Abstract

The ability to produce large cutting tools (LCTs) is considered as the technological marker of the Acheulean and the indicator of a greater technological complexity compared to the previous Oldowan. Although Acheulean techno-complexes are also composed of a concurrent core-and-flake technology, the iconic handaxes have attracted more attention than any other lithic component. Consequently, little is known of the small and medium-sized flake productions (small flaking), especially starting from 1 Ma, when handaxe and cleaver manufacture becomes intensive and widespread across Africa, including the Atlantic coastal regions of Morocco. Research at Thomas Quarry I yielded a rich early Acheulean lithic assemblage, mainly composed of quartzite LCTs and small flaking, together with a small-sized flint production. Here, we report a particular aspect of this flint assemblage, i.e. a flint bladelet-like flake production. This process represents a discrete technical behaviour among those related to small flaking both in quartzite and flint: pebbles were flaked using the bipolar-on-anvil technique repeatedly employing a specific method to produce bladelet-like flakes. This production represents the oldest dated occurrence of bladelet-like technology in Africa and reveals technical competencies hitherto unknown for these periods, providing further elements for the techno-economic diversification of the African Acheulean.

Similar content being viewed by others

Introduction

Large shaped tools (length or width ≥ 10 cm), made on large flakes, cobbles, or tabular clast blanks, are the hallmark of the African Acheulean from its emergence at ~1.8 Ma and for the subsequent 1.5 million years1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22. From the first definition of the term Acheulean23, although the techno-complexes are also composed of a concurrent core-and-flake technology, only handaxes and cleavers were used for grouping together different lithic assemblages scattered over space and time under this label18,19,24. Their degree of refinement was adopted as a parameter for defining Acheulean technological development and variability1,2,5,6,14 and the ability to shape macro-tools was equated to a more complex behaviour than the Oldowan core-and-flake based technology22,25,26.

In recent years, research focused on small-medium sized flake productions in the early East African Acheulean has modified previously established paradigms identifying the main innovations that distinguish the early Acheulean from the Oldowan technology, partially superseding the handaxe focus in Acheulean studies8,11,15,17,27,28,29,30,31,32. Unfortunately, the study of large tools clearly overshadows occurrences of smaller artefacts among African late Early/early Middle Pleistocene Acheulean assemblages. Little is known of these tool kits, when macro-tool productions become intensive and standardized19, and the relevance of the small flaking to hominin behavioural variability remains to be investigated.

Here, we present a bladelet-like flake production identified in the late Early Pleistocene African Acheulean of Thomas Quarry I (ThI-L1) at Casablanca (Morocco). This production was achieved through a techno-economic process never documented in the African Acheulean. A set of flint cores and flakes display a specific technical process for a recurrent bladelet-like flake production, flaking pebbles through the bipolar-on-anvil technique. Although this technique is the best solution to exploit very small clasts33,34, in this case the core convexity management and maintenance show a more complex know-how intentionally involved for detaching as many as possible bladelet-like products. This process is independent from the rest of the flint artefacts focused on the small flake production and it has not been identified within the quartzite small flaking. Furthermore, this is the only known case in the African Acheulean of a bladelet-like production recorded with LCT manufacture in the same archaeological layer35,36,37.

THI–L1 context

The Casablanca region is well known for its exceptional development of Quaternary littoral deposits, beginning in the Upper Miocene and spreading over the Plio-Quaternary times with an extremely detailed registration of the global climatic cycles38,39,40,41,42. Construction works that started at the dawn of the twentieth century in the city of Casablanca demanded the opening of large quarries and incidentally revealed the longest Acheulean sequence in North Africa recorded in an indisputable stratigraphic context37,43. One of these quarries, Thomas Quarry I (ThI; Fig. 1a), was made famous in 1969 by the discovery of a human half-mandible in the Grotte à Hominidés44. In 1985, ThI was re-examined revealing the presence of the earliest North African Acheulean in the lower unit L45.

(a) Location of ThI (drawing by M. Rué). (b) ThI: the Oulald Hamida Formation Members OH1 to OH3 (photo and drawing by D. Lefèvre 2014). (c) ThI-L1, Zone 1: OH1 Bed 2 - Unit L deposits (photo and drawing by D. Lefèvre 2016). (d) ThI: stratigraphy of the OH1 and OH2 Members (drawing by D. Lefèvre 2019). OH1 Member: unconformity above the Cretaceous limestone (K); Bed 1: (a) coarse calcirudite; (b) coarse coquinoid biocalcarenite, (c) coarse biocalcarenite and (d) coquinoide calcarenite; Bed 2- Unit L: (e) large scale trough cross-bedded fine to coarse sands and calcareous mudstone banks. L1 and L5 archaeological layers; (f) bioturbated and decarbonated bioclastic aeolian sands. OH2 Member: erosional surface boundary; (g) curved cross-bedded coarse biocalcarenites; (h) finer inclined planar-bedded biocalcarenites; (i) massive banks of aeolianites; (j) fersialsol pedogenesis at the top. (e) ThI-L1 during 2007 excavation (photo by J.-P. Raynal 2007); (f) map of ThI with extension of unit L and location of the excavation zones (drawing by R. Gallotti).

Unit L corresponds to the Bed 2 of the Oulad Hamida Formation Member 1 (Fig. 1b-d). It is a 2–3 m succession of yellow lenticular limestone beds with a cross-bedded architecture, deposited in a littoral fluvio-lacustrine hydrosystem with shifting channels and a temporary water table, followed by pedogenised aeolian sands40,41,42. Archaeological layers are distributed on temporarily exposed surfaces at several levels of the sedimentary piling. Unit L was dated using the OSL signal of quartz grains to between 0.8 and 1.2 Ma46, with large uncertainties. However, the detailed analysis of the complete lithostratigraphy of the Casablanca sequence demonstrates that OHF Member 1 lays below formations representing three highstand sea-levels older than MIS 15, probably MIS 17 to 21 if the record is complete, more if it is not, pushing it back to 1 Ma at least in the Early Pleistocene41,42 (see Supplementary Information text and Supplementary Fig. S1).

Faunal remains are rare and consist mostly of hippopotamus, with some Elephas and Equus. A Kolpochoerus tooth probably belongs to K. maroccanus, in agreement with an Early Pleistocene age. Only a few rodent teeth have been recovered. Ellobius, a genus that appears at Tighenif, is absent; this might merely be absence of evidence, but both the Paraethomys and Gerbillus differ from those found in later units of the quarry, suggesting a significant age difference47. Bone surfaces are usually unreadable, preventing a detailed taphonomic analysis.

In Bed 2, the archaeology is limited to archaeo-stratigraphic sub-units L1 at the base and L5 at the top. L1 has been systematically excavated (1988–1996 and 2006–2009) on two areas (Zone 1 of 68 m2 and Zone 2 of 75m2) and several test trenches (Fig. 1e,f).

