Abstract

The variation in energy bandgaps of amorphous oxide semiconducting SiZnSnO (a-SZTO) has been investigated by controlling the oxygen partial pressure (Op). The systematic change in Op during deposition has been used to control the electrical characteristics and energy bandgap of a-SZTO. As Op increased, the electrical properties degraded, while the energy bandgap increased systematically. This is mainly due to the change in the oxygen vacancy inside the a-SZTO thin film by controlling Op. Changes in oxygen vacancies have been observed by using X-ray photoelectron spectroscopy (XPS) and investigated by analyzing the variation in density of states (DOS) inside the energy bandgaps. In addition, energy bandgap parameters, such as valence band level, Fermi level, and energy bandgap, were extracted by using ultraviolet photoelectron spectroscopy, Kelvin probe force microscopy, and high-resolution electron energy loss spectroscopy. As a result, it was confirmed that the difference between the conduction band minimum and the Fermi level in the energy bandgap increased systematically as Op increases. This shows good agreement with the measured results of XPS and DOS analyses.

Similar content being viewed by others

Introduction

In recent decades, transparent amorphous oxide semiconductors (TAOSs) have been studied in various fields, such as optoelectronics, active-matrix displays, and integrated circuits1,2,3. The most important advantage of TAOS is that it can provide high field-effect mobility even though it is amorphous, and it can be applied to transparent electronic devices because it has high transmittance in the visible light region4. This is because the energy bandgap of the oxide semiconductor is known to be greater than 3 eV, and the outermost orbital of the metal cation is composed of spherical S-orbitals; therefore, the movement of electrons overlap smoothly2. In addition, TAOS can be applied to a wide range of industrial fabrication methods. For example, sol-gel5, pulse layer deposition6, magnetron sputtering7, chemical vapor deposition8, and atomic layer deposition7 are known to be very attractive materials with no significant limitations on their deposition methods. These TAOS can be designed in various configurations from binary material (ex. ZnO) to quaternary materials (e.g., IGZO), and their characteristics vary depending on the composition ratio of materials8,9,10. The most widely known TAOS material is amorphous indium–gallium–zinc–oxide (a-IGZO). a-IGZO has excellent characteristics because of the composition of In3+ and Ga4+ 8. However, In and Ga are very rare elements on earth11. Studies are being conducted to find their nontoxic and abundant alternatives, and amorphous zinc–tin–oxide (a-ZTO) based materials are receiving considerable attention12,13. Recently, our group reported a-SZTO with improved stability by containing Si on the a-ZTO system14,15. Our study showed that Si atoms on the a-ZTO system inhibit oxygen vacancies. This is because they have a strong bonding strength with oxygen (799.6 kJ/mol)15. Many groups are conducting research on carrier enhancer elements and oxygen vacancy suppressor elements3,5,9. In general, TAOS materials generate electrons through oxygen vacancies16. The more oxygen vacancies, the better the electrical properties. However, it is very important to optimize oxygen vacancies because they can also act as traps. For a simple solution process, such as a sol-gel, oxygen vacancies should be controlled according to the composition ratio; however, in a vacuum process, such as a magnetron sputtering process, oxygen vacancies can be controlled by applying oxygen as the active gas17,18. Research on various deposition condition is being carried out, and the changes in electrical properties as well as energy bandgap have been analyzed in detail19. Among them, the oxygen partial pressure (Op) has a very important effect on the oxide semiconductor material. In the case of crystalline oxide semiconductors, As increase Op the crystallinity improved but the energy bandgap decreases20. but in the case of TAOS, the energy bandgap increases according to Op18. Therefore, it is very important to analyze the correlation between Op and energy bandgap. Zhao et al. analyzed BexMgyZn1-x-yO as an oxide material having crystallinity, using the modified simplified coherent potential approximation method. The energy bandgap change according to the composition ratio of the material could be derived using the equation21. Recently, our group tried to derive the energy bandgap directly using methods such as high-resolution electron energy loss spectroscopy (HR-EELS), Kelvin probe force microscopy (KPFM), and ultraviolet photoelectron spectroscopy (UPS) to extract the energy bandgap14,19.

