Abstract

Two-dimensional coordination nanosheets (CONASHs) are grown at the spherical liquid–liquid interface of a dichloromethane droplet in water to form zero-dimensional nano- and micro-capsules using a simple dropping method, a syringe-pump method, and an emulsion method. Reaction of 1,3,5-tris[4-(4′-2,2′:6′,2″-terpyridyl)phenyl]benzene (1) with Fe(BF4)2 affords electrochromic Fe(tpy)2 CONASH capsules and that of ligand 1 with ZnSO4 does photoluminescent Zn2(μ-O2SO2)2(tpy)2 CONASH capsules. Fe(tpy)2 CONASH capsules containing magnetite particles were produced by the syringe-pump method by adding magnetite to the aqueous phase, with the assembly and dispersion of the magnetite-containing CONASH capsules being easily controlled with a magnet. This indicates that physicochemically functional CONASH capsules are suitable for incorporating other functional materials to develop hybrid systems.

Similar content being viewed by others

Introduction

Two-dimensional (2D) materials such as graphene1,2 and transition-metal dichalcogenides3,4, have unique properties and functions for various applications5,6,7,8. Coordination nanosheets (CONASHs) are 2D materials that consist of metal ions and organic π-ligands9,10. Since the discovery of an electronically conducting bis(dithiolato)nickel nanosheet11, a range of CONASHs have been synthesized and various physical properties such as electronic conductivity12,13, energy storage14, redox activity15, luminescence16, photoelectric conversion17, and electrocatalytic activity18 have been enhanced by tuning the chemical structures. Films can be directly synthesized by a reaction at the liquid–liquid or gas–liquid interface, where metal ions and organic ligands exist in different phases. Most previous work on CONASHs has used planar interfaces to obtain planar films; however, other spherical functional nanomaterials have been extensively studied19,20,21,22,23,24,25,26,27,28,29,30,31.

In this study, we used the spherical liquid–liquid interface of droplets to synthesize spherical CONASHs focusing on their functions. Using 1,3,5-tris[4-(4′-2,2′:6′,2″-terpyridyl)phenyl]benzene (1), which is a three-way bridging tris(terpyridine) ligand, we obtained electrochromic Fe(tpy)232,33,34 CONASH capsules and photoluminescent Zn2(SO4)2(tpy)216,35 CONASH capsules by a simple dropping method, a syringe pump method and an emulsion method. The formation of the CONASHs at the liquid–liquid interfaces is accelerated by the addition of surfactant such as sodium dodecyl sulfate (SDS), allowing the CONASH capsules to be formed within 15 min36,37. The surfactant also stabilizes the droplets during synthesis38,39. We also encapsulated magnetite (Fe3O4) particles40 in the Fe(tpy)2 shell, and the magnetite-containing Fe(tpy)2 CONASH capsules could be controlled with a magnet. Our results show that physicochemically functional CONASH capsules are suitable for incorporating other functional materials to develop hybrid systems.

Synthesis of electrochromic Fe(tpy)2 CONASH capsules using the dropping method

We previously synthesized a planar Fe(tpy)2 CONASH film (Fig. 1a) using the coordination reaction at the planar interface between Fe(BF4)2 in water and the tris(terpyridine) ligand, 1. The reaction was sluggish and took several hours to grow a film of sub-micron thickness. The reaction to fabricate CONASH capsules occurs at the spherical liquid–liquid interface between an aqueous phase containing metal ions and an organic phase containing organic ligands (Fig. 1b). Because the reaction is slow, the droplets easily fuse (Fig. 1c I). Adding a surfactant, such as SDS, accelerated the coordination reaction at the interface, shortening the reaction time to 15 min (Fig. 1c II). To grow the Fe(tpy)2 capsules with a shell thickness of 20 nm (Supplementary Fig. S1), droplets of ligand 1 in dichloromethane (DCM) were created in an aqueous solution of Fe(BF4)2. Due to the fast reaction, Fe(tpy)2 capsules were fabricated without the droplets fusing. Amphiphilic SDS makes a metal complex with a ferrous ion in an aqueous phase. The formed complex easily moves to organic phase and works as an iron ion source of Fe(tpy)2 complex. Hence, SDS can work as an accelerator of the complexation reaction of Fe(tpy)2 complex at the organic-water solution interface.