L1 yielded a rich artefact assemblage of quartzite and flint together with unmodified cobbles/pebbles and few faunal remains. In this work we only take into consideration the lithic assemblage belonging to the excavation Zone 2, composed of 2973 artefacts and 3109 unmodified lithic items, stored in the field laboratory at ThI (Table 1). Here, we briefly present the lithic assemblage composition, a summary of the quartzite knapping activities, and we focus on a detailed description of the flint industry, especially of the bladelet-like flake production.

Lithic Assemblage Composition

The ThI-L1 lithic assemblage of Zone 2 is composed of quartzite, which dominate numerically (81.9% of the unmodified items and 84.1% of the artefacts), and flint (18.1% of the unmodified items and 15.9% of the artefacts). Flint derived from the phosphatic plateau in the hinterland of the Meseta and is available in secondary deposits near the site. Quartzites are abundantly available in local primary and secondary sources.

Unmodified quartzite and flint material recorded in L1 layer is mainly composed of pebbles and cobbles (Table 1; Fig. 2a,e), which represent both material accumulated by natural agents and manuports as a potential source of raw material for knappers. Some small quartzite and flint pebbles are present at bottom of water assisted deposits of Bed 2 sub-unit L1. This sedimentary architecture implies that low current transported and deposited sediments. Fabric analysis of large elongated quartzite artefacts and bones distributed on the archaeological surfaces attests of their slight re-orientation48. Nevertheless, large quartzite cobbles and implements were not water deposited, preserving cutting edges as fresh as the flint artefacts, though small pebbles and fragments may have been displaced. However, observation made during the excavation and states of preservation of both quartzite and flint objects do not bring any argument in favour of a residual deposit cumulating different occupational sub-units eroded down to a single layer. Some hippopotamus remains found in layer L1 could suggest that flooded archaeological surfaces may have been disturbed by these animals. Detailed observation of the flint artefact and pebble cortex reveals a long history in marine environment, which is not erased by fluvial transportation. This means that either pebbles derive from marine deposits very close to their final deposition place (THI-L1 deposit) or that humans collected them directly in marine beaches or in slightly derived deposits (for a more detailed description of the mineral resources exploited by hominins at ThI-L1 see the Supplementary Information text and Supplementary Figs S2 to S4).

The size distribution of flint and quartzite artefacts reflects that of the unmodified pebbles and cobbles recovered in the archaeological deposit (Fig. 2). Two main quartzite artefact production systems coexisted at ThI-L1: one is focused on the production of small to medium-sized flakes, the other is devoted to the manufacture of LCTs (Table 1). LCTs (picks, cleavers, bifacial and trihedral tools) are mainly made on large cobbles. Large flakes from cobbles and boulders used as LCT blanks are rather rare. The quartzite assemblage also contains numerous cores and small-medium sized flakes (Table 1)36,37. Several flaking methods (unifacial unidirectional, bifacial partial, peripheral unidirectional, multifacial multidirectional and discoid) mainly exploited medium-sized cobbles to produce small-medium sized flakes. Small quartzite cores (25–50 mm) usually correspond to an overexploitation of the cobble blanks through a multifacial multidirectional method. Flint was exclusively exploited for small flaking.

The number of flakes (whole, broken, and retouched flakes) does not fit with the number of the negative scars that can be observed on the whole cores. Additionally, some cores have been intensively exploited and some flakes exhibit more than one negative scar on the dorsal face, which suggests that the deficit of flakes is larger than we can estimate based on the negative scar count only. This deficit increases if we also consider the shaping of the LCTs. In any case, flakes represent all the flaking stages and methods identified in core analysis. Thus, the large deficit of flakes does not document a spatial and temporal segmentation of the chaînes opératoires and the presence of very small lithic elements (<10 mm; Fig. 2a,b,d-g) does not point to a winnowing by natural agents. We have to consider in this matter that at Thomas Quarry I Bed 2 deposits outcrop on a thousand square meters (Fig. 1f). This surface only represents a fraction of the Bed 2 which extends on several hundred meters to the South-West and is fossiliferous all along. In such an extended open-air site, organized on the edge of a fluctuating water body, we must expect a fragmentation of tasks and mobility of artefacts within it, along with disturbance caused by temporary flooding. Thus, counts of the different knapping products belonging to the excavations may not be representative of the site composition and limits discussion of the actual chaîne opératoire segmentation.

Flint Knapping Activities

The flint assemblage is composed of 472 artefacts (2591 g) and 562 unmodified items (3492 g) (Table 1). The flaked flint assemblage was exclusively produced from pebbles (30 to 60 mm). Flint pebbles do not have angles generated by the intersection of two or more surfaces that can facilitate the first production phases. They are rounded with mainly ovoid and subcircular shapes and bi-convex, plano-convex, and flat cross-sections (Supplementary Figs S5, S6).

Small flake cores

Small flake production is documented by 68 cores exploited by simple (n = 29; one or two removal scars without obvious organization49) and organized flaking (n = 39) performed using the free-hand percussion with hard hammerstones. Other seven cores have been exploited through the bipolar-on-anvil longitudinal exploitation.

Among the cores flaked using a freehand percussion and organized exploitation, three flaking methods have been identified:

-

unifacial unidirectional (n = 17). Core blanks are mainly ovoid bi-convex and plano-convex pebbles, rarely subcircular bi-convex. The flaked surface usually corresponds to the longest natural face of the pebble, exploited to produce one to two series of three to seven elongated flakes from a striking platform rectified by one or two removals to create a suitable angle between 62° and 89° (Fig. 3: 1–3).

Figure 3 Flint freehand exploitations. 1–3: unifacial unidirectional cores with rectified striking platform; 4,5: flakes with unidirectional negative scars on the dorsal face; 6–8: bifacial partial alternating cores; 9,10: multifacial multidirectional orthogonal cores; 11: hinged flake with multidirectional negative scars on the dorsal face (photos and drawings by R. Gallotti).

-

bifacial partial alternating (n = 12). Cores exhibit removals on two adjacent surfaces, and each negative scar is used alternatively as a striking platform to flake the adjacent plane. The blanks are bi-convex ovoid pebbles, systematically exploited on the transversal axis (Fig. 3: 7,8). Only one core shows a semi-peripheral exploitation (Fig. 3: 6). Angles between the two flaking surfaces vary from 45° to 70°.

-

multifacial multidirectional orthogonal (n = 10). These cores are overexploited (five to seven flakes on three to four surfaces) and smaller than the previous ones (Fig. 4a). Core surfaces were alternatively flaked through multidirectional removals respecting the orthogonal angles among flaking surfaces. No specific platform rectification was conducted insofar as each negative served as a striking platform for the following removal on a secant and orthogonal face (Fig. 3: 9,10).

