Abstract

β-stabilized Ti-alloys present several unexplored and intriguing surprises in relation to orthorhombic α″ phases. Among them are (i) the diffusion-controlled formation of transitional α″iso, α″lean and α″rich phases and ii) the highly anisotropic thermal expansion of martensitic α″. Using the prototypical Ti-Nb system, we demonstrate that the thermodynamic energy landscape reveals formation pathways for the diffusional forms of α″ and may lead to a stable β-phase miscibility gap. In this way, we derive temperature-composition criteria for the occurrence of α″iso and resolve reaction sequences during thermal cycling. Moreover, we show that the thermal expansion anisotropy of martensitic α″ gives rise to directions of zero thermal strain depending on Nb content. Utilizing this knowledge, we propose processing routes to achieve null linear expansion in α″ containing Ti-alloys. These concepts are expected to be transferable to other Ti-alloys and offer new avenues for their tailoring and technological exploitation.

Similar content being viewed by others

Introduction

β-stabilized Ti-alloys provide the basis for a multitude of future applications in biomedicine and aeronautics1,2. Their low elastic moduli, shape memory and superelastic effects, blended with pronounced hardenability and attractive ductility captivates the attention of engineers and material scientists alike. Despite their seemingly simple phase diagrams β-stabilized systems, such as Ti-Nb (Fig. 1) show a vast array of phase transformations and transient states, attributed to the extensive α-β two-phase field. The ensuing exceptionally pronounced metastability necessitates large diffusional compositional changes and extended aging durations (up to many weeks or months) to reach (meta)stable equilibrium.

Calculated Ti-Nb phase diagrams. (a) Adapted from Zhang, Liu and Jin22, (b) calculated using the TiGen database24. The stable α-β diagram is shown in blue and on top of it the metastable ω-β diagram is drawn in green. Solid lines indicate phase boundaries if diffusion is allowed and dashed lines those without diffusion. The crystal structures are illustrated as insets in (a).

The nature of compositional fluctuations decisively influences the refinement of precipitation products3,4,5 and the β ↔ α″ martensitic transformation6. For instance, detailed (micro)structural studies uncovered non-conventional transformation pathways for α-precipitation3,7,8,9. Of particular note is the discovery of transitional α″-like structures (α″iso, α″lean, α″rich) during martensite decomposition and prior to α precipitation7,8,9,10,11. Furthermore, recently extraordinarily large anisotropic thermal expansion was revealed in α″ martensite of the Ti-Nb system9,12.

The successful development of novel structural and functional Ti-alloys with bespoke mechanical and shape memory behaviour depends critically on accurate descriptions of precipitation and decomposition processes. In addition, key for dimension critical components is the ability to control thermal expansion13,14. Nowadays, the core challenge in developing new Ti-alloys lies in unravelling the complexity of phase reactions and in deriving robust thermodynamic and structural descriptions to assist the alloy design process. Empirical trial-and-error methods still prevail today, nevertheless systematic attempts are made to develop and employ predictive capabilities through ab-initio15,16,17,18,19, phase-field20,21 and CALPHAD22,23,24,25,26,27 methods.

The present treatment takes a novel perspective to predict temperature-induced structural changes and phase transformations in Ti-Nb alloys from the Gibbs free energy landscape with primary focus on martensitic alloy formulations. We calculate the binary Ti-Nb phase diagram from the recently published TiGen database24. It turns out, the TiGen formulation differs substantially from an earlier formulation22 by giving rise to a stable miscibility gap in the β-phase. Informed by the Gibbs free energetics we explore precipitation pathways involving diffusion-mediated α″ phases. In this way, we delineate and compare against each other α″iso formation and α″ martensite decomposition. By correlating the predicted pathways with experimental observations from synchrotron X-ray diffraction (SXRD) and Differential Scanning Calorimetry (DSC) these results can be conclusively rationalized, evidencing the efficacy of the presented strategy. In addition, we then examine the thermal expansion anisotropy of α″ martensite and propose 3 approaches to control thermal expansion in macroscopic polycrystalline Ti-alloy components by exploiting the thermal anisotropy on the single crystal level. These outcomes may guide the design of next-generation Ti-alloys and parts manufactured thereof.