The characterization of the Fe(tpy)2 capsules was conducted using UV–Vis and Raman spectra. The capsule gives a peak derived from MLCT of Fe(tpy)2 complex at 580 nm corresponding with that of Fe(tpy)2 nanosheet (Fig. 2a). In addition, Raman spectra of Fe(tpy)2 capsule and nanosheet show good agreement each other (Fig. 2b). These spectroscopic results suggest that the capsule is composed of Fe(tpy)2 nanosheet which was formed at the spherical liquid–liquid interface. In the simple dropping method using a micro-syringe, the place and size of the spherical capsules in the size range 1–2.5 mm were easily controlled (Supplementary Fig. S2).

Electrochemical and spectral properties. (a) UV–Vis absorption spectra of Fe(tpy)2 CONASH capsules (solid line) and a CONAH film (broken line). (b) Raman spectra of Fe(tpy)2 CONASH capsules (solid line) and a CONASH film (broken line). (c) Cyclic voltammogram of Fe(tpy)2 CONASH capsules and schematic of the capsules on an ITO electrode. (d) Images of Fe(tpy)2 CONASH capsules oxidized electrochemically. (b) Cyclic voltammogram of Fe(tpy)2 CONASH capsules and schematic of the capsules on an ITO electrode.

Cyclic voltammetry of a single Fe(tpy)2 CONASH capsule 0.95 mm in diameter on an indium–tin oxide (ITO) glass plate was performed in 0.1 M Na2SO4 aq (Fig. 2c, Supplementary Fig. S3). Small oxidation and re-reduction peaks derived from the redox reaction of [Fe(tpy)2]3+/2+ appeared at 1.10 and 0.98 V (vs. Ag/AgCl) and thus E0′ = 1.04 V (vs. Ag/AgCl) with a peak-to-peak potential of 120 mV, indicating a chemically reversible, slow electron-transfer process, probably because of the weak physical contact between the droplet and ITO.

We previously reported that the planar Fe(tpy)2 CONASH film on an ITO electrode undergoes rapid and durable electrochromism34; the color changed reversibly between purple and pale yellow for [Fe(tpy)2]2+ and [Fe(tpy)2]3+, respectively. In the present study, we observed a similar color change (Fig. 2d), although the color was faint because the Fe(tpy)2 shell was thin. The color of the whole shell changed, even though the contact area of the CONASH capsule with the electrode was very small indicating rapid electron hopping between Fe(tpy)2 sites through the molecular framework of the shell.

Synthesis of Fe(tpy)2 CONASH capsules using the syringe-pump method and encapsulation of magnetite particles

The syringe-pump method, in which water droplets are formed and flow continuously in the moving organic solution, was used to obtain Fe(tpy)2 CONASH capsules with a narrow size distribution, easily and constantly (Fig. 3a). The size of the droplets depended on the radius of tubes41,42, while the flow rate and tube length controlled the reaction time at the liquid–liquid interface, and thus the thickness of the Fe(tpy)2 shells (Fig. 3b). Fe(tpy)2 CONASH capsules were collected at the end of the tube in a saucer solution (Fig. 3a,c). We synthesized Fe(tpy)2 CONASH capsules using DCM as the organic phase of the reaction. Capsules with a diameter of 843 ± 28 μm and a shell thickness of 250 nm were obtained under typical conditions involving 25 mM Fe(BF4)2; 10 mM SDS; aqueous solution flow rate of 0.5 mL h−1; syringe inner diameter 0.15 mm; 60 μM ligand 1; DCM solution flow rate 10 mL h–1, and tube inner diameter 0.86 mm (Supplementary Fig. S4). Capsule size depended on the saucer solution, and was 659 ± 29 μm in DCM, 684 ± 44 μm in hexane, 677 ± 57 μm in toluene, and 534 ± 48 μm in diethyl ether (Fig. 3d,e, Supplementary Fig. S5). The diameter of Fe(tpy)2 CONASH capsules was thus expected to depend on the solubility of water in the saucer solvent; larger in hydrophobic solvents than in hydrophilic solvents. In hydrophilic solvents, water dissolved in the outer organic solvents and was transferred out of the Fe(tpy)2 shell. This dependency of capsule size on the outer environment suggests that the capsules might have the permeability of water due to the porous structures of Fe(tpy)2 CONASH.