In this study, we have investigated the change in energy bandgap states systematically by using different Op during the deposition to introduce different density of states (DOSs) inside the energy bandgap. In addition, the electrical and optical properties of a-SZTO thin films as TAOS materials have been characterized depending on the change in Op during the deposition using the magnetron sputtering technique. It was observed that the energy bandgap systematically changed, and the performance also changed depending on the change in Op. In addition, we extracted the energy levels of the energy bandgap, Fermi level, and valence band maximum directly through HR-EELS, KPFM, and UPS. As a result, it was found that the change in Op during the deposition directly affected the trap density within the TAOS thin film, and it was observed that the energy bandgap parameter can also be controlled by varying Op.

Methods

Device fabrication

The a-SZTO thin films with varying Op were deposited on heavily doped p+-type silicon substrate (resistivity 0.001–0.002 Ω/cm), which has 100-nm thick SiO2 deposited through the thermal oxidation process, using radio frequency (RF) sputtering at room temperature. The fabricated TFTs have typical bottom gate and top source/drain electrode structures. Prior to deposition, the substrates were cleaned in acetone, methanol, and DI-water in an ultrasonication bath. The a-SZTO ceramic target was prepared by high purity (99.99%) powder mixtures of SiO2, SnO2, and ZnO. The Si was incorporated into the ZTO (Zn:Sn = 65:35) system at 1 wt.%. The sputtering conditions were: sputtering power of 60 W; deposition pressure of 3 mtorr; Ar partial pressure of 40 sccm; and Op was varied among 0, 3, and 5 sccm. After the deposition, the a-SZTO thin films were annealed at 500 °C in ambient air for 2 h in a furnace. Then, the channels were patterned by conventional photolithography and wet-etching processes. The lift-off process was used to form the source/drain electrodes on the patterned channels. The source/drain electrodes were deposited with 10 nm and 40 nm of Ti and Al, respectively, using an E-beam and a thermal evaporator. The thicknesses of all fabricated a-SZTO thin films was fixed at 27 nm. The gate electrode and gate insulator of TFTs used heavily doped p+-Si and SiO2, respectively.

Characterization

The crystallinity of a-SZTO thin films was analyzed through XRD (XRD, JP/SmartLab, Rigaku Co.). The transmittance of the thin films was measured using a UV-VIS-NIR spectrometer. The electrical properties were measured using a semiconductor parameter analyzer (HP-4145B, Hewlett-Packard Co.) and vacuum probe station (MS-TECH Co.). The O1s peaks of the thin films were measured through XPS, and fitting was performed using the general Gaussian–Lorentzian method. To calculate the energy bandgap parameters, each value was obtained using the following methods: Eg from HR-EELS (concentric hemispherical analyzer (CHA)-type, 23.5 eV energy resolution); valence band level from ((monochromatic He II); and Fermi level from KPFM.

Results and Discussion

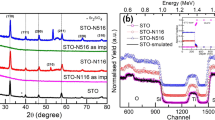

Figure 1(a) shows the X-ray diffraction patterns (XRD) of a-SZTO thin film depending on Op. The XRD pattern clearly shows that no additional peaks are observed except for the broad peak located at approximately 23°. A broad peak was the peak output from the quartz glass substrate (corning 1737), used for the XRD measurement22. From the XRD results, it was confirmed that the a-SZTO thin film was amorphous, which did not exhibit crystallinity. In addition, the measurement results of transmittance with a variation in Op is shown in Fig. 1(b). The transmittance of the visible region at 550 nm increased from 94.53% to 96.25% with an increase in Op, and the overall transmittance was above 90%. This is because of the wide energy bandgap of 3 eV or greater, which is a characteristic of the previously reported oxide semiconductor3,9. Fig. 1(c) shows the transfer curve of a-SZTO TFT depending on the change in Op. As Op increased, the threshold voltage (Vth) in the transfer curve systematically shifted to the positive direction from 5.21 to 13.10 V. Vth was obtained by applying the square-root to the drain-source current (Ids) value output from the transfer curve. Vth and other electrical characteristics are listed in Table 1. The field-effect mobility (μfe) was obtained using the following equation19:

