Abstract

This research is focused on understanding the phase behavior of gas hydrate formation in the gas dominant multiphase pipelines containing mixed gas with high CO2, crude oil, and deionized water. The experimental conditions are in the pressure range of 3–7 MPa with water cut as 20% of the volume. Initially, the effect of high CO2 content in natural gas on the phase boundary conditions of hydrates is studied through simulation (CSMGEM software) and experiments. Later, an additional phase of crude oil was introduced, with 15% of the volume to study the multiphase system. From the experimental analysis, thermodynamic equilibrium conditions were found, and the hydrate-liquid–vapor-equilibrium (HLVE) curves were drawn. The phase behavior is comprehended by comparing the HLVE curves of pure and multiphase systems. It is found that the high CO2 content tends to promote the gas hydrate formation. Based on the results, temperature variance and enthalpy of formation were calculated for the multiphase system. With a difference of 1.32 average temperature variance, the multiphase system exhibits inhibition. A basic statistical regression model was made to predict the gas hydrate formation in multiphase transmission pipelines. This work helps in understanding the effect of a new phase on gas hydrate formation.

Similar content being viewed by others

Introduction

Gas hydrates are ice-like solid compounds in which gas molecules are sheathed in cages and are formed by hydrogen-bonded water (H2O) molecules and stabilized by van der Waals forces1,2. Usually, at high pressure and low-temperature conditions, these non-stoichiometric compounds are developed. Methane (CH4), carbon dioxide (CO2), ethane (C2H6), propane (C3H8), hydrogen sulfide (H2S), and butane (i-C4H10) are among the typical hydrate formers frequently encountered in deep-sea situations. Throughout the extraction of oil and gas, water is often present together with an abundance of hydrocarbons in proximity. Thus, clathrate hydrates are formed within the oil, gas, and multiphase flow lines mostly under thermodynamically favorable conditions (low temperature and high pressure) such as the deep-sea conditions3,4,5.

One of the significant problems in flow assurance is the formation of gas hydrates. Gas hydrate formation leads to the blockage in pipelines, therefore becoming the reason for the loss in hydrocarbon production, transportation, and processing facilities. Flow assurance challenges become more significant as oil and gas explorations field development has progressed into deeper water (> 500 m), where longer pipelines in hostile operating environments are prone to gas hydrate formation. Multiphase flow through pipelines contends with many engineering applications besides installations6. In petroleum production and processing, chemical processing, problems associated with the concurrent flow of multiple phases through flowlines has been a long-time interest7. This interest has risen substantially in recent years due to solicitations to new developments in petroleum production and refining. By transporting multiple phases like gas, oil, and water together from wells in satellite fields to existing processing facilities, it would be more economical for expanding production. The hydrate formation in transmission pipelines, which leads to blockage, is always the main issue affecting transmission safety. During production, processing, and gas transmission, there is a high possibility for the plugging of pipelines due to hydrate formation, which poses the major flow assurance challenge8.

Many conventional hydrate mitigation methods are adapted over the years9,10,11,12. However, many of them are either incompetent or required an enormous amount of chemical solvents occasioning in high operational cost along with the severe environmental impact on operating gas and oil facilities13. Besides, the existing inhibitors are still not able to provide an economical solution particularly at high pressure and rapid subcooling conditions. Also, there is no detailed research regarding multiphase systems, which are mostly operating conditions during natural gas production. Likewise, none of the previous investigations dealt with the hydrate phase behavior modeling of the multiphase mixed gases system. Hydrate phase behavior modeling is required to optimize the usage of chemical inhibitors.

Currently, there are several research conclusions available on the formation of gas hydrates and their degree of plugging in natural gas pipelines. However, the research related to them in multiphase pipelines or multiphase flow is very minutely discussed14,15. Meantime, adjudicating the formation of gas hydrates and the determination of the formation region is essential. The phase behavior study is so important as it helps in the development of dynamic prediction capabilities with the existing simulation tools. Also, quantification of the degree of blockage in pipelines due to gas hydrate formation plays a significant role for safer transmission in pipelines16.

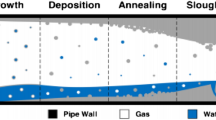

The initial discussion about the gas hydrates formation in multiphase flow lines was noted to be in the 1980s. As a part of the Conoco Hydrate program in Colorado School of Mines, a theoretical study has been done on gas hydrates formation in the multiphase system. From this, phase behavior of hydrate formation is studied. The temperature and pressure conditions, the quantity of liquid in a gas pipeline to form hydrates were estimated. Later, the study of multiphase pipelines and gas hydrate formation in them drawn significant interest. The research was carried out and found that the flow parameters like velocity and discharge of fuel in the pipelines also affect the kinetics of gas hydrates. Various flow velocities ranging from 0 to 5 m/s is considered for experimental evaluation for gas hydrate formation. It was found that the higher the velocity, the faster the gas hydrate plugging in the pipeline17.