Syringe-pump method to form Fe(tpy)2 CONASH capsules. (a) Schematic of the syringe-pump method. (b) Photograph of Fe(tpy)2 CONASH capsules during the formation in tubes. (c) Photograph of Fe(tpy)2 CONASH capsules in hexane. (d) Size distribution of Fe(tpy)2 CONASH capsules in the tube (solid line) and saucer organic solvents; diethyl ether (two-dot chain line), DCM (dotted line), toluene (broken line), and hexane (chain line). (e) Diameter of Fe(tpy)2 CONASH capsules vs. solubility of water in a given organic solvent; diethyl ether (red), DCM (purple), toluene (orange), and hexane (blue). The diameter in the tube, 843.2 μm is given for comparison.

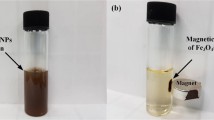

The space in Fe(tpy)2 CONASH capsules could be used to add further functionality. Magnetic particles and beads have been used for various applications in fields such as biomedical engineering and heterogeneous catalysis because their aggregation and dispersion are easily controlled by an external magnetic field. We introduced magnetite (Fe3O4) particles into CONASH capsules by a simple syringe-pump method. Magnetite particles with a diameter of 250 nm40 were dispersed in an aqueous solution of Fe(BF4)2. The Fe(tpy)2 CONASH capsules emerged at the water–DCM interface and contained the magnetite particles (Fig. 4a). This method of assembly of CONASH capsules could be controlled externally. The magnetite-containing CONASH capsules were strongly attracted by magnets (Fig. 4b–e), demonstrating that the Fe(tpy)2 CONASH capsules showed the functionality of the original Fe(tpy)2 CONASH shell and the incorporated magnetite.

Synthesis of photoluminescent Zn2(SO4)2(tpy)2 CONASH capsules

We previously reported that the liquid–liquid interfacial coordination reaction of a DCM solution of ligand 1 and an aqueous solution of ZnSO4 produces a photoluminescent sulfate-bridged dimeric zinc terpyridine complex polymer film called Zn2(SO4)2(tpy)2 CONASH (Fig. 5a)16. Therefore, we investigated the synthesis of Zn2(SO4)2(tpy)2 CONASH capsules using not only the dropping method but also the emulsion method, in which a DCM solution of ligand 1 and an aqueous solution of ZnSO4 (1:3 v/v) were shaken together vigorously in a test tube to obtain an emulsion. The emulsion interface was left to stand for 1 h, and Zn2(SO4)2(tpy)2 CONASH formed at the interface as a transparent film (Fig. 5b). Note that in the case of the emulsion method, shaking a mixture of the dichloromethane solution and the aqueous solution in a test tube makes smaller microcapsules than those produced by the other methods. We think they have sufficiently large surface area so that the interfacial reaction proceeds rapidly even without adding SDS. The Zn2(SO4)2(tpy)2 CONASH capsules were 20–50 μm in size, showed UV absorption bands at 372 and 281 nm in DCM and exhibited solvatoluminochromism16; pale yellow-green photoluminescence with an emission maximum at 580 nm in water and pale blue photoluminescence with an emission maximum at 484 nm in DCM upon UV irradiation (365 nm) (Fig. 5c).

Zn2(SO4)2(tpy)2 CONASH capsules. (a) Synthesis of Zn2(SO4)2(tpy)2 CONASH capsules. (b) Photographs and microscope images of Zn2(SO4)2(tpy)2 CONASH capsules obtained by the dropping method (1) and by the emulsion method (2, 3) under ambient and 365 nm UV light. (c) Absorption (A), emission (B) and excitation (C) spectra of Zn2(SO4)2(tpy)2 CONASH capsules in DCM, and emission (D) and excitation (E) spectra of Zn2(SO4)2(tpy)2 CONASH capsules in water.

