Abstract

Herein, we introduce continuous sub-irrigation with treated municipal wastewater (TWW) as a novel cultivation system to promote resource recycling and cost-effective forage rice production in Japan. However, both TWW irrigation and forage rice cultivation were previously considered to intensify CH4 and N2O emissions. In the present study, therefore, we evaluate the emissions of greenhouse gases (GHGs) and yielding capacity of forage rice between conventional cultivation and continuous sub-irrigation systems employing different water supply rates. Results indicated that continuous sub-irrigation with TWW resulted in high rice yields (10.4–11 t ha−1) with superior protein content (11.3–12.8%) compared with conventional cultivation (8.6 t ha−1 and 9.2%, respectively). All TWW irrigation systems considerably reduced CH4 emissions, while higher continuous supply rates significantly increased N2O emissions compared with the conventional cultivation. Only the continuous irrigation regime employing suitable supply rates at appropriate timings to meet the N demand of rice plants decreased both CH4 and N2O emissions by 84% and 28%, respectively. Overall, continuous sub-irrigation with TWW provides high yields of protein-rich forage rice without the need for synthetic fertilisers and effectively mitigated GHG emissions from paddy fields.

Similar content being viewed by others

Introduction

Cultivation of forage rice (Oryza sativa L.) has been promoted by the Japanese government to reduce the cost of domestic animal husbandry by reducing the use of imported feedstuffs, which can be of unstable supply and highly priced depending on global markets1. As a result, there has been a recent increase in forage rice cultivation. However, this has been accompanied by high levels of N fertiliser use to ensure high-yield production, which might lead to inefficient N use and considerable N loss to the environment2.

Effluents from wastewater treatment plants (WWTPs) contain high concentrations of organic and inorganic nutrients beneficial for plant growth and development. Thus, reusing these effluents for agricultural irrigation has major advantages for crop production and environmental management3. Paddy rice cultivation generally demands large amounts of irrigation water and synthetic fertilisers, and thus, would greatly benefit from recycling water and valuable nutrients from WWTPs. To promote forage rice production and establish an effective resource circulation model for the management of agricultural water, we developed new cultivation systems, and treated municipal wastewater (TWW) was effectively reused in paddy fields to produce high yields of forage rice without applying synthetic fertilisers1,4,5.

The reuse of wastewater or TWW for rice cultivation has been intensively investigated and is widely practiced owing to its undeniable benefits. For instance, prior studies have demonstrated that rice grain yield from fields irrigated with treated wastewater could be 35–55% higher than that from groundwater-irrigated fields6. Furthermore, reusing wastewater could lower the total cost of rice production by 8.8–11.9%7 and reduce ~45% of chemical N fertiliser without jeopardising grain yield8. The increase in grain yield and decrease in N fertiliser use could be due to the sufficient supply of nutrients from the wastewater6,8,9, which could simultaneously improve soil fertility and increase the metabolic activity of soil microorganisms3.

To our knowledge, however, no prior study has thoroughly examined the use of TWW as a sole source of both water and nutrients for paddy rice cultivation, especially for cultivating forage rice, which commonly has higher N demands compared with staple rice varieties10,11,12. In our previous studies, we reported the development of an innovative approach for continuous irrigation with TWW in forage paddy fields, which used TWW as the only source for irrigation and fertilisation1,4. In such cultivation systems, TWW was continuously supplied into paddy fields at a constant rate throughout the crop seasons either through an underground drain pipe (sub-irrigation) or on the soil surface (surface irrigation)1,4. High grain yields of protein-rich forage rice have been produced using those novel systems, in which higher yield and rice protein content were achieved using the continuous sub-irrigation system compared with the surface irrigation system4. As a result, our cultivation systems are expected to promote the low-cost production of protein-rich forage rice and improve the efficiency of farmland, which inevitably secures domestic livestock production and stops the increase in abandoned farmland that has been observed in Japan since the 1970s13.

However, forage rice varieties have been recently reported to emit more CH4 than common staple rice probably owing to the increased biomass production when cultivated under similar growth conditions, which indicates a possible increase in CH4 emissions from the agricultural sector in Japan owing to the increasing production of forage rice13. In addition, an earlier study on wastewater irrigation in rice paddy fields claimed that the increased emissions of CH4 and N2O from wastewater-irrigated fields resulted from the high availability of elements in the wastewater, such as organic C and N14. Particularly, paddy fields irrigated with sewage water emitted higher CH4 and N2O by 27–33% and 68–170%, respectively, compared with conventional fields irrigated with river water14. Thus, irrigating forage rice fields with TWW might result in a synergic effect to boost emissions of these greenhouse gases (GHGs) to the atmosphere. Nevertheless, GHG emissions from paddy fields are ultimately influenced by agronomic practices, such as water regime, N fertilisation, and C input8,12,14,15. For example, under straw return, TWW irrigation could decrease CH4 and N2O emissions from paddy fields by 24.5–26.6% and 37–39%, respectively, compared with tap water irrigation8. Given the differences in reported GHG emissions from paddy fields under different water and fertilisation practices, our continuous TWW irrigation system requires a thorough investigation to understand its effects on the GHG emissions from forage paddy fields.