where gm is the transconductance, Ci is the oxide capacitance of the gate insulator, and W and L are the channel width and length, respectively. Electrical performance, such as μfe, on-current (Ion), subthreshold slope (SS), and on/off current ratio (Ion/off) tends to decrease steadily as Op increases. This is because when Op increases during the deposition, the oxygen vacancy (Vo) inside the thin film is suppressed23. Therefore, carrier concentration decreases with the suppression of Vo, and electrical properties degrade. However, the suppression of these Vo can provide better stability2,3. In general, in oxide semiconductors, Vo provides electrons inside the thin film16. However, the optimization of the mobility enhancement and the stability is an important issue because Vo can also act as defected states24,25. Therefore, from Fig. 1(d) and Table 1, it can be clearly seen that, the oxygen atoms suppress the formation of Vo, and the electrical properties degrade as Op increases. In addition, we obtained the amount of trap state (NT) by using the SS value. The SS value and NT have the following relationship26:

where SS is the subthreshold slope, k is Boltzmann’s constant, T is the temperature, and Ci (3.45 × 10−8 F/cm2) is the unit gate capacitance. As Op increased, NT be decreased from 8.68 × 1011 cm−2 to 7.60 × 1011 cm−2. It was confirmed that the oxygen atom clearly decreased the NT inside the a-SZTO thin film.

Furthermore, we used X-ray photoelectron spectroscopy (XPS) to analyze the effect of the increase in Op on the a-SZTO film. Figure 2(a–c) shows the XPS O1s peak of a-SZTO thin films with increasing Op. The binding energy of O 1 s peak was calibrated by taking C 1s as the reference at 284.25 eV. The O1s peak could be de-convoluted into three Gaussian–Lorentzian peaks: low binding energy (OI), middle binding energy (OII), and high binding energy (OIII)27. The OI peak can be attributed to metal–oxide bonding (M-O) and was observed at 530 ± 0.3 eV. The OII peak is related to oxygen-deficient vacancies known as Vo and was observed at 531.2 ± 0.3 eV. The OIII peak is attributed to the surface oxygen owing to the hydroxide and was observed at 532.2 ± 0.3 eV27,28. From the XPS O1s results, it was observed that, the OII peak (OII/OI + OII + OIII), which is closely related to Vo, decreased from 14.39% to 9.73% as Op increased systematically as shown in Fig. 2(d). These results are the same as the decrease in trap density observed from the electrical properties. It is clear that the increase in Op during the deposition suppresses Vo inside the a-SZTO thin film, thus degrading the electrical properties. Although the electrical properties degrade, the reduction of Vo can provide better stability. To confirm the stability enhancement, we measured the temperature stress (TS) and observed the relationship between the trap density in a-SZTO thin films and the change in Op.

X-ray photoelectron spectroscopy (XPS) spectra of O 1 s peak of a-SZTO thin films depending on Op: (a) Ar:O2 = 40:0 sccm, (b) Ar:O2 = 40:3 sccm, and (c) Ar:O2 = 40:5 sccm. (d) The oxygen-deficient related peak (OII) in a-SZTO thin films with varying Op. Note that as the Op increases, the OII decreases.

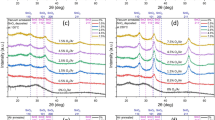

Figure 3(a–c) shows the TS results of a-SZTO TFT as Op increases. The temperature dependency of TS was measured from room temperature to 353 K in intervals of 20 K. As Op increased, the amount of shift of Vth (ΔVth) decreased from 2.16 to 0.55 V. Regardless of the increase in Op, it was confirmed that Vth moves toward the negative direction as temperature increases in the TS. It is expected that the thermal energy releases electrons in the trapped state inside the thin film with an increase in temperature29. We only applied the temperature parameter to analyze the effect on trap states inside the energy bandgap and did not add any additional stress, such as bias and illumination. In general, the operating mechanism of the oxide semiconductor occurs when electrons in the valence band are excited to the conduction band by an increase in energy30. However, electrons fill the trap states inside the energy bandgap31. This implies that, there are more electrons trapped inside the bandgap if the thin-film has more trap states. In addition, as the temperature increases, the trapped electrons receive a greater amount of energy. This allows the electrons in deep states to be excited into the conduction band as they absorb sufficient thermal energy. Therefore, a device with large trap states inside the energy bandgap will exhibit high ΔVth value, which is not desirable. Here, we can see that the a-SZTO thin film deposited in pure Ar ambient shows the highest ΔVth (2.16 V) value. It was also observed that ΔVth decreases systematically as Op increases. It is clear that the oxygen atom during the depositions fills the trap state associated with the Vo inside the a-SZTO thin film. The activation energy (Ea) in the area below the subthreshold region was calculated using the TS results. The gate voltage (Vgs) is plotted against Ea graphs from the TS results with a variation in Op in Fig. 3(d–f), including the obtained Ea falling rate through the slope. The thermally activated drain current in the subthreshold region is obtained using the equation29