In multiphase flow, the effect of the various flow regimes like bubble flow, annular flow and slug flow are investigated to predict the growth kinetics of gas hydrates18. With the advancements in software simulation capabilities, the prediction of gas hydrates with theoretical modelling increased vividly. Also, the application of computational fluid dynamics (CFD) increased and a prediction model is proposed to evaluate the particle deposition on the pipeline walls during gas hydrates formation19. The development and proposal of hydrodynamic models to predict the gas hydrates formation in multiphase pipelines eased the path for advanced research studies20. There is an upsurge in the experimental investigation and analysis as most of the numerical modelling as well as simulations by commercial software’s are to be validated by experimental data or real time field data21.

Studies increased about the gas hydrate formation/dissociation in multiphase systems as the experiments were carried out with fuel oils like Diesel. Various researchers also carried out work on emulsion pipelines with different water cuts to experimentally find the phase behavior conditions of gas hydrates in multiphase pipelines. The mixed gas system with CH4, C2H6, and C3H8 is used, and the formation of gas hydrates is studied in the crude oil emulsion system with 50–80% water cuts variations. It has been found that at 50% water cut, the formation of gas hydrates was high when compared to that of 80% water cut22. The research about the occurrence of the methane hydrate in dispersed oil medium by experimental and simulation has drawn attention furthermore. Research on gas hydrate formation in multiphase pipelines with gas dominant or oil dominant system containing black oil or crude oil is later done vividly to estimate the real-time subsea conditions and the kinetics of gas hydrates23. So, these days, experiments and simulation on the gas dominant multiphase pipelines with the presence of crude oil and different water cuts is the trend of research24. Currently, due to the decrease in the quality of the natural gas wells, the quality of natural gas is depleted, and the presence of high carbon dioxide is observed25.

In this work, the phase behavior of gas hydrate formation in the gas dominant multiphase pipelines containing mixed gas with high CO2, crude oil, and deionized water has been studied under the pressure range of 3–7 MPa with water cut as 20% of the volume through the means of experiments, simulation, and a basic statistical regression model. The mixed gas studied consists of 70% carbon dioxide, 26% methane, 2% nitrogen, 1% propane, and 1% butane.

Discussion and results

Verification of experimental conditions

Generally, natural gas pipelines are operated at extremely high pressures during their transmission. They are operated around 1–10 MPa depending upon the composition of the natural gas as containing heavier carbon compound gases impacts the pipeline flow conditions26. But, when there is a high carbon dioxide content in natural gas, these pipelines cannot be operated at same environments due to acidic nature of carbon dioxide gas and low saturation point of its gaseous state. The gas once liquified impacts the pipelines due to corrosion and other issues. So, to understand the operating conditions of high CO2 content natural gas pipelines, a phase diagram has been constructed for natural gas with high CO2 using the PVTSIM software package. This helps in understanding the critical point of the gas used for this analysis and helps in validating the experimental conditions chosen. The phase diagram is presented in Fig. 1.

From the phase diagram, the critical point for the gas is found to be 283.57 K and 9.276 MPa. So, from this, it can be concluded that the hydrate region of the chosen gas is below the curve towards the axis. From this, it can be verified that the experimental conditions to replicate the real-time operating conditions of natural gas with high CO2 are acceptable.

Validation of experimental setup

Thermodynamic equilibrium conditions are analyzed from the plot of T-cycle curves. The cyclic plotting of the pressure and temperature changes in the reactor brings up the T-cycle. The cooling, stabilization, and heating due to which the pressure and temperature fluctuations were recorded. Typically, the thermodynamic equilibrium point is usually the temperature and pressure condition where the heating and cooling curve meet27. This T-cycle curve is represented in Fig. 2. Experiments are conducted with carbon dioxide gas and methane gas at various pressure conditions to obtain the thermodynamic equilibrium points. From these points, the HLVE plot is drawn and compared with the simulation results of CSMGEM and literature. The results for the carbon dioxide gas and methane gas are presented in Figs. 3 and 4, respectively. For both carbon dioxide and methane gas, the equipment gave results that are in line with the CSMGEM results as well as literature results. The literature results for validation when carbon dioxide gas is used were taken from28,29,30, whereas for methane gas, the results are made from30,31,32. The simulation values of nitrogen and butane are not mentioned as the considered pressure range is out of their respective hydrate zones33. According to the literature, the minimum pressure required for nitrogen to maintain at the hydrate zone is 10.5 MPa. For butane, the value of pressure is out of the range of the considered pressure. When the thermodynamic equilibrium points are defined by simulation, the HLVE curve has been plotted.

