Abstract

Polymeric nanofibers fabricated by electrospinning either blank (PVA) or loaded with minoxidil sulphate have yielded optimum fibers with an average diameter 273 nm, and 511 nm, respectively. Thermal analysis of nanofibers indicated no chemical interaction. The NMR spectrum confirmed stability of nanofiber as there were no interactions between functional groups. Prepared nanofibers showed a 47.4% encapsulation efficiency and 73% yield. In vitro drug release of minoxidil sulphate from nanofiber exhibited an initial burst release followed by a slower release pattern. Stability studies revealed that minoxidil nanofiber was stable if stored at room temperature and protected from light with only loss of 9.6% of its nominal concentration within 6 months. As a result, the prepared solid/colored formula serves as an ideal formulation for such instable drug in liquid formula taking the advantage of the attractiveness of beauty colored coverage, and the simple, and non-tousled application.

Similar content being viewed by others

Introduction

Electrospund nanofibers is widely used in a number of applications owing to their distinctive properties, such as high surface to volume ratio, high absorbency, tunable physicomechanical properties, easy adjustment of polymeric solutions and process parameters to produce anticipated fiber morphology and mechanical properties, and broad variety of naturally occurring and synthetic polymers that can be electrospun into nanofibers1,2,3. Regarding biological perspective, the human tissues and organs consists of native extracellular matrix (ECM) network of micro/nano-scaled fibers containing protein and glycosaminoglycan that offer support to resident cells and control cellular activities1. Owing to the resemblance between the fibrous architecture of native ECM and electrospun nanofibers, nanofibers were exploited in a number of biomedical applications; namely tissue-engineering, drug delivery, cosmetics, as well as biosensors1,2,4.

Minoxidil, applied topically, is widely used for the treatment of androgenic alopecia5, a hair loss in men and women6,7. It was reported that about 40% of men experience hair regrowth after 3–6 months8,9. Minoxidil must be applied for an indefinite period for continuous care of existing hair follicles and the repair of any encountered hair regrowth6,10.

Minoxidil, like all medications, has common side effects that are generally minor and in many cases are well tolerated. Depending on the formulation, these effects include: burning sensation, skin irritation at or near the treated area, as well as unwanted hair growth on different parts of the body have been reported11,12. Minoxidil sulphate is a potassium channel opener, causing hyperpolarization of cell membranes. Additionally, it can widen the blood vessels and open the potassium channels, thus allowing more oxygen, blood, and nutrients to the follicles13. The mechanism might promote follicles in the telogen phase to shed, which are then replenished by thicker hairs in a new anagen phase. Dose-response studies showed that minoxidil sulphate is more potent (nearly 14 folds) than minoxidil in stimulating hair follicles6.

Recently, there are varieties of cosmetics fibers that can conceal the thin hair areas but without any therapeutic value. In addition, most minoxidil formulations have disadvantages including instability, and messy application of the available liquid formula as well as its high coast11,12. Therefore, this research aims to prepare a colored nanofiber loaded with minoxidil sulphate that with constant use will help regrow hair and at the same time offers easy application of solid stable formula that will conceal the thin area during restoring hair regrowth of this area.

Results and Discussion

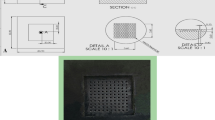

Morphology of nanofibers

The optimized fibers with desirable characteristics (average diameter of 273 nm) were produced by electrospinning of PVA solution using 5% polymer concentration under an applied electric potential of 15 kV and over a TCD of 20 cm. High density of the fiber, along with the formation of beads at regular intervals. No droplet formation observed at flow rates increased to 25 µl/min. This finding clearly indicated that with an increase in flow rate, at a high electrical force, and low PVA concentration, resulting in the stream formation of fibers and no drops observed. The brown color added to the polymeric solution and subjected to elecrtospun showed a faint color, that’s why more color powder was added after drying the fibers to achieve the required color to provide the desirable concealing to the applied area. Figure 1 showed SEM images of blank (PVA) and minoxidil sulphate-loaded nanofibers, respectively.