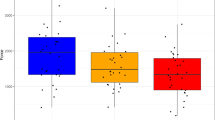

Figure 4 Dimensional distribution of flint cores and flakes. (a) Length (L), width (W), and thickness (T) distribution (mm) of the cores that belong to flint flaking, grouped by flaking method; (b) length (L), width (W), and thickness (T) distribution (mm) of the whole flakes; (c) length (L), and width (W) distribution (mm) of the whole flake butts; (d) log flake length to width ratio; (e) log flake width to thickness ratio. BLE: bipolar-on-anvil longitudinal exploitation. BPE: bipolar-on-anvil semi-peripheral exploitation.

The bipolar-on-anvil longitudinal exploitation (BLE) concerns flint bi-convex and plano-convex ovoid pebbles (n = 7). The bipolar percussion simultaneously yielded two flakes generated along the longitudinal axis from the pebble extremity in contact with the anvil (Fig. 5: 1,2), given the rebound force generated by the anvil’s resistance to the force of the hammerstone. The other pebble extremity, located along the same axis, shows the percussion impact damages produced by the hammerstone’s action (Fig. 5: 1). Some of the percussion marks identified on few pebbles could correspond to an attempt of splitting along the longitudinal axis (Supplementary Information text and Supplementary Fig. S8).

Flint cores belonging to bipolar-on-anvil flaking. 1,2: BLE cores showing two negative scars generated along the longitudinal axis from the pebble extremity in contact with the anvil. The opposite cortical extremity displays marks of percussion (n.1). 3–7: BPE cores showing a split surface along the transversal axis of the pebble and elongated peripheral negative scars. Percussion marks on the opposite cortical side are visible in core n. 3. Core n. 5 shows a split fracture along the longitudinal axis (photos and drawings by R. Gallotti). BLE: bipolar-on-anvil longitudinal exploitation. BPE: bipolar-on-anvil semi-peripheral exploitation.

Bladelet-like flake cores

Bladelet-like flake production has been identified mainly thanks to the analysis of 32 flint cores showing a specific process, the bipolar-on-anvil semi-peripheral exploitation (BPE), independent from the other flint flaking methods and absent in the quartzite flaking (Fig. 6a). These cores show one horizontal or slightly oblique split surface along the transversal axis of the pebble and percussion marks on the opposite side (Fig. 5: 3,4). The battered area could be associated to one small negative scar which seems due to the percussion rather than to an intentional rectification of the striking platform (Fig. 5: 4). The semi-peripheral flaking surface displays several negatives of bladelet-like flakes, most of them with a rippled surface, whose impact point generated from the split surface. In some cases (n = 6), cores exhibit small negative scars with an opposite direction (Fig. 5: 3,6,7). The edge of the split surface shows micro-fractures and micro-detachments which overlap one to each other. These cores are overexploited as documented by the high number of the negative scars varying from five to 10 distributed in one to three series. They document attention to the semi-peripheral longitudinal convexity during flaking, which allows the detachment of a high number of bladelet-like flakes (always relative to the small dimensions of the blank).When the blank morphology can be recognized after the residual cortical part, we observe that the convexity management is favoured by the choice of ovoid biconvex and thick pebbles as core blanks. The choice of the blank morphology is fundamental in the convexity management, because it is maintained mainly through core rotation. Flake negatives are visible on the cores: they are related to the first phase of the flaking and/or they are due to a failed attempt of convexity maintenance.

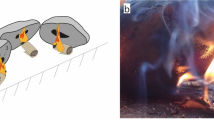

In order to understand the role of the pebble split surface and the core positioning on the anvil, we performed experimentation to reproduce this type of core reduction. Our experimental replication demonstrates that these bipolar cores derive from an indirect fracture technique that follows the pebble splitting along the transversal axis. When a pebble is split, the fragments can be hemispheric or plano-convex. The flat surface is appropriate to stabilize the half-pebble on the anvil (proximal portion) and strike the convex opposite surface (distal portion) with the hammerstone. According to the archaeological core exploitation patterns, the position of the striking surface (distal portion) and the split surface resting on the anvil stabilizing the core (proximal portion) remains stable during pebble exploitation (Fig. 6). Core is rotated according to the longitudinal axis to exploit its periphery and no orthogonal rotation of the core is operated. Detachments usually occur one at a time, rarely in multiples. Micro-fractures and micro-flake scars are generated by the proximal rebound force along the edge of the split surface in contact with the anvil. A large quartzite hammerstone has been used to split the pebble along the transversal axis, while a smaller hammerstone on flint or quartzite has been used for flaking so that an excessive force does not split the plano-convex core in half. Nevertheless, it cannot be excluded that a split fracture along the longitudinal axis can intervene when the core is overexploited, as demonstrated by two archaeological cores (Fig. 5: 5).

The dimensions of these bipolar cores do not differ significantly from those of the cores flaked by freehand technique (Fig. 4a). However, their overexploitation coupled with the fact that these cores are flaked on half-pebbles suggest that larger pebbles were selected by the knappers to operate the transversal split.

Flakes and bladelet-like flakes

A total of 259 flakes (175 whole, 35 bladelet-like, 46 broken, and three retouched) belong to the flaking of flint pebbles (Table 1). Thirteen whole flakes <2 cm with a plain butt display a dorsal face created by a large negative scar whose direction is impossible to recognize. Accordingly, these flakes are counted in waste category including the flake fragments that cannot be situated in the chaîne opératoire50.

The proportion of flakes bearing cortex is high (n = 180; 69.5% of the flakes) since, even in the case of overexploited cores, the small size of the flaked pebbles hardly allows the production of flakes that do not bear residual cortical portions.

Sixty-six entame flakes are present in the flint assemblage (31.4% of the whole flakes). Five of them display some technical traits of the bipolar-on-anvil percussion such as sheared or crushed bulbs and butts as well as rippled ventral surfaces and a cracked outline (Fig. 7: 10). They are mostly subquadrangular and subcircular in shape and only a few are elongated. Their dimensions do not substantially differ from those of the other whole flakes (Fig. 4b).

Fifteen flakes are completely cortical with a plain butt (7.1% of the whole flakes). The flaking angle (interior platform angle) is comprised between 90° and 121°. No indisputable traits of the bipolar-on-anvil technique have been recognized. Their dimensions are very similar to those of the entame flakes (Fig. 4b).