where ID0 is the pre-factor, k is Boltzmann’s constant, T is the absolute temperature, and Ea is the activation energy. The calculated Ea falling rate increased systematically from 0.077 eV/V to 0.082 eV/V as Op increased. An increase in the falling rate implies a decrease in the channel and/or interface trap states29,30. In other words, in the graph of Ea, the state can be changed more quickly if the amount of trap states is small for electrons to transit from the valence band to the conduction band. Therefore, as Op increases, the amount of traps states in the energy bandgap decreases, and the Ea falling rate increases accordingly. Furthermore, to analyze the DOSs inside the a-SZTO thin film depending on Op, we used Ea to calculate DOSs based on the following equation19:

where εi and di are the permittivity and thickness of the gate insulator, respectively, t is the thickness of the a-SZTO thin film (t = 27 nm), and q is the electron charge (1.602 × 10−19 C).

Figure 4 shows the result of DOSs versus Ea calculated from Ea depending on Op. As Op increases, the DOS tends to decrease systematically. This results from the oxygen atoms reducing the trap states that are closely related to the decrease of Vo inside the a-SZTO thin film during the deposition mentioned above. From the DOS results, we note that increasing Op decreases the trap states in the shallow levels within the energy bandgap. As described above, the XPS O1s peak, electrical characteristics, and DOSs result from decreasing Vo as Op increases. This implies that the energy bandgap can be adjusted indirectly according to Op and, thus, the carrier concentration or the Fermi level can be controlled23. Therefore, to derive the energy bandgap directly, each energy level has been measured using ultra-violet photoelectron spectroscopy (UPS), Kelvin probe force microscopy (KPFM), and high-resolution electron energy loss spectroscopy (HR-EELS).

Figure 5(a–c) shows the UPS results, He (II) spectra of valence band edge (EV,edge), and secondary electron cut-off energy (ES,cutoff) of the a-SZTO thin films with varying Op. When a thin film is exposed to ultraviolet rays in a UPS measurement, it is known that a thin film surface and an impurity cause a chemical reaction to generate a surface dipole, which may cause a change in work function32,33. However, in order to produce a high-quality a-SZTO thin film according to Op, RF magnetron sputter was used in a high vacuum condition (<10−6 Torr) to minimize the surface impurities. In addition, considering the change of thin film by UV-induction, UPS was measured using separate specimens fabricated at the same time during sample fabrication. The points EV,edge and ES,cutoff depending on Op were determined by the fitting method from the baseline. Based on the above results, the valence band level (EV) of the a-SZTO thin films can be directly calculated by the following equation33:

where \(h{\rm{\upsilon }}\) is the energy of the monochromatic He (II) line emission at 40.813 eV, ES,cutoff is secondary electron cut-off energy, EV,edge is valence band edge. In addition, EV,edge can be defined as the separation between the EV and EF as shown in Fig. 5(b). The calculated EV shows little change from −7.490 eV to −7.510 eV with increasing Op. This indicates that the oxygen atoms during deposition do not directly affect the EV region of the a-SZTO material. EF according to the change of OP measured by KPFM is shown in Fig. 5(d). The EF contact potential difference was calibrated with respect to the reference of Pt/Ir (Tip Φ of 4.91 eV)34,35. Interestingly, it was observed that EF has a large change of 0.1 eV or more in the a-SZTO thin films with increasing Op (40:5 device). This large change means that oxygen atoms are more likely to suppress Vo as Op increases, which means that the decrease in Vo in oxide semiconductors implies a decrease in the carrier concentration. In general, EF is closely related to the carrier concentration. As the carrier concentration increases, EF moves in the conduction band direction. Conversely, when the carrier concentration decreases, it moves in the valence band direction36,37. Therefore, EF shifts toward the EV direction due to the reduced carrier concentration.