Nanofibers specifications

The chemical structure of minoxidil sulfate and the NMR spectra of pure minoxidil sulphate, PVA polymer and electrospun nanofibers both blank (PVA nanofibers) and loaded with minoxidil sulphate are shown in Fig. 2(A–F, respectively). NMR spectroscopy was used to confirm the encapsulation of the drug by PVA nanofiber. 1H and 13C NMR spectra of pure minoxidil sulphate Fig. 2(B,C) and PVA nanofiber Fig. 2(D,E) were obtained and compared with the minoxidil-loaded PVA nanofiber. The following 1H NMR peaks of minoxidil sulphate were observed in the loaded 1H NMR spectrum Fig. 2(F): 1.47, 1.58, 3.43, 5.30, 7.25 and 7.33. Moreover, the 13C NMR peaks of the drug 24.01, 25.09, 44.88, 72.26, 155.97, 153.61 and 156.74 were detected in the loaded nanofiber spectrum Fig. 2(G). Similarly, 1H NMR spectrum of the pure PVA showed that the characteristic peaks of methylene (1.24–1.56), methine (3.74–3.94) and hydroxyl (4.18–4.74) protons were detected in the loaded nanofiber as well. In addition, the peaks of methylene (44.52–46.37) and methine (63.40–68.20) carbons in 13C NMR spectrum appeared in the loaded nanofiber spectrum. All of these findings confirmed that minoxidil sulphate was encapsulated successfully by PVA nanofiber.

NMR spectra: 1H and 13C respective NMR spectra of pure minoxidil sulphate (B and C), and for PVA nanofiber (D,E). 1H NMR peaks of minoxidil sulphate were observed in the loaded PVA (F), 13C NMR peaks of minoxidil sulphate were observed in the loaded PVA (G). (A) Is the chemical structure of minoxidil sulfate.

DSC thermograms of PVA-minoxidil sulphate are depicted in Table 1. The loaded nanofibers prepared by electrospinning. DSC provides information about decomposition and changes in heat capacity, melting, or crystallization of the drug. Distinguished peaks were observed at 100.63 °C, as a characteristic peak of PVA, and minoxidil sulphate showed characteristic peak observed at 169.63 °C.

The DSC of loaded nanofiber depicted the presence of minoxidil sulphate in the nanofibers; indicating stable nanofibers with no interaction between the drug and the PVA. Furthermore, the peaks have also shown not only a stable polymer, but also confirmed the stability of the drug in the nanofibers. On the other hand, the minor decrease in the melting point of the drug in the electrospun nanofibers may be ascribed to the amorphous state of the drug. The distinguished peak of the drug and polymer further indicate that there is no chemical interaction between the drug and polymer.

HPLC analysis of minoxidil sulphate

Selectivity is the ability of the method to distinguish and quantify the analyte in the presence of endogenous interferences. A representative chromatogram of spiked minoxidil sulphate 0.5 µg/ml is depicted in Fig. 3. The peak of minoxidil sulphate was well resolved, with retention times of approximately 1.62 min for minoxidil sulphate. The total chromatographic run time was 5.0 min.

The calibration curves were all linear with a coefficient of determination (r2) > 0.99 over the concentration range of 0.25–0.75 µg/ml on all tested concentrations. The calibration curve was Y = 6864.9 × −753.84 with correlation coefficient r = 0.9996, where X represents the concentration of minoxidil sulphate and Y is the area under the peak area ratio of the drug. The results implied that the method developed was linear over the specified range.

Figure 4 is showing the representative chromatograms of pure sample (minoxidil sulphate (A)), sample spiked with 0.5 µg/ml minoxidil sulphate (B), while the chromatogram for formulated minoxidil sulphate nanofiber is shown in Fig. 4(C). The peak of minoxidil sulphate was well resolved, with retention times of nearly 3.28 ± 0.14 min for the drug. The total chromatographic run time was 5 min. Compared to spiked released samples, Fig. 4(A,B) showed no significant peaks, at the retention times of the drug; which proves the assay specificity. It is well observed also that the representative chromatogram of real formulation sample showed similar chromatographic behavior to quality control samples.

Drug entrapment efficiency

The %EE of the minoxidil sulphate in the nanofiber showed minimum EE for loaded minoxidil sulphate of 47.4% which is considered suitable for delivering a therapeutically active dose. However, the yield of minoxidil sulphate-nanofiber was 73%.

In vitro release study

The in vitro release study of minoxidil sulphate was conducted in phosphate buffer14 due to its ability to maintain sink conditions. The drug release pattern for 24 h is shown in Fig. 5. The profile indicated biphasic release of minoxidil sulphate from the nanofiber. The release pattern indicated that in the initial phase (5 h, r > 0.9), there was a rapid release of about 48% according to the formulation followed a slow phase from 7 to 24 h where about 20% was released. From the results obtained, it was found that there no lag time which indicates a burst in drug release during the first 15 min (about 4–10%) of the adsorbed drug on the nanofiber.

Stability study of the prepared formulations

Minoxidil sulphate was stable in the processed samples held in the autosampler at 25 °C for 24 h with mean calculated values within 3.2% of the nominal concentration (Fig. 6). However, the samples lost only 9.6% (RSD of 4.2%) of its nominal concentration within 6 months if protected from light in the autosampler. Therefore, it is stable drug formulation and can be kept at room temperature.

