Abstract

Tsetse flies are the transmitting vector of trypanosomes causing human sleeping sickness and animal trypanosomiasis in sub-saharan Africa. 3-alkylphenols are used as attractants in tsetse fly traps to reduce the spread of the disease. Here we present an inexpensive production method for 3-ethylphenol (3-EP) and 3-propylphenol (3-PP) by microbial fermentation of sugars. Heterologous expression in the yeast Saccharomyces cerevisiae of phosphopantetheinyltransferase-activated 6-methylsalicylic acid (6-MSA) synthase (MSAS) and 6-MSA decarboxylase converted acetyl-CoA as a priming unit via 6-MSA into 3-methylphenol (3-MP). We exploited the substrate promiscuity of MSAS to utilize propionyl-CoA and butyryl-CoA as alternative priming units and the substrate promiscuity of 6-MSA decarboxylase to produce 3-EP and 3-PP in yeast fermentations. Increasing the formation of propionyl-CoA by expression of a bacterial propionyl-CoA synthetase, feeding of propionate and blocking propionyl-CoA degradation led to the production of up to 12.5 mg/L 3-EP. Introduction of a heterologous ‘reverse ß-oxidation’ pathway provided enough butyryl-CoA for the production of 3-PP, reaching titers of up to 2.6 mg/L. As the concentrations of 3-alkylphenols are close to the range of the concentrations deployed in tsetse fly traps, the yeast broths might become promising and inexpensive sources for attractants, producible on site by rural communities in Africa.

Similar content being viewed by others

Introduction

Kairomones are messenger substances for the transfer of information between different species, which are beneficial for the receiving organism only. 3-alkylphenols (3-methyl-, 3-ethyl- and 3-propylphenol) are kairomones, e.g. contained in cattle urine1, and attract tsetse flies that feed on the blood of vertebrate animals and humans. Tsetse flies, Glossina sp., inhabit sub-saharan Africa and are the main transmitting vector of trypanosomes, unicellular parasitic flagellate protozoa causing the widespread diseases human sleeping sickness and animal trypanosomiasis2,3. Animal trypanosomiasis considerably limits agricultural production and causes rural poverty by increasing livestock morbidity and mortality4. Human sleeping sickness is fatal if untreated and severely impacts human health especially in rural communities with inefficient health care provision3. An attractive way to combat the trypanosome transmission is to reduce the size of populations of tsetse flies. To do so, traps are impregnated with 3-alkylphenols among other compounds which serve as odour to attract the tsetse flies1,5. 3-Propylphenol (3-PP), optionally in combination with 3-methylphenol (3-MP), mainly attracts the tsetse fly species G. pallidipes, whereas 3-ethylphenol (3-EP) preferentially attracts G. morsitans5,6. Currently, 3-alkylphenols are mainly produced from fossil resources or are chemically synthesized e.g. from cashew nut shell liquids thereby relying on elaborate extraction procedures and expensive catalysts7.

In order to make 3-alkylphenols accessible for the poor rural communities in sub-saharan Africa, microbial fermentation offers an alternative method for the inexpensive and simple production of these compounds on site. Microbial fermentations are used since millennia e.g. for brewing beer and baking bread. Recent progress in metabolic engineering has fostered the development of microbial fermentation into a valid technology capable of producing a plethora of technologically relevant chemicals8,9. The yeast Saccharomyces cerevisiae is one of the most prominent microbes harnessed for fermentations. Its use as microbial production platform is advantageous, because it is well characterized, robust, simple to handle and easily genetically accessible10,11,12. Moreover, recombinant strains have been proven capable of fermenting agricultural waste materials, making compounds available at low costs13.

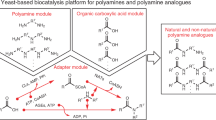

We have recently developed an S. cerevisiae strain with a de novo 3-MP (m-cresol) production pathway from sugars14. In this recombinant yeast, a heterologous phosphopantetheinyltransferase (NpgA)-activated 6-methylsalicylic acid synthase (MSAS) utilizes acetyl-CoA as priming and malonyl-CoA as extender units to synthesize 6-methylsalicylic acid (6-MSA) that is further converted by 6-MSA decarboxylase (PatG) to 3-MP (Fig. 1). Since 3-EP and 3-PP show higher potential as tsetse fly attractants than 3-MP5, we focused on broadening this pathways for producing the 3-alkylphenols 3-EP and 3-PP.

Metabolic pathways for 3-alkylphenol production in S. cerevisiae. In S. cerevisiae the heterologous polyketide synthase MSAS, activated by phosphopantetheinyl transferase (NpgA), catalyses the formation of 6-methylsalicylic acid (6-MSA) utilizing malonyl-CoA as extender unit and acetyl-CoA as priming unit. Intracellular propionyl-CoA can be increased by expression of a bacterial propionyl-CoA synthase (PrpE), propionate feeding and deletion of (methyl) citrate synthase genes CIT2/3 to abolish its degradation. MSAS can then utilize propionyl-CoA as priming unit to catalyse the formation of 6-ethylsalicylic acid (6-ESA). The heterologous ‘reverse ß-oxidation’ pathway21,22 is providing the priming unit butyryl-CoA from acetyl-CoA for the formation of 6-propylsalicylic acid (6-PSA). Finally, 6-MSA decarboxylase (PatG) converts the 6-alkylsalicylic acids, 6-MSA, 6-ESA or 6-PSA, to their respective 3-alkylphenols (3-methylphenol, 3-ethylphenol or 3-propylphenol) that are valuable tsetse fly attractants.