(a) Ultraviolet photoelectron spectroscopy (UPS) spectrum of the a-SZTO thin films depending on Op; (b) Expanded views of the low binding energy region for valence band edge (EF-EV), and (c) secondary electron cut-off energy with varying Op. (d) Kelvin probe force microscopy (KPFM) images of the a-SZTO as function of Op.

Figure 6(a–d) shows the energy bandgap (Eg) of the a-SZTO thin film with increasing Op measured by using HR-EELS. The HR-EELS spectra were obtained by the transmitting electron beams with an energy of 1.5 keV. Eg was extracted by linear fitting the slope with respect to the baseline in the graph output from HR-EELS. As Op increased, Eg showed an increasing tendency increase from 3.743 eV to 3.902 eV systematically. This is also consistent with the transmittance results shown in Fig. 1(b) above. We defined Eg using the energy bandgap parameters extracted from UPS, KPFM, and HR-EELS, as shown in Fig. 7. In addition, Table 2 summarizes the Eg values for each region. It was clearly observed that Eg increases systematically as Op increases. Interestingly, it is particularly noteworthy that the area between the conduction band minimum (EC) and EF varies greatly. It is observed that the increase in the overall Eg is mostly due to the expansion of the EC-EF interval, which means that as Op increases, the trap density in the EC-EF interval, that is, the shallow level trap states, reduces significantly. The results of these measurements have been verified through DOS analysis, as shown above in Fig. 4. It is evident that the increase of Op increases the EC-EF region by filling the trap state at the shallow level. Additionally, it is observed to be the widest when Op is 40:5. This large change is due to two main reasons: i) EF shifts toward the EV direction as the carrier concentration decreases, and ii) the reduction of the trap at the shallow19,34. Based on these results, it has been observed that the energy bandgap parameters of the oxide semiconductors can be controlled by the change in Op during depositions resulting in the change of the EC-EF interval significantly.

Conclusion

In summary, we investigated the electrical properties and energy bandgap of the a-SZTO thin film by varying Op during the deposition. Theoretical and experimental analyses were conducted to analyze the influence of Op on the electrical characteristics of a-SZTO TFTs. An assumption was made that an increase in Op can increase the energy bandgap, based on the transmittance measurements and the DOS results calculated via temperature stress. The increase in Op during deposition was found to suppress the formation of oxygen vacancies within the a-SZTO thin film, which was mainly found to reduce the trap density of shallow levels. To observe the changes in the exact energy bandgap, HR-EELS, KPFM, and UPS were used to observe Eg, EF, and EV, respectively. The increase in Op observed a clear extension of the EC-EF interval (0.943–1.234 eV) over the energy bandgap, which was found to be in good agreement with the DOS results. It was clearly observed that the change in Op during deposition makes it possible to control the oxygen vacancy, which freely changes the energy bandgap of the oxide semiconductor. Therefore, the change of the a-SZTO thin film depending on Op greatly affects the electrical characteristics and thermal stability of the TFT.

References

Dattoli, E. N. et al. Fully transparent thin-film transistor devices based on SnO2 nanowires. Nano Lett. 7, 2463–2469 (2007).

Nomura, K. et al. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488–492 (2004).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistor: A review of recent advances. Adv. Mater. Weinheim 24, 2945–2986 (2012).

Nomura, K. et al. Amorphous oxide semiconductors for high-performance flexible thin-film transistors. Jpn. J. Appl. Phys. 45, 4303–4308 (2006).

Yoon, S., Kim, S. J., Tak, Y. J. & Kim, H. J. A solution-processed quaternary oxide system obtained at low-temperature using a vertical diffusion technique. Sci. Rep. 7, 43216 (2017).