Phase behavior based on experiments

Effect of high CO2 in natural gas system

Based on the experimental procedure mentioned, the experiments are conducted with a mixed gas system containing high CO2. All the thermodynamic points are calculated by analyzing the data logged into the system during the experimental procedure and then plotting the pressure–temperature profile. All these points are used for developing the HLVE curve. The HLVE curve to determine phase behavior is presented in Fig. 5.

To determine the effect of high CO2 content in the natural gas system, the comparison is made with the experimental results of methane and carbon dioxide gases. According to CSMGEM, the HLVE curve of the mixed gas system tends to move towards a higher temperature region when a fixed pressure point is considered. So, it can be concluded that the natural gas system with higher carbon dioxide tends to promote gas hydrate formation. This is because of the gas molecular structure of carbon dioxide. The size of the molecule is small compared to that of the other pure gases that are a part of general natural gas and is highly acidic. Due to this, the nucleation point of CO2 hydrates is also quite low compared to other gases because of which there is a brisk formation of hydrates in the presence of high CO234,35. When a hydrate is formed in the natural gas system with high CO2, hydrate structure that is more viable to form is sI structure. This is due to the occupancy of CH4 and CO2 gas molecules in the larger cavities of hydrate structure. The other heavy carbon elements in composition like C3H8 and C4H10, which are larger in molecular structure, will act as gas diluents and do not participate in the hydrate formation36. For the validation of the simulation, experimental data is considered and compared to that of the CSMGEM data. The results are in accordance with the simulation.

Multiphase system experimental analysis

Like that of the experimental procedure mentioned, the multiphase system consisting of crude oil, natural gas with high CO2, and deionized water is taken. When the multiphase system is simulated with the flow conditions using magnetic stirrer with a suitable RPM, the emulsions are formed within the system. These emulsions effects the gas hydrates formation because of the Void fraction and liquid hold up37,38. The thermodynamic equilibrium points are determined based on the P–T curve. Then, based on these thermodynamic equilibrium points, the HLVE curve has also been developed. A comparison is made with simulation results of pure gas systems and mixed gas together with the experimental results of the mixed gas system. These results as well are included in Fig. 5 to compare it with a simple system and determine the phase behavior.

When compared with simulation results and experimental results, the HLVE curve shifted towards lower temperature and higher-pressure region. This reflects that the system is displaying an inhibition effect. This could be because of the inhibiting effect shown by more substantial inhibiting gases like nitrogen and butane reaction in the mixture. As mentioned, the nitrogen and butane tend to form gas hydrates at much higher pressures than the considered pressure range of 3–7 MPa. The interaction parameters in mixed gas that influence the solubility of gases in liquids resulting in gas hydrates formation tend to allow the lighter gases to be dissolved more when compared to that of the heavier gases39. This could be a reason they inhibit the formation of mixed gas hydrates with high CO2 content. Also, the higher stability of crude oil can be a contributing factor for hydrate inhibition. The crude oil is a viscous hydrocarbon liquid and is a raw material that contains various unprocessed salts. According to literature, the presence of polymers and salts tends to inhibit the gas hydrates formation kinetically as well as thermodynamically40. However, the natural gas system containing crude oil displays gas hydrate promotion behavior promote gas hydrate formation when compared to that of the pure gas systems like methane and carbon dioxide. This may occur due to the presence of a mixed gas system alongside the higher carbon chain availability in the crude oil, which results in the quicker formation of gas hydrates.

Temperature variance and enthalpy

The temperature variance (Ŧ) for the pure and multiphase systems are calculated to determine the effect of additional phases on the phase behavior of gas hydrates. The thermodynamic equilibrium points of the pure and multiphase gas dominant systems studied are compared and analyzed. Temperature variance (ΔT) is computed according to the following Eq. (1)

where T0,pi represents the equilibrium temperature of studied gas in the pure system, i.e., without the addition of any compound, while T1,pi is the equilibrium temperature of the multiphase system. The values of both dissociation temperatures should be attained at the same pressure. The n denotes the number of pressure points taken into consideration for the study.

The results of the temperature variance are presented in Table 1.

The dissociation enthalpies denoted as ΔH for gas hydrates are determined by using the Clausius–Clapeyron equation through differentiating the experimental HLVE data. The values of ΔH are achieved by calculating the slope of HLVE data attained by the Clausius–Clapeyron Eq. (2).

where P and T show the equilibrium pressure and temperature, respectively, R represents the universal gas constant, z is the compressibility factor of the gas involved in the study. At the same time, ΔH signifies the enthalpy of gas hydrates dissociation.