The polyketide synthase MSAS natively functions with acetyl-CoA as priming unit for 6-MSA synthesis. It has been reported that enlarging the product spectrum is possible when priming MSAS with different priming units. For example, MSAS accepts propionyl-CoA and butyryl-CoA as priming units in vitro forming 6-ethylsalicylic acid (6-ESA) and 6-propylsalicylic acid (6-PSA), respectively15,16. Moreover, PatG was shown to decarboxylate 6-ESA to 3-EP in vitro17, while no data are available for the decarboxylation of 6-PSA.

From in vitro data, showing slow formation of 6-ESA from propionyl-CoA (13% of 6-MSA formation) and even slower formation of 6-PSA from butyryl-CoA (9% of 6-MSA formation)15,16, we expected that the competing formation of 6-MSA from acetyl-CoA dominates in vivo. The same limitations were anticipated to occur for the conversion of 6-ESA and 6-PSA by PatG again competing with 6-MSA. 3-MP production with yeast was not accompanied by noticeable 3-EP or 3-PP formation14, indicating that propionyl-CoA and butyryl-CoA are not available in high enough amounts in the yeast cells. We hypothesized that providing increased levels of cytosolic propionyl-CoA and butyryl-CoA could enable 3-EP and 3-PP production via MSAS and PatG in S. cerevisiae.

Propionyl-CoA is an intermediate in threonine catabolism in mitochondria but is probably directly degraded in the 2-methylcitrate cycle by 2-methylcitrate synthases Cit2 and Cit318,19. Moreover, transport out of the mitochondria might further limit its accessibility for MSAS. To enhance propionyl-CoA levels in the yeast cells, we blocked its degradation and increased its production, finally leading to the formation of 3-EP (Fig. 1).

Butyryl-CoA in yeast cells might be derived from ß-oxidation of fatty acids in peroxisomes. However, normally it is further degraded to acetyl-CoA by fatty acyl-CoA oxidase Pox1 and ß-oxidation20. We increased butyryl-CoA levels by expressing a heterologous ‘reverse ß-oxidation’ pathway originally developed for n-butanol production from glucose21,22, leading to the production of 3-PP (Fig. 1).

Our data indicate that the promiscuities of MSAS and MSA decarboxylase can be harnessed for the in vivo production of various 3-alkylphenols, provided that the corresponding substrates are supplied in sufficient quantities.

Material and Methods

Strains and plasmids

Yeast strains and plasmids used in this study are described in Hitschler and Boles14 or are listed in Table 1. S. cerevisiae was cultivated in YPD medium (20 g/L peptone, 10 g/L yeast extract, 20 g/L glucose) from freshly streaked YPD agar plate cultures. For fermentations the medium was supplemented with 100 mM potassium phosphate (KPi) buffer (pH 6.5). Appropriate antibiotics (200 mg/L hygromycin or 200 mg/L G418) were added to media for plasmid maintenance. Escherichia coli DH10ß (Gibco BRL, Gaithersburg, MD) was grown in lysogeny broth (LB)-medium (10 g/L trypton, 5 g/L yeast extract, 5 g/L sodium chloride, pH 7.5) supplemented with appropriate antibiotics (100 mg/L carbenicillin, 50 mg/L kanamycin or 25 mg/L chloramphenicol) for plasmid maintenance and cloning.

Plasmid and strain construction

The codon-optimized DNA sequences, optpatG (GeneBank accession number MK791645), PpoptMSAS (MK791642), optnpgA (MK791644) and optprpE (MT219994), were obtained with the JCat tool29 and ordered as GeneArt Strings DNA fragments from Thermo Fischer Scientific. Genomic DNA of CEN.PK2-1C or plasmids were used as templates for PCR amplification of yeast open reading frames, promoters and terminators with 35 bp homologous overlaps. Primers and genes used in this study are described in Hitschler and Boles14, Schadeweg and Boles21,22 or are listed in Supplementary Tables S1 and S2.

Plasmid assembly in yeast via homologous recombination or in E. coli via Gibson assembly30 and plasmid propagation were conducted as described previously14. Genomic integrations into the ura3 locus of CEN.PK2-1C were performed with the CRISPR/Cas9 system25 as described in Hitschler and Boles14. For deletions, CRISPR/Cas9 plasmids carrying the guide RNA (gRNA) for the specific deletion were amplified via PCR and assembled via Gibson. The donor DNA consisting of 40 bp upstream and 40 bp downstream sequences of the open reading frame were ordered as primers and were annealed to double-stranded DNA as described in Reifenrath and Boles31. However, for deletion of ACS2 in the JHY185 strain a pUG6-based deletion cassette23 was amplified, conferring resistance to hygromycin and carrying 40 bp overhangs to the ACS2 locus for integration via homologous recombination.