The freeze–thaw temperature cycles did not significantly (p > 0.05) affect the stability of Minoxidil sulphate in all three cycles, even after 72 h, with the mean calculated values within 2.3% of the nominal concentration. Expectedly, exposing minoxidil sulphate to drastic conditions revealed that Minoxidil sulphate unstable in 2 M HCl solution and in alkaline solution, losing only 54.2% (RSD of 7.3%) of its nominal value.

Conclusion

Based on several previous studies, the applicability and efficacy of minoxidil sulphate in restoring hair growth in both male and female who suffer from alopecia is well established and proved. However, the available formulation in-use are all in liquid unstable formula, and vastly expensive. Knowing the advantage of nanofibers prepared by electrospinning and raw materials polyvinylpyrrolidone (PVP) and minoxidil are inexpensive, and solid formula generally exhibit high stability. It is believed that this work will be valuable to produce solid nanoformula of easy use and inexpensive. The resultant minoxidil sulphate nanofibers were successfully prepared with water soluble and a biocompatible polymer, polyvinyl alcohol with desirable characteristics. The fabricated nanofibers revealed an acceptable average diameter for both unloaded and loaded fibers. Additionally, the physicochemical compatibility studies of nanofibers specified compatibility between minoxidil and used polymer and the prepared nanofibers were stable at room temperature. Therefore, the designed PVA-minoxidil sulphate loaded nanofiber serves as a potential stable solid nanoformula to be used for hair restoring as previously prov and it’s shading color as beauty coverage upon application.

Material and Methods

Materials

Polyvinyl alcohol PVA (1700–1800) was acquired from Loba Chemie Pvt. Ltd. (Mumbai, Indi), and minoxidil sulphate was obtained from Xi’an Fengzu Biological Technology, Co., Ltd., (Xi’an, China). Powdered Food Color of brown color PF04 was ordered from AmeriColor (Placentia, CA, USA).

Preparation of polymer solutions

The polymer solutions were prepared using a modified version of a previously reported research work in 2016 by Sharma et al.15. In brief, PVA solutions (aqueous) of 5%, was made by dissolving of PVA in 100 ml of deionized water, with stirring for 3 h using magnetic stirrer (PTFE, SterliTech Co., North Chesterfield, VA, USA). Once PVA clear solutions achieved the result mixture of polymer was named blank nanofiber. The solution was then subjected to electrospinning (NaBond Technologies Co., Ltd., ShenZhen, Guangdong, China)2,3. Minoxidil sulphate (5%) was prepared by dissolving the calculated amount in ethanol that was then added dropwise and mixed by stirring with the above polymeric solution and the result formula was named loaded nanofiber.

Preparation of nanofiber

Two different subsets of solutions were prepared and subjected to electrospinning, (a) 5% PVA, and (b) 5% PVA to be loaded with 5% minoxidil sulphate as reported15. The solutions were put into a 5-ml syringe fitted to a needle with a tip diameter of 22 gauges, and the syringe was then placed in the electrospinning apparatus. The polymeric solution at flow rate of 25 µl/min (voltage of 15 kV) was delivered using a syringe pump. The collector was covered with an aluminum foil of (23 cm \(\ast \) 24 cm) on which the nanofibers were collected. After collection, the yielded nanofibers were dried overnight at room temperature.

Coloring the nanofiber

The food color used does not contain any nuts products and was choose as it is safe and approved for human use. The color agent was mixed with polymeric solution and also added to the final solid fibers.

Electrospun nanofibers characterization

Morphological evaluation

The size and shape of the electrospun fibers were determined by scanning electron microscopy (SEM) JSM-5510 (Jeol Ltd., Tokyo, Japan) equipped with a digital camera, at 15 kV accelerating voltage. Fibers were examined in different positions to estimate the electrospun fibers diameters15. A segment of the fibers was positioned on the sample holder, then sputter-coated with platinum palladium (Au/Pd) using a vacuum evaporator (Edwards)15,16.

Physicochemical compatibility studies of nanofibers

1H and 13C and NMR spectra were recorded in deuterated dimethyl sulfoxide (DMSO-d6) which was obtained from Cambridge Isotope Laboratories on a Bruker 700 MHz NMR spectrometer (Cambridge Isotope Laboratories, Inc., Tewksbury, MA, USA) using tetramethylsilane as an internal standard. Bruker Topspin software (Bruker BioSpin Corporation, Billerica, MA, USA) was used to analyze the NMR spectra generated17.