Since the continuous irrigation systems use TWW as the sole source for water and fertilisation management, changing irrigation regime would likely lead to substantial shifts in both water and nutrient inputs, which would subsequently influence the emissions of CH4 and N2O. To estimate the GHG emissions and optimise water regimes of the continuous TWW irrigation systems, we performed a growth chamber experiment to compare CH4 and N2O emissions from forage paddy fields under continuous sub-irrigation with three different water regimes (R1, R2, and R3) and those under conventional cultivation practices (control). R1 was adapted from our previous study as the preferred irrigation regime4, while R2 and R3 were alternatives modified from R1 to test for the optimal regime. The continuous sub-irrigation system was selected for further investigation in the present study owing to its superior agronomic performance compared with the surface irrigation1,4. Furthermore, we thoroughly elaborated the differences in grain yield and quality of forage rice under the examined cultivation practices.

Results

Grain yield and nutritional quality

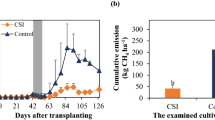

Although the treatments employing the continuous sub-irrigation systems (R1, R2, and R3) were not supplemented with synthetic fertilisers, their grain yields were not significantly different (p > 0.05) from those attained in the control. The lack of fertilisers in R1, R2, and R3 did not decrease the yield but rather tended to increase the yield compared with the application of fertilisers in the control. In particular, the TWW-irrigated treatments produced higher yields (10.1–11 t ha−1) than the control (8.6 t ha−1) (Fig. 1a), regardless of the water regime used. The yields of R1, R2, and R3 averaged 10.5 t ha−1, which was 22% higher than that of the control.

The nutritional quality of rice is generally evaluated based on protein content, which is especially important for feedstuffs. The protein content responded differently to the four cultivation treatments (Fig. 1b). The highest protein content (12.8%) was observed under R3, followed by R1 (11.6%) and R2 (11.3%), while the lowest (9.2%) was observed in the control.

Heavy metal/metalloid concentrations

Most of the examined elements (except for Cr and Pb) responded differently to the four cultivation treatments (p < 0.05), as indicated by the concentrations shown in Table 1. Compared with the control, the TWW-irrigated treatments tended to decrease the concentration of As, Cr, and Cu, but slightly increased the concentration of Cd, Pb, and Zn.

In particular, the concentration of As decreased by 17% under continuous sub-irrigation with TWW. Although As concentration did not differ among R1, R2, and R3 (p > 0.05), the lowest As concentration was observed under R2 (0.16 mg kg−1). Similarly, TWW irrigation decreased Cr concentration (0.04–0.05 mg kg−1) compared with the control (0.06 mg kg−1), but this difference was not significant (p > 0.05). The same trend was observed for Cu, in which TWW irrigation (R1 and R2) decreased Cu concentration compared with the control, except for a minor increase under R3. The lowest Cu concentration (4.61 mg kg−1) was observed under R2 and was 20% lower than that in the control (5.51 mg kg−1) (Table 1). The concentration of Cd slightly increased with TWW irrigation under R1 and R3 (0.03 and 0.04 mg kg−1, respectively), while R2 maintained the same level as that in the control (0.02 mg kg−1). Similarly, Pb concentration increased slightly under R1 and R2, but this increase was not significant (p > 0.05), whereas R3 resulted in the same level as the control. TWW irrigation significantly increased Zn concentration (21.7–23.3 mg kg−1) compared with the control (18.6 mg kg−1) (p < 0.05).

Overall, all the examined elements were observed at concentrations lower than the thresholds for contaminants and toxins in foods recommended by FAO/WHO16 as well as the Japanese standard for heavy metal/metalloid concentration in animal feed17 (Table 1). Among the TWW-irrigated treatments, R2 likely resulted in the lowest accumulation of heavy metals/metalloids.