Flakes with a unidirectional negative scar pattern on the dorsal face, parallel to the flaking axis, with frequent cortical edge(s) constitute a large set (n = 91; 43.3% of the whole flakes). Thirty-five of them show two to six negative scars and bear traits of the bipolar-on-anvil percussion and notably:

-

hackles on the ventral face and on the negative scars on the dorsal face (a fracture mark, which develops perpendicular to a fracture front, and therefore spreads radially from the impact point; Fig. 7: 1,3);

-

a rippled ventral face (Fig. 7: 1, 3–5);

-

battering marks on the cortex distal end when present (n = 15), corresponding to the percussion of the distal part of the core (Fig. 7: 2,4,7,8), especially visible in the case of plunging flakes (n = 7; Fig. 7: 1,8);

-

a cracked outline mainly in the case of cortical edges (Fig. 7: 1, 6–8,9);

-

frequent bulb scars (Fig. 7: 2,3);

-

crushing and splintering of the proximal part of the dorsal face adjacent to the butt (Fig. 7: 4,7);

-

crushed (n = 8) or plain (n = 27) butts. Plain butts are slightly narrower and thinner than those of freehand flakes with the same dorsal pattern (Fig. 4c). The flaking angles varies between 92° and 116° and match the angles between the flat split surface of the core laid on the anvil and the flaking surface. Bipolar flakes are more elongated than the freehand unidirectional flakes and other whole flakes with a multidirectional flake scar system (Fig. 4b). The mean ratio of length to width is 1.94, a value that points to a bladelet-like flake production (Fig. 4d). Besides, bipolar flakes have slightly thinner cross-sections (average W:T ratio = 2.02) than freehand flakes do (average W:T ratio = 1.85; Fig. 4e).

Some technical traits related to the bipolar-on-anvil percussion are recognizable on 38 of the 46 broken flakes (Fig. 7: 8,9), although their identification must be taken with caution given the lack of a portion of the flake. However, bipolar-on-anvil percussion usually produces more fragments than freehand percussion, simply because of breakage of immobilised flakes51.

The remaining 56 flakes bearing unidirectional scar pattern on the dorsal face (one to four removals) belong to the freehand percussion. They are smaller than the bipolar ones (Fig. 4b) and less elongated (average L:W ratio = 1.23; Fig. 4d). 78% of them retain cortex on the distal-lateral portion. The high percentage of flakes with residual cortex is probably due to the limited exploitation of the unifacial unidirectional and bifacial partial cores from which they could derive. Plain butts are present on 38 flakes, with flaking angles between 95° and 126°. Usually, plain butts are present on elongated flakes, according to the unifacial unidirectional exploitation (Fig. 3:4,5). The smaller flakes, generally with sub-quadrangular or sub-circular shapes, present mainly cortical or cortical/flat butts with obtuse flaking angles (114° to 127°), probably because they belong to the bifacial partial exploitation.

Flakes with a multidirectional scar pattern on the dorsal face (n = 25; 11.9% of the whole flakes) do not show technical traits of the bipolar-on-anvil technique. Moreover, no rotation of the core in the bipolar-on-anvil exploitation has been identified. They are frequently subquadrangular and smaller than the flakes previously described (Fig. 4b). Eleven of them retain cortex on the distal and/or lateral portions and core edge flakes, implying core rotation. Negative scars, mainly orthogonal both with each other and with the flaking axis, range between two and eight and confirm the overexploited aspect of the multifacial multidirectional cores. Twelve flakes and most of the negative scars on the dorsal face are hinged removals (Fig. 3: 11). They have thicker and asymmetrical cross-sections (Fig. 4b) and longer and wider plain butts (Fig. 4c) with obtuse flaking angles (91°–105°).

Only three flint flakes have been retouched. The first two are cortical flakes with an abrupt retouch on the right lateral edge (Supplementary Information Fig. S7: 1,2); the third one is a cortical flake with a negative scar on the left side and a sub-parallel and invasive retouch on the distal edge (Supplementary Information Fig. S7: 3).

Discussion

Knappers of ThI-L1 frequented a local lithospace rich in quartzites of all possible sizes abundantly available in primary and secondary sources, in which flint was present only as pebbles and in very small quantity52.

Large quartzite cobbles were turned into LCTs by shaping, whereas quartzite small and medium-sized cobbles were exploited to produce flakes. Knappers flaked also flint pebbles to produce small flakes, adopting some of the flaking methods documented for quartzite (unfacial unidirectional, bifacial partial, multifacial multidirectional) and mainly the free-hand technique.

Nevertheless, flint production at ThI-L1 shows also evidence of a specific technical process hitherto unknown for these periods: the intentional production of recurrent bladelet-like flakes through bipolar-on-anvil technique. Furthermore, this process is closely related to the use of flint and is absent in quartzite knapping activities, although knappers had a large quantity of pebbles available that could have been flaked according to the same process. Accordingly, the production of bladelet-like flakes exclusively of flint is most likely driven by specific needs, which for now remain unknown.

This process has wide implications on the current knowledge of the African Acheulean technical behaviors. The main novelty is the production of bladelet-like flakes itself in an Acheulean techno-complex with a strong macrolithic tendency. This production is not documented only by the mere presence of a few “laminar” small products, but is supported by the identification of an independent technical process (BPE) mainly based on the core analysis, that was achieved to detach products with specific metric features (i.e. length approximately twice than width) from a specific raw material. Another novelty is the exclusive use of an improved bipolar-on-anvil technique in two steps: 1) the splitting of the pebbles along the transversal axis to create a surface suitable to stabilize the core on the anvil, and 2) the extraction of bladelet-like products. Usually, the bipolar-on-anvil technique has been explained as a response to raw material constraints in order to maximally exploit small core blanks53,54 and sometimes considered as a technique used by less skilled knappers55. Recent experimentations to distinguish bipolar from free-hand technique in the early technologies show that bipolar knapping is conditioned by the blank morphology and produced shorter and thicker flakes with a high variability in shape and dimensions, and often involves core rotation usually orthogonal to the previous platform/flaking surface in order to pursuit flaking and to guarantee an intense exploitation56,57.

At ThI-L1, the adoption of a peculiar bipolar-on-anvil technique for a different process required more advanced competencies and skills and the respect of three requisites: 1) the application of the concept of anticipation in the choice of blanks (elongated pebbles suitable to be split along the transversal axis and with long peripheral convexities); 2) the opening of a surface laying on the anvil to ensure core stability during reduction; 3) an attempt to manage and maintain the natural peripheral convexity allowing a recurrent bladelet-like flake production.

For long time blade and bladelet productions were considered to be an indicator of distinctive cognitive capabilities mostly attributed to Homo sapiens58,59. Recent research demonstrates that this is clearly no longer the case60,61. A blade production dating to 545–509 ka has been discovered in the GnJh-42 and GnJh-50 Acheulean sites from the lower portion of the Kapthurin Formation (Kenya). Blades are of small dimensions and were detached through the free-hand technique. In these sites the production of LCTs is not documented and blade production has been interpreted as an increasing diversification of the Middle Pleistocene technical behaviours in East Africa which foreshadows the Acheulean-Middle Stone Age (MSA) transition61. A systematic and intense blade production is known in the Amudian assemblages of Qesem Cave (Israel) at 400–200 ka62. In Near East sequences, this is a locally new technology showing “planning and intensity not significantly different from Middle Paleolithic Mousterian industries, thus possibly reflecting a considerable change in human lithic technological behavior prior to the Middle Paleolithic period”62. Blade/bladelet productions are rare also at the late Middle/early Late Pleistocene. In North Africa, blades are present in the undated pre-Aurignacian of Libya63, in the early MSA in the valley of Egypt64, and in Aterian assemblages65. In sub-Saharan Africa also blade/bladelet production are present within certain assemblages attributed to the MSA66,67,68. However, blade/bladelet production becomes intensive and widespread only in later periods and is the hallmark of the Late Stone Age in Africa69,70. It is usually associated with microlith manufacture (small retouched or small backed geometric tools) and composite tool technology and considered as a “modern” technical behaviour71.