For genomic integration of the ‘reverse ß-oxidation’ pathway genes (Schadeweg and Boles) the Golden Gate system27 was utilized for construction of an integration vector. Part plasmids were obtained from Lee et al.27 or PCR fragments with part type specific overhangs and pYTK01 as backbone were assembled with Esp3I as described previously27 incubating the reaction mixture for 10 min at 37 °C, using 15 cycles of digestion and ligation (37 °C 2 min, 16 °C 5 min) and heat inactivating the enzymes at 60 °C for 10 min and 80 °C for 10 min and transformed into E. coli. Next cassette plasmids were formed carrying BsmBI overhangs flanking the cassette for subsequent assembly of the integration plasmid. To build the cassette plasmid pJHV62, part plasmids pYTK3.41, pYTK05, pYTK09, pYTK053, pYTK72 and pYTK95 were assembled with BsaI-HF. For assembly of the integration vector pJHV65 with Esp3I, the reaction mixture containing the cassette plasmids pYTK_ERG10, pYTK_hbd, pYTK_crt, pJHV62 and SiHV110 were incubated for 10 min at 37 °C, using 25 cycles of digestion and ligation (37 °C 1.5 min, 16 °C 3 min), 37 °C for 5 min and heat inactivating the enzymes at 50 °C for 5 min and 80 °C for10 min and transformed into E. coli. The integration vector pJHV65 was digested with NotI and 500 bp homologous sequences to the upstream and downstream region of LEU2 flanked the integration cassette and natMX cassette for homologous recombination and selection in yeast. After transformation of yeast with respective DNA fragments according to Gietz and Schiestl32, cells were grown on selective YPD agar plates.

Cell cultivation

Cells were cultivated in 150 mL YPD medium supplemented with corresponding antibiotics and buffered with 100 m potassium phosphate buffer (KPi) at pH 6.5 to avoid unwanted effects of weak acids. Overnight cultures were harvested in exponential phase and utilized for inoculation of 25 mL KPi buffered YPD medium (pH 6.5) to an optical density (OD600 nm) of 4 or more. For consumption or biotransformation experiments, 10 mM butyrate or propionate were added, respectively. Cultures were shaken at 180 rpm at 30 °C for 144 h in a waterbath (Memmert, Germany) or in a 30 °C container to prevent inhalation of 3-alkylphenols.

Growth and metabolite analysis

The spectrophotometer Ultrospec 2100 pro (GE Healthcare, USA) was utilized to follow cell growth at an optical density of 600 nm. Culture supernatants for HPLC analysis of 3-alkylphenol formation were prepared as described previously14 and analysis was performed via HPLC (Dionex) with an Agilent Zorbax SB-C8 column (4.6 ×150 mm, 3.5 µm) at 40 °C and at a flow rate of 1 mL/min. 3-methylphenol and 3-ethylphenol were separated by the same gradient of solvent A (0.1% (v/v) formic acid in ddH2O) and solvent B (0.1% (v/v) formic acid in acetonitrile) mentioned before14. The same gradient applied for 3-propylphenol analysis with the exception that the gradient stayed at 40% B for 5 min before it switched to 100% B to prolong the separation before the washing step. The 3-alkylphenols were detected at 270 nm in an UV detector (Dionex UltiMate 3000 Variable Wavelength Detector). For quantification and calibration, 3-alkylphenol standards were prepared in ddH2O from m-cresol purchased from Carl Roth (9269.1), 3-ethylphenol from Sigma-Aldrich (210-627-3) and 3-propylphenol from Alfa Aesar (621-27-2).

For propionate analysis 50 µL 50% (w/v) sulfosalicylic acid was added to 450 µL culture supernatant. Samples were analysed in the HPLC equipped with the ion exchange column HyperREZ XP Carbohydrate H + (7.7 × 300 mm, 8 µm) and a refractive index detector (Thermo Shodex RI-101). The metabolites were separated with 5 mM sulfuric acid as liquid phase at a flow rate of 0.6 mL/min and 65 °C. For quantification, propionate standards of different concentrations were prepared in ddH2O from propionic acid purchased from Carl Roth (6026.2). Data analysis and graphing were performed utilizing the software Prism 5 (Graphpad).

Results and Discussion

Production of 3-ethylphenol from propionyl-CoA

Propionate supplementation enables 3-ethylphenol formation

We aimed to synthesize 3-ethylphenol (3-EP) in vivo from glucose via MSAS and MSA decarboxylase by provision of propionyl-CoA as a priming unit for MSAS. This approach relies on high intracellular levels of propionyl-CoA to successfully compete with acetyl-CoA as the cognate priming unit of MSAS. In principle, enhanced propionyl-CoA concentrations can be achieved by either manipulating endogenous pathways leading to propionyl-CoA, feeding of propionate to the cells, blocking of propionyl-CoA degradation and/or enhancing direct propionyl-CoA synthesis. In yeast cells, endogenous pathways for generation of propionyl-CoA exist. For example, propionyl-CoA is an intermediate in yeast threonine catabolism which takes place in the mitochondria18,19. Threonine degradation to propionyl-CoA is initiated by threonine deaminase, catalyzing the conversion of threonine to 2-ketobutyrate. The 2-ketoacid dehydrogenase complex can then catalyze the oxidative decarboxylation of 2-ketobutyrate to propionyl-CoA. In addition, the acetyl-CoA synthases of S. cerevisiae are able to convert externally supplied propionate to propionyl-CoA33.

We first wanted to test whether it is possible to rely on endogenous pathways to provide enough propionyl-CoA for 3-EP production. For this, we utilized the 3-methylphenol (3-MP) production strain JHY162 from our previous work14. Strain JHY162 expresses PpoptMSAS, optnpgA and optpatG under control of the strong constitutive pPGK1, pHXT7-1–392 and pFBA1 promoters, respectively, which were stably integrated in the ura3 locus of the S. cerevisiae strain CEN.PK2-1C14. A high-OD fermentation (starting OD = 5) in KPi buffered YPD at pH 6.5 revealed that strain JHY162 only produced 3-MP (296 mg/L) but 3-EP could not be detected in the supernatants of the cultures (Fig. 2). This indicated that propionyl-CoA, either generated by threonine catabolism18,19 or other endogenous pathways, is not available at sufficient concentrations to outcompete acetyl-CoA for conversion by MSAS. Moreover, endogenous propionyl-CoA might be directly degraded in the 2-methylcitrate cycle by 2-methylcitrate synthases Cit2 and Cit318,19,34.

