-substituted ferrite magnets, a new class of high-grade ceramic magnets; intrinsic and microstructural aspects. J. Magn. Magn. Mater. 242–245, 1270–1276. https://doi.org/10.1016/S0304-8853(01)00988-X (2002).

Shariq, M. et al. Successful synthesis of gold nanoparticles through ultrasonic spray pyrolysis from a Gold(III) nitrate precursor and their interaction with a high electron beam. ChemistryOpen 7, 533–542. https://doi.org/10.1002/open.201800101 (2018).

Senzaki, Y., Caruso, J., Hampden-Smith, M. J., Kodas, T. T. & Wang, L.-M. Preparation of strontium ferrite particles by spray pyrolysis. J. Am. Ceram. Soc. 78, 2973–2976. https://doi.org/10.1111/j.1151-2916.1995.tb09072.x (1995).

Ganguly, A. Fundamentals of Inorganic Chemistry (Pearson Education India, Noida, 2012).

Lucchini, E. & Sloccari, G. Subsolidus equilibria in the pseudoternary system CaO–SrO–Fe2O3. Ceram. Int. 2, 13–17. https://doi.org/10.1016/0390-5519(76)90003-X (1976).

Trolier-McKinstry, S. & Newnham, R. E. Materials Engineering: Bonding, Structure, and Structure–Property Relationships (Cambridge University Press, Cambridge, 2017).

Khanal, G. P. et al. Optimization of preparation conditions of highly textured piezoelectric (Bi0.5K0.5)TiO3 ceramics. J. Ceram. Soc. Jpn. 127, 362–368. https://doi.org/10.2109/jcersj2.19009 (2019).

Xu, X., Hong, Y.-K., Park, J., Lee, W. & Lane, A. M. Ex situ synthesis of magnetically exchange coupled SrFe12O19/Fe–Co composites. AIP Adv. 6, 056026. https://doi.org/10.1063/1.4944703 (2016).

Pullar, R. Hexagonal ferrites: a review of the synthesis, properties and applications of hexaferrite ceramics. Prog. Mater. Sci. 57, 1191–1334 (2012).

Pan, S., Huang, W., Li, Y., Yu, L. & Liu, R. A facile diethyl-carbonate-assisted combustion process for the preparation of the novel magnetic α-Fe2O3/Fe3O4 heterostructure nanoparticles. Mater.Lett. 262, 127071. https://doi.org/10.1016/j.matlet.2019.127071 (2020).

Kim, D. et al. Enhanced magnetic properties of FeCo alloys by two-step electroless plating. J. Electrochem. Soc. 166, D131–D136. https://doi.org/10.1149/2.1251902jes (2019).

Devi, E. C. & Soibam, I. Magnetic properties and law of approach to saturation in Mn–Ni mixed nanoferrites. J. Alloys Compd. 772, 920–924. https://doi.org/10.1016/j.jallcom.2018.09.160 (2019).

Rashad, M. M., El-Sayed, H. M., Rasly, M., Sattar, A. A. & Ibrahim, I. A. Magnetic and dielectric properties of polycrystalline La doped barium Z-type hexaferrite for hyper-frequency applications. J. Mater. Sci. Mater. Electron. 24, 282–289. https://doi.org/10.1007/s10854-012-0740-7 (2013).

Acknowledgements

This research was supported by Future Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2016M3D1A1027836); This work was supported by the Human Resources Development program (No. 20174030201830) of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government Ministry of Trade, Industry and Energy. This research was also supported by Future Materials Discovery Program through the National Research Foundation of Korea(NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2019M3D1A210415).

Author information

Authors and Affiliations

Contributions

J.L. and E.J.L. conceived the experiments and prepared the manuscript. T.-Y.H. helped perform analysis. T.-Y.H. and J.K. discussed the results and contributed toward editing the manuscript. Y.-H.C. contributed to this manuscript and accepted responsibility for the conducted research and provided final approval. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, J., Lee, E.J., Hwang, TY. et al. Anisotropic characteristics and improved magnetic performance of Ca–La–Co-substituted strontium hexaferrite nanomagnets. Sci Rep 10, 15929 (2020). https://doi.org/10.1038/s41598-020-72608-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-72608-0

This article is cited by

-

Tunable structural, morphological, and hysteresis characteristics of SrFe12O19/Fe3O4 composites

Journal of Materials Science: Materials in Electronics (2024)

-

Trends in Structural and Magnetic Properties of Sol- Gel Routed Ca-Mg Based Ca0.5Mg0.5Fe12−xCrxO19 Hexaferrites by Chromium Substitution

Journal of Inorganic and Organometallic Polymers and Materials (2024)

-

Structural and Magnetic Impressions of Rare Earth Tb Doping on Ba–In Based Hexaferrites Prepared Through Sol–Gel Route for Magnetic Aspects

Journal of Inorganic and Organometallic Polymers and Materials (2024)

-

Synthesis and characterization of titanium-substituted nanocrystalline Co2-Y hexaferrite: magnetically retrievable photocatalyst for treatment of methyl orange contaminated wastewater

Environmental Science and Pollution Research (2023)

-

Significantly improved magnetic parameters of Co–La co-doped strontium hexagonal ferrites for recording applications: structural, hysteresis, and mössbauer performance metrics

Journal of Materials Science: Materials in Electronics (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.