The results of the enthalpy are presented in Table 2, and the graphical representation is presented in Fig. 6. It is observed that the enthalpy for the water or pure system is less than compared to that of the multiphase system. This calculation was attempted to understand further the effect of additional phases in gas hydrate formation. The presence of the oil phase in the multiphase system shows that additional energy is required to form or dissociate gas hydrates in the system. For the calculation of enthalpy, the light hydrocarbons/volatile compounds in crude oil are not considered as the carbon chain is very long and it is almost impossible to calculate compressibility factor41,42,43.

Based on the analysis and results from the simulation tool, it can be concluded that high CO2 content in the natural gas system tends to promote gas hydrate formation. This is due to the lower nucleation behavior of CO2 hydrates. When a hydrate is formed in the natural gas system with high CO2, a hydrate structure that is more viable to form is sI structure. This is due to the occupancy of CH4 and CO2 gas molecules in the larger cavities of hydrate structure. The other heavy carbon elements in composition like C3H8 and C4H10, which are more massive in molecular structure, will act as gas diluents and do not participate in the hydrate formation36. Then, an additional phase of crude oil was introduced into the system. The effect of the multiphase system was studied. The results indicated that the presence of crude oil has an inhibition effect on the mixed gas HLVE phase boundary. This is because of the higher stability of crude oil that can be a contributing factor for hydrate inhibition. This is because of the presence of crude oil results in a reduction of the chemical potential of water. From the literature, crude oil has less chance of the existence of carboxylic acid groups (or if present not in a detectable amount). This was also suggested by the low acid number of crude oils. The most common functional groups observed were –OH, aromatic, and amide groups. From this and satisfactory stability of the O/W emulsion, a consensus was that the surface-active asphaltenes might be responsible for such organic inhibition44.

Statistical regression analysis

Analysis with deionized water

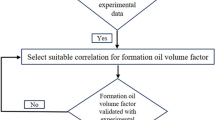

Precise statistical regression analysis is also carried out for the prediction of hydrate formation temperature (HFT) at a given pressure condition theoretically. Based on the experimental results, a validation model has been developed by the optimization algorithm that helps in the prediction of HFT.

The regression analysis data of deionized water are presented in Tables 3 and 4.

The regression model predicted that the R2 is 0.980425081. This is also in high accordance with the adjusted R2 value. The standard error for the regression is predicted as 0.463137122. This implies that the regression model is significant, and the data produced by the model is accurate45. Based on the regression results, ANOVA statistical analysis is carried out to estimate the error between the actual vs. predicted data. The plot that suggests the actual vs. predicted is presented in Fig. 7. The plot suggests a linear regression, which means that with varying pressure, the temperature is affected or simply pressure and temperature are directly proportional to each other. Also, the equation obtained is mentioned in Fig. 7.

Analysis with the multiphase system

Similarly, a precise statistical regression analysis is also carried out for the prediction of hydrate formation temperature (HFT) at a given pressure condition theoretically in the multiphase system. The regression analysis data of deionized water are presented in Tables 5 and 6.

The regression model predicted that the R2 is 0.960590458. This is also in high accordance with the adjusted R2 value. According to literature45,46, the model can be considered as a valid prediction model with an R2 value > 0.75 and adjusted R2 value > 0.5. Therefore, this regression analysis can be used to define HFT and HFP. The standard error for the regression is predicted as 0.633652262. This implies that the regression model is significant, and the data produced by the model is accurate. Based on the regression results, ANOVA statistical analysis is carried out to estimate the error between the actual vs. predicted data. The plot that suggests the actual vs. predicted is presented in Fig. 8. The plot suggests a linear regression, which means that with varying pressure, the temperature is affected or simply pressure and temperature are directly proportional to each other. Also, the equation obtained is mentioned in Fig. 8.

Since the gas hydrate thermodynamic experiments take approximately 48 h for each experiment, the data used for the prediction model development is limited. But the equation can be reliable and can be used as a preliminary prediction equation for the gas hydrate formation conditions prediction.

Methodology

Materials

The list of materials used for experimental investigation of gas hydrate formation in multiphase pipelines are as follows:

For equipment validation

-

a)

CH4

-

b)

CO2

-

c)

Deionized water

The gases are acquired from Gas Walker Sdn Bhd. The deionized water was prepared at gas hydrates research laboratory.

For phase behavior investigation

-

a)

Natural gas + deionized water

-

b)

Natural gas + deionized water + crude oil

The mixed gas system is taken in the following composition, as mentioned in Table 7.