Blade/bladelet production since the Middle Pleistocene onwards is ruled by the predetermination of the products (i.e. the pre-planning of the metrical and morphological flake patterns before its detachment through one or more previous detachments72). Predetermination implies a “pre-planned débitage, organized in such away as to repeatedly produce blades or bladelets from a single core” and allows the production of standardized blade/bladelets, with parallel or nearly parallel edges50. This definition of pre-planning, formulated from the analysis of recent Palaeolithic assemblages, cannot be transferred to the bladelet-like flake production of THI-L1. The pre-planning in this specific Acheulean production dated to the end of the Early Pleistocene is achieved through a selection of the core blanks and the management of their geometrical features during flaking and not through the technical predetermination as defined above. Thus, the standardized morphological features of “classical” bladelets are absent at ThI-L1 and the identification of bladelet-like flakes rests on a length to width ratio that approximately equals 2. In a broader perspective, while the concept of predetermination appears for the production of LCTs from ~1 Ma20,22, it is not documented in the Acheulean small flaking, appearing with the Levallois concept from ~0.4–0.3 Ma onwards37,73,74.

Bladelet-like flake production of ThI-L1 seems to be episodic at the end of the Early Pleistocene and not followed by any further similar production for 0.5 Myr. The sporadic appearance and disappearance of technological innovations in Africa is not unusual59, as documented also in previous periods by for example the late Oldowan obsidian small points from Garba IVE75. Even the laminar production from the Kapturin Formation at ~0.5 Ma disappeared then reappeared 200,000 years later61. It has been argued that these occasional technical behaviours did not play a significant role in the hominin behavioral adaptations and in the evaluation of the Early/Middle Pleistocene technological complexity61. However, the complexity of a technical or adaptive behavior is difficult to establish in absolute terms, since the variables involved are multiple and diversified because strongly linked to different contexts, activities, and hominin species. The first appearance of new technical strategies, though sporadic as the bladelet-like flake production at ThI-L1, is important not because it indicates more complex cognitive skills by itself, but because it demonstrates hominins possessed technical know-how to create new solutions when need arose. Providing further data to the small flaking strategies, flint knapping from ThI-L1 well demonstrates that African Acheulean techno-economic strategies were much more flexible and diversified than the mere production of LCTs can document.

Methods

Excavation of Th1-L was performed according to the stratigraphic sediment deposition. Spatial (x, y, z) data of all remains (worked and unworked lithics, as well as faunal remains) have been recorded. Sediments have been collected each 1 m2, dissociated with diluted acetic acid and sieved by water to recover lithic and faunal small fragments.

All knapped and unmodified lithic items have been analysed and measured. The study of the artefacts is founded on the technological approach, which is widely used in lithic analyses of most Early/Middle Pleistocene assemblages in East Africa, Europe, and Near East4,8,10,11,15,16,17,18,20,21,22,24,27,28,29,30,31,32,49,75,76,77,78. Following the chaîne opératoire concept50,79,80,81,82, we examined all of the technical sequences involved in lithic production as well as the related technical and cognitive competencies.

Unmodified items were classified according to their shape and size to appraise the blank geometry and dimensions in order to understand 1) if knappers operated specific choice of the blanks and, if so, which parameters guided them; 2) the technical responses to the different qualities/limits of the raw materials; 3) if technical variability reveals occasional choices or an invariant knowledge independent from the several raw material constraints18. Four morphological types has been defined in frontal view (ovoid, sub-quadrangular, subtriangular, and subcircular) and four in lateral view (flat, bi-convex, plano-convex, and concavo-convex). We recorded length, width, thickness, and weight of each specimen. According to the Wentworth grain scale classification83, pebbles are comprised between 4 and 63 mm and cobbles between 64 and 256 mm.

We classified cores according to 1) technique; 2) the number of flaking surfaces; 3) the direction of flaking; 4) the presence/absence of a distinct striking platform; 5) the features of the striking platform; 6) the angle between the striking platform and the flaking surface; and 7) the angle(s) between/among flaking surfaces. Considering these features, core analysis allows us to identify exploitation modalities and volume management10,11,15,18,24.

The flake analysis takes into account the dimensions (length, width, and thickness measured according to the flaking axis), the number and direction of negative scars on the dorsal face, the type of butt, the shape and cross-section, the correspondence between morphological and flaking axis, the presence of overshot/hinged removals, the presence of retouch, the location and type of retouch, and possible correspondence among shapes, sizes and flaking methods10,11,15,18,24. As Hayden53 has noted, the identification of bipolar-on-anvil flakes relies on the presence of several diagnostic patterns, not all of which need to be present. It is therefore not possible to unquestionably distinguish bipolar-on-anvil from freehand flakes, especially in the case of entame (opening) flakes and of cortical flakes with flaked butts. However, among flakes with unidirectional removals on the dorsal face we have isolated some distinctive technical traits, sufficient to separate them from the other flakes with the same negative scar pattern belonging to freehand percussion. They are listed in the section devoted to flake description.

About bladelet-like flakes, Bordes84 refers to blade/bladelet when the length of a flake is at least equal to twice its width and adds (p. 6) that “English-speaking authors, among others, make a distinction between true blades and blade-like flakes, a true blade showing traces of previous parallel removals on its upper face, and also having more or less parallel edges. Although the distinction is perfectly valid in theory, it is often difficult to make in practice, and will therefore be disregarded”. Tixier85 introduces for bladelets of the Epipaleolithic of Maghreb the limit of length equal to 50 mm and limit of width equal to 12 mm. In this work we refer to Bordes’ definition and we consider these products bladelet-like flakes because length/width ratio is not exactly 2, but it is only approaching 2.

References

Isaac, G.L. Olorgesailie. Archaeological studies of a Middle Pleistocene lake basin in Kenya (Univ. Chicago Press 1977).

Leakey, M. D. Cultural Patterns in the Olduvai Sequence in After the Australopithecines. Stratigraphy, Ecology, and Cultural Change in the Middle Pleistocene (eds. Butzer, K.W. & Isaac, G. Ll.), 477-493 (Mouton 1975).

Gowlett, J. A. J., Harris, J. W. K., Walton, D. & Wood, B. A. Early archaeological sites, hominid remains and traces of fire from Chesowanja, Kenya. Nature 294, 125–129 (1981).