Results

The quest for a faithful thermodynamic description for Ti-Nb

Based on the recent assessment by Yan and Olson24 we calculated the pertaining phase diagram (see Methods for details) and compare the results to the assessment by Zhang, Liu and Jin22 in Fig. 1. Crucially, in contrast to the assessment by Zhang, Liu and Jin22 a stable miscibility gap is predicted in the β-phase, similar to Ti-V, Ti-Mo and Ti-W. A stable miscibility gap is contingent on adequately high Gibbs free energies of competing phases under consideration (α and ω in the present case) in addition to the signs of the Redlich-Kister coefficients βL > 0, Eq. (1). On the other hand, the emergence of a metastable miscibility gap, as present in Fig. 1a, depends solely on the signs of the Redlich-Kister coefficients, i.e. if one βL is positive phase separation occurs. Therefore, two factors are responsible for the stable miscibility gap in Fig. 1b compared to Fig. 1a. (i) the depressed α-β transus at low Nb content ascribed mainly to the relatively larger αL0 and (ii) the larger (positive) β-interaction parameters (Table 1). Because βL1 > 0 the miscibility gap is asymmetric and shifted towards the Nb-rich side. Further, the ω-α equilibrium in Ti in Fig. 1b is 35 K lower than in Fig. 1a, resulting in a reduced temperature for the eutectoid point β1 → ω + β2. Both diffusionless equilibrium temperatures T0β-α and T0β-ω are lower than in Fig. 1a, especially T0β-ω is strongly suppressed in the TiGen database relative to22. The existence of a stable miscibility gap in Ti-Nb, as predicted in Fig. 1b and hypothesized early on28, lacks definite experimental verification and remains speculative. We note that the underlying TiGen database24 was optimized using low-temperature data and, as the database authors remark, may not be accurate at high temperature. Therefore, we base the following treatment on the thermodynamical Ti-Nb assessment by Zhang, Liu and Jin (22, Fig. 1a). This description has proven itself suitable across a wide temperature range in previous studies29,30.

Gibbs energetics: ω-α cascade vs. α″iso formation vs. α″ decomposition

Figure 2 shows the free enthalpy landscape of α, β and ω-phases for Ti-Nb depending on temperature and composition based on the description by Zhang, Liu and Jin22. Phase transformations, may they be martensitic or diffusion-based, and associated precipitation processes are rooted upon the relative stability of the phases involved; the free enthalpy surfaces in Fig. 2a delineate the corresponding energetics for Ti-Nb.

Free enthalpy landscape of Ti-Nb α, β and ω-phases calculated using the thermodynamic parameters in Zhang, Liu, Jin22. (a) Overview of effect of temperature on the free energy relations. (b) Sections of the free enthalpy landscape at constant temperatures over the full composition space. (c) Illustrations of ω-assisted α-precipitation, α″iso formation and α″ decomposition. Grey dashed straight lines indicate (meta)stable tie lines. Arrows show the system’s path from the metastable initial state towards (meta)stable equilibrium.

Figure 2b illustrates snapshots of the free enthalpy curves for selected temperatures. Informed by these, it is straight-forward to identify energetically favourable transformation sequences (i.e. likely reactions): Any likely reaction is synonymous with a spontaneous reaction and as such reduces the free enthalpy. On quenching a given alloy from the β-phase field, the phase exhibiting the lowest free enthalpy at the quench end temperature forms. When re-heated, the quenched metastable state is subject to contending compositional instabilities depending on the β-stabilizer content, temperature and exposure time. These instabilities are driven by gradual reductions in the free enthalpy facilitated by compositional changes of the constituents (α-, ω-, β-phases, martensites α′ and α″). Depending on composition and temperature the Gibbs free energy landscape forecasts several different precipitation and decomposition processes. Below we concentrate our discussion on 3 of them: (i) the precipitation of ωiso and α, labelled here ω-α cascade, (ii) α″iso-formation and (iii) α″ decomposition; Fig. 2c illustrates the underlying Gibbs free energetics.

ω-α cascade: Metastable β, produced by quenching or martensite reversion, may precipitate ωiso and α phases to reach equilibrium (Fig. 2c left). This precipitation cascade (with and without intermediate formation of ωiso) can be triggered almost within the entire α-β two phase field. It is an already well-established route for material engineers to strengthen β-stabilized Ti-alloys31,32,33. Due to its importance and relatively easy triggerability it is being widely researched from experimental and theoretical (modelling) point of views5,20,27,34,35.