Conclusions

We produced CONASH capsules from 2D coordination polymers using the spherical liquid–liquid interface of DCM droplets in water. The simple dropping method, the syringe-pump method, and the emulsion method were used to synthesize Fe(tpy)2 CONASH capsules and Zn2(SO4)2(tpy)2 CONASH capsules. The Fe(tpy)2 CONASH capsules retained the electrochromism of the nanosheet and the Zn2(SO4)2(tpy)2 CONASH capsules retained the photoluminescence. The syringe-pump method incorporated magnetite into the Fe(tpy)2 CONASH capsules by mixing magnetite in the aqueous phase. The assembly and dispersion of the capsules could be controlled by a magnet. Our results demonstrate that the application range of CONASHs can be expanded by using a zero-dimensional material instead of a 2D material.

Methods

Synthesis of Fe(tpy)2 CONASH capsules by the dropping method

A DCM solution of ligand 133, 43 (60 μM) and an aqueous solution containing 25 mM Fe(BF4)2 and saturated SDS were prepared. The aqueous solution (10 mL) was poured into a vial. A droplet of DCM solution (1 μL) was placed in the aqueous solution by slow pipetting. After 15 min, the purple Fe(tpy)2 CONASH sphere emerged at the interface. Some measurements were conducted in situ or the sphere was removed with the substrate and washed with deionized water, ethanol, and DCM.

Synthesis of Fe(tpy)2 CONASH capsules by the syringe pump method

A DCM solution of the ligand 1 (60 μM) and an aqueous solution containing 25 mM Fe(BF4)2 and saturated SDS were prepared. The aqueous phase was injected through a hollow needle (25 s gauge, 90° tip, inner diameter of 0.15 mm, outer diameter at the tip of 0.51 mm) in a co-floating stream of the DCM phase floating through polytetrafluoroethylene tubing (inner diameter 0.86 mm). The Fe(tpy)2 CONASH capsules were collected and kept in organic solvent. The aqueous and DCM phases were both supplied by syringe pump set at 0.5 and 10 mL h−1, respectively.

Synthesis of Zn2(SO4)2(tpy)2 CONASH capsules by the emulsion method

A DCM solution of ligand 1 (0.1 mM) and an aqueous solution of ZnSO4 (5.0 mM) were used to synthesize Zn2(SO4)2(tpy)2 CONASH capsules by the liquid–liquid interfacial coordination reaction. The DCM solution and aqueous solution (1:3 v/v) were injected into a test tube and mixed by vigorous shaking at room temperature. The emulsion interface was allowed to stand for 1 h, and the Zn2(SO4)2(tpy)2 CONASH film generated at the interfaces of the emulsion and Zn2(SO4)2(tpy)2 CONASH droplets emerged as light-yellow spheres.

Data availability

The data for the plots in this work and other findings from this study are available from the corresponding author upon reasonable request.

References

Han, W., Kawakami, R. K., Gmitra, M. & Fabian, J. Graphene spintronics. Nat. Nanotechnol. 9, 794–807 (2014).

Li, L. et al. Functionalized graphene for high-performance two-dimensional spintronics devices. ACS Nano 5, 2601–2610 (2011).

Eda, G. et al. Photoluminescence from chemically exfoliated MoS2. Nano Lett. 11, 5111–5116 (2011).

Mak, K. F. & Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat. Photonics 10, 216–226 (2016).

Zhang, H. Ultrathin two-dimensional nanomaterials. ACS Nano 9, 9451–9469 (2015).

Bauer, T. et al. Synthesis of free-standing, monolayered organometallic sheets at the air/water interface. Angew. Chem. Int. Ed. 50, 7879–7884 (2011).

Cassabois, G., Valvin, P. & Gil, B. Hexagonal boron nitride is an indirect bandgap semiconductor. Nat. Photonics 10, 262–266 (2016).

Burch, K. S., Mandrus, D. & Park, J. G. Magnetism in two-dimensional van der Waals materials. Nature 563, 47–52 (2018).