Effect of deletion of methylcitrate synthase genes CIT2 and CIT3 on 3-ethylphenol (A) and 3-methylphenol (B) formation with or without supplementation of external propionate and on propionate consumption (C). CEN.PK2-1C expressing the 3-methylphenol pathway (JHY162) (PpoptMSAS, optnpgA and optpatG14) and with the Δcit2Δcit3 double deletion (JHY197) were utilized for high-OD fermentations (starting OD = 5.0) at 30 °C in KPi buffered YPD medium (pH 6.5) with or without supplementation of 10 mM propionate. Propionate consumption was followed in S. cerevisiae wild-type strain CEN.PK2-1C and deletion strains that either had peroxisomal (Δcit2), mitochondrial (Δcit3) or both methylcitrate synthases (Δcit2/Δcit3) deleted and were cultured (starting OD = 4) at 30 °C in KPi buffered YPD medium (pH 6.5) supplemented with 10 mM propionate. Culture supernatants were analysed via HPLC for 3-alkylphenol production and propionate. Error bars represent standard deviations of biological duplicates.

Nevertheless, when adding 10 mM propionate to the medium, the same strain (JHY162) produced up to 4.4 mg/L 3-EP (Fig. 2A), indicating synthesis of propionyl-CoA and its conversion by MSAS and PatG to 3-EP. We assume that propionate is converted to propionyl-CoA by the endogenous acetyl-CoA synthetases of S. cerevisiae33. In spite of this success, the main product was still 3-MP which accumulated up to 372 mg/L (Fig. 2B) reflecting the preference of MSAS for acetyl-CoA as priming unit and of PatG for MSA15,16,17. Surprisingly, also 3-MP formation was stimulated by the addition of propionate.

To increase propionyl-CoA levels as the priming unit for 3-EP formation, we aimed at blocking propionyl-CoA degradation which is mediated by 2-methylcitrate synthases. It was shown that abolishment of 2-methylcitrate synthase activity in a Δcit2 Δcit3 deletion strain prevented propionate degradation34. To confirm this in our strains, we deleted CIT2 or CIT3 individually or both together in CEN.PK2-1C and performed fermentations with a starting OD of 4 in KPi buffered YPD medium at pH 6.5 supplemented with about 10 mM propionate. Indeed, the Δcit2 Δcit3 strain JHY174 did not consume any propionate over 144 hours. The single knock-out strains revealed that even a cit3 deletion alone (JHY175) is enough to abolish propionate degradation. Externally added propionate was completely consumed by the CEN.PK2-1C wildtype strain and the Δcit2 strain JHY164 (Fig. 2C).

Although deletion of only CIT3 already abolished propionate degradation, we used the Δcit2 Δcit3 double deletion strain to test an influence on 3-EP formation. We expressed PpoptMSAS, optnpgA and optpatG together under control of the strong constitutive pPGK1, pHXT7-1–392 and pFBA1 promoters, respectively, integrated into the ura3 locus of strain JHY174 (resulting in strain JHY197), and performed high-OD fermentations (starting OD = 5.0) in KPi buffered YPD at pH 6.5. Strain JHY197 showed a slightly better growth (not shown) and 3-MP production (296 mg/L) compared to JHY162 (247 mg/L) (Fig. 2B). However, obviously deletion of CIT2 and CIT3 was not sufficient to provide enhanced endogenous propionyl-CoA levels for 3-EP formation (Fig. 2A). Even when supplemented with 10 mM propionate in the medium, blocked propionyl-CoA degradation did not further increase 3-EP formation (up to 3.6 mg/L in JHY197) (Fig. 2A). Interestingly, also in the cit2/3 deletion strain 3-MP formation was somehow stimulated by the addition of propionate. The results indicate that degradation of propionyl-CoA is not limiting 3-EP formation in the yeast cells.

A heterologous propionyl-CoA synthetase increased 3-EP formation

In order to provide additional propionyl-CoA, we expressed the codon-optimized propionyl-CoA synthetase gene optprpE from Salmonella typhimurium35 under control of the strong promoter pTDH3, integrated into the sfa1 locus in both strains JHY162 and JHY197 (resulting in strains JHY218 and JHY185, respectively). Fermentations were performed as described above. 3-MP production with JHY218 and JHY185 was not significantly influenced compared to the strains without optPrpE (Fig. 3B). When the medium was supplemented with 10 mM propionate, 3-EP production noticeably increased to titers of up to 12.5 mg/L with strain JHY218 and 11.6 mg/L with strain JHY185 (Fig. 3A). This result demonstrates that normally endogenous yeast propionyl-CoA synthetase activity is limiting 3-EP formation. Moreover, as both strains – with or without the 2-methylcitrate cycle – produced comparable amounts of 3-EP it confirms that degradation of propionyl-CoA is not limiting 3-EP production.

Influence of overexpression of a propionyl-CoA synthetase on 3-ethylphenol (A) and 3-methylphenol (B) formation with and without supplementation of external propionate. Yeast strains CEN.PK2-1C expressing the 3-methylphenol pathway (PpoptMSAS, optnpgA and optpatG14) and additionally the propionyl-CoA synthase optprpE, with or without the Δcit2Δcit3 double deletion (strains JHY185 and JHY218, respectively), were inoculated at an OD of 5 and cultivated for 144 h in KPi buffered YPD medium (pH 6.5) with or without supplementation of 10 mM propionate. Culture supernatants were analysed via HPLC for 3-alkylphenol production. Error bars represent standard deviations of biological duplicates.