α″iso-formation: If intermediate ω formation is energetically unfavourable, orthorhombic α″iso may form instead before α appears. While a handful of studies observed α″iso in different β-stabilized Ti-alloys7,11,36,37, the present treatment provides for the first time an intuitive explanation for its occurrence based on the system’s free energy landscape. This situation is illustrated in Fig. 2c (centre). When ω is energetically unfavourable, α″iso provides a low energy pathway for Nb-depleted domains to transition from the β-phase to α-phase. Quite clearly, occurrence of α″iso is mediated by the diffusional flux of Nb in contrast to the diffusionless formation of α″ martensite during quenching. Recent in-situ measurements of the α″iso lattice parameters have revealed that they gradually evolve into those of hexagonal α9. α″iso is therefore a partially transformed intermediate structure found between the reaction end members, parent β and product α. The displacive component that defines the orthorhombic geometry of α″iso is linked in this way to its specific chemistry, in a similar manner as was proposed for the {222}β plane collapse leading to ωiso38. In this sense, it seems justified to classify the formation of α″iso as a mixed-mode diffusive-displacive phase transformation akin to ωiso formation from β38. It is important to point out that to date no independent thermodynamic description for α″ exists and the α″G curves in Fig. 2c consequently represent educated guesses as detailed below. For purposes of calculating T0β-α″ the Gibbs free energy of α″ is, for the lack of a more suitable formulation, commonly approximated through α″G ≅ αG (24,22 and Fig. 1). While this approach is tenable for low solute content where α″ strongly resembles α structurally, it becomes contentious at high solute content where α″ more closely resembles β. Instead, at high solute content we propose to approximate α''G by βG + A where A is a positive value reflecting the difference between α″G and βG in concentrated alloys. This ensures that βG < α″G in martensite forming alloys and agrees with the free energy representation put forward by Davis, Flower and West39. At this point we would like to draw attention to the behaviour of α″G at the intersections with αG and βG. Early and recent studies have shown that the lattice parameters and specific volume vary smoothly across the α′-α″ transition at \({x}_{0}^{\alpha -{\alpha }^{{\prime\prime} }}\) and that hexagonal α′ and orthorhombic α″ do generally not coexist23,39,40,41,42. In contrast, the transition from β to α″ around \({x}_{0}^{\beta -{\alpha }^{{\prime\prime} }}\) involves a strong disruption in crystal symmetry that carries forward an expansion of the specific volume23,42. Thus, an accurate thermodynamic depiction of the experimentally observed (dis)continuity requires a smooth behaviour (equal slopes) of αG and α″G at \({x}_{0}^{\alpha -{\alpha }^{{\prime\prime} }}\) and a discontinuous behaviour (unequal slopes) of α″G and βG at \({x}_{0}^{\beta -{\alpha }^{{\prime\prime} }}\). Metastable β may then - once kinetics permit - nucleate α″iso which then continuously evolves into α by rejection of Nb.

From the thermodynamic landscape we derive a temperature criterion in terms of a necessary condition for α″iso occurrence. Assuming that α″iso formation is conditional on α″G < ωG around \({x}_{0}^{\alpha -\beta }\), the minimum temperature for α″iso formation is the temperature for which the Gibbs free energies αG, βG and ωG at \({x}_{0}^{\alpha -\beta }\) are identical, i.e. they intersect at a single point. This temperature is 631 K (358 °C) as derived from22. Above 631 K, ω is energetically not favoured relative to α″ and the lowest energy path from β to α leads via α″iso. Further, the alloy content of β must be above \({x}_{0}^{\beta -{\alpha }^{{\prime\prime} }}\). As we will see later these conditions reflect well the experimental observations.

α″-martensite decomposition: Figure. 2c (right) illustrates the martensite decomposition process in solute lean Ti-Nb. In contrast to α″iso formation which starts from metastable β, α″ has lowest free energy at the decomposition start. Due to the negative curvature of \({}^{\alpha {}^{{\prime\prime} }}G\) around the start composition (indicated by the vertical grey arrow, \(\frac{{\partial }^{2}{}^{{\alpha }^{{\prime\prime} }}G}{\partial {{x}_{Nb}}^{2}} < 0\)) small compositional fluctuations become amplified. In this way Nb depleted (α″lean) and Nb enriched (α″rich) domains form, which evolve continuously into equilibrium α and β phases. Interestingly, even though conceptualized for the first time more than 35 years ago10,39,43, α″ decomposition has only recently come into focus8,9,44,45. Its investigation has benefited significantly from the use of high temperature in-situ diffraction set-ups at synchrotron facilities8,9, similarly to the study of α″iso. Most notably, while ex-situ XRD in earlier work struggled to detect variations of the α″lean lattice parameters with holding time25, in-situ measurements clearly revealed their evolution towards α9.

At this point, we would like to draw the reader’s attention to the metastability pertaining to all athermal and diffusion-mediated forms of α″. This contrasts with the Gibbs energetics in ternary Ti-Al-Nb and related Ti-Al-X systems (X denoting a β-stabilizer), where chemically ordered orthorhombic O-phase is thermodynamically stable and appears as an equilibrium phase46,47.