Emissions of CH4 and N2O

Emissions of CH4 were not affected by the different cultivation treatments from the beginning of the crop season until the heading stage, around 80 days after transplanting (DAT), whereas substantial fluctuations were observed during the flowering and ripening stages (96 DAT onwards) (Fig. 2a). Before the heading stage, there was no significant difference in CH4 flux among the four treatments (0.05–1.76 mg CH4 m−2 h−1). However, the treatments did have a considerable effect as the rice plants started flowering (Fig. 2a). Typically, the control exhibited the highest increase until peaking (13.1 mg CH4 m−2 h−1) at ~103 DAT. Thereafter, CH4 emissions gradually decreased at the end of the ripening stage, although at a higher level than those observed under any of the continuous sub-irrigation treatments. A constant supply rate of 25 L m−2 day−1 throughout the crop season in R1 (Fig. 3) emitted remarkably more CH4 than the other water regimes (R2 and R3) under which CH4 emissions were likely at the same level (Fig. 2a). The highest seasonal average flux of CH4 (4.75 mg CH4 m−2 h−1) was observed in the control, followed by R1 (1.4 mg CH4 m−2 h−1) and R3 (0.79 mg CH4 m−2 h−1), while the lowest was observed under R2 (0.76 mg CH4 m−2 h−1).

Water status was generally divided into two conditions throughout the crop season: a non-waterlogged period during mid-season drainage (MSD) and waterlogging throughout the growth period (Fig. 3). N2O emissions were high during the MSD and for ~3 days after (Fig. 2b). Drainage resulted in two high-peak fluxes in R1 (628.4 and 674.4 µg N2O m−2 h−1) and R3 (294.8 and 231.7 µg N2O m−2 h−1), whereas only one peak flux was observed in R2 and the control (112.4 and 293.3 µg N2O m−2 h−1, respectively). Thereafter, fluctuations in N2O emissions were observed among the four treatments, regardless of the cultivation practice used. Seasonal fluxes of N2O averaged 155.3 and 101.6 µg N2O m−2 h−1 for R1 and R3, which were 163% and 72% higher than that of the control (59.2 µg N2O m−2 h−1), respectively. The lowest average flux was recorded in R2 (38.8 µg N2O m−2 h−1), which emitted 35% less than the control.

Seasonal cumulative emissions of CH4 and N2O are shown in Table 2. The continuous sub-irrigation systems considerably decreased CH4 emissions, regardless of the water regime used. Compared with the control (146.89 kg CH4 ha−1), continuous sub-irrigation decreased CH4 emissions by 70%, 84%, and 83% under R1 (44.77 kg CH4 ha−1), R2 (24.17 kg CH4 ha−1), and R3 (25.06 kg CH4 ha−1), respectively. However, continuous sub-irrigation with TWW increased N2O emissions by 170% and 110% for R1 (3.6 kg N2O ha−1) and R3 (2.81 kg N2O ha−1), respectively, compared with the control (1.34 kg N2O ha−1). Conversely, R2 (0.96 kg N2O ha−1) decreased N2O emissions by 28% compared with the control. Overall, although all three continuous irrigation regimes could decrease CH4 emissions, R1 and R3 exhibited a trade-off by increasing N2O emissions. Only R2 could effectively decrease the emissions of both GHGs.

Net global warming potential and greenhouse gas intensity

Global warming potential (GWP) is an index of the radiative forcing potential of GHGs, with a larger GWP indicating that the gas warms the Earth more efficiently than CO2 over a given period of time. Irrespective of irrigation regimes, continuous sub-irrigation considerably decreased net GWP over a 100-year time horizon compared with conventional cultivation (Table 2). The net GWPs of R1, R2, and R3 averaged 1529 ± 643 (kg CO2−eq ha−1), which was 66% lower than that of the control (4468 kg CO2−eq ha−1). This result suggests that continuous sub-irrigation with TWW would substantially diminish the radiative forcing of forage rice paddy fields. The modified regimes R2 and R3 reduced the net GWP of R1 by 58% and 35%, respectively. Overall, the lowest net GWP (932 kg CO2−eq ha−1) among the four examined treatments was observed in R2 (Table 2).

Greenhouse gas intensity (GHGI) is an index commonly used to represent the efficiency of rice production systems by linking grain yield with the corresponding net GWPs, for which the effects of producing a certain grain yield on the climate during cultivation is estimated. Since no significant difference was observed among grain yields (Fig. 1a), the GHGIs of the four treatments followed the same trend observed in the net GWP, in which the highest (525 ± 65 kg CO2−eq t−1) was recorded in the control and the lowest (95 ± 16 kg CO2−eq t−1) in R2.

Discussion

The higher grain yields achieved in the TWW-irrigated systems were probably attributed to the continuous supply of plant nutrients, especially N, contained in the TWW at high concentrations during the growing season (Table 3). Being the most yield-limiting nutrient in rice production, N is generally applied through high doses of synthetic fertilisers to ensure high levels of rice production, especially for high-yielding cultivars such as the forage rice ‘Bekoaoba’ used in this study12,15. In this experiment, the continuous sub-irrigation systems supplied large amounts of N into R1, R2, and R3 (~811, 575, and 778 kg N ha−1, respectively), which were 3.1, 2.2, and 3.0-fold higher than that supplemented by the fertilisers in the control (260 kg N ha−1). As a result, the TWW-irrigated plants maintained considerably higher leaf greenness, which was measured using a chlorophyll meter and expressed as SPAD values4, compared with the rice under conventional cultivation during the flowering and grain filling stages (~80 DAT onwards, Fig. 4).

