Abstract

Methods to make microcapsules – used in a broad range of healthcare and energy applications – currently suffer from poor size control, limiting the establishment of size/property relationships. Here, we use microfluidics to produce monodisperse polyurea microcapsules (PUMC) with a limonene core. Using varied flow rates and a commercial glass chip, we produce capsules with mean diameters of 27, 30, 32, 34, and 35 µm, achieving narrow capsule size distributions of ±2 µm for each size. We describe an automated method of sizing droplets as they are produced using video recording and custom Python code. The sustainable generation of such size-controlled PUMCs, potential replacements for commercial encapsulated systems, will allow new insights into the effect of particle size on performance.

Similar content being viewed by others

Introduction

Microcapsules – that is, sub-mm size capsules with a solid shell and a solid or liquid core – have diverse applications across sustainability and energy, in healthcare, and in consumer products1,2,3,4,5,6,7,8,9. For example, microcapsules have been used for self-healing anticorrosion coatings10,11, energy storage materials12,13, and in catalysis14. By using encapsulation technology, manufacturers and researchers are able to use much smaller quantities of expensive or harmful ingredients15,16, or achieve a controlled release of the liquid core on response to a stimulus17,18,19. Despite the utility of polymer microcapsules, there are considerable environmental concerns regarding their persistence in the environment20 or use of harmful additives such as formaldehyde21,22. As the properties of microcapsules – such as release profile, permeability, and stability over time – often depend on particle size23,24,25, there is a strong drive to produce monodisperse microcapsules such that robust size/property relationships can be established. However, commonly used industrial methods of microcapsule production result in polydisperse populations, limiting the information that can be gained concerning the effect of size on their properties. A sustainable method of generating monodisperse, size-controlled polymer microcapsules is therefore highly desirable for research and development into the next generation of environmentally benign microcapsules.

The most common method of polymer microcapsule production is interfacial polymerisation (IFP) at the interface of an oil-in-water (o/w) or water-in-oil (w/o) emulsion produced by high-shear mixing with a homogenizer24. First, a stable emulsion must be produced with the required droplet diameter; the droplet will form the core of the microcapsule. Polymerization occurs only at the boundary of the emulsion, ensuring that a thin film is formed around the droplet template. The size regime of the droplets produced is chiefly dependent on the emulsification device, surfactants present, and the energy applied to the system26; standard batch high-shear mixing methodologies result in poor control over the size distribution of the droplets (Fig. 1a), and hence the polymer microcapsules formed.

Size distribution of emulsion droplets produced by standard and microfluidic methods (a,b) Optical microscope images of o/w emulsions produced by (a) homogenizer and (b) microfluidic chip (Qc = 100 µL min−1, Qd = 5 µL min−1); (c,d) histograms of droplet size distribution from (a,b) analysed by ImageJ for (c) homogenized and (d) microfluidic chip produced droplets (Qc = 100 µL min−1, Qd = 5 µL min−1).

Microfluidic methods27 – that is, where reagents are flowed through micrometre-sized channels and mixed at a junction – are, by contrast, capable of extremely precise control over both droplet size and dispersity28,29,30. At the point of mixing, a high shear force is generated between the two immiscible fluids, resulting in droplet formation29,31. The shear force can be adjusted by altering the relative flow rates of the two input streams, which, along with channel size, controls the size of the resultant droplet. Thus, it is possible to continuously produce monodisperse emulsions of a desired size. Examples of such droplet production methods have been used in the synthesis of multifunctional magnetoresponsive microcapsules32, core-shell organosilicon capsules33, and biopolymer hydrogels34. Monodisperse polymer microcapsules of between 10–50 microns in diameter are of particular interest to the personal care industry35 to avoid the potential hazards of nanoparticles; microfluidic methods can readily access this size regime. Furthermore, microfluidic methods require very small amounts of material, and are sustainable due to the short reaction times, low energy usage, waste minimization, and energy and cost efficiency achievable with a continuous process36,37.