Differential scanning calorimetry of minoxidil-loaded nanofibers

Minoxidil-loaded polymeric nanofibers were thermally analyzed using differential scanning calorimetry (DSC). The DSC was performed using a Perkin Elmer Diamond hyper differential scanning calorimetry (Perkin Elmer, USA). The samples were loaded in the DSC pan and sealed, then heated from 25 to 350 °C at a rate of 10 °C/min under the flow of nitrogen gas. Melting temperature was determined from the heating curve15,18.

High performance liquid chromatography (HPLC) assay for minoxidil sulphate

A modified HPLC method for minoxidil published by Rudrapal et al.19 was utilized in this study. Minoxidil sulphate concentration was quantified using a Waters HPLC system. The system consists of a Waters 2707 autosampler delivery system (Waters Inc., Bedford, MA, USA), and a symmetry C18 column (4.6 ×1.0 cm) packed with 5-µm spherical particles (Waters Inc., Bedford, MA, USA). The mobile phase contains of methanol:phosphate buffer pH 3.0 (60:40, v/v) at a flow rate of 1.0 ml/min. The mobile phase was prepared daily during the study, filtered through a 0.22-µm Millipore filter and degassed under vacuum. The volume injection was 10 µl, and the detection was performed at 250 nm at a run time of 4 min, and the HPLC system was operated at 40 °C. Data were analysed using an Empower Pro chromatography manager data collection system (Waters Corporation, Milford, MA, USA).

Standard and sample solutions

Stock solutions containing 250 mg of drug in mobile phase were stored in 4.0 ml glass vials at −20 °C. Standard calibration curve (n = 3) ranging from 0.25, 0.357, 0.5, 0.635, and 0.75 µg/ml was prepared on a daily basis to estimate the unknown minoxidil sulphate concentration for the determination of drug entrapment efficiency and drug release. Standards were transferred to glass autosampler vials with pre-slit septum, where 10 µl was injected into the HPLC system for analysis.

Drug entrapment efficiency and polymeric nanofiber yield determination

Minoxidil sulphate drug content in the nanofibers were precisely determined. Weighed nanofiber (10 mg) dissolved in mixture of methanol:water (1:20 v/v). Then, the solution was stirred for 60 min to assure complete dissolution of the samples. An aliquot (1.25 ml) of the stock solution was transferred into a glass autosampler vial with pre-slit septum and injected (30 µl) into the HPLC instruments using a developed validated HPLC method20. The minoxidil sulphate concentration was calculated using the following equations:

In vitro drug release study

The in vitro release test was performed using US Pharmacopeia XXXII dissolution apparatus 1 (basket). The dissolution was performed in 900 ml of phosphate buffer pH 7.2 ± 0.1 at 75 rpm and the temperature was maintained at 37 ± 0.5 °C. A sample of Minoxidil beads equivalent to 10 mg of Minoxidil was used. At appropriate time intervals (0.5, 1, 3, 5, 7 and 24 h), 2.0 ml samples were withdrawn from each vessel, mixed with 5.0 ml of methanol: water (75:25)14,20,21,22. The solution was filtered through a 0.22 µm Millipore membrane filter and analyzed using HPLC assay20. The volume was replaced each time with 2 ml of fresh medium and was kept at 37 ± 0.5 °C to maintain a sink condition21.

Stability study of released minoxidil sulphate from the formulation

Stability studies (freeze-thaw) of the quality control samples were assessed by exposing samples to different cycles, namely: three freeze (−20 °C) and thaw (room temperature) after 0, 72 h, 1 week, 2 weeks, 4 weeks, 3 months as well as after 6 months of preparation (nanofibers), which were stored at −20 °C. The processed samples were kept in vials sealed with parafilm at 25 °C. Similarly, minoxidil sulphate was exposed to a drastic condition, in an amber volumetric glass, by diluting it in water, 1 M solution of NaOH and 2 M HCl solution (n = 6). The area under the peak (AUP) of minoxidil sulphate was measured as the zero AUP. Each solution was carefully heated to boiling and left to cool down and minoxidil sulphate AUP after boiling was measured15,19.

References

Kai, D., Liow, S. S. & Loh, X. J. Biodegradable polymers for electrospinning: towards biomedical applications. Materials Science and Engineering: C 45, 659–670 (2014).

Wang, Y. et al. Electrospun composite nanofibers containing nanoparticles for the programmable release of dual drugs. Polymer journal 43(5), 478 (2011).

Ramakrishna, S. et al. Electrospun nanofibers: solving global issues. Materials today 9(3), 40–50 (2006).

