Abstract

Quinoa (Chenopodium quinoa) is a climate resilient crop having superior nutritional profile compared to other cereal grains and may help to ensure future food security. Commercial cultivation of quinoa is dependent upon availability of quality seed. Adoption of Dry Chain Technology: drying before storage and maintaining seed dryness through hermetic packaging, may prevent quinoa seed deterioration. Quinoa seeds were dried to 8, 10, 12 and 14% initial seed moisture content (SMC) and stored in conventional (Paper, polypropylene, cloth and jute) and hermetic Super Bags for 6, 12 and 18 months. Seed stored in Super Bag at 8% initial SMC maintained low seed moisture and higher germination. Total soluble sugars and α-amylase activity were higher while EC, reducing sugars and MDA contents were low for the seeds stored in hermetic bag at 8% initial SMC. Seed stored in traditional packaging materials irrespective of initial seed moisture contents, gained moisture due to ambient high relative humidity which resulted in seed deterioration as indicated by increased reducing sugars, MDA contents and seed leachates conductivity and reduced vigor, viability, soluble sugars. The Dry Chain Technology preserves seed quality by maintaining low seed moisture and reducing deteriorative physiological and biochemical changes in the quinoa seed.

Similar content being viewed by others

Introduction

Quinoa is an important crop selected by WHO which may ensure future food and nutritional security. UNO celebrated year 2013 as “International Year of Quinoa” with a chanted slogan “A future sown thousands of years ago”1. Its protein quantity and quality is better than traditional cereals due to presence of all essential amino acids. Furthermore, higher quantities of minerals (Ca, Fe, Zn) along with “healthy supportive fatty acid profile” (omega 3 fatty acid) makes it an excellent super food2.

Quinoa was restricted to its native countries up to 1980 but now quinoa has expanded all over the world with its cultivation in more than 100 countries3,4. Successful commercial cultivation of any crop depends upon availability of quality seed. Quinoa seed has higher oil contents compared to cereals such as corn5, which suggests the need of special care during production and storage to make available quality seeds at the time of sowing. Quinoa seed contains both perisperm and reduced endosperm, embryo consisting of hypocotyl radicle axis and two cotyledons, seed coat having pericarp on outer side6.

Quinoa seed absorbs and desorbs water very quickly due to porosity in integuments and loses viability very quickly7. In quinoa seed, moisture gain can be used as indicator to predict seed longevity8. Seed stored in conventional packaging materials gains moisture from the environment9 when external relative humidity is higher which is normally prevailing in the farmer’s seed stores during monsoon season in developing countries10. Quinoa seed imbibe water quickly due to small hole in the middle of the seed, far from the micropyle and there is no interference with absorption of water from the surroundings11. At high seed moisture contents increase metabolism of soluble sugars and higher rate of Maillard reaction has been reported in seed of Vigna radiata12.

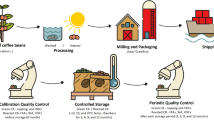

Quinoa originated from the Andean Mountains and its adaptation in tropics at low altitude having high temperature is challenging for the researchers. Thus, its seed quality is very tricky after harvest to next growing season especially in high relative humidity and temperature prevailing environment13. Quick decline in viability of quinoa seed after harvest to next growing season emphasized to investigate the physiological and biochemical changes associated with seed longevity under ambient storage conditions. Moreover, this crop is gaining massive importance yet there is no on farm seed storage technology and packaging material available to the farmers in the developing countries. Reducing seed moisture contents through drying has been an important strategy to prevent the seed deterioration. The Dry Chain Technology, proposed in this study identified high relative humidity as major factor that could accelerate the deterioration of stored commodities14. Unlike cold chain which requires continuous refrigeration, the dry seeds can be stored at ambient temperature using Dry Chain thus reducing the energy requirement for short term safe storage. Seed drying can be carried out either thorough sun drying or using desiccants such as drying beads. Farmers can easily adopt this technology as it is simple, economical and require no energy for refrigeration. In this study, packaging materials have been optimized for short term storage of quinoa seed in relation to the moisture variation and associated physiological changes. In Dry Chain Technology, product dryness is maintained during storage by use of hermetic packaging such as Super Bag. Super Bags are made up of triple layer of poly have very low oxygen (< 4 ccm−2 day−1) and water vapor transmission rate (< 5 gm−2 day−1) due to gas coated barrier layers15. Prospects of Dry Chain Technology have been explored in this study to maintain seed quality and to prevent deterioration during different storage durations at ambient temperatures by using different packaging materials.