Since the SPAD value is strongly associated with N status in leaves18, it is one of the best indicators of photosynthetic activities in rice. Generally, starch and sugar accumulate at high levels in rice culms and leaf sheaths before flowering, and the accumulated carbohydrates are translocated into rice grains during the grain filling stage, which causes the rice culms and leaves to senesce and turn yellowish19. By delaying the senescence and maintaining effective photosynthesis, more carbohydrates could be produced and be available for grain filling, subsequently resulting in higher grain yields. Our results suggest that the N derived from TWW could sufficiently substitute for the N supplemented by synthetic fertilisers. These results are consistent with those of a previous study20, which demonstrated that N-rich wastewater was as effective as commercial N fertiliser at achieving optimum rice yields. This was further supported by our previous study, which reported that continuous sub-irrigation removed 85–90% of the N available in TWW4, and the utilisation of newly absorbed N until the late growth period is critical for producing the high yields of high-yielding rice varieties21.

Water regime R1 was the preferred water scheme demonstrated in our previous study4; however, continuous irrigation at a constant rate of 25 L m−2 day−1 throughout the growing season probably reduced the efficient use of N owing to the variable N demand of rice plants in each growth stage19. In the present study, we modified this water regime into R2 and R3 to test for an optimal regime. The lower supply rate of 8.3 L m−2 day−1 was used during the early growth stage and near maturity when the rice plants generally had a low N-absorbing capacity19. A higher supply rate of either 25 L m−2 day−1 or 36 L m−2 day−1 was used in R2 or R3, respectively, from 31 to 114 DAT, which was a period of high N demand, whereas active tillering, panicle initiation, heading, and grain filling occurred consecutively (Fig. 3) with a high N-use efficiency to maximise tiller number, increase panicle size, improve filled-grain percentage, and enhance grain weight19. Compared with R1, R2 and R3 did not cause significant yield losses (p > 0.05, Fig. 1a), suggesting an opportunity to apply suitable supply rates at appropriate timings to meet the N demands of the rice plants. The better N assimilation during the late growth period also explained the increased rice protein content observed in R1, R2, and R3 (Fig. 1b). The highest protein content obtained in R3 (p < 0.05) can be attributed to the higher supply rate of 36 L m−2 day−1 maintaining the most efficient photosynthesis in the rice plants from 67 DAT onwards (Fig. 4).

Overall, our study provides evidence to suggest that continuous sub-irrigation with TWW is an effective means to reuse the effluents from WWTPs to produce high yields with high protein content without using exogenous synthetic fertilisers. This result agreed with those of previous studies1,4,9, suggesting a cost-effective strategy for recycling water and plant nutrients that simultaneously reduces the demand for synthetic fertilisers and the amount of nutrients discharged into surface water bodies. Furthermore, eliminating the use of fertilisers will not only decrease the adverse environmental effects but will also increase profits for farmers7,9. Relative to the constant supply rate in R1, combining more suitable supply rates with relevant timings in R2 and R3 could maintain the high yielding capacity and high rice protein content (Fig. 1).

Accumulation of heavy metals/metalloids by crops irrigated with wastewater has generally been considered an environmental problem since those metals tend to accumulate in soil and could become bioavailable for crops3. However, in the present study, there was no notable adverse effect of TWW irrigation on the accumulation of toxic elements, like As, Cr, Cu, Cd, and Pb, in the rice grains. This result is in accordance with those of other studies5,6,9, which reported that the chemical compositions of rice irrigated with TWW were within the common range observed in conventional paddy fields. The slight increase in Zn content in the rice grains under TWW irrigation compared with that under the control (Table 1) was probably due to the higher concentration of Zn in TWW relative to other elements (Table 3). Interestingly, Zn is one of the most essential micronutrients for humans, and thus, attempts have been made to improve Zn content in rice22. The lower concentrations of As, Cr, and Cu observed under continuous sub-irrigation with TWW relative to the control were probably attributed to the continuous overflow of water that might carry these elements out of the paddy soils. Ultimately, although minor variation in the concentrations of the examined elements was observed among the continuous sub-irrigation water regimes (R1, R2, and R3), and between those and the control, all the concentrations were lower than the maximum limits recommended by FAO/WHO16 and the Japanese standard17 (Table 1), suggesting that the rice grains harvested from the continuous sub-irrigation systems are safe to use as feedstuffs.