Interestingly, expression of optprpE led to the formation of 3-EP even without externally added propionate with both strains (Fig. 3A) (3.1 mg/L with JHY185 and 2.9 mg/L with JHY218 after 144 hours). This indicates an endogenous unknown source of propionate. We speculate that this propionate derives from endogenous propionyl-CoA which is hydrolyzed (unspecifically) by thioesterases. Obviously, hydrolyzation of propionyl-CoA to propionate is very efficient and the released propionate needs to be reactivated to propionyl-CoA by a highly active propionyl-CoA synthetase. In this regard it is revealing that also feeding threonine (20 g/L), which is degraded to propionyl-CoA, increased 3-EP production only in the presence of the propionyl-CoA synthetase PrpE (up to 14.3 mg/L 3-EP) (Supplementary Fig. S1). In the absence of PrpE threonine feeding resulted only in 0.18 mg/L 3-EP. This result further confirms the intermediate formation of propionate.

Deletion of endogenous acetyl-CoA synthetase to change precursor ratio

All the strains producing 3-EP still produced much higher amounts of 3-MP (Figs. 2B and 3B). The 3-EP/3-MP ratio is influenced by (i) the substrate preferences of acyl-CoA synthetases, MSAS and MSA decarboxylase and (ii) the ratio of intracellular propionate/acetate, propionyl-CoA/acetyl-CoA respectively ESA/MSA. Acetyl-CoA is the preferred priming unit of MSAS and is an essential metabolite in yeast produced from acetate which is an intermediate of yeast carbon metabolism. Moreover, acetyl-CoA is even necessary for 3-EP formation as it is the substrate of acetyl-CoA carboxylase for the synthesis of the extender unit malonyl-CoA, the second substrate of MSAS.

Acetyl-CoA in yeast is mainly produced by acetyl-CoA synthetases Acs1 and Acs233. As the additional expression of the bacterial propionyl-CoA synthase led to a noticeably increase in 3-EP formation, we aimed at increasing the ratio of 3-EP/3-MP by replacing the acetyl-CoA synthetase of yeast with the propionyl-CoA synthetase of S. typhimurium. We thought this is possible because the propionyl-CoA synthetase is known to be able to synthesize also acetyl-CoA36. Accordingly, feeding of propionate should increase the ratio of propionyl-CoA/acetyl-CoA.

Acetyl-CoA synthetase in yeast is encoded by the glucose-repressed ACS1 gene and by ACS233. On medium with glucose as the carbon source, the ACS2 gene is essential for the production of acetyl-CoA and for growth. We deleted ACS2 in strain JHY185 expressing the propionyl-CoA synthetase gene of S. typhimurium (resulting in strain JHY229). As JHY229 could grow on glucose this confirmed that the propionyl-CoA synthetase is able to provide acetyl-CoA. Interestingly, in fermentations in the absence of external propionate JHY229 produced slightly more 3-EP than the parent strain JHY185 (5.4 mg/L compared to 3.5 mg/L), indicating that the propionyl-CoA/acetyl-CoA ratio indeed might be increased. However, when the medium was supplemented with 10 mM propionate strain JHY229 did no longer grow nor produced any 3-MP or 3-EP (Supplementary Fig. S2). These results suggest that the intracellular propionate/acetate ratio became too high, and as the propionyl-CoA synthetase prefers propionate as its substrate the essential conversion of acetate to acetyl-CoA was blocked by propionate. To conclude, although the increase of the propionyl-CoA/acetyl-CoA ratio is a possible approach to improve production of 3-EP finding a suitable balance of propionyl-CoA to acetyl-CoA concentrations seems to be a difficult task.

Production of 3-propylphenol from butyryl-CoA

Butyrate feeding is not sufficient for 3-propylphenol formation

3-Propylphenol (3-PP) is another promising attractant for tsetse flies5. In principle, it can be formed from butyryl-CoA as a priming unit of MSAS followed by decarboxylation of the formed 6-propylsalicylic acid (PSA). It has already been shown in vitro that MSAS can use butyryl-CoA as a substrate although conversion to PSA proceeds with 9% of the activity with acetyl-CoA15,16. The MSA decarboxylase PatG has not yet been tested for its activity with PSA.

In order to enable 3-PP production in S. cerevisiae, the priming unit butyryl-CoA is required in sufficient amounts. As shown above the endogenous acyl-CoA synthetases are able to convert propionate to propionyl-CoA. Moreover, Luo et al.37 recently even demonstrated the conversion of exogenously supplied hexanoic acid to hexanoyl-CoA for the production of olivetolic acid. Therefore, we tested whether the supplementation of 10 mM butyrate in KPi buffered YPD medium can provide enough butyryl-CoA for 3-PP formation via MSAS and MSA decarboxylase. However, high-OD fermentations of strain JHY162 expressing PpoptMSAS, optnpgA and optpatG under control of the strong constitutive pPGK1, pHXT7-1–392 and pFBA1 promoters, respectively, did not result in any 3-PP formation (Supplementary Fig. S3A). Butyrate supplementation did not influence 3-MP production (Supplementary Fig. S3B).