Results

Seed moisture contents

Quinoa seed moisture contents after six months of storage were significantly (P ≤ 0.05) lower in Super Bag having seed at 8% initial SMC. Moisture contents stayed near to the initial in Super Bag (Fig. 1a). Maximum moisture contents were measured for the seeds stored in Super Bag and all conventional packaging materials at 14% initial SMC and in PP bag and jute bag at 12% initial SMC (Fig. 1a). In conventional packaging materials especially for the seeds which were initially dried to 8 and 10% (28.2 and 40.4% eRH respectively), SMCs increased to 12%. The eRH of seed in conventional packaging materials increased up to 55% from initial 28.2% due to high ambient RH (Fig. 8).

After 12 months, maximum seed moisture contents were recorded for the seeds stored in Super Bag at 14% SMC and in paper bag at 14% initial SMC. Quinoa seed stored in Super Bag at 8% initial SMC have lowest (8.17%) seed moisture contents (Fig. 1b). Overall seed moisture dropped in all bags having seed at 12 and 14% initial SMC due to low RH in storage environment. After 18 month of storage, quinoa seed in Super Bag at 8% initial SMC had lowest seed moisture contents (8.73%) while seed stored in paper, PP, jute and Super Bags at 14% initial SMC had maximum moisture contents. Super Bag retained nearly initial seed moisture for all moisture levels. Seed stored in PP and paper bags at 12 and 14% initial SMC gained moisture from its surroundings (Fig. 1c).

Germination

Quinoa seed storage in Super Bag at 8 and 10% initial SMC and in paper bag at 10% SMC resulted into highest germination (80%) after 6 months. Lowest germination (28%) was exhibited by quinoa seeds stored in Super Bag at 14% initial SMC (Fig. 2a). Similarly, germination also dropped significantly in conventional bags. After 12 months of storage in Super Bag at 14% initial SMC, quinoa seed completely lost its germination (Fig. 2b). More than 50% reduction in germination was observed in all conventional bags irrespective of the initial moisture contents. Maximum germination was recorded of seeds that were stored in Super Bag at 8 and 10% initial SMC. Similarly, after 18 months, there was no germination observed for the seeds stored in the Super Bag at 12 and 14% initial SMC (Fig. 2c). Highest germination was recorded for seeds stored in Super Bag at 8 and 10% initial SMC.

Seed vigor

Quinoa seed subjected to accelerated aging, after sampling at 6, 12 and 18 month of storage showed a significant difference in vigor of seeds stored in various packaging materials at all four levels of initial SMC (Fig. 3a). After 6 months, quinoa seeds stored in Super Bag at 14% initial SMC had minimum percent vigor. Seeds stored in Super Bag at 8 and 10% initial SMC and in cloth bag at 8% initial SMC had maximum vigor (Fig. 3a). After 12 and 18 months, vigor of quinoa seed was higher for the seeds stored in Super Bag at 8 and 10% initial SMC while seed vigor was completely lost by the seeds stored in Super Bag at 14% initial SMC (Fig. 3b,c).

Electrical conductivity of seed’s leachates

Electrical conductivity of quinoa seed leachates was substantially lower when stored in Super Bag for 6 months at 8% initial SMC. Electrical conductivity of seed leachates was higher for seed store in Super Bag at 14% initial SMC (Fig. 4a). Similarly, seeds stored in conventional bags also have higher EC indicating rapid deterioration due to high moisture (61% eRH and 13.5% SMC). After 12 months, seed stored in Super Bag at 8 and 10% initial SMC had markedly lower values of seed leachate’s EC. Seed leachate’s EC was more for the seeds stored in porous packaging materials (paper, PP, jute and cloth) at 8, 10, 12 and 14% SMC and in Super Bag at 12% initial SMC (Fig. 4b,c).