The production of CH4 in rice fields generally results from the anaerobic decomposition of organic matter in rhizosphere soil. In contrast with a previous study14, which reported an increase in CH4 emissions from paddy fields irrigated with wastewater, continuous sub-irrigation considerably decreased the seasonal emissions of CH4 by 70–84% compared with conventional cultivation (Table 2). This decrease was probably due to the substantial amounts of dissolved oxygen maintained in the TWW (Table 3) being continuously supplied into the rhizosphere as TWW was pumped into the deep soil layers, which might subsequently inhibit methanogen communities and their activities regarding CH4 production. The high peaks of CH4 fluxes recorded in all treatments during the grain filling stage were mainly attributed to the higher availability of C substances in the paddy soil as a result of enhanced root exudation during flowering. The highest exudation rates were observed during the grain filling stage compared to the other growth stages23. Since root exudates provide C substrates for methanogenesis in rice fields, the higher root exudation during flowering could greatly stimulate CH4 emissions in the following grain filling stage23. Among the three continuous irrigation regimes tested in the present study, R2 was the most effective in terms of CH4 mitigation (Fig. 2, Table 2), probably owing to the lowest input amount of available C accompanied by the lowest irrigation rates (Fig. 3).

The emissions of N2O in the control, which contributed to the net GWP by 8%, were low compared with CH4 emissions. This result agrees with those of other studies that reported negligible N2O emissions in flooded paddy fields under conventional cultivation24,25. The high peaks of N2O fluxes observed in all treatments during MSD were consistent with the common phenomenon in paddy fields under field drainage that promotes N2O emissions due to enhanced nitrification-denitrification processes under favourable conditions14,15. The additional peaks recorded in R1 and R3 within 3 days afterwards were likely due to the high N concentration in the soil and surface water when TWW was re-supplied into the experimental chambers. Emissions of N2O from R1, R2, and R3 contributed to 43%, 27%, and 51% of the net GWP, respectively, probably due to the high N concentration in the TWW continuously supplied into the chambers (Table 3). The lowest emission of N2O recorded in R2 relative to the other TWW-irrigated treatments (Table 2) was mainly attributed to the lowest N input accompanied by lower irrigation rates. It is likely that the lower fertilisation in R2 ensured the efficient use of nutrients by the rice plants, leaving very little residual N for nitrification and denitrification, thereby reducing N2O emissions. The higher N2O emissions from R1 and R3 were essentially due to the enhanced nitrification/denitrification process induced by the considerable N contained in the TWW and the higher supply rates (Fig. 3). Furthermore, the rich sources of organic matter supplied by TWW could also benefit N-cycling bacterial communities14, subsequently increasing N2O emissions. Overall, our results indicate that R2 is the most effective mitigator that can overcome the trade-off between N2O and CH4 emissions compared with R1 and R3.

Efficient cultivation practices must involve producing the optimum rice yield along with low environmental effects. Prior studies have reported many potential practices to increase rice yield and simultaneously mitigate GHG emissions from paddy fields26,27. In the present study, continuous TWW irrigation considerably decreased net GWPs primarily owing to the considerable decrease in CH4 emissions (Table 2). The combination of two supply rates in R2 and R3 (Fig. 3) tended to decrease seasonal CH4 and N2O emissions (Fig. 2), and subsequently diminish the net GWPs compared with the constant supply rate in R1. The lowest net GWP and GHGI attained in R2 is attributed to its most effective minimisation of both CH4 and N2O emissions. Our results have shown that appropriately matching the lower (8.3 L m−2 day−1) and higher (25 L m−2 day−1) supply rates with the periods of low and high N demand of rice plants (Fig. 3), respectively, leads to R2 being the optimised irrigation regime for continuous sub-irrigation with TWW to reduce the GHG budget of rice paddy fields without significant yield loss or protein reduction.

In conclusion, the continuous sub-irrigation systems produce high yields of protein-rich forage rice through the reuse of TWW as the sole source for both irrigation and fertilisation in paddy fields. Importantly, by employing the optimal water regime (R2), continuous sub-irrigation with TWW can effectively mitigate CH4 and N2O emissions from the rice paddies. The practice of recycling valuable plant nutrients contained in TWW to meet the high nutrient demand of forage rice production instead of applying high doses of synthetic fertilisers demonstrates the potential to minimise the dependence of rice production on fertilisers, which would simultaneously mitigate GHG emissions and promote sustainable rice paddy farming. Our results will motivate local farmers to adopt the continuous irrigation systems to reuse TWW for rice cultivation. The agronomic performance and cost efficiency of adopting these practices under real farm conditions will be analysed by our research team in future studies.