Sakamoto, R. et al. Coordination nanosheets (CONASHs): Strategies, structures and functions. Chem. Commun. 53, 5781–5801 (2017).

Sakamoto, R. et al. The coordination nanosheet (CONASH). Coord. Chem. Rev. 320–321, 118–128 (2016).

Kambe, T. et al. Redox control and high conductivity of nickel bis(dithiolene) complex π-nanosheet: A potential organic two-dimensional topological insulator. J. Am. Chem. Soc. 136, 14357–14360 (2014).

Sun, X. et al. Conducting π-conjugated bis(iminothiolato)nickel nanosheet. Chem. Lett. 46, 1072–1075 (2017).

Pal, T. et al. Interfacial synthesis of electrically conducting palladium bis(dithiolene) complex nanosheet. ChemPlusChem 80, 1255–1258 (2015).

Wada, K., Sakaushi, K., Sasaki, S. & Nishihara, H. Multielectron-transfer-based rechargeable energy storage of two-dimensional coordination frameworks with non-innocent ligands. Angew. Chem. Int. Ed. 57, 8886–8890 (2018).

Phua, E. J. H. et al. Oxidation-promoted interfacial synthesis of redox-active bis(diimino)nickel nanosheet. Chem. Lett. 47, 126–129 (2018).

Tsukamoto, T. et al. Coordination nanosheets based on terpyridine-zinc(II) complexes: As photoactive host materials. J. Am. Chem. Soc. 139, 5359–5366 (2017).

Sakamoto, R. et al. Photofunctionality in porphyrin-hybridized bis(dipyrrinato)zinc(II) complex micro- and nanosheets. Angew. Chem. Int. Ed. 56, 3526–3530 (2017).

Sun, X. et al. Bis(aminothiolato)nickel nanosheet as a redox switch for conductivity and an electrocatalyst for the hydrogen evolution reaction. Chem. Sci. 8, 8078–8085 (2017).

Zhou, D. et al. SiO2 hollow nanosphere-based composite solid electrolyte for lithium metal batteries to suppress lithium dendrite growth and enhance cycle life. Adv. Energy Mater. 6, 1502214 (2016).

Jeong, G. Y. et al. Bioactive MIL-88A framework hollow spheres via interfacial reaction in-droplet microfluidics for enzyme and nanoparticle encapsulation. Chem. Mater. 27, 7903–7909 (2015).

Guan, C. et al. Hollow Co3O4 nanosphere embedded in carbon arrays for stable and flexible solid-state zinc-air batteries. Adv. Mater. 29, 1704117 (2017).

Xia, X. H., Tu, J. P., Wang, X. L., Gu, C. D. & Zhao, X. B. Mesoporous Co3O4 monolayer hollow-sphere array as electrochemical pseudocapacitor material. Chem. Commun. 47, 5786–5788 (2011).

Furukawa, S., Reboul, J., Diring, S., Sumida, K. & Kitagawa, S. Structuring of metal-organic frameworks at the mesoscopic/macroscopic scale. Chem. Soc. Rev. 43, 5700–5734 (2014).

Liang, Z. et al. A protein@metal–organic framework nanocomposite for pH-triggered anticancer drug delivery. Dalton Trans. 47, 10223–10228 (2018).

Xu, Z. et al. Encapsulation of hydrophobic guests within metal−organic framework capsules for regulating host−guest interaction. Chem. Mater. 32, 3553–3560 (2020).

Kandambeth, S. et al. Self-templated chemically stable hollow spherical covalent organic framework. Nat. Commun. 6, 6786 (2015).

Lu, Z. et al. A hollow microshuttle-shaped capsule covalent organic framework for protein adsorption. J. Mater. Chem. B 7, 1469–1474 (2019).

Guo, J. et al. Engineering multifunctional capsules through the assembly of metal-phenolic networks. Angew. Chem. Int. Ed. 53, 5546–5551 (2014).

Ameloot, R. et al. Interfacial synthesis of hollow metal-organic framework capsules demonstrating selective permeability. Nat. Chem. 3, 382–387 (2011).