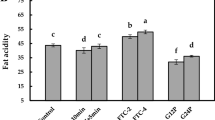

Biochemical attributes

The α-amylase activity was not significantly different for all types of bags at 8, 10, 12 and 14% initial SMC. Quinoa seeds stored in hermetic Super Bag showed maximum α-amylase activity (Fig. 5a) showing effectiveness of maintaining low seed moisture in hermetic bags. Malondialdehyde (MDA) contents were minimum in seeds that were stored in Super Bag at 8 and 10% initial SMC indicating protection against lipid peroxidation in dry seeds. Seeds stored in rest all types of packaging materials at all levels of initial SMC had higher MDA contents (Fig. 5b). Overall MDA contents were positively related to seed moisture contents i.e. higher the seed moisture contents higher were the MDA contents and lipid peroxidation.

Maximum quantity of total soluble sugars (TSS) were measured from seeds stored in Super Bag at 8 and 10% initial SMC. Lower TSS were quantified from seeds stored in cloth bag at 14% initial SMC (Fig. 6a). Lowest reducing sugars were present in seeds that were stored in Super Bag at 8 and 10% initial SMC while quinoa seeds stored in rest of the packaging materials at all levels of initial SMC had highest reducing sugars (Fig. 6b).

Discussion

Seed moisture content contributes significant role in all biological and metabolic activities occurring within the living seeds, which modulates seed behavior either towards longevity or deterioration during storage. Biplot analysis indicated that seed germination, total soluble sugars and α-amylase activity were negatively correlated with final seed moisture contents and positively correlated with EC, MDA and reducing sugars (Fig. 7). Overall germination, vigor and seed quality were higher for seeds stored in Super bag at 8 and 10% initial SMC. Hermetic nature of Super Bag hindered both moisture entry and exit into the seeds as it has very low (≤ 5 gm−2 day−1) water vapor transmission rate15. Moreover, lack of fresh oxygen supply due to very low oxygen transmission rate in Super Bag decreased deteriorative changes in seeds. Seed moisture contents in porous packaging materials varied with the ambient RH due to hygroscopic nature of seed16 and seed quality was damaged under high seed moisture contents.

With the passage of time germination decreased (almost 60% reduction in conventional bags and at 14%) as is evident from the germination data after 6, 12 and 18 months of sampling but that decline was slow in Super Bag at 8% initial SMC. High germination of seed stored in Super Bag at 8% initial SMC showed a negative relation with seed moisture contents and deteriorative process (Fig. 7). Previous well-known fact is that each 1% reduction in seed moisture contents doubles the storage life of the seeds17. Seeds stored in Super Bag at 14% initial SMC quickly lost their germination as Super Bag continuously maintained high moisture contents near to initial seed moisture contents i.e. 14% due to gas coated barrier layers. Seed germination declined in all conventional packaging materials indicating almost similar moisture gain and aging pattern in these bags. Decline in germination of the seeds stored in porous packaging materials can be attributed to high seed moisture contents that lead to the production of reactive oxygen species (ROS) causing seed deterioration18. Seeds in conventional bags gained moisture from their surroundings as ambient RH approached to 70% during some part of the year (Fig. 8). Dry seeds are unable to respire as there is limited biological activity at such low water activity. Seeds at high moisture contents continue to respire and lost viability when there is free supply of oxygen but under limited oxygen supply seeds continue anaerobic respiration and ethanol is produced causing seed deterioration19. So seed deterioration and ethanol production are most likely the reasons for seed deterioration and viability losses in Super Bags at 12 and 14% seed moisture contents.

Rate of seed vigor and viability losses are the functions of seed moisture contents and temperature of storage environment20,21. Seed leachates electrical conductivity was low after first 6 months and increased with the passage of time, which confirms that deterioration is a continuous process, and with the passage of time seed loses its vigor and viability due to deterioration. Higher the value of the seed leachate’s EC, higher will be the seed deterioration and lower will be the seed viability and vigor. With passage of time, seed leachate’s EC generally increased during storage indicating the process of seed aging and loss of membrane integrity22.