To exclude the possibility that the formed butyryl-CoA is rapidly degraded via ß-oxidation, we deleted the fatty acyl-CoA oxidase encoding gene POX1 in CEN.PK2-1C to abolish ß-oxidation20, and integrated the heterologous 3-MP production pathway as above, resulting in strain JHY211. For improved uptake of butyrate we transformed JHY211 with multi-copy plasmids overexpressing the endogenous monocarboxylic acid transporters Jen1 or Ady238,39,40 under control of the strong pHXT7-1–392 promoter or an empty vector as control. However, high-OD fermentations in KPi buffered YPD medium supplemented with 10 mM butyrate did not result in any 3-PP formation in any of the strains (Supplementary Fig. S3C). These results indicate that either butyryl-CoA concentrations cannot be enhanced to levels at which it can compete with acetyl-CoA for priming MSAS or that MSAS and/or MSA decarboxylase are not able to convert butyryl-CoA and/or PSA, respectively, in vivo.

Heterologous ‘reverse ß-oxidation’ pathway supplies enough butyryl-CoA as precursor for 3-propylphenol production

Recently, our group established a ‘reverse ß-oxidation’ pathway for efficient n-butanol production from acetyl-CoA in yeast21,22. This pathway forms butyryl-CoA as an intermediate. In the pathway, two acetyl-CoA are condensed by endogenous thiolase Erg10 to acetoacetyl-CoA, which is then converted to 3-hydroxybutyryl-CoA and crotonyl-CoA by hydroxybutyryl-CoA dehydrogenase Hbd and crotonase Crt from Clostridium acetobutylicum and finally reduced to butyryl-CoA by trans-2-enoyl-CoA reductase Ter from Treponema denticola. To use the pathway for 3-PP production, we integrated the genes required up to butyryl-CoA formation (ERG10 from S. cerevisiae, codon-optimized opthbd and optcrt from C. acetobutylicum and optter from T. denticola) under control of the strong constitutive promoters pPGK1, pCCW12, pENO2, pTDH3, respectively, into the leu2 locus of yeast strains JHY162 and JHY211, resulting in strains JHY194 and JHY212, respectively.

High-OD fermentations of JHY194 and JHY212 and their parent strains as controls were performed in KPi buffered YPD (pH 6.5) at 30 °C. As observed before, strain JHY162, with the 3-methylphenol production pathway, and JHY211, with additional pox1 deletion, were unable to produce 3-PP (Fig. 4A). However, expression of the ‘reverse ß-oxidation’ pathway resulted in up to 2 mg/L 3-PP formation with strain JHY194 (Fig. 4A). The highest 3-PP titer (2.6 mg/L) was achieved when POX1 was additionally deleted (strain JHY212), indicating that butyryl-CoA degradation was partially limiting 3-PP production. As expected, 3-methylphenol was still produced in high amounts by all strains (Fig. 4B).

3-Propylphenol formation via ‘reverse ß-oxidation’. 3-Propylphenol (A) and 3-methylphenol production (B) was measured in culture supernatants of CEN.PK2-1C expressing the 3-methylphenol pathway (PpoptMSAS, optnpgA and optpatG14) with or without additional expression of the ‘reverse ß-oxidation’ pathway (ERG10, opthbd, optcrt and optter21,22) (strains 194 and 162, respectively), and with additional pox1 deletion (strains JHY212 and JHY211, respectively). High-OD fermentations (starting OD = 5) were performed in biological duplicates at 30 °C in KPi buffered YPD medium at pH 6.5. Culture supernatants were analysed via HPLC for 3-alkylphenol production. Error bars represent standard deviations.

The ‘reverse ß-oxidation’-based n-butanol production was limited by the trans-2-enoyl-reductase Ter, and additional Tdoptter overexpression improved the final butanol titers21. To test whether Ter might also limit 3-PP formation, Tdoptter was additionally overexpressed from a multi-copy plasmid under control of the strong constitutive pHXT7-1–392 promoter in JHY194 and JHY212 and high-OD fermentations (starting OD = 5) were performed. However, additional Tdoptter overexpression did not increase 3-PP titers (1.1 mg/L and 0.7 mg/L with or without Ter overexpression in JHY194 and JHY212, respectively) indicating that other factors limit 3-PP production.

To conclude, obviously the ‘reverse ß-oxidation’ pathway provides more butyryl-CoA than exogenous addition of butyrate, and these levels are high enough to compete at least partially with acetyl-CoA and to be transformed into 3-PP.

Conclusions

In this work we show that yeast engineered to provide increased intracellular formation of propionyl-CoA or butyryl-CoA and expressing MSAS and MSA decarboxylase can be exploited to produce 3-EP and 3-PP from sugars. The approach is based on the broad substrate tolerance of MSAS and MSA decarboxylase, shown before in vitro. In spite of this success, 3-MP derived from acetyl-CoA as the preferred priming substrate of MSAS and decarboxylation of the intermediate 6-MSA by MSA decarboxylase remained the main product of the engineered strains. Acetyl-CoA cannot be eliminated as it is an essential metabolite and is required for the production of malonyl-CoA as the elongation substrate of MSAS. Therefore, further approaches to increase production of 3-EP and 3-PP will require the engineering of the substrate specificity of MSAS. Since all the enzymatic domains of MSAS can essentially account for reduced rates in the turnover of substrates with elongated alkyl moiety, an elaborate engineering strategy is necessary including mutations of binding sites and swaps of catalytic domains41. A corresponding engineering of the MSA decarboxylase will be necessary.