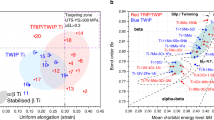

Reaction sequences during thermal cycling reinterpreted

Ti-Nb alloys undergo a series of transformation events when temperature-cycled in the martensitic state, as illustrated in Figs. 3a,b. Alloy composition plays a central role in determining the transformations’ nature and sequence29,30. Here we restrict our discussion to salient features of α″-martensitic alloys of intermediate Nb content (9–19 at.%) in the context of the foregoing analysis of the thermodynamic landscape. The Gibbs free energy relationships (Fig. 2) predict the formation of intermediate orthorhombic products α″iso, α″lean and α″rich for appropriate temperature and composition regimes. In recent experiments it was possible to detect and follow these transitional structures in binary Ti-Nb in-situ by high temperature XRD9. By now, transitional orthorhombic phases have been observed in several β-stabilized Ti-alloys including a few commercially important formulations7,8,9,10,11. Informed by the energy landscape and the experimental evidence9 we reinterpret the heat flow signatures of 9–19 at% Nb alloys recorded by DSC (Figs. 3a,b). The exothermic peak I (Fig. 3a) between 700–900 K in 9–13.5 at% Nb is thus attributed to martensite decomposition α″ → α″lean + α″rich → α + β mediated by Nb-enriched (α″rich) and Nb-impoverished (α″lean) α″. In the higher solute alloys of 15.5–19 at% Nb above α″ → β0 martensite reversion and below the α-β transus, α precipitation from β occurs via transitional α″iso, viz. β0 → α″iso + β → α + β. This reaction was observed over a broad temperature range of up to ~200 K9 in parallel with the dissolution of ωiso into β around 758 K. Its broad exothermic signal is therefore largely superimposed by the endothermic signal of ωiso → β. Appreciating the uncertainty of the thermodynamic description of α″ we note that the temperature and composition regimes in which α″iso occurs correspond very well with the conditions derived from the Gibbs energy landscape previously. Furthermore, the occurrence of β → α during cooling from the β-phase field depends on the kinetics. For instance, in the present case β → α occurred for xNb ≤ 0.17 while it was suppressed for higher Nb content (Fig. 3b).

Temperature-induced structural changes in Ti-Nb alloys. Role of Nb content on transformation sequences triggered by (a) heating the quenched state and by (b) cooling from the β-phase field. Data for xNb = 0.075–0.295 in (a) and (b) were recompiled from29,30. For visualization purposes values of xNb in (a,b) are multiplied by 100. (c) Variation of lattice parameters of α″ martensite with temperature. Of the 4 compositions illustrated, xNb = 0.225 exhibits the largest positive and negative expansion rates. Data in (c) are replotted from9.

Findings like these motivate the development of thermodynamic models with predictive capabilities for assessing and tailoring thermal protocols. It largely remains to be seen how α″ martensite decomposition and α″iso formation can be effectively exploited to improve mechanical and functional properties of Ti-alloys. Promising effects were reported for Ti-V and Ti-Mo in the early days of the exploration of Ti-alloys, inasmuch they experience substantial strengthening when aged by spinodal decomposition of α″-martensite25,43.

Thermal expansion control in Ti-alloys

Recently, giant and highly anisotropic linear thermal expansion rates were uncovered in solute rich α″ martensite of Ti-Nb9,12. These are illustrated in Fig. 3c by the response of the orthorhombic unit cell to a temperature change as derived from in-situ SXRD. When heated a lengthens drastically and b shortens similarly strongly; c lengthens only weakly. A unit sphere of a hypothetical martensite single crystal thus gets distorted into an ellipsoid, Eq. (2), as showcased in Fig. 4a for xNb = 0.225. Importantly, due to the contraction along b for xNb > 0.09 the thermal expansion of α″ becomes zero for particular crystallographic directions of the unit cell (i.e. αuvw = 0 for certain [uvw], see Eq. (3)). The unstretched directions form an elliptical cone about b (Eqs. (4) and (5)), which is exemplarily illustrated in Fig. 4b for xNb = 0.225 inside a single α″ unit cell. It runs from approximately [012] over [111] to [110]. This behaviour is hardly affected by composition albeit the alloy content sensitively projects onto the expansion magnitude, as demonstrated in Fig. 4c. Larger expansion rates correlate with higher Nb content leading to exceptionally large stretches and contractions observed for xNb = 0.225 across more than 150 K. Only for xNb = 0.09 deviating behaviour is found, to the extent that directions of zero expansion are absent since all its expansion coefficients are positive. The volumetric expansion rates for the 4 alloys presented are positive and range between αV = 24.7–91 ppm/K. Together with the contraction along b this provides a remarkable materials design situation inasmuch it opens the door to bespoke thermal expansion properties through texture and composition control. Taking advantage of the described thermal expansion anisotropy in α″ we propose 3 approaches to engineer zero thermal expansion in Ti-alloys:

- i)

Single crystal-like textures: By synthetizing α″ microstructures with a very strong texture approaching that of a single α″ variant, zero expansion is obtained along directions αuvw = 0 (see Methods) and illustrated by Fig. 4. This approach has the benefit of yielding low thermal stresses across interfaces of adjacent grains.

- ii)

Introduction of a [010]α″ texture component: Starting from a random initial orientation distribution function, texture components favouring the alignment of [010]α″ (or a nearby contracting direction) along a specific sample direction are introduced. By adjusting this component’s strength via e.g. imposing the required level of deformation the initially isotropic linear expansion of αV/3 can be reduced to zero along this sample direction.

- iii)

Controlling the α″ volume fraction: An appropriate volume fraction of α″ is introduced into a parent single- or multi-phase microstructure and α″ is intentionally oriented or limited to a single variant (e.g. by external stress). Likewise, α″ may be combined with other alloys or materials in a composite fashion to directionally compensate thermal expansion. Similar to ii), null thermal expansion may be obtained for sample directions co-linear with contracting directions in α″ (i.e. for which αuvw < 0).

Anisotropic thermal expansion in Ti-Nb alloys. (a) Thermal expansion ellipsoid and (b) the cone of zero stretch directions inside the α″ unit cell for Ti77.5Nb22.5. Directions off the cone either contract or expand. For visualization purposes the thermal expansion coefficients in (a) were scaled by a factor of 2000. (c) Stereographic projections of the thermal expansion for orthorhombic martensite α″ depending on the Nb content. Directions of zero stretch are marked red.

The controlled creation of crystallographic textures of α″ is central to all 3 approaches. Yet, to date deformation textures in Ti-alloys consisting to a large part or completely of α″ have been rarely studied. For rolling of α″-martensitic Ti-Nb, it was reported that [010]α″ aligns along the rolling direction12,48. Consequently, by taking approach ii and by adjusting the rolling thickness reduction, zero temperature-induced length change along the rolling direction may be obtained12. Furthermore, compositional fluctuations in the β-phase - which are often considered a nuisance - could instead help control the volume fraction and spatial distribution of mechanically induced α″ when following approach iii. In this way, tuning of the linear thermal expansion was recently demonstrated in Ti‒24 Nb‒4Zr‒8Sn49. In future, to be able to successfully exploit the thermal expansion anisotropy solid knowledge of formation and manipulation of α″ textures will be necessary. This calls for detailed experimental studies of texture formation in α″ containing alloys.

Discussion

The development of an accurate thermodynamic description for β-stabilized Ti-alloys that is valid both at low and high temperatures remains a challenging task. Our calculations demonstrated that the question about the existence of a stable β miscibility gap in Ti-Nb is not answered consistently by the current models and should receive special attention in future modelling efforts. Overall, composition and temperature trends of pathways triggered experimentally (ω-α cascade, α″iso formation, α″ decomposition) follow those anticipated by Gibbs free energy calculations. These findings encourage to consult the alloys’ energetics more regularly during experimental composition and processing design. Furthermore, the highly anisotropic thermal expansion of α″ martensite gives rise to zero thermal stretch along specific directions in the orthorhombic unit cell. Most relevantly, through customizing the crystallographic texture and α″ volume fraction null thermal expansion can be obtained in polycrystalline aggregates. Summarizing, this work offers new design avenues for novel single and multi-phase Ti-alloys and invites to further explore these versatile materials.

Methods

Material preparation and characterization

Experimental results presented are for binary Ti-Nb alloys fabricated through arc-melting and cold crucible casting followed by homogenization at 1273 K for 24 h and water quenching. Phases and their structural characteristics were studied with transmission X-ray diffraction (XRD). Thermal analysis was carried out via temperature cycling at constant heating and cooling rate using Differential Scanning Calorimetry (DSC). Temperature dependent lattice parameters were derived from in-situ synchrotron XRD. In detail descriptions of the alloy preparation and characterization are given in9,29,41.