Lipid peroxidation is a key process involved in seed aging and malondialdehyde (MDA) contents are the end product of this deteriorative process. Higher MDA contents were present in quinoa seed stored in conventional porous bags as compared to Super Bag (Fig. 5b) as seed in conventional bags gained moisture from its surroundings. High seed moisture contents resulted into higher activities of ROS in the seeds that resulted into production of MDA through lipid peroxidation18. However, at low moisture contents role of secondary ROS (Hydroxyl radical and hydroperoxides) cannot be excluded which are involved in seed’s cell deterioration through autoxidation processes. Use of available oxygen for aerobic respiration by dry seeds is very low and is almost absent in some cases. The oxygen absorbed by the seeds in such dry conditions is most likely is related to formation of ROS that are involved in oxidation of biomolecules such as DNA, lipids and phospholipids19. Hermetically sealed Super Bags have very low oxygen permeation rate that restricted the free access of oxygen to the stored seeds hence reduced the seed deterioration due to ROS attack. Seed storage in anoxia have been proposed as an effective strategy to protect lettuce germplasm from deteriorative activities and viability losses19. Low oxygen and high carbon dioxide concentrations within the Hermetic PICS bags have proven to provide protection against storage insect pests and viability losses in sorghum23. Use of hermetic bags under anoxia may offer another opportunity to preserve seed quality. At higher moisture contents use of Super Bag with only twist and tie approach badly affect seed quality due to anaerobic respiration and ethanol production19. However, research is needed to study the practical applications of creating anoxia in hermetic bags for commercial scale seed storage.

Deteriorative biochemical changes in quinoa seeds were linked with high seed moisture contents in conventional packaging materials. Higher α-amylase activity indicates vigorous seeds with less deterioration. Reduced α-amylase activities24 and total soluble sugars have been observed in aged seeds25. Total soluble sugars were maximum in the seeds that were stored in the Super Bag at 8 and 10% initial SMC, indicating slow speed of metabolic activities in the seeds having low moisture contents. Seed deterioration in porous packaging materials resulted into decreased total soluble sugars as was observed in wheat seeds in previous studies26. The reasons for reduced total soluble sugars are higher metabolism rate in respiring seeds at high seed moisture contents and Maillard reaction12. Studies have revealed the consumption of starch reserves in endosperm and high malondialdehyde contents in primed rice seed at high relative humidity which is the driving force for increased seed moisture contents27. Reducing sugars were formed as result of sugar hydrolysis under high seed moisture contents12. Moreover, ROS are produced due to aging that react with sugars and convert them into reducing sugars which interfere with the normal functioning of membranes.

Conclusion

Dry quinoa seeds can be stored for longer period under ambient conditions in hermetic packaging like Super Bag. Seed deterioration occurs more rapidly due to slight increase in seed moisture contents that triggers harmful physiological and biochemical changes in the seed. Seed drying to low moisture is a prerequisite for storage in hermetic bags, as is evident from deterioration of seed stored in hermetic bags at higher moisture contents which is most likely due to anaerobic respiration and ethanol production. Seed stored in traditional packaging materials gained moisture due to ambient high RH, which resulted in deterioration.

Methods

Experimental and treatment details

Experiment was performed in Seed Physiology Lab, University of Agriculture Faisalabad, during July, 2015 to January 2017. Seeds of well adapted quinoa genotype of Pakistan; UAF Q-728 was obtained from Alternate Crops Lab, Department of Agronomy, University of Agriculture Faisalabad, Pakistan. Initial seed germination and moisture contents were 80.5% and 10.2% respectively. Conventional bags used in this study including woven polypropylene (PP bag), paper, cloth and jute bags were purchased from local grain market. Super Bags of 10 kg capacity were obtained from GrainPro Inc. Philippines. After equilibrating seed to four different moisture contents i.e. 8, 10, 12 and 14% moisture isotherms were drawn by using equilibrium relative humidity (eRH) values at 28 °C. Quinoa seed, having 6.5% oil contents has 28.2, 40.4, 52.5 and 63.7% eRH at 8, 10, 12 and 14% seed moisture contents (Fig. 9). After that three replicates of 5 kg seed were packed in Super Bag and conventional packaging materials making total 180 experimental units (three replicates of each bag at all moisture levels and sampling intervals) and then stored up to 18 months. Relative humidity and temperature of the storehouse were recorded during the whole period of study with the help of Data Logger (Fig. 8). Seed sampling was done after every six months from each of 60 bags. Seed samples were subjected to germination, vigor and electrical conductivity test. Biochemical attributes were determined at last sampling after 18 months of storage.