Suresh, A., Gollakota, P., Wellenius, P., Dhawan, A. & Muth, J. F. Transparent, high mobility InGaZnO thin films deposited by PLD. Thin Solid Films 516, 1326–1329 (2008).

Cho, M. H. et al. Comparative study on performance of IGZO transistor with sputtered and atomic layer deposited channel layer. IEEE Trans. Electron Devices 66, 1783–1788 (2019).

Dang, G. T., Kawaharamura, T., Furuta, M. & Allen, M. W. Metal-semiconductor field-effect transistors with In−Ga−Zn−O channel grown by nonvacuum-processed mist chemical vapor deposition. IEEE Electron Device Lett. 36, 463–465 (2015).

Hosono, H. Ionic amorphous oxide semiconductors: Material design, carrier transport, and device application. J. Noncryst. Solids 352, 851–858 (2006).

Sheng, J. et al. Design of InZnSnO semiconductor alloys synthesized by supercycle atomic layer deposition and their rollable applications. ACS Appl. Mater. Interfaces 11, 12683–12692 (2019).

Nakamura, E. & Sato, K. Managing the scarcity of chemical elements. Nat. Mater. 10, 158–161 (2011).

Lee, J. et al. Theoretical and experimental studies on the electronic structure of crystalline and amorphous ZnSnO3 thin films. Appl. Phys. Lett. 102, 242111 (2013).

Görrn, P., Lehnhardt, M., Riedl, T. & Kowalsky, W. The influence of visible light on transparent zinc tin oxide thin film transistors. Appl. Phys. Lett. 91, 193504 (2007).

Choi, J. Y. et al. Engineering of band gap states of amorphous SiZnSnO semiconductor as a function of Si doping concentration. Sci. Rep. 6, 36504 (2016).

Lee, B. H., Sohn, A., Kim, S. & Lee, S. Y. Mechanism of carrier controllability with metal capping layer on amorphous oxide SiZnSnO semiconductor. Sci. Rep. 9, 886 (2019).

Jeong, S., Ha, Y. G., Moon, J., Facchetti, A. & Marks, T. J. Role of gallium doping in dramatically lowering amorphous-oxide processing temperatures for solution-derived indium zinc oxide thin-film transistors. Adv. Mater. Weinheim 22, 1346–1350 (2010).

Choi, J. Y., Kim, S. & Lee, S. Y. Threshold voltage shift by controlling Ga in solution processed Si-In-Zn-O thin film transistors. Thin Solid Films 520, 3774–3777 (2012).

Zhang, Y. C. et al. Oxygen partial pressure ratio modulated electrical performance of amorphous InGaZnO thin film transistor and inverter. J. Alloys Compd. 765, 791–799 (2018).

Lee, B. H. et al. Direct investigation on energy bandgap of Si added ZnSnO system for stability enhancement by X-ray photoelectron spectroscopy. J. Alloys Compd. 715, 9–15 (2017).

Cuong, H. B. & Lee, B.-T. Effects of oxygen partial pressure on the characteristics of magnetron-sputtered ZnMgBeO thin films. Appl. Surf. Sci. 355, 582–586 (2015).

Zhao, C.-Z., Sun, S.-Y., Sun, X.-D., Wang, S.-S. & Wang, J. The band gap energy of BexMgyZn1-x-yO calculated by modified simplified coherent potential approximation. Superlattice Microst. 113, 255–260 (2018).

Chang, T.-H., Lee, T.-E., Hsueh, N.-K., Lin, C. H. & Yang, C.-F. Investigation of TiO2-Al2O3 bi-layer films as Bragg reflector of blue light by using electron beam evaporation. Microsyst. Technol. 24, 3941–3948 (2018).

Chen, X. F. et al. Modulation of optical and electrical properties of sputtering-derived amorphous InGaZnO thin films by oxygen partial pressure. J. Alloys Compd. 615, 636–642 (2014).

Flewitt, A. J. & Powell, M. J. A thermalization energy analysis of the threshold voltage shift in amorphous indium gallium zinc oxide thin film transistors under simultaneous negative gate bias and illumination. J. Appl. Phys. 115, 134501 (2014).