Thermodynamic calculations

Thermodynamic calculations served two purposes: (i) examine and validate experimentally observed transformation pathways against the system’s thermodynamics in terms of the participating phases’ free enthalpy curves; (ii) derive the Ti-Nb phase diagram from the recently published TiGen database24. Within the current scope two differing thermodynamic descriptions were employed; that by Zhang, Liu and Jin from 200122 and that by Yan and Olson (TiGen database) from 201624. Each phase (indicated by ϕ) is modelled as a disordered substitutional solid solution with its molar Gibbs free energy formulated as

ϕGNb and ϕGTi are the Gibbs free energies of the unary systems (Nb and Ti), R the gas constant, T the absolute temperature; xNb and xNb = 1 − xNb denote the mole fractions of Nb and Ti. Unary Gibbs free energies of α and β above 298.15 K are based on the SGTE database50 and those below 298.15 K follow the expressions by Vřešt’ál, Štrof and Pavlů51. ωGNb and ωGTi are constructed relative to βGNb and αGTi, respectively:

The corresponding coefficients ui are provided in Table 2. For ωGTi below 298.15 K Yan and Olson used an expression different from Eq. (1) formulated independently of ωGTi24. Chemical interactions between Ti and Nb are accounted for by the excess Gibbs free energy expressed as a Redlich-Kister polynomial (last 2 terms in Eq. (1)) with interaction parameters ϕL0 and ϕL152; Table 2 lists them. While Zhang, Liu and Jin used strictly regular descriptions (ϕL0 T-independent) for all phases, Yan and Olson proposed a subregular description with constant interaction parameters for β and T-dependent ϕL0 for α and ω.

To analyse precipitation and decomposition pathways against the system’s energetics, free enthalpy plots for α, β and ω were calculated at selected temperatures. To calculate the Ti-Nb phase diagram from the TiGen database24 a customized code was developed in GNU Octave (www.octave.org,53) which determines equilibrium concentrations by finding common tangents to the ϕG curves. All thermodynamic parameters are given in J, mol and K.

Thermal expansion anisotropy

Thermal expansion distorts a unit sphere of material into the ellipsoid

x1, x2 and x3 are the α″ crystal frame coordinates parallel to a, b, c, respectively, and the αi’s denote the pertaining expansion coefficients given by the thermal expansion tensor

The magnitude of αij along the crystallographic direction [uvw] is54

with

In the present case, α1 > 0, α2 < 0, α3 > 0 for xNb > 0.09. The unstretched directions then form an elliptical cone about x2 and are obtained as

where \(t\in [0,2\pi ]\) and

Data availability

The data on which the results of this study are based can be made available by contacting the corresponding author.

References

Leyens, C. & Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications. (Wiley-VCH Verlag GmbH & Co. KGaA, 2005).

Chen, Q. & Thouas, G. A. Metallic implant biomaterials. Mater. Sci. Eng. R 87, 1–57 (2015).

Nag, S. et al. Non-classical homogeneous precipitation mediated by compositional fluctuations in titanium alloys. Acta Mater. 60, 6247–6256 (2012).

Zheng, Y. et al. Role of ω phase in the formation of extremely refined intragranular α precipitates in metastable β-titanium alloys. Acta Mater. 103, 850–858 (2016).

Li, T. et al. New insights into the phase transformations to isothermal ω and ω-assisted α in near β-Ti alloys. Acta Mater. 106, 353–366 (2016).

Hao, Y. L. et al. Continuous and reversible atomic rearrangement in a multifunctional titanium alloy. Materialia, (2018).

Barriobero-Vila, P., Requena, G., Schwarz, S., Warchomicka, F. & Buslaps, T. Influence of phase transformation kinetics on the formation of α in a β-quenched Ti–5Al–5Mo–5V–3Cr–1Zr alloy. Acta Mater. 95, 90–101 (2015).

Barriobero-Vila, P., Biancardi Oliveira, V., Schwarz, S., Buslaps, T. & Requena, G. Tracking the αʺ martensite decomposition during continuous heating of a Ti-6Al-6V-2Sn alloy. Acta Mater. 135, 132–143 (2017).

Bönisch, M. et al. Giant thermal expansion and α-precipitation pathways in Ti-alloys. Nat. Commun. 8, 1429 (2017).

Williams, J. C. & Hickman, B. S. Tempering behavior of orthorhombic martensite in titanium alloys. Metall. Trans. 1, 2648–2650 (1970).

Aeby-Gautier, E. et al. Isothermal α″ formation in β metastable titanium alloys. J. Alloys Compd. 577, S439–S443 (2013).

Monroe, J. A. et al. Tailored thermal expansion alloys. Acta Mater. 102, 333–341 (2016).