Seed drying and equilibrating seed moisture contents

Zeolite drying beads were mixed with seed in airtight plastic boxes to dry seed up to 8 and 10% moisture contents. Seed drying beads (Rhino Research, Thailand) are made up of aluminium silicate clay having very small, uniform pores where water molecule can be adsorbed and are able to dry seeds very quickly29,30. Total 579 g drying beads were added in 5 kg seed to lower down moisture contents from 10.2% to 8% at drying temperature of 30ºC. Similarly, to dry down seed from 10.2% up to 10% seed moisture contents, 50 g drying beads were mixed with 5 kg seeds14. Oven dry method for determination of seed moisture contents was used to calculate the amount of water required to raise the seed moisture content up to 12 and 14% using following equation:

In order to increase seed moisture from 10.2% (initial moisture contents) to 12%, 12 ml water was added drop wise with continuous stirring for thorough mixing. Similarly, 22 ml water was added to increase the moisture from 10.2 to 14% SMC. After drying when seed reached to desired moisture levels, seed was packed in selected packaging materials. After filling the seed in Super Bag, the upper part of bag was twisted and folded back and then closed with the help of cable tie.

Seed moisture and germination test

Seed moisture contents were determined using oven dry method by drying weighed amount of seeds at 103 °C for 17 h31 and dry weight of each replicate was recorded to calculate the seed moisture contents using following equation:

Germination test was conducted by placing quinoa seeds in sterilized and well moist filter paper following ISTA standards31. Seed sample was taken from each replicate bag and from that sample total four hundred seeds were tested in four replicates of 100 seeds. Temperature of the germinator was maintained at 20 °C.

Determination of seed vigor

Seeds were artificially aged in a climatic chamber (F.lli Della Marca S.r.l. Rome) by placing in seed vigor trays at 45 °C for 72 h. Relative humidity of the chamber was maintained at 95% during this incubation period32. Following, accelerated aging, standard seed germination test was conducted as mentioned earlier.

Measurement of electrical conductivity of seed leachates

From each replicate 50 seeds were counted, and their weight was recorded. Seeds were placed in glass beaker containing 250 ml distilled water of known EC. The glass beakers were covered with aluminum foil and then placed at 20 ± 2 °C for 24 h31. After 24 h of soaking, conductivity readings (EC) were recorded with an electrical conductivity meter (HI 99,300). EC of per gram seed’s leachates was calculated using equation following equation:

Seed biochemical attributes

Total 50 g seed was ground to conduct biochemical assays. Activity of α-amylase was measured in 0.5 mg ground seed sample extracted in 5 mL sodium phosphate buffer33. For measurement of reducing sugars, 0.5 mg seed was extracted in 5 mL sodium phosphate buffer (pH 6.9) by DNS method34. Amount of reducing sugars in samples were calculated from the standard curve prepared from standard glucose solution.

Anthrone method was used to measure total soluble sugars from the 0.5 g seed sample ground in 0.5 mL methanol34. Malondialdehyde contents were measure in 0.5 g seed uniformly ground in 10% trichloroacetic acid (TCA). Supernatant was reacted with 0.6% thiobarbituric acid (TBA) prepared in 20% TCA35. After incubation, cooling and centrifugation, absorbance of supernatant was taken at 600, 532 and 450 nm to calculate MDA contents using following equation;

Statistical design and data analysis

Experiment was laid out in Completely Randomized Design (CRD) with factorial arrangement keeping three replications. Different levels of seed moisture contents and packaging materials were taken as factors. Data were analyzed using statistical software Statistix 8.1. Means are presented in bar graphs along with standard error and p values. R statistical computing software was used to make biplot showing relationship among different parameters of seed quality.