The choice of polymer, oil, and surfactant have a significant effect on the kinetics of polymerisation and the resultant microcapsule shell thickness24,38,39,40. Here, we also consider sustainability of the raw materials and the resultant polymer capsules. The ideal polymer shell from an industrial perspective is stable over the shelf-life of the product, capable of payload delivery at the required moment or rate, and not hazardous to the environment. Polyurea microcapsules (PUMCs) have been suggested as candidate materials that fulfil these criteria38,41. In terms of feedstocks, the oil used should ideally be from a cheap, renewable source, and function as an active ingredient in a product formulation. Limonene, commonly used in fragrance and foods, can be used as both a template and a payload, and is a sustainable by-product of the citrus industry found in peel42. Although polydisperse limonene microcapsules have been previously prepared43,44,45, there are no studies using microfluidic chips to generate limonene-containing microcapsules.

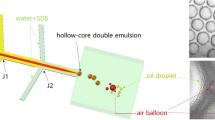

In this research, we use a microfluidic chip to generate monodisperse emulsion microdroplets of limonene containing diisocyanate monomer in an aqueous carrier fluid containing sodium dodecyl sulfate (SDS) and NaCl. We compare the size and polydispersity of the resultant droplets to samples produced by homogenization methods. By systematically varying the flow rate of the oil, we generate emulsions of tunable droplet diameter. Droplet formation is monitored in situ; the droplet size and polydispersity is measured from both still images and videos, the latter using an automated method. Methods of video processing of droplets using Labview have been previously reported46,47; here we use Python code for ease of accessibility. Interfacial polymerisation is achieved offline by collecting the droplets in a stirred solution of aqueous polyamine, which reacts with the diisocyanate to form a polyurea shell (see SI for reaction scheme). The resultant microcapsules are characterised by optical microscopy, SEM, and fluorescence microscopy, and found to have narrow size dispersity, high stability in air over at least 24 h, and the ability to carry a fluorescent payload. Having developed a sustainable method to produce size-controlled microcapsules on demand, we now seek to exploit this to understand the effect of size and dispersity on the performance of microcapsules in product formulations.

Methods

Batch synthesis

An aqueous solution of SDS and NaCl (1.0 wt. % and 1.5 wt. % respectively in 200 ml) and a solution of methylene diisocyanate (MDI) in limonene (0.3 wt. %, 10 ml) were prepared, mixed and homogenised at 8000 RPM for 2 minutes using an ULTRA-TURRAX T-25 homogeniser. The use of SDS and NaCl in these quantities resulted in the formation of emulsion droplets that were stable for at least 24 h. To form capsules, the resulting emulsion was allowed to stand for 10 minutes before a portion (1 mL) was injected into an aqueous solution of tetraethylenepentamine (TEPA), SDS, and NaCl (3.0 wt. %, 1.0 wt. %, and 1.5 wt. % respectively in 10 mL) and stirred at 100 RPM with a magnetic flea for 15 minutes. Capsules were left unstirred for 24 hours before being isolated via pipette and dried in air on a glass slide for imaging and SEM analysis.

Microfluidic setup, droplet and capsule synthesis

A Dolomite system equipped with 2 Mitos compressed air pumps was used to generate flow rates of between 1–100 µL min−1. MDI dispersed in limonene (0.3 wt. %) and an aqueous solution of SDS and NaCl (1.0 and 1.5 wt. % respectively) were delivered to a Dolomite glass 2-reagent droplet chip with a junction size of 50 µm to generate monodisperse emulsion droplets (see SI for full details). The flow rate of the dispersed oil phase, Qd, was varied; the flow rate of the continuous water phase, Qc, was kept constant at 100 µL min−1. To avoid the potential for blockages, polymerisation was accomplished offline. Droplets were collected in a stirred (100 rpm, magnetic flea) solution of TEPA, SDS, and NaCl in water (3.0, 1.0, and 1.5 wt. % respectively in 10 mL). Droplets were collected for 15 minutes, after which time stirring was stopped and the solution left undisturbed for 24 h prior to being collected via pipette and dried in air on a glass slide for