Roche, H., Brugal, J.-P., Lefèvre, D. & Texier, P.-J. Isenya: état des recherches sur un nouveau site acheuléen de l’Afrique orientale. Afr. Archaeol. Rev. 6, 27–55 (1988).

Gowlett, J. A. J. Le site Acheuléen de Kilombe: Stratigraphie, geochronology, habitat et industrie lithique. L’Anthropologie 97, 69–84 (1993).

Gowlett, J. A. J. & Crompton, R. H. Kariandusi: Acheulan morphology and the question of allometry. Afr. Archaeol. Rev. 12, 3–42 (1994).

Kuman, K. & Clarke, R. J. Stratigraphy, artefact industries and hominid associations for Sterkfontein, Member 5. J. Hum. Evol. 38, 827–847 (2000).

Torre de la, I. & Mora, R. Technological strategies in the Lower Pleistocene at Olduvai Beds I and II (Univ. of Liege Press, ERAUL 112 2005).

Gibbon, R. J., Granger, D. E., Kuman, K. & Partridge, T. C. Early Acheulean technology in the Rietputs Formation, South Africa, dated with cosmogenic nuclides. J. Hum. Evol. 56, 152–160 (2009).

Gallotti, R. et al. The Early Middle Pleistocene site of Gombore II (Melka Kunture, Upper Awash, Ethiopia) and the issue of Acheulean Bifacial Shaping Strategies. Afr. Archaeol. Rev. 27, 291–322 (2010).

Gallotti, R., Raynal, J.-P., Geraads, D. & Mussi, M. Garba XIII (Melka Kunture, Upper Awash, Ethiopia): A new Acheulean site of the late Lower Pleistocene. Quat. Int. 343, 17–27 (2014).

Torre de la, I. The origins of the Acheulean: Past and present perspectives on a major transition in human evolution. Philos. Trans. R. Soc. Lond. B Biol. Sci. 371, 20150245 (2016).

Lepre, C. J. et al. An earlier origin for the Acheulean. Nature 477, 82–85 (2011).

Beyene, Y. et al. The characteristics and chronology of the earliest Acheulean at Konso, Ethiopia. Proc. Natl. Acad. Sci. USA 110, 1584–1591 (2013).

Gallotti, R. An older origin for the Acheulean at Melka Kunture (Upper Awash, Ethiopia). Techno-economic behaviors at Garba IVD. J. Hum. Evol. 65, 594–620 (2013).

Diez-Martín, F. et al. The Origin of the Acheulean: The 1.7 Million-Year-Old Site of FLK West, Olduvai Gorge (Tanzania). Sci. Rep. 5, 17839 (2015).

Diez-Martín, F., Sánchez Yustos, P. & de Luque, L., 2018. The East African Early Acheulean of Peninj (Lake Natron, Tanzania) in The Emergence of the Acheulean in East Africa and Beyond. Contributions in Honor of Jean Chavaillon (eds. Gallotti, R. & Mussi, M.) 129-151 (Springer 2018).

Gallotti, R. & Mussi, M. Two Acheuleans, two humankinds: From 1.5 to 0.85 Ma at Melka Kunture (Upper Awash, Ethiopian highlands). J. Anthropol. Sci. 95, 1–46 (2017).

Gallotti, R. & Mussi, M. The Emergence of the Acheulean in East Africa: Historical Perspectives and Current Issues in The Emergence of the Acheulean in East Africa and Beyond. Contributions in Honor of Jean Chavaillon (eds. Gallotti, R. & Mussi, M.) 1-12 (Springer 2018).

Gallotti, R. & Mussi, M. Before, During, and After the Early Acheulean at Melka Kunture (Upper Awash, Ethiopia): A Techno-economic Comparative Analysis in The Emergence of the Acheulean in East Africa and Beyond. Contributions in Honor of Jean Chavaillon (eds. Gallotti, R. & Mussi, M.) 53-92 (Springer 2018).

Santonja, M. et al. Bifacial Shaping at the TK Acheulean Site (Bed II, Olduvai Gorge, Tanzania): New Excavations 50 Years After Mary Leakey in The Emergence of the Acheulean in East Africa and Beyond. Contributions in Honor of Jean Chavaillon (eds. Gallotti, R. & Mussi, M.) 153-181 (Springer 2018).

Texier, P.-J. Technological Assets for the Emergence of the Acheulean? Reflections on the Kokiselei 4 Lithic Assemblage and Its Place in the Archaeological Context of West Turkana, Kenya in The Emergence of the Acheulean in East Africa and Beyond. Contributions in Honor of Jean Chavaillon (eds. Gallotti, R. & Mussi, M.) 33-52 (Springer 2018).

de Mortillet, G. Classification des diverses périodes de l’âge de la pierre. Revue d’Anthropologie 1, 432–435 (1872).

Gallotti, R. & Peretto, C. The Lower/early Middle Pleistocene small débitage productions in Western Europe: New data from Isernia La Pineta t.3c (Upper Volturno Basin, Italy). Quat. Int. 357, 264–281 (2015).

Diez-Martín, F. et al. Testing cognitive skills in Early Pleistocene hominins: An analysis of the concepts of hierarchization and predetermination in the lithic assemblages of Type Section (Peninj, Tanzania) in Stone tools and fossil bones. Debates in the archaeology of human origins (ed. Domínguez-Rodrigo, M.) 245–309 (Cambridge University Press 2012).

Stout, D., Hecht, E., Khreisheh, N., Bradley, B. & Chaminade, T. Cognitive demands of Lower Palaeolithic toolmaking. PlosOne 10, e0121804 (2015).

de la Torre, I., Mora, R. & Martínez-Moreno, J. The early Acheulean in Peninj (Lake Natron, Tanzania). J. Anthropol. Archaeol. 27, 244–264 (2008).

de la Torre, I. The Early Stone Age lithic assemblages of Gadeb (Ethiopia) and the developed Oldowan/early Acheulean in East Africa. J. Hum. Evol. 60, 768–812 (2011).

Diez-Martín, F. et al. Early Acheulean technology at Es2- Lepolosi (ancient MHS-Bayasi) in Peninj (Lake Natron, Tanzania). Quat. Int. 322-323, 209–236 (2014).

Diez-Martín, F. et al. Reassessment of the Early Acheulean at EN1-Noolchalai (Ancient RHS-Mugulud) in Peninj (Lake Natron, Tanzania). Quat. Int. 322-323, 237–263 (2014).

Sánchez Yustos, P. et al. Diversity and significance of core preparation in the Developed Oldowan technology: reconstructing the flaking processes at SHK and BK (Middle-Upper Bed II, Olduvai Gorge, Tanzania). Boreas 46, 874–893 (2017).