The natural gas system mentioned in Table 7 is considered for experiments based on the significant components available in natural gas with high carbon dioxide (CO2) content. It replicates the gas composition from the K5 Gas field in Malaysia. In the K5 Gas field, natural gas is produced with high CO2 content. So, in this study, natural gas with high CO2 content has been chosen31,47. The Air Product Sdn. Bhd. Delivers the mixed gas system with the respective composition. The deionized water used for experimental evaluation is taken from gas hydrates research laboratory.

Experimental apparatus

Figure 9 represents the schematic representation of the experimental setup that is used in this work. The apparatus engaged for determining the phase behavior of gas hydrates in pure and multiphase systems work is equipped with a high-pressure reactor made from stainless-steel with a capacity of 650 ml. The reactor can be operated in the temperature range of – 20 to 40 °C and a pressure of 20 MPa. Pressure and temperature sensors which are connected to a data logging system are installed in the reactor to measure pressure and temperature changes for every fixed interval. The time interval for the recording was taken as 10 s. A 4-bladed impeller magnetic stirrer is installed inside the reactor to provide enough agitation during the hydrate experiment. The system temperature is controlled by a thermostatic bath equipped with a PID controller within ± 0.3 °C accuracy.

Experimental procedure

For determining the phase equilibrium of the pure and multiphase systems, the T-cycle method with the isochoric step heating method is applied in this work. Before experiments, the reactor was washed with distilled water thoroughly to avoid any impurities and completely dried. For the pure system, a sample of 200 ml of deionized water is poured into the reactor cell. After that, the cell was inserted into the reactor and can cool down to the chosen operating condition to stabilize. Once the temperature is steadied, a small amount of gas is entered the reactor cell employing a high-pressure boosting pump. The gas that has introduced is again released to make sure that the reactor cell is vacuum. After the distinct temperature condition is achieved, gas was flowed into the reactor cell up to the anticipated pressure. In these experiments, the pressure range was chosen between 3 and 7 MPa pressures.

Once the stabilization of temperature and pressure conditions is attained, the magnetic stirrer was brought into the play by setting it at 400 RPM to disrupt the gas–liquid boundary interface. Adequate mixing is achieved during the formation of gas hydrates. According to literature, the velocity of multiphase transmission pipelines is usually maintained at 1 m/s48,49,50. To maintain this, the speed of the magnetic stirrer was chosen as 400 RPM. The quick cooling approach is utilized to lower the temperature of the reactor cell and to enhance the formation of gas hydrates. After the desired temperature is achieved, the reactor was maintained at similar conditions for an all-encompassing time (varies from 4 to 8 h). Gas hydrate formation can be confirmed with the evidence of a sharp or sudden drop in pressure with the rise in temperature in the data logging system. This is due to the exothermic reaction that takes place during gas hydrate formation. When the pressure is stabilized, and no further pressure drop is observed, it can be decided that the hydrate fully formed. Then the reactor is heated slowly with a rate of 0.5 K/h stepwise until the gas hydrate is dissociated completely. For the determination of the hydrate equilibrium point, the length of each step must be in the range of 2–6 h. The accomplishment of each experiment analysis required roughly 48 h. The same process is followed for the multiphase system as well, except the way of loading fuels into reactor cell varies. As mentioned after cleaning the cell, a sample of 100 ml of Crude oil is first poured into the cell. This crude oil was already preheated to make sure that the precipitant more massive particles get liquefied and merged with crude oil. Then deionized water of volume 200 ml is added to this.

Statistical regression model

The experimental results are used to develop a statistical regression model to predict the gas hydrate formation conditions. Initially, the experimental results are tabulated and using data solver function, and a correlation is developed between the X and Y components. Then, the correlation equation is used to run the regression statistics. From these regression results, the prediction equation is developed to determine Y based on X. This equation is used to predict the gas hydrate formation temperature at a given pressure condition.

CSMGEM details

For hydrate prediction, there are several software packages available for hydrate phase equilibria prediction. The commonly used hydrate prediction programs in the petroleum industry are CSMGem (CSM, USA), PVTsim (Calsep), and MultiFlash (Info-chem). However, all the commercial prediction software is only able to predict the hydrate properties for common hydrate former gases (guest molecules) in the presence of pure water and/without common hydrate inhibitors (methanol, MEG, NaCl, and KCl. The commercial prediction software is unable to accommodate (predict) the new inhibitor's behavior. The CSMGem software was developed in 2007 at the Colorado School of Mines, USA, and recognized as one of the right software among the commercial predictive soft wares. The CSMGem (the last three initials are the first letters of “Gibbs energy minimization”). The CSMGem is based upon the Gibbs energy minimization method, which allows the calculations of the formation conditions for any phase (including the hydrate). It also consents for the calculation of phases present at any temperature and pressure conditions (whether hydrates are present or not). Therefore, included are the options to perform all thermodynamic calculations with every phase and not just the hydrate.