Bae, J., Jeong, I. & Lee, S. Wavelength-dependent optical instability mechanisms and decay kinetics in amorphous oxide thin-film devices. Sci. Rep. 9, 2920 (2019).

Yang, Z., Yang, J., Meng, T., Qu, M. & Zhang, Q. Influence of channel layer thickness on the stability of amorphous indium zinc oxide thin film transistor. Mater. Lett. 166, 46–50 (2016).

Rim, Y. S., Kim, D. L., Jeong, W. H. & Kim, H. J. Effect of Zr addition on ZnSnO thin-film transistors using a solution process. Appl. Phys. Lett. 97, 233502 (2010).

Kim, J. W. et al. Atomistic aspects of carrier concentration variation in post-annealed indium tin oxide films. J. Phys. D: Appl. Phys. 48, 395307 (2015).

Lee, B. H. & Lee, S. Y. Influence of channel layer thickness on the instability of amorphous SiZnSnO thin film transistor under negative bias temperature stress. Phys. Status Solidi A 215, 1700698 (2018).

Choi, J. Y., Kim, S., Kim, D. H. & Lee, S. Y. Role of metal capping layer on highly enhanced electrical performance of In-free Si−Zn-Sn-O thin film transistor. Thin Solid Films 594, 293–298 (2015).

Ryu, M. K., Yang, S., Park, S.-H. K., Hwang, C.-S. & Jeong, J. K. Impact of Sn/Zn ratio on the gate bias and temperature-induced instability of Zn−In−Sn−O thin film transistors. Appl. Phys. Lett. 95, 173508 (2009).

Schlaf, R., Murata, H. & Kafaf, Z. H. Work function measurements on indium tin oxide films. J. Electron Spectrosc. Relat. Phenom. 120, 149–154 (2001).

Choi, J. Y. et al. Effect of Si on the energy band gap modulation and performance of silicon indium zinc oxide thin-film transistors. Sci. Rep. 7, 15392 (2017).

Sommerhalter, C., Matthes, T. W., Glatzel, T., Jäger-Waldau, A. & Ch, M. Lux-Steiner, High-sensitivity quantitative Kelvin probe microscopy by noncontact ultra-high-vacuum atomic force microscopy. Appl. Phys. Lett. 75, 286–288 (1999).

Glatzel, T., Sadewasser, S. & Lux-Steiner, M. C. Amplitude or frequency modulation-detection in Kelvin probe force microscopy. Appl. Surf. Sci. 210, 84–89 (2003).

Rhoderick, E. H. Metal-Semiconductor contacts. IEE Proc. 129, 1–14 (1982).

Aldao, C. M. et al. Dopant concentration dependences and symmetric Fermi-level movement for metal/n-type and p-type GaAs(110) interfaces formed at 60 K. Phys. Rev. B 39, 12977–12980 (1989).

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No.20172010104940). The Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2017R1D1A3B06033837). We thank J-G. Chung for UPS and HR-EELS measurements and analysis.

Author information

Authors and Affiliations

Contributions

S.Y.L., S.P. S.-W.K., H. C. and S.K. designed and executed the study and analysed the data; B.H.L., K.-S.C., D.-Y.L., J.Y.L. and A.S. performed the experiments and analysed data using HR-EELS, UPS, XPS, and KPFM; B.H.L. analysed the data and wrote the main manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors (B.H. Lee, K.-S. Cho, D.-Y. Lee, A. Sohn, J.Y. Lee, H. Choo, S. Park, S.-W. Kim, S. Kim and S.Y. Lee) declare that they have no competing interests as defined by Nature Research, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, B.H., Cho, KS., Lee, DY. et al. Investigation on energy bandgap states of amorphous SiZnSnO thin films. Sci Rep 9, 19246 (2019). https://doi.org/10.1038/s41598-019-55807-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-55807-2

This article is cited by

-

Amorphous non-doped and Se-, Cu-, and Zn-doped Sb2S3 nanoparticles prepared by a hot-injection method: bandgap tuning and possible observation of the quantum size effect

Journal of Nanoparticle Research (2023)

-

Electrical Performance of Amorphous Oxide/Colloidal Quantum Dot/Amorphous Oxide Hybrid Thin Film Transistor

Transactions on Electrical and Electronic Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.