Yoo, H. S., Kim, T. G. & Park, T. G. Surface-functionalized electrospun nanofibers for tissue engineering and drug delivery. Advanced drug delivery reviews 61(12), 1033–1042 (2009).

Kelly, Y., Blanco, A. & Tosti, A. Androgenetic alopecia: an update of treatment options. Drugs 76(14), 1349–1364 (2016).

Buhl, A. E. et al. Minoxidil sulfate is the active metabolite that stimulates hair follicles. Journal of Investigative Dermatology 95(5), 553–557 (1990).

Varothai, S. & Bergfeld, W. F. Androgenetic alopecia: an evidence-based treatment update. American journal of clinical dermatology 15(3), 217–230 (2014).

Purnak, T., Senel, E. & Sahin, C. Liquid formulation of minoxidil versus its foam formulation. Indian journal of dermatology 56(4), 462 (2011).

Goren, A. et al. Clinical utility and validity of minoxidil response testing in androgenetic alopecia. Dermatologic therapy 28(1), 13–16 (2015).

Gugle, A. S. et al. Comparative Study of Efficacy of Topical Minoxidil 5% and Combination of Topical Minoxidil 5%, Topical Azelaic Acid 1.5% and Topical Tretinoin 0.01% on the Basis of Dermoscopic Analysis in Androgenetic Alopecia. MVP. Journal of Medical Sciences 2(2), 90–99 (2015).

Dubrey, S., VanGriethuysen, J. & Edwards, C. A hairy fall: syncope resulting from topical application of minoxidil. BMJ case reports 2015, bcr2015210945 (2015).

Rossi, A. et al. Minoxidil use in dermatology, side effects and recent patents. Recent patents on inflammation & allergy drug discovery 6(2), 130–136 (2012).

Meisheri, K. D., Cipkus, L. A. & Taylor, C. J. Mechanism of action of minoxidil sulfate-induced vasodilation: a role for increased K+ permeability. Journal of Pharmacology and Experimental Therapeutics 245(3), 751–760 (1988).

Rani, D. et al. Formulation development and in-vitro evaluation of minoxidil bearing glycerosomes. Am. J. Biomed. Res 4, 27–37 (2016).

Sharma, R. et al. Development, optimization and evaluation of polymeric electrospun nanofiber: A tool for local delivery of fluconazole for management of vaginal candidiasis. Artificial cells, nanomedicine, and biotechnology 44(2), 524–531 (2016).

Beachley, V. & Wen, X. Effect of electrospinning parameters on the nanofiber diameter and length. Materials Science and Engineering: C 29(3), 663–668 (2009).

Sharma, Y. et al. Fabrication of conducting electrospun nanofibers scaffold for three-dimensional cells culture. International journal of biological macromolecules 51(4), 627–631 (2012).

Kaur, S. et al. The characterization of electrospun nanofibrous liquid filtration membranes. Journal of Materials Science 49(18), 6143–6159 (2014).

Rudrapal, M. et al. Development and Validation of RP-HPLC Method for Simultaneous Estimation of Minoxidil and Aminexil in Topical Formulation. Asian Journal of Chemistry 28(1), 157 (2016).

Ahmed, F. E., Lalia, B. S. & Hashaikeh, R. A review on electrospinning for membrane fabrication: challenges and applications. Desalination 356, 15–30 (2015).

Akhgari, A. et al. Indomethacin electrospun nanofibers for colonic drug delivery: In vitro dissolution studies. Colloids and Surfaces B: Biointerfaces 152, 29–35 (2017).

Kajdič, S., Vrečer, F. & Kocbek, P. Preparation of poloxamer-based nanofibers for enhanced dissolution of carvedilol. European Journal of Pharmaceutical Sciences 117, 331–340 (2018).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding this work through research group NO (RGP- 1438–003).

Author information

Authors and Affiliations

Contributions

F.S.A. conceived and designed the experiments, write and revised the paper, and led the project and performed electrospun experiments and contributed reagents and materials. F.Y.A. performed experiments, analyzed the data, and wrote the initial paper. H.M.A. performed the NMR experiments, analyzed the data. B.T.A. designed the HPLC experiments and analyzed the data. E.K.E. performed DSC measurement and analyzed the data. A.A. analyzed the data and revised the paper. H.G.A. analyzed the data and revised the paper. I.A.A. analyzed the data and revised the paper. All authors confirmed the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sfouq Aleanizy, F., Yahya Alqahtani, F., Alkahtani, H.M. et al. Colored Polymeric Nanofiber Loaded with Minoxidil Sulphate as Beauty Coverage and Restoring Hair Loss. Sci Rep 10, 4084 (2020). https://doi.org/10.1038/s41598-020-60863-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-60863-0

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.