Conclusion

In this research work, an attempt to understand the phase behavior of gas hydrate formation in the multiphase system is made. A multiphase system with natural gas containing high CO2, Crude oil, and deionized water with a 20 vol% fixed water cut has been used for the experimental approach. The simulations were carried out with the CSMGEM tool, and predictions were made using the basic statistical regression model. It has been found that the presence of crude oil in the multiphase system has a suppression effect on the gas hydrate formation. Besides, it is confirmed through this work that the increment of CO2 level in the depleting gas well resources may lead to a surge in the occurrence of gas hydrates in the industry. The mixed gas with high CO2 studied displayed a promotion in gas hydrate formation in the presence of high CO2 content. This presents a first of its kind data with experimental, simulation, and statistical analysis on multiphase transmission systems. The difference observed in the phase behavior of the pure and multiphase system is notably significant. The authors recommend that more works are done on multiphase systems as the findings of this current work may highlight the lack of accuracy in simulation techniques of the existing software packages in predicting gas hydrate formation in multiphase flow based on the available data on single and binary phase transmission pipelines.

References

Ai Krishna Sahith, S. J., Pedapati, S. R. & Lal, B. Application of artificial neural networks on measurement of gas hydrates in pipelines. Test Eng. Manag. 81, 5769–5774 (2019).

Khan, M. S. et al. Assessing the alkyl chain effect of ammonium hydroxides ionic liquids on the kinetics of pure methane and carbon dioxide hydrates. Energies 13, 3272 (2020).

Nygaard, H. F. Hydrate properties in multiphase transportation systems. (1990).

Khan, M. S., Lal, B., Bavoh, C. B., Keong, L. K. & Bustam, A. Influence of ammonium based compounds for gas hydrate mitigation: A short review. Indian J. Sci. Technol. 10, 1–6 (2017).

Chen, F. & Yapa, P. D. Estimating hydrate formation and decomposition of gases released in a deepwater ocean plume. J. Mar. Syst. 30, 21–32 (2001).

Erickson, D. & Brown, T. Natural Gas Hydrates, Annals of the New York Academy of Sciences Vol 715 40–58 (New York Academy of Science, NewYork, 1994).

Jakobsen, T., Sjöblom, J. & Ruoff, P. Kinetics of gas hydrate formation in w/o-emulsions the model system trichlorofluoromethane/water/non-ionic surfactant studied by means of dielectric spectroscopy. Colloids Surf. A Physicochem. Eng. Asp. 112, 73–84 (1996).

Zheng, D., Che, D. & Liu, Y. Experimental investigation on gas-liquid two-phase slug flow enhanced carbon dioxide corrosion in vertical upward pipeline. Corros. Sci. 50, 3005–3020 (2008).

Khan, M. S., Lal, B., Keong, L. K. & Ahmed, I. Tetramethyl ammonium chloride as dual functional inhibitor for methane and carbon dioxide hydrates. Fuel 236, 251–263 (2019).

Khan, M. S. et al. Impacts of ammonium based ionic liquids alkyl chain on thermodynamic hydrate inhibition for carbon dioxide rich binary gas. J. Mol. Liq. 261, 283–290 (2018).

Khan, M. S., Cornelius, B. B., Lal, B. & Bustam, M. A. Kinetic assessment of tet-ramethyl ammonium hydroxide (ionic liquid) for carbon dioxide, methane andbinary mix gas hydrates. Recent Adv. Ionic Liquids https://doi.org/10.5772/32009 (2018).

Partoon, B., Sahith, S. J. K., Lal, B., Maulud, A. S. & Bin, Gas hydrate models. In Chemical Additives for Gas Hydrates 67–85 (Springer, Berlin, 2020). https://doi.org/10.1007/978-3-030-30750-9_4.

Jassim, E., Abdi, M. A. & Muzychka, Y. A new approach to investigate hydrate deposition in gas-dominated flowlines. J. Nat. Gas Sci. Eng. 2, 163–177 (2010).

Talatori, S. & Barth, T. Rate of hydrate formation in crude oil/gas/water emulsions with different water cuts. J. Pet. Sci. Eng. 80, 32–40 (2011).

Sahith, S. J. K., Pedapati, S. R. & Lal, B. Investigation on gas hydrates formation and dissociation in multiphase gas dominant transmission pipelines. Appl. Sci. 10, 5052 (2020).