Concerning the use of the 3-alkylphenols (3-MP, 3-EP, 3-PP) as baits in tsetse fly traps the titers achieved in our work are close to the natural concentrations in cattle urine (50 mg/L 3-MP, 5.5 mg/L 3-EP and 12.5 mg/L 3-PP) and the concentrations deployed in tsetse fly traps1,5. However, as higher concentrations improved catch rates5 and 3-EP and 3-PP are more effective than 3-MP, MSAS and MSA decarboxylase engineering might be useful to improve the effects. It remains to be tested whether it will be possible to simply use the whole yeast cultures, yeast extracts or supernatants to prepare the traps. Our work is a first step in facilitating the preparation of the traps by the simple and direct “brewing” of 3-alkylphenols. As they shall be produced locally by poor rural communities it is desirable to use waste residues from agriculture, food or feed as suitable substrates. This might require further engineering of the yeasts for utilisation of substrates deriving from materials such as lignocellulosic biomass, pectin or fats.

Apart from being used as tsetse fly attractants alkylphenols are also valuable organic industrial chemicals used e.g. in the production of lubricating oil additives and as surface-active substances in cleaning products. However, to replace or supplement these mainly fossil resources-derived alkylphenols the fermentative production process still needs to be improved considerably.

Data availability

Materials and data are made available on request.

References

Bursell, E. et al. Identification of components of cattle urine attractive to tsetse flies, Glossina spp. (Diptera: Glossinidae). Bull. Entomol. Res. 78, 281–291 (1988).

Cecchi, G. et al. Assembling a geospatial database of tsetse-transmitted animal trypanosomosis for Africa. Parasites and Vectors 7, 1–10 (2014).

Cecchi, G. et al. Towards the atlas of human African trypanosomiasis. Int. J. Health Geogr. 8, 1–12 (2009).

Shaw, A. P. M., Cecchi, G., Wint, G. R. W., Mattioli, R. C. & Robinson, T. P. Mapping the economic benefits to livestock keepers from intervening against bovine trypanosomosis in Eastern Africa. Prev. Vet. Med. 113, 197–210 (2014).

Vale, G. A., Hall, D. R. & Gough, A. J. E. The olfactory responses of tsetse flies, Glossina spp. (Diptera: Glossinidae), to phenols and urine in the field. Bull. Entomol. Res. 78, 293–300 (1988).

Saini, R. K. Responses of tsetse, Glossina spp. (Diptera: Glossinidae) to phenolic kairomones in a wind tunnel. Insect Sci. Its Appl. 11, 369–375 (1990).

Baader, S., Podsiadly, P. E., Cole-Hamilton, D. J. & Goossen, L. J. Synthesis of tsetse fly attractants from a cashew nut shell extract by isomerising metathesis. Green Chem. 16, 4885–4890 (2014).

Liao, J. C., Mi, L., Pontrelli, S. & Luo, S. Fuelling the future: microbial engineering for the production of sustainable biofuels. Nat. Rev. Microbiol. 14, 288–304 (2016).

Nielsen, J. & Keasling, J. D. Engineering cellular metabolism. Cell 164, 1185–1197 (2016).

Gibson, B. R., Lawrence, S. J., Leclaire, J. P. R., Powell, C. D. & Smart, K. A. Yeast responses to stresses associated with industrial brewery handling. FEMS Microbiol. Rev. 31, 535–569 (2007).

Liu, Z. L. Molecular mechanisms of yeast tolerance and in situ detoxification of lignocellulose hydrolysates. Appl. Microbiol. Biotechnol. 90, 809–825 (2011).

Weber, C. et al. Trends and challenges in the microbial production of lignocellulosic bioalcohol fuels. Appl. Microbiol. Biotechnol. 87, 1303–1315 (2010).

Claes, A., Deparis, Q., Foulquié-Moreno, M. R. & Thevelein, J. M. Simultaneous secretion of seven lignocellulolytic enzymes by an industrial second-generation yeast strain enables efficient ethanol production from multiple polymeric substrates. Metab. Eng. 59, 131–141 (2020).

Hitschler, J. & Boles, E. De novo production of aromatic m-cresol in Saccharomyces cerevisiae mediated by heterologous polyketide synthases combined with a 6-methylsalicylic acid decarboxylase. Metab. Eng. Commun. 9, e00093 (2019).

Dimroth, P., Ringelmann, E. & Lynen, F. 6-methylsalicylic acid synthetase from Penicillium patulum - some catalytic properties of the enzyme and its relation to fatty acid synthetase. Eur. J. Biochem. 68, 591–596 (1976).

Richardson, M. T., Pohl, N. L., Kealey, J. T. & Khosla, C. Tolerance and specificity of recombinant 6-methylsalicyclic acid synthase. Metab. Eng. 1, 180–187 (1999).

Light, R. J. & Vogel, G. 6-methylsalicylic acid (2,5-cresotic acid) decarboxylase. Methods Enzymol. 43, 530–540 (1975).

Luttik, M. A. H. et al. The Saccharomyces cerevisiae ICL2 gene encodes a mitochondrial 2-methylisocitrate lyase involved in propionyl-coenzyme A metabolism. J. Bacteriol. 182, 7007–7013 (2000).

Pronk, J. T., van der Linden-Beuman, A., Verduyn, C., Scheffers, W. A. & van Dijken, J. P. Propionate metabolism in Saccharomyces cerevisiae: implications for the metabolon hypothesis. Microbiology 140, 717–722 (1994).

Dmochowska, A., Dignard, D., Maleszka, R. & Thomas, D. Y. Structure and transcriptional control of Saccharomyces cerevisiae POX1 gene encoding acyl-coenzyme A oxidase. Gene 88, 247–252 (1990).