References

Bazile, D., Bertero, D. & Nieto, C. State of the Art Report on Quinoa around the World in 2013 (Food and Agriculture Organization of the United Nations (FAO) and Centre de coopération internationale en recherche agronomi quepourle développement (CIRAD), Rome, 2015).

VegaGálvez, A. et al. Nutrition facts and functional potential of quinoa (Chenopodium quinoa willd.), an ancient Andean grain: a review. J. Sci. Food Agric. 90, 2541–2547 (2010).

Bazile, D., Jacobsen, S.-E. & Verniau, A. The global expansion of quinoa: Trends and limits. Front. Plant Sci. https://doi.org/10.3389/fpls.2016.00622 (2016).

Muzaffar, M. How Quinoa is taking over the world—In 100 countries and counting. https://www.ozy.com/fast-forward/how-quinoa-is-taking-over-the-world-in-100-countries-and-counting/94409/ (2019).

Filho, A. M. M. et al. Quinoa: Nutritional, functional, and antinutritional aspects. Crit. Rev. Food Sci. Nutr. https://doi.org/10.1080/10408398.2014.1001811 (2017).

Prego, I., Maldonado, S. & Otegui, M. Seed structure and localization of reserves in Chenopodium quinoa. Ann. Bot. 82, 481–488 (1998).

Spehar, C. R. (ed.) Quinoa alternativa para diversificação agrícola alimentar (Embrapa Cerrados, Brasília, 2007).

Ceccato, D. et al. Seed physiology and response to germination conditions. In State of the Art Report of Quinoa in the World in 2013 (FAO, CIRAD, 2015).

Bakhtavar, M. A., Afzal, I. & Basra, S. M. A. Moisture adsorption isotherms and quality of seeds stored in conventional packaging materials and hermetic Super Bag. PLoS ONE 14, e0207569 (2019).

Qaiser, G. Climate of Pakistan in 2013 (National Drought Monitoring & Early Warning Centre Pakistan Meteorological Department, Islamabad, 2013).

Ceccato, D. V., Daniel Bertero, H. & Batlla, D. Environmental control of dormancy in quinoa (Chenopodium quinoa) seeds: Two potential genetic resources for pre-harvest sprouting tolerance. Seed Sci. Res. https://doi.org/10.1017/S096025851100002X (2011).

Murthy, U. M. N., Kumar, P. P. & Sun, W. Q. Mechanisms of seed ageing under different storage conditions for Vigna radiata (L.) Wilczek: lipid peroxidation, sugar hydrolysis, Maillard reactions and their relationship to glass state transition. J. Exp. Bot. 54, 1057–1067 (2003).

de Jesus Souza, F. I., Devilla, I. A., de Souza, R. T., Teixeira, I. R. & Spehar, C. R. Physiological quality of quinoa seeds submitted to different storage conditions. African J. Agric. Res. 11, 1299–1308 (2016).

Bradford, K. J. et al. The dry chain: Reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 71, 84–93 (2018).

GrainPro. Product specification of GrainPro super grain bag. https://grainpro.com/grainpro-twist-tie/ (2020).

FAO. Seeds toolkit—Module 6: Seed storage. https://www.fao.org/3/ca1495en/CA1495EN.pdf (2018)

Harrington, J. F. Seed storage and longevity. In Seed Biology (ed. Kozlowski, T. T.) 145–245 (Academic Press, Cambridge, 1972).

Bailly, C. Active oxygen species and antioxidants in seed biology. Seed Sci. Res. 14, 93–107 (2004).

Groot, S. P. C., de Groot, L., Kodde, J. & van Treuren, R. Prolonging the longevity of ex situ conserved seeds by storage under anoxia. Plant Genet. Resour. 13, 18–26 (2015).

McDonald, M. B. Seed deterioration: Physiology, repair and assessment. Seed Sci. Technol. 27, 177–217 (1999).