Methods

Experimental design

The experiment was conducted in the 2018 crop season at Yamagata University, Tsuruoka City, Japan, using four polyethylene growth chambers (36 cm height, 30 cm width, 60 cm length) to simulate paddy fields of 0.18 m2 (Fig. 5a). At the bottom of each chamber, a perforated drainage pipe (21 cm diameter) was installed and covered by a layer of gravel. The chambers were filled with 30 kg of a loamy soil (air-dried, 20% moisture) with a pH of 5.5, an EC of 9.3 mS m−1, and total C, N, P, and K content of 20000, 1710, 920, and 1839 mg kg−1, respectively. In each chamber, four hills of forage rice ‘Bekoaoba’ were transplanted at a plant density of 15 × 30 cm (Fig. 5a).

Four treatments were used in the present study, including one under conventional farming practices (control) and three under continuous sub-irrigation with TWW each with a different water regime (Fig. 3). TWW used for the continuous irrigation was collected from a local WWTP and monitored weekly for its physicochemical properties following the standard methods described in our previous study5. The basic properties of the irrigation TWW were shown in Table 3.

The control treatment was fertilised with 160 kg N-P2O5-K2O ha−1 as basal at 1 day before transplanting and 100 kg N-K2O ha−1 at the panicle–initiation stage. The fertiliser dose was adjusted based on the chamber’s surface area basis, while daily watering involved manually adding tap-water to maintain 5-cm standing water above the soil surface. The treatments employing continuous sub-irrigation systems were setup by pumping TWW stored in an influent tank into the chambers through the perforated pipes, from which TWW infiltrated the soil layer and ultimately overflowed into effluent tanks via the outlets installed at 5 cm above the soil surface (Fig. 5a). Three water regimes of continuous sub-irrigation were controlled by electric pumps (EYELA Cassette Tube Pump SMP-23), set to a constant supply rate of 25 L m−2 day−1 throughout the crop season (R1); a supply rate of either 25 (R2) or 36 L m−2 day−1 (R3) from 31 to 114 DAT combined with a lower rate of 8.3 L m−2 day−1 for the other growing periods (Fig. 3). Irrigation with TWW was initiated at 3 DAT and maintained continuously throughout the crop season, except for 1 week of MSD that is conventionally practiced locally (Fig. 3). The treatments employing three continuous sub-irrigation regimes were not supplemented with exogenous fertilisers; thus, TWW was the only source of water and fertilisation inputs. Total N inputs of R1, R2, and R3 were approximately 811, 575, and 778 kg N ha−1, respectively, which were theoretically estimated based on the supply rates and the N concentration in the TWW during the crop season.

Measurement of grain yield and rice quality

Grain yield was measured at harvesting and presented as the weight of brown rice after being adjusted to 14% moisture content. The nutritional quality of the harvested grains was evaluated based on rice protein content, which was calculated by multiplying a conversion factor of 5.9528 by the total N content of the brown rice analysed by an automatic high-sensitivity NC analyser (Sumigraph NC-220F, SCAS, Japan). Concentrations of heavy metals/metalloids (As, Cr, Cu, Cd, Pb, and Zn) in the brown rice were determined by the standard wet-digestion method followed by measuring with either an atomic absorption spectrometer (AAS Model AA7000 equipped with hydride generator, Shimadzu Corporation, Japan) for As, or an inductively coupled plasma mass spectrometer (ICP-MS) (Elan DRC II, PerkinElmer, Japan) for the other elements29.

Gas sampling and analysis

Gas samples of CH4 and N2O were collected during the growing season (May to September 2018) following the manually operated closed chamber method30. We used transparent compartments (top chambers) (95 cm height, 30 cm width, 60 cm length) that could be mounted on the growth chambers on water-seal collars for gas-sampling events (Fig. 5b). Each compartment was equipped with one battery-driven fan to homogenise the air inside, an air-buffer 2-L plastic bag to compensate for pressure changes, a thermometer to monitor temperature changes during the gas-sampling period, and a gas-sampling port equipped with a 3-way stopcock valve for collecting gas samples from the compartment (Fig. 5b).

Gas samples was collected weekly from 10.00 to 11.00 am. A 50-mL plastic syringe equipped with a 3-way stopcock valve was used to collect gas samples from the top chambers at 0, 15, and 30 min after deployment. The collected gas samples were immediately transferred to 10-mL air-evacuated glass vials and transported to the laboratory for measuring CH4 and N2O concentrations using a gas chromatograph (Shimadzu GC-2014, Kyoto, Japan). Fluxes and seasonal cumulative emissions of CH4 and N2O were estimated following standard procedures30. Briefly, CH4 and N2O fluxes were calculated by examining the linear increases in CH4 and N2O concentrations in the top chambers over time. The seasonal cumulative CH4 and N2O emissions from all chambers were calculated directly from the fluxes. To estimate the net GWP of each treatment, the seasonal cumulative CH4 and N2O emissions were converted to CO2−equivalents (CO2−eq) using a radiative forcing potential relative to CO2 over a 100-year time horizon of 28 for CH4 and 265 for N2O31. The GHGI was calculated by dividing the net GWP by the grain yield27.