Schadeweg, V. & Boles, E. Increasing n-butanol production with Saccharomyces cerevisiae by optimizing acetyl-CoA synthesis, NADH levels and trans-2-enoyl-CoA reductase expression. Biotechnol. Biofuels 9, 257 (2016).

Schadeweg, V. & Boles, E. n-Butanol production in Saccharomyces cerevisiae is limited by the availability of coenzyme A and cytosolic acetyl-CoA. Biotechnol. Biofuels 9, 44 (2016).

Güldener, U., Heck, S., Fiedler, T., Beinhauer, J. & Hegemann, J. H. A new efficient gene disruption cassette for repeated use in budding yeast. Nucleic Acids Res. 24, 2519–2524 (1996).

Taxis, C. & Knop, M. System of centromeric, episomal, and integrative vectors based on drug resistance markers for Saccharomyces cerevisiae. Biotechniques 40, 73–78 (2006).

Generoso, W. C., Gottardi, M., Oreb, M. & Boles, E. Simplified CRISPR-Cas genome editing for Saccharomyces cerevisiae. J. Microbiol. Methods 127, 203–205 (2016).

Generoso, W. C. Exploring the limitations of isobutanol production by engineered industrial Saccharomyces cerevisiae strains. Dr. Thesis (2016).

Lee, M. E., DeLoache, W. C., Cervantes, B. & Dueber, J. E. A highly characterized yeast toolkit for modular, multipart assembly. ACS Synth. Biol. 4, 975–986 (2015).

Entian, K. D. & Kötter, P. 25 yeast genetic strain and plasmid collections. Methods Microbiol. 36, 629–666 (2007).

Grote, A. et al. JCat: A novel tool to adapt codon usage of a target gene to its potential expression host. Nucleic Acids Res. 33, 526–531 (2005).

Gibson, D. G. et al. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nat. Methods 6, 343–5 (2009).

Reifenrath, M. & Boles, E. Engineering of hydroxymandelate synthases and the aromatic amino acid pathway enables de novo biosynthesis of mandelic and 4-hydroxymandelic acid with Saccharomyces cerevisiae. Metab. Eng. 45, 246–254 (2018).

Gietz, R. D. & Schiestl, R. H. Quick and easy yeast transformation using the LiAc/SS carrier DNA/PEG method. Nat. Protoc. 2, 35–37 (2007).

van den Berg, M. A. et al. The two acetyl-coenzyme A synthetases of Saccharomyces cerevisiae differ with respect to kinetic properties and transcriptional regulation. J. Biol. Chem. 271, 28953–28959 (1996).

Graybill, E. R., Rouhier, M. F., Kirby, C. E. & Hawes, J. W. Functional comparison of citrate synthase isoforms from S. cerevisiae. Arch. Biochem. Biophys. 465, 26–37 (2007).

Mutka, S. C., Bondi, S. M., Carney, J. R., Da Silva, N. A. & Kealey, J. T. Metabolic pathway engineering for complex polyketide biosynthesis in Saccharomyces cerevisiae. FEMS Yeast Res. 6, 40–47 (2006).

Horswill, A. R. & Escalante-Semerena, J. C. The prpE gene of Salmonella typhimurium LT2 encodes propionyl-CoA synthetase. Microbiology 145, 1381–1388 (1999).

Luo, X. et al. Complete biosynthesis of cannabinoids and their unnatural analogues in yeast. Nature 567, 123–126 (2019).

Casal, M., Paiva, S., Andrade, R. P., Gancedo, C. & Leao, C. The lactate-proton symport of Saccharomyces cerevisiae is encoded by JEN1. J. Bacteriol. 181, 2620–2623 (1999).

Paiva, S., Devaux, F., Barbosa, S., Jacq, C. & Casal, M. Ady2p is essential for the acetate permease activity in the yeast Saccharomyces cerevisiae. Yeast 21, 201–210 (2004).

Cassio, F., Leao, C. & Uden, N. V. A. N. Transport of lactate and other short-chain monocarboxylates in the yeast Saccharomyces cerevisiae. Appl. Environ. Microbiol. 53, 509–513 (1987).

Klaus, M. & Grininger, M. Engineering strategies for rational polyketide synthase design. Nat. Prod. Rep. 35, 1070–1081 (2018).

Acknowledgements

We thank Alexander Bissl, Fernando Garcés Daza and Simon Harth (all working group of Eckhard Boles; Goethe-University Frankfurt) for provision of plasmids. We thank Mislav Oreb for helpful advice. This work has been financially supported by the Hessen State Ministry of Higher Education, Research and the Arts as part of the LOEWE research initiative MegaSyn.

Author information

Authors and Affiliations

Contributions

J.H. and E.B. contributed equally in the design of the study. M.G. contributed to the initial project design. J.H. performed the experimental work. J.H. and E.B. wrote the paper. M.G. reviewed and edited the paper. All authors have read and approved the submission of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors are inventors of EP patent application No. 19 201 003.1 filed on October 2, 2019, by Goethe-University Frankfurt. The authors declare no other competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hitschler, J., Grininger, M. & Boles, E. Substrate promiscuity of polyketide synthase enables production of tsetse fly attractants 3-ethylphenol and 3-propylphenol by engineering precursor supply in yeast. Sci Rep 10, 9962 (2020). https://doi.org/10.1038/s41598-020-66997-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-66997-5

This article is cited by

-

Saccharomyces cerevisiae as host for the recombinant production of polyketides and nonribosomal peptides

Microbial Cell Factories (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.