Chen, J., Hu, L., Deng, J. & Xing, X. Negative thermal expansion in functional materials: controllable thermal expansion by chemical modifications. Chem. Soc. Rev. 44, 3522–3567 (2015).

Lagow, B. W. Materials Selection in Gas Turbine Engine Design and the Role of Low Thermal Expansion Materials. JOM 68, 2770–2775 (2016).

Friák, M. et al. Theory-Guided Materials Design of Multi-Phase Ti-Nb Alloys with Bone-Matching Elastic Properties. Materials 5, 1853 (2012).

Pathak, A., Banumathy, S., Sankarasubramanian, R. & Singh, A. K. Orthorhombic martensitic phase in Ti–Nb alloys: A first principles study. Comput. Mater. Sci. 83, 222–228 (2014).

Gutiérrez Moreno, J. J. et al. Ab-initio and experimental study of phase stability of Ti-Nb alloys. J. Alloys Compd. 696, 481–489 (2017).

Lekka, C. E., Gutiérrez-Moreno, J. J. & Calin, M. Electronic origin and structural instabilities of Ti-based alloys suitable for orthopaedic implants. J. Phys. Chem. Solids 102, 49–61 (2017).

Mei, W., Sun, J. & Wen, Y. Martensitic transformation from β to α′ and α″ phases in Ti–V alloys: A first-principles study. J. Mater. Res. 32, 3183–3190 (2017).

Appolaire, B., Héricher, L. & Aeby-Gautier, E. Modelling of phase transformation kinetics in Ti alloys – Isothermal treatments. Acta Mater. 53, 3001–3011 (2005).

Appolaire, B., Settefrati, A. & Aeby-Gautier, E. Stress and Strain Fields Associated with the Formation of α″ in near-β Titanium Alloys. Mater. Today Proc. 2, S589–S592 (2015).

Zhang, Y., Liu, H. & Jin, Z. Thermodynamic assessment of the Nb-Ti system. Calphad 25, 305–317 (2001).

Yan, J.-Y. & Olson, G. B. Molar volumes of bcc, hcp, and orthorhombic Ti-base solid solutions at room temperature. Calphad 52, 152–158 (2016).

Yan, J.-Y. & Olson, G. B. Computational thermodynamics and kinetics of displacive transformations in titanium-based alloys. J. Alloys Compd. 673, 441–454 (2016).

Davis, R., Flower, H. M. & West, D. R. F. The decomposition of Ti-Mo alloy martensites by nucleation and growth and spinodal mechanisms. Acta Metall. 27, 1041–1052 (1979).

Heo, T. W., Shih, D. S. & Chen, L.-Q. Kinetic Pathways of Phase Transformations in Two-Phase Ti Alloys. Metall. Mater. Trans. A 45, 3438–3445 (2014).

Zheng, Y. et al. The indirect influence of the ω phase on the degree of refinement of distributions of the α phase in metastable β-Titanium alloys. Acta Mater. 103, 165–173 (2016).

Koul, M. K. & Breedis, J. F. Phase transformations in beta isomorphous titanium alloys. Acta Metall. 18, 579–588 (1970).

Bönisch, M. et al. Thermal stability and phase transformations of martensitic Ti–Nb alloys. Sci. Technol. Adv. Mater. 14, 055004 (2013).

Bönisch, M. et al. Thermal stability and latent heat of Nb–rich martensitic Ti-Nb alloys. J. Alloys Compd. 697, 300–309 (2017).

Mantani, Y. & Tajima, M. Phase transformation of quenched α″ martensite by aging in Ti–Nb alloys. Mater. Sci. Eng., A 438-440, 315–319 (2006).

Sun, F. et al. Strengthening strategy for a ductile metastable β-titanium alloy using low-temperature aging. Mater. Res. Letters 5, 547–553 (2017).

Helth, A. et al. Effect of thermomechanical processing on the mechanical biofunctionality of a low modulus Ti-40Nb alloy. J. Mech. Behav. Biomed. Mater. 65, 137–150 (2017).

Coakley, J. et al. Isothermal omega formation and evolution in the Beta-Ti alloy Ti-5Al-5Mo-5V-3Cr. Philos. Mag. Lett. 96, 416–424 (2016).

Hua, K. et al. Composite structure of α phase in metastable β Ti alloys induced by lattice strain during β to α phase transformation. Acta Mater. 132, 307–326 (2017).

Ivasishin, O. M., Markovsky, P. E., Matviychuk, Y. V. & Semiatin, S. L. Precipitation and recrystallization behavior of beta titanium alloys during continuous heat treatment. Metall. Mater. Trans. A 34, 147–158 (2003).