Statistical analysis

The four rice plants transplanted into each treatment chamber were treated as four replicates to analyse the data pertaining to grain yield, rice protein content, and concentration of heavy metals/metalloids. Data were subjected to analysis of variance (ANOVA), and the means of significant treatment effects were compared using Tukey’s honestly significant difference test (HSD) at the 5% probability level using IBM SPSS Statistics 24.0. Differences in CH4 and N2O emissions among four treatments were examined based on a single data point basis.

References

Tran, D. L. et al. High yield and nutritional quality of rice for animal feed achieved by continuous irrigation with treated municipal wastewater. Paddy Water Environ. 17(3), 507–513, https://doi.org/10.1007/s10333-019-00746-x (2019).

Win, K. T., Okazaki, K., Ookawa, T., Yokoyama, T. & Ohwaki, Y. Influence of rice-husk biochar and Bacillus pumilus strain TUAT-1 on yield, biomass production, and nutrient uptake in two forage rice genotypes. PLoS One 14(7), e0220236, https://doi.org/10.1371/journal.pone.0220236 (2019).

Toze, S. Reuse of effluent water- benefits and risks. Agri. Water Manage. 80, 147–159, https://doi.org/10.1016/j.agwat.2005.07.010 (2006).

Pham, D. D. et al. Rice cultivation without synthetic fertilizers and performance of Microbial Fuel Cells (MFCs) under continuous irrigation with treated wastewater. Water 11(7), 1516, https://doi.org/10.3390/w11071516 (2019).

Pham, D. D. et al. Bottom-to-top irrigation of treated municipal wastewater for effective nitrogen removal and high quality rice for animal feeding. Water Sci. Tech. Water Supply 18(4), ws2017190, https://doi.org/10.2166/ws.2017.190.

Kang, M. S., Kim, S. M., Park, S. W., Lee, J. J. & Yoo, K. H. Assessment of reclaimed wastewater irrigation impacts on water quality, soil, and rice cultivation in paddy fields. J. Environ. Sci. Heal. A 42(4), 439–445, https://doi.org/10.1080/10934520601187633 (2007).

Papadopoulos, F. et al. Assessment of Reclaimed Municipal Wastewater Application on Rice Cultivation. Environ. Manage. 43(1), 135–143, https://doi.org/10.1007/s00267-008-9221-4 (2009).

Xu, S., Hou, P., Xue, L., Wang, S. & Yang, L. Treated domestic sewage irrigation significantly decreased the CH4, N2O and NH3 emissions from paddy fields with straw incorporation. Atmos. Environ. 169, 1–10, https://doi.org/10.1016/j.atmosenv.2017.09.009 (2017).

Jung, K., Jang, T., Jeong, H. & Park, S. Assessment of growth and yield components of rice irrigated with reclaimed wastewater. Agri. Water Manage. 138, 17–25, https://doi.org/10.1016/j.agwat.2014.02.017 (2014).

Zhou, S. & Hosomi, M. Nitrogen transformations and balance in a constructed wetland for nutrient-polluted river water treatment using forage rice in Japan. Ecol. Eng. 32(2), 147–155, https://doi.org/10.1016/j.ecoleng.2007.10.004 (2008).

Zhou, S., Nishiyama, K., Watanabe, Y. & Hosomi, M. Nitrogen budget and ammonia volatilization in paddy fields fertilized with liquid cattle waste. Water Air Soil Poll. 201(1-4), 135–147, https://doi.org/10.1007/s11270-008-9933-3 (2008).

Riya, S. et al. Mitigation of CH4 and N2O emissions from a forage rice field fertilized with aerated liquid fraction of cattle slurry by optimizing water management and topdressing. Ecol. Eng. 75, 24–32, https://doi.org/10.1016/j.ecoleng.2014.11.034 (2015).

Cheng, W. et al. Forage rice varieties Fukuhibiki and Tachisuzuka emit larger CH4 than edible rice Haenuki. Soil Sci. Plant Nutr. 64(1), 77–83, https://doi.org/10.1080/00380768.2017.1378569 (2017).

Zou, J., Liu, S., Qin, Y., Pan, G. & Zhu, D. Sewage irrigation increased methane and nitrous oxide emissions from rice paddies in southeast China. Agr. Ecosyst. Environ. 129, 516–522, https://doi.org/10.1016/j.agee.2008.11.006 (2009).

Riya, S. et al. Effects of N loading rate on CH4 and N2O emissions during cultivation and fallow periods from forage rice fields fertilized with liquid cattle waste. J. Environ. Manage. 161, 124–130, https://doi.org/10.1016/j.jenvman.2015.06.051 (2015).