Wu, S., Xin, Z., Zhao, S. & Sun, S. High-throughput droplet microfluidic synthesis of hierarchical metal-organic framework nanosheet microcapsules. Nano Res. 12, 2736–2742 (2019).

Wang, B. et al. Macroporous materials: Microfluidic fabrication, functionalization and applications. Chem. Soc. Rev. 46, 855–914 (2017).

Mondal, S., Yoshida, T. & Higuchi, M. Electrochromic devices using Fe(II)-based metallo-supramolecular polymer: Introduction of ionic liquid as electrolyte to enhance the thermal stability. J. Soc. Inf. Disp. 27, 661–666 (2019).

Takada, K. et al. Electrochromic bis(terpyridine)metal complex nanosheets. J. Am. Chem. Soc. 137, 4681–4689 (2015).

Maeda, H., Sakamoto, R. & Nishihara, H. Interfacial synthesis of electrofunctional coordination nanowires and nanosheets of bis(terpyridine) complexes. Coord. Chem. Rev. 346, 139–149 (2017).

Jiang, T. et al. Dimethoxy triarylamine-derived terpyridine-zinc complex: A fluorescence light-up sensor for citrate detection based on aggregation-induced emission. J. Mater. Chem. C 4, 10040–10046 (2016).

Bode, G., Lade, M. & Schomäcker, R. The kinetics of an interfacial reaction in microemulsions with excess phases. Chem. Eng. Technol. 23, 405–409 (2000).

Piradashvili, K., Alexandrino, E. M., Wurm, F. R. & Landfester, K. Reactions and polymerizations at the liquid-liquid interface. Chem. Rev. 116, 2141–2169 (2016).

Soma, J. & Papadopoulos, K. D. Ostwald ripening in sodium dodecyl sulfate-stabilized decane-in-water emulsions. J. Colloid Interface Sci. 181, 225–231 (1996).

Lin, Y., Ng, K. M., Chan, C. M., Sun, G. & Wu, J. High-impact polystyrene/halloysite nanocomposites prepared by emulsion polymerization using sodium dodecyl sulfate as surfactant. J. Colloid Interface Sci. 358, 423–429 (2011).

Liu, J. et al. Highly water-dispersible biocompatible magnetite particles with low cytotoxicity stabilized by citrate groups. Angew. Chem. Int. Ed. 48, 5875–5879 (2009).

Christopher, G. F. & Anna, S. L. Microfluidic methods for generating continuous droplet streams. J. Phys. D. Appl. Phys. 40, 437–446 (2017).

Garstecki, P., Fuerstman, M. J., Stone, H. A. & Whitesides, G. M. Formation of droplets and bubbles in a microfluidic T-junction—Scaling and mechanism of break-up. Lab Chip 6, 437–446 (2006).

Cavazzini, M. et al. Synthesis, characterization, absorption spectra, and luminescence properties of multinuclear species made of Ru(II) and Ir(III) chromophores. Inorg. Chem. 48, 8578–8592 (2009).

Acknowledgements

This work was financially supported by JST-CREST JPMJCR15F2, and JSPS KAKENHI Grant Number 19H05460 for H.N, and the China Scholarship Council (No. 201706795025) for M.L.

Author information

Authors and Affiliations

Contributions

H.N. conceived the research. R.A., M.L. and R.T. designed the experiments and prepared the samples. R.A and M.L. performed the measurements of Fe(tpy)2 CONASH capsules and Zn2(SO4)2(tpy)2 CONASH capsules, respectively. H.M. contributed to the electrochemical measurements. All authors discussed the results. R.A. wrote the paper with input from all authors. H.M., M.L., R.T. and H.N. revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arai, R., Li, M., Toyoda, R. et al. Redox-active, luminescent coordination nanosheet capsules containing magnetite. Sci Rep 10, 13818 (2020). https://doi.org/10.1038/s41598-020-70715-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-70715-6

This article is cited by

-

A Bis(terpyridine)nickel(II)-Based Coordination Nanosheet: A Redox-Active Material with Flexibility and Transparency

Journal of Inorganic and Organometallic Polymers and Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.