Tripathi, P. C. & Lawande, K. E. Effect of seed moisture and packing material on viability and vigour of onion seed. J. Eng. Comput. Appl. Sci. 3, 1–5 (2012).

Chirchir, G. J., Mwangi, M., Nyamongo, D. O. & Gweyi-Onyango, J. P. Effects of genotype and agro-ecological conditions on storability of soybean [Glycine max (L.) Merr.] seed. Trop. Plant Res. 4, 126–133 (2017).

Waongo, A. et al. Effects of PICS bags on insect pests of sorghum during long-term storage in Burkina Faso. J. Stored Prod. Res. 83, 261–266 (2019).

Marques, E. R. et al. Dormancy and enzymatic activity of rice cultivars seeds stored in different environments. J. Seed Sci. 36, 435–442 (2014).

Garcia, I. S., Souza, A., Barbedo, C. J., Dietrich, S. M. C. & Figueiredo-Ribeiro, R. C. L. Changes in soluble carbohydrates during storage of Caesalpinia echinata LAM. (Brazilwood) seeds, an endangered leguminous tree from the Brazilian Atlantic Forest. Brazilian J. Biol. 66, 739–745 (2006).

Lehner, A. et al. Changes in soluble carbohydrates, lipid peroxidation and antioxidant enzyme activities in the embryo during ageing in wheat grains. J. Cereal Sci. 47, 555–565 (2008).

Wang, W. et al. The effect of storage condition and duration on the deterioration of primed rice seeds. Front. Plant Sci. 9, 1–17 (2018).

Iqbal, S., Basra, S. M. A., Afzal, I. & Wahid, A. Exploring potential of well adapted quinoa lines for salt tolerance. Int. J. Agric. Biol. 19, 933–940. https://doi.org/10.17957/IJAB/15.0399 (2017).

Hay, F. R., Thavong, P., Taridno, P. & Timple, S. Evaluation of zeolite seed drying beads for drying rice seeds to low moisture content prior to longterm storage. Seed Sci. Technol. 40, 374–395 (2012).

Bradford, K. J. & Asbrouck, J. Desiccant beads for efficient seed drying and storage. In 10th ISSS Conference on “Seed Science in the 20th Century”, April 10–15, Salvador, Brazil (2011).

ISTA. International Rules for Seed Testing (International Seed Testing Association, Switzerland, 2015).

AOSA. Seed Vigor Testing Handbook (Association of Official Seed Analysts, Ithaca, 2009).

Kim, Y.-M., Jeong, Y.-K., Wang, M.-H., Lee, W.-Y. & Rhee, H.-I. Inhibitory effect of pine extract on α-glucosidase activity and postprandial hyperglycemia. Nutrition 21, 756–761 (2005).

Sadasivam, S. & Manickam, A. Biochemical Methods for Agricultural Sciences (Wiley Eastern Limited, New Delhi, 1992).

Zheng, X. & Tian, S. Effect of oxalic acid on control of postharvest browning of litchi fruit. Food Chem. 96, 519–523 (2006).

Acknowledgements

Authors are thankful to the Higher Education Commission Pakistan for supporting this research work.

Author information

Authors and Affiliations

Contributions

IA conceived and designed the experiments. MAB conducted the experiment, collected data and analyzed data. MAB wrote the manuscript with input from IA.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bakhtavar, M.A., Afzal, I. Climate smart Dry Chain Technology for safe storage of quinoa seeds. Sci Rep 10, 12554 (2020). https://doi.org/10.1038/s41598-020-69190-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-69190-w

This article is cited by

-

Physiological and Biological Responses of Ca2+-Primed Quinoa Seed Longevity Stored at Different Hermetic Storage Conditions

Journal of Plant Growth Regulation (2024)

-

Insights into carbon and nitrogen metabolism and antioxidant potential during vegetative phase in quinoa (Chenopodium quinoa Willd.)

Protoplasma (2022)

-

Nature-inspired wax-coated jute bags for reducing post-harvest storage losses

Scientific Reports (2021)

-

Enhancing seed conservation in rural communities of Guatemala by implementing the dry chain concept

Biodiversity and Conservation (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.