Barriobero-Vila, P. et al. Phase transformation kinetics during continuous heating of a β-quenched Ti–10V–2Fe–3Al alloy. J. Mater. Sci. 50, 1412–1426 (2015).

Nag, S. et al. Novel Mixed-Mode Phase Transition Involving a Composition-Dependent Displacive Component. Phys. Rev. Lett. 106, 245701 (2011).

Davis, R., Flower, H. M. & West, D. R. F. Martensitic transformations in Ti-Mo alloys. J. Mater. Sci. 14, 712–722 (1979).

Bywater, K. A. & Christian, J. W. Martensitic transformations in titanium-tantalum alloys. Philos. Mag. A 25, 1249–1273 (1972).

Bönisch, M. et al. Composition-dependent magnitude of atomic shuffles in Ti-Nb martensites. J. Appl. Crystallogr. 47, 1374–1379 (2014).

Bönisch, M., Waitz, T., Calin, M., Skrotzki, W. & Eckert, J. Tailoring the Bain strain of martensitic transformations in TiNb alloys by controlling the Nb content. Int. J. Plast. 85, 190–202 (2016).

Flower, H. M., Davis, R. & West, D. R. F. In Titanium and Titanium Alloys: Scientific and Technological Aspects Volume 3 (eds J. C. Williams & A. F. Belov) 1703–1715 (Springer US, 1982).

Zhou, Y. L., Niinomi, M. & Akahori, T. Decomposition of martensite α″ during aging treatments and resulting mechanical properties of Ti−Ta alloys. Mater. Sci. Eng., A 384, 92–101 (2004).

Tang, B. et al. Kinetics of orthorhombic martensite decomposition in TC21 alloy under isothermal conditions. J. Mater. Sci. 47, 521–529 (2012).

Banerjee, D. The intermetallic Ti2AlNb. Prog. Mater Sci. 42, 135–158 (1997).

Witusiewicz, V. T., Bondar, A. A., Hecht, U. & Velikanova, T. Y. The Al–B–Nb–Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al–Nb and ternary Al–Nb–Ti systems. J. Alloys Compd. 472, 133–161 (2009).

Khromova, L. P., Dyakonova, N. B., Rodionov, Y. L., Yudin, G. V. & Korms, I. Martensitic transformations, thermal expansion and mechanical properties of titanium-niobium alloys. J. Phys. IV France 112, 1051–1054 (2003).

Hao, Y. L. et al. Superelasticity and Tunable Thermal Expansion across a Wide Temperature Range. J. Mater. Sci. Technol. 32, 705–709 (2016).

Dinsdale, A. T. SGTE data for pure elements. Calphad 15, 317–425 (1991).

Vřešt’ál, J., Štrof, J. & Pavlů, J. Extension of SGTE data for pure elements to zero Kelvin temperature—A case study. Calphad 37, 37–48 (2012).

Lukas, H., Fries, S. G. & Sundman, B. Computational Thermodynamics: The Calphad Method. (Cambridge University Press, 2007).

GNU Octave version 4.4.0 manual: a high-level interactive language for numerical computations (2017).

Nye, J. F. Physical Properties of Crystals: Their Representation by Tensors and Matrices. 352 (Oxford University Press, USA, 1985).

Acknowledgements

We thank Prof. Jürgen Eckert (ESI Leoben, Montanuniversität Leoben) and Prof. Marc Seefeldt (KU Leuven) for their encouraging support. This work benefited from the use of beamline ID11 at the European Synchrotron Radiation Facility (ESRF) in Grenoble, France. Assistance by Dr. Jonathan Wright, Dr. Nicholas Harker and Dr. Ajit Panigrahi is gratefully acknowledged. This work further benefited from funding by the European Commission under grant agreement No. 264635 (BioTiNet-ITN). The publication of this article was funded by the Open Access Fund of the Leibniz Association.

Author information

Authors and Affiliations

Contributions

M.B. and M.C. conceived the framework for this study. M.B. and M.S. carried out measurements. M.B. performed thermodynamic calculations, analysed data and wrote the manuscript draft. All authors discussed the results and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bönisch, M., Stoica, M. & Calin, M. Routes to control diffusive pathways and thermal expansion in Ti-alloys. Sci Rep 10, 3045 (2020). https://doi.org/10.1038/s41598-020-60038-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-60038-x

This article is cited by

-

Effect of Electric Field-Assisted Heat Treatment on Microstructure and Phase Transformation of Zrtialv Alloy

Metals and Materials International (2023)

-

Preparation and characterization of novel as-cast Ti-Mo-Nb alloys for biomedical applications

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.