Sánchez-Yustos, P. et al. Acheulean without handaxes? Assemblage variability at FLK West (Lowermost Bed II, Olduvai, Tanzania). J. Anthropol. Sci. 96, 53–73 (2018).

Pargeter, J. & de la Peña, P. Milky quartz bipolar reduction and lithic miniaturization: Experimental results and archaeological implications. J. Field. Archaeol. 42, 551–565 (2017).

Pargeter, J. & Eren, M. I. Quantifying and Comparing Bipolar Versus Freehand Flake Morphologies, Production Currencies, and Reduction Energetics During Lithic Miniaturization. Lithic Technol. 42, 90–108 (2017).

Raynal, J.-P. et al. The earliest occupation of North-Africa: the Moroccan perspective. Quat. Int. 75, 65–75 (2001).

Raynal, J.-P. et al. Casablanca and the earliest occupation of North Atlantic Morocco. Quaternaire 13, 65–77 (2002).

Raynal, J.-P., Gallotti, R., Mohib, A., Fernandes, P. & Lefèvre, D. The western quest, First and Second Regional Acheuleans at Thomas-Oulad Hamida Quarries (Casablanca, Morocco) in Vocation préhistoire. Hommage à Jean-Marie Le Tensorer (eds. Wojtczak, M. et al.) 309–322 (ERAUL 148 2017).

Biberson, P. Le cadre paléogéographique de la Préhistoire du Maroc atlantique (Publications du Service des Antiquités du Maroc 16 1961).

Stearns, C. Pliocene-Pleistocene emergence of the Moroccan Meseta. Geol. Soc. Am. Bull. 89, 1630–1644 (1978).

Lefèvre, D. Du continent à l’océan. Morphostratigraphie et paléogéographie du Quaternaire du Maroc atlantique. Le modèle casablancais. Habilitation à diriger des recherches, vol. 3, Université de Montpellier III (2000).

Lefèvre, D. & Raynal, J.-P. Les formations plio-pléistocènes de Casablanca et la chronostratigraphie du Quaternaire marin du Maroc revisitées. Quaternaire 13, 9–21 (2002).

Texier, J.-P., Lefèvre, D., Raynal, J.-P. & El Graoui, M. Lithostratigraphy of the littoral deposits of the last one million years in the Casablanca region (Morocco). Quaternaire 13, 23–41 (2002).

Biberson, P. Le Paléolithique inférieur du Maroc atlantique (Publications du Service des Antiquités du Maroc 17 1961).

Raynal, J.-P. et al. Hominid Cave at Thomas Quarry I (Casablanca, Morocco): recent findings and their context. Quat. Int. 223-224, 369–382 (2010).

Raynal, J.-P. &Texier, J.-P. Découverte d’Acheuléen ancien dans la carrière Thomas 1 à Casablanca et problème d’ancienneté de la présence humaine au Maroc. C. R. Acad. Sci. 308, série II, 1743–1749 (1989).

Rhodes, E. J., Singarayer, J., Raynal, J.-P., Westaway, K. & Sbihi-Alaoui, F.-Z. New age estimations for the Palaeolithic assemblages and Pleistocene succession of Casablanca, Morocco. Quat. Sci. Rev. 25, 2569–2585 (2006).

Geraads, D. Plio-Pleistocene mammalian biostratigraphy of Atlantic Morocco. Quaternaire 13, 43–53 (2002).

Raynal, J.-P., Magoga, L. & Sbihi-Alaoui, F.-Z. Quelques caractères des industries acheuléennes du niveau L de la carrière Thomas 1 (Casablanca, Maroc) - Fouilles 1988-1991. Bull. d’Archéol. Marocaine 19, 9–43 (2002).

Delagnes, A. & Roche, H. Late Pliocene knapping skills: the case of Lokalalei 2C, West Turkana, Kenya. J. Hum. Evol. 48, 435–472 (2005).

Inizan, M. L., Reduron-Ballinger, M., Roche, H. & Tixier, J. Technology and Terminology of Knapped Stone (CREP 1999).

Knight, J. Technological Analysis of the Anvil (Bipolar) Technique. Lithics 12, 57–87 (1991).

Fernandes, P., Mohib, A., & Raynal, J.-P. L’exploitation des ressources minérales par les hommes du Second Acheuléen régional (Grotte des Rhinocéros, Casablanca, Maroc) in Préhistoire de Casablanca. I - La grotte des Rhinocéros (fouilles 1991 et 1996) (eds. Raynal, J.-P. & Mohib, A.) 145-154 (Institut National des Sciences de l’Archéologie et du Patrimoine, VESAM volume VI 2016).

Hayden, B. Confusion in the bipolar world: bashed pebbles and splintered pieces. Lithic Technol. 9, 2–7 (1980).

Pargeter, J. & Shea, J.J. Going big versus going small: Lithic miniaturization in hominin lithic technology. Evol. Anthropol., 1-14, https://doi.org/10.1002/evan.21775.2019 (2019).

Devriendt, I. Bipolar pieces. A question of function, raw material availability, or skill? A case study of the Neolithic sites at Swifterbant (The Netherlands). Lithic Technol. 36, 177–188 (2011).

Díez-Martín, F., Yustos, P., Domínguez-Rodrigo, M. & Prendergast, M. An experimental study of bipolar and freehand knapping of Naibor Soit quartz from Olduvai Gorge (Tanzania). Am. Antiq. 76, 690–708 (2011).

Byrne, F., Proffitt, T., Arroyo, A. & de la Torre, I. A comparative analysis of bipolar and freehand experimental knapping products from Olduvai Gorge, Tanzania. Quat. Inter. 424, 58–68 (2016).

Mellars, P. A. Archaeology and the population-dispersal hypothesis of modern human origins in Europe in The Origin of Modern Humans and the Impact of Chronometric Dating (eds. Aitken, M.J., Stringer, C.B. & Mellars, P.A.) 196–216 (Princeton University Press 1989).

Mithen, S. The singing Neanderthals: The origins of music, language, mind, and body (Weidenfeld & Nicholson 2005).

Bar-Yosef, O. & Kuhn, S. L. The big deal about blades: laminar technologies and human evolution. Am. Anthropol. 101, 322–338 (1999).

Johnson, C. R. & McBrearty, S. 500,000 year old blades from the Kapthurin Formation, Kenya. J. Hum. Evol. 58, 193–200 (2010).

Shimelmitz, R., Barkai, R. & Gopher, A. Systematic blade production at late Lower Paleolithic (400-200 kyr) Qesem Cave, Israel. J. Hum. Evol. 61, 458–479 (2011).

McBurney, C. B. M. The Haua Fteah (Cyrenaica) and the Stone Age of the South-East Mediterranean (Cambridge University Press 1967).

Vermeersch, P., Van Peer, P. & Rots, V. A Middle Palaeolithic site with blade technology at Al Tiwayrat, Qena, Upper Egypt. Antiquity 79, 1–7 (2005).