Xiang, C.-S. et al. Hydrate formation/dissociation in (natural gas + water + diesel oil) emulsion systems. Energies 6, 1009–1022 (2013).

Qasim, A., Khan, M. S., Lal, B. & Shariff, A. M. Phase equilibrium measurement and modeling approach to quaternary ammonium salts with and without monoethylene glycol for carbon dioxide hydrates. J. Mol. Liq. 282, 106–114. https://doi.org/10.1016/j.molliq.2019.02.115 (2019).

Ding, L. et al. Hydrate formation and plugging mechanisms in different gas-liquid flow patterns. Ind. Eng. Chem. Res. 56, 4173–4184 (2017).

Kakati, H., Kar, S., Mandal, A. & Laik, S. Methane hydrate formation and dissociation in oil-in-water emulsion. Energy Fuels 28, 4440–4446 (2014).

Daraboina, N., Pachitsas, S. & Von Solms, N. Natural gas hydrate formation and inhibition in gas/crude oil/aqueous systems. Fuel 148, 186–190 (2015).

Yuha, Y. B. M., Bavoh, C. B., Lal, B. & Broni-bediako, E. South African Journal of Chemical Engineering Methane hydrate phase behaviour in EMIM-Cl water based mud (WBM): An experimental and modelling study. South Afr. J. Chem. Eng. 34, 47–56 (2020).

Chen, J. et al. Insights into methane hydrate formation, agglomeration, and dissociation in water + diesel oil dispersed system. Energy Convers. Manag. 86, 886–891 (2014).

Wang, Y., Fan, S. & Lang, X. Reviews of gas hydrate inhibitors in gas-dominant pipelines and application of kinetic hydrate inhibitors in China. Chin. J. Chem. Eng. 27, 2118–2132 (2019).

Chaudhari, P., Zerpa, L. E. & Sum, A. K. A correlation to quantify hydrate plugging risk in oil and gas production pipelines based on hydrate transportability parameters. J. Nat. Gas Sci. Eng. 58, 152–161 (2018).

Raza, A. et al. Well selection in depleted oil and gas fi elds for a safe CO2 storage practice: A case study from Malaysia. Petroleum 3, 167–177 (2017).

Trust, P. S. Pipeline basics and specifics about natural gas pipelines. Pipeline Brief. Pap. #2 1–9 (2015).

Qasim, A., Khan, M. S., Lal, B., Ismail, M. C. & Rostani, K. Quaternary ammonium salts as thermodynamic hydrate inhibitors in the presence and absence of monoethylene glycol for methane hydrates. Fuel 259, 116219 (2020).

Khan, M. S. et al. Thermodynamic effect of ammonium based ionic liquids on CO2 hydrates phase boundary. J. Mol. Liq. 238, 533–539 (2017).

Bavoh, C. B. et al. Inhibition effect of amino acids on carbon dioxide hydrate. Chem. Eng. Sci. 171, 331–339 (2017).

Partoon, B., Sabil, K. M., Roslan, H., Lal, B. & Keong, L. K. Impact of acetone on phase boundary of methane and carbon dioxide mixed hydrates. Fluid Phase Equilib. 412, 51–56 (2016).

Khan, M. S., Partoon, B., Bavoh, C. B., Lal, B. & Mellon, N. B. Influence of tetramethylammonium hydroxide on methane and carbon dioxide gas hydrate phase equilibrium conditions. Fluid Phase Equilib. 440, 1–8 (2017).

Bavoh, C. B., Khan, M. S., Lal, B., Bt Abdul Ghaniri, N. I. & Sabil, K. M. New methane hydrate phase boundary data in the presence of aqueous amino acids. Fluid Phase Equilib. 478, 129–133 (2018).

van Cleeff, A. & Diepen, G. A. M. Gas hydrates of nitrogen and oxygen. Recl. des Trav. Chim. des Pays-Bas 79, 582–586 (1960).

Nasir, Q., Sabil, K. M. & Partoon, B. CO2 rich gas mixture hydrate-liquid water-vapor (H-Lw-V) equilibrium measurement and prediction. Appl. Mech. Mater. 625, 386–389 (2014).

Li, L., Zhao, S., Wang, S. & Rao, Y. CO2 hydrate formation kinetics based on a chemical affinity model in the presence of GO and SDS. RSC Adv. 10, 12451–12459 (2020).

Azmi, N., Mukhtar, H. & Sabil, K. M. Purification of natural gas with high CO2 content by formation of gas hydrates: Thermodynamic verification. J. Appl. Sci. 11, 3547–3554 (2011).