Joint FAO/WHO Food Standards Programme, Codex Committee on Contaminants in Foods. Working Document for Information and Use in Discussions Related to Contaminants and Toxins in the GSCTFF. Eleventh Session, Rio de Janeiro, Brazil, 3-7 April 2017; http://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FMeetings%252FCX-735-11%252FWD%252Fcf11_INF01x.pdf.

Food and Agricultural Materials Inspection Center. Standard values of harmful substance in feed http://www.famic.go.jp/ffis/feed/r_safety/r_feeds_safetyj22.html#metals (In Japanese) (2019).

Ata-Ul-Karim, S. T. et al. Non-destructive Assessment of Plant Nitrogen Parameters Using Leaf Chlorophyll Measurements in Rice. Front. Plant Sci. 7 https://doi.org/10.3389/fpls.2016.01829 (2016).

Yoshida, S. Fundamental of Rice Crop Science. International Rice Research Institute, Los Baños, Laguna, Philippines, 269pp (1981).

Sun, H., Zhang, H., Wu, J., Jiang, P. & Shi, W. Laboratory Lysimeter Analysis of NH3 and N2O Emissions and Leaching Losses of Nitrogen in a Rice-Whear Rotation System Irrigated with Nitrogen-Rich Wastewater. Soil Sci. 178(6), 316–323, https://doi.org/10.1097/SS.0b013e3182a35c92 (2013).

Ida, M., Ohsugi, R., Sasaki, H., Aoki, N. & Yamagishi, T. Contribution of Nitrogen Absorbed during Ripening Period to Grain Filling in a High-Yielding Rice Variety, Takanari. Plant Prod. Sci. 12(2), 176–184, https://doi.org/10.1626/pps.12.176 (2009).

Swamy, B. P. M. et al. Advances in breeding for high grain Zinc in rice. Rice 9, 49, https://doi.org/10.1186/s12284-016-0122-5 (2016).

Aulakh, M. S., Wassmann, R., Bueno, C., Kreuzwieser, J. & Rennenberg, H. Characterization of Root Exudates at Different Growth Stages of Ten Rice (Oryza sativa L.) Cultivars. Plant Biol. 3(2), 139–148, https://doi.org/10.1055/s-2001-12905 (2001).

Denmead, O. T., Freney, J. R. & Simpson, J. R. Nitrous Oxide Emission During Denitrification in a Flooded Field. Soil Sci. Soc. Am. J. 43(4), 716, https://doi.org/10.2136/sssaj1979.03615995004300040017x (1979).

Smith, C. J., Brandon, M. & Patrick, W. H. Jr. Nitrous oxide emission following Urea-N fertilization of Wetland rice. Soil Sci. Plant Nutr. 28(2), 161–171, https://doi.org/10.1080/00380768.1982.10432433 (1982).

Sun, H., Lu, H. & Feng, Y. Greenhouse gas emissions vary in response to different biochar amendments: an assessment based on two consecutive rice growth cycles. Environ. Sci. Pollut. Res. 26(1), 749–758, https://doi.org/10.1007/s11356-018-3636-0 (2018).

Zhang et al. Effect of biochar amendment on yield and methane and nitrous oxide emissions from a rice paddy from Tai Lake plain, China. Agr. Ecosyst. Environ. 139, 469–475, https://doi.org/10.1016/j.agee.2010.09.003 (2010).

Jones, D. B. Factors for converting percentage of nitrogen in foods and feeds into percentage of protein. US Department of Agriculture, Washington, DC, USA (1941).

Method of sediment quality. Ministry of the Environment, Tokyo, Japan (in Japanese) (2001).

Minamikawa, K., Tokida, T., Sudo, S., Padre, A. & Yagi, K. Guidelines for measuring CH4 and N2O emissions from rice paddies by a manually operated closed chamber method. National Institute for Agro-Environmental Sciences, Tsukuba, Japan (2015).

IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T. F. et al. Eds; Cambridge University Press: Cambridge, United Kingdom and New York, NY, USA; 1535 pp.

Acknowledgements

This study was partially supported by Ministry of Land, Infrastructure, Transportation and Tourism, Japan. We also thank Bureau of Sewerage System, Tsuruoka City Government for providing treated municipal wastewater for our experiment.

Author information

Authors and Affiliations

Contributions

L.D.P. and T.W. conceived the experiment, L.D.P and D.V.P. conducted the experiment, L.D.P. analysed the results, S.M., F.T., N.K. and Y.S. provided resources, L.D.P prepared a manuscript draft, T.W. and L.D.P. edited the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Phung, L.D., Pham, D.V., Sasaki, Y. et al. Continuous Sub-Irrigation with Treated Municipal Wastewater for Protein-Rich Rice Production with Reduced Emissions of CH4 and N2O. Sci Rep 10, 5485 (2020). https://doi.org/10.1038/s41598-020-62247-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-62247-w

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.