Bouzouggar, A. & Barton, N. The identity and the timing of the Aterian in Morocco in Modern Origins: A North African Perspective (eds. Hublin, J.-J. & McPherron, S.P.) 93–105 (Springer 2012).

Lombard, M. The Howiesons Poort of South Africa: what we know, what we think we know, what we need to know. S. Afr. Hum. 17, 33–55 (2005).

Yellen, J. et al. The Archaeology of Aduma Middle Stone Age sites in the Awash Valley, Ethiopie. PaleoAnthropology 10, 25–100 (2005).

Pleurdeau, D. et al. After the Dispersal: cultural change or continuity in the Late MSA/Early LSA of southeastern Ethiopia? Quat. Int. 343, 117–135 (2014).

Clark, J. D. 1985. The microlithic industries of Africa: their antiquity and possible economic implications in Recent Advances in Indo-Pacific Prehistory (eds. Misra, V.N. & Bellwood, P.S.) 95-103 (Proceedings of the International Symposium Held at Poona, December 19-21 1978).

Doerschner, N. et al. A New Chronology for Rhafas, Northeast Morocco, Spanning the North African Middle Stone Age through to the Neolithic. PLoS ONE 11, e0162280 (2016).

Leplongeon, A. Microliths in the Middle and Later Stone Age of eastern Africa: New data from Porc-Epic and Goda Buticha cave sites, Ethiopia. Quat. Int. 343, 100–116 (2014).

Mourre, V. Émergence et évolution de la prédétermination au Paléolithique in Normes techniques et pratiques sociale: de la simplicité des outillages pré-et protohistoriques (eds. Astruc, L., Bon, F., Léa, V., Milcent, P.-Y. & Philibert, S.) 61-74 (Éditions APDCA 2006).

Tryon, C. A., McBrearty, S. & Texier, P. J. Levallois lithic technology from the Kapthurin Formation, Kenya: Acheulean origin and Middle Stone diversity. Afr. Archaeol. Rev. 22, 199–229 (2006).

Richter, D. et al. The age of the hominin fossils from Jebel Irhoud, Morocco, and the origins of the Middle Stone Age. Nature 546, 293–296 (2017).

Gallotti, R. & Mussi, M. The Unknown Oldowan: ~1.7-Million-Year-Old Standardized Obsidian Small Tools from Garba IV, Melka Kunture, Ethiopia. PLoS One 10, e0145101 (2015).

Sharon, G. Acheulean large flake industries: Technology, chronology, and significance (British Archaeological Reports, International Series 1701, Archaeopress (2007).

Sharon, G. Large flake Acheulean. Quat. Int. 223–224, 226–233 (2010).

Chevrier, B. Les assemblages à pièces bifaciales au Pléistocène inférieur et moyen ancien en Afrique de l’Est et au Proche-Orient. Nouvelle approche du phénomène bifacial appliquée aux problématiques de migrations, de diffusion et d'évolution locale. Ph.D. Dissertation, Université Paris Ouest Nanterre La Défense (2012).

Leroi-Gourhan, A. Le Geste et la Parole. Technique et Langage (Albin Michel 1964).

Leroi-Gourhan, A. Evolution et Technique. L’Homme et la Matière (Albin Michel 1971).

Boëda, E., Geneste, J.-M. & Meignen, L. Identification de chaînes opératoires lithiques du Paléolithique Ancien et Moyen. Paléo 2, 43–80 (1990).

Geneste, J. M. Systèmes techniques de production lithique: Variations technoéconomiques dans les processus de réalisation des outillages paléolithiques. Tech. Cult. 17(18), 1–35 (1991).

Wentworth, C. K. A scale of grade and class terms for clastic sediments. J. Geol. 30, 377–392 (1922).

Bordes, F. Typologie du Paléolithique ancien et moyen (Delmas 1961).

Tixier, J. Typologie de l’Epipaléolithique de Maghreb (Arts et métiers graphiques 1963).

Acknowledgements

The Franco-Moroccan Casablanca program is conducted and supported by the Institut National des Sciences de l’Archéologie et du Patrimoine (INSAP) of the Ministère de la Culture, de la Jeunesse et des Sports/Département de la Culture of the Kingdom of Morocco, and the Paul Valéry Montpellier 3 University (France). It is also financially supported by the Department of Human Evolution of the Max Planck Institute for Evolutionary Anthropology in Leipzig (Germany) and the LabEx Archimede (ANR-11-LABX-0032-01) within the framework of the Origines project. It has received funding from the Aquitaine Region through the Origines projects, the Collège de France, the Muséum National d’Histoire Naturelle in Paris, and the University of Bordeaux (France). We are grateful to Fatima-Zohra Sbihi-Alaoui, co-director of the French-Morocco Casablanca project with André Debénath (1978-1989) then with Jean-Paul Raynal (1990-2010). We thank Mathieu Rué for Fig. 1a. We express deep thanks to the editor and to the anonymous reviewers who gave us much advice and helped us to improve this paper.

Author information

Authors and Affiliations

Contributions

R.G. designed research, made the study of the lithic industry, and wrote the paper with contribution of all the authors. D.L. and J.P.R. wrote the text of the Supplementary Information focused on the Casablanca stratigraphic sequence. J.P.R. and P.F. wrote the text of the Supplementary Information devoted to the mineral resources exploited by hominins at ThI-L1. R.G. and A.M. made lithic experimentation. D.L. and A.M are co-directors of the French-Moroccan Casablanca program since 2016. J.P.R., A.M., and R.G. made excavations at ThI; P.F. made petro-archaeological study and conducted flint sourcing with J.P.R., A.M. and M.E.G.; D.L., M.E.G., and J.P.R. performed stratigraphic research at ThI. All authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gallotti, R., Mohib, A., Fernandes, P. et al. Dedicated core-on-anvil production of bladelet-like flakes in the Acheulean at Thomas Quarry I - L1 (Casablanca, Morocco). Sci Rep 10, 9225 (2020). https://doi.org/10.1038/s41598-020-65903-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-65903-3

This article is cited by

-

New Approaches to the Bipolar Flaking Technique: Qualitative, Quantitative, and Kinematic Perspectives

Journal of Archaeological Method and Theory (2024)

-

Not Just Scraping By: Experimental Evidence for Large Cutting Tools in the High Lodge Non-handaxe Industry

Journal of Paleolithic Archaeology (2024)

-

Technological diversity in the tropical-subtropical zone of Southwest China during the terminal Pleistocene: excavations at Fodongdi Cave

Archaeological and Anthropological Sciences (2024)

-

Miniaturization and Abstraction in the Later Stone Age

Biological Theory (2023)

-

Brief interviews with hideous stone: a glimpse into the butchery site of Isernia La Pineta — a combined technological and use-wear approach on the lithic tools to evaluate the function of a Lower Palaeolithic context

Archaeological and Anthropological Sciences (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.