Koryakina, V. V., Ivanova, I. K. & Semenov, M. E. Oil emulsions as medium of natural gas hydrate formation. IOP Conf. Ser. Earth Environ. Sci. 193, 20 (2018).

Ruan, C., Ding, L., Shi, B., Huang, Q. & Gong, J. Study of hydrate formation in gas-emulsion multiphase flow systems. RSC Adv. 7, 48127–48135 (2017).

Rasoolzadeh, A., Raeissi, S., Shariati, A. & Peters, C. J. Experimental measurement and thermodynamic modeling of methane solubility in triethylene glycol within the temperature range of 343.16–444.95 K. J. Chem. Eng. Data https://doi.org/10.1016/j.supflu.2020.104881 (2020).

Kamal, M. S., Hussein, I. A., Sultan, A. S. & Von Solms, N. Application of various water soluble polymers in gas hydrate inhibition. Renew. Sustain. Energy Rev. 60, 206–225 (2016).

Sloan, E. Jr., Koh, C. & Koh, C. Clathrate Hydrates of Natural Gases (CRC Press, Boca Raton, 2007). https://doi.org/10.1201/9781420008494.

Sloan, E., Koh, C., Creek, J., & Sum, A. Natural Gas Hydrates in Flow Assurance. In Koh, C.; Sum, A., Eds.; Gulf Professional Publishing Elsevier B.V., 2010.

Zerpa, L. E., Aman, Z. S., Joshi, S., Rao, I., Sloan, E. D., Koh, C. A., & Sum, A. K. Predicting hydrate blockages in oil, gas and waterdominated systems. in Proceedings of the Offshore Technology Conference; Houston, TX, April 30−May 3, 2012.

Kar, S., Kakati, H., Mandal, A. & Laik, S. Experimental and modeling study of kinetics for methane hydrate formation in a crude oil-in-water emulsion. Pet. Sci. 13, 489–495 (2016).

Abbasi, A. & Hashim, F. M. Development of a hydrate formation prediction model for sub-sea pipeline. Pet. Sci. Technol. 35, 443–450 (2017).

Garapati, N. & Anderson, B. J. Statistical thermodynamics model and empirical correlations for predicting mixed hydrate phase equilibria. Fluid Phase Equilib. 373, 20–28 (2014).

Jorat, M. E. et al. Sequestering atmospheric CO2 inorganically: A solution for Malaysia’s CO2 emission. Geoscience 8, 1–14 (2018).

Luo, W. et al. Experimental study of gas-liquid two-phase flow for high velocity in inclined medium size tube and verification of pressure calculation methods. Int. J. Heat Technol. 34, 455–464 (2016).

Al-Hadhrami, L. M., Shaahid, S. M., Tunde, L. O. & Al-Sarkhi, A. Experimental study on the flow regimes and pressure gradients of air–oil–water three-phase flow in horizontal pipes. Sci. World J. 2014, 1–11. https://doi.org/10.1155/2014/810527 (2014).

Leporini, M. et al. Sand transport in multiphase flow mixtures in a horizontal pipeline: An experimental investigation. Petroleum 5, 161–170 (2019).

Acknowledgements

The authors are grateful to the CO2RES center for the laboratory facilities in Universiti Teknologi PETRONAS and Yayasan UTP (YUTP) Grant 015LCO154 for financial supporting this research.

Author information

Authors and Affiliations

Contributions

The conceptualization of this research work is carried out by S.J.K.S. and B.L. The research work was carried out under the supervision of S.R.P. and B.L. B.L procured the resources for the research. The methodology, experiments, characterization, and other tests were carried out by S.J.K.S. S.J.K.S. wrote the original draft. S.R.P. and B.L. reviewed the manuscript draft. The project administration and funding acquisition for this project were carried out by S.R.P. and B.L.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sayani, J.K.S., Pedapati, S.R. & Lal, B. Phase behavior study on gas hydrates formation in gas dominant multiphase pipelines with crude oil and high CO2 mixed gas. Sci Rep 10, 14748 (2020). https://doi.org/10.1038/s41598-020-71509-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-71509-6

This article is cited by

-

Experience of virtual commissioning of a process control system for the production of high-paraffin oil

Scientific Reports (2022)

-

Experimental investigation and ANN modelling on CO2 hydrate kinetics in multiphase pipeline systems

Scientific Reports (2022)

-

Comprehensive Review on Various Gas Hydrate Modelling Techniques: Prospects and Challenges

Archives of Computational Methods in Engineering (2022)

-

Experimental and modeling studies on enhancing the thermodynamic hydrate inhibition performance of monoethylene glycol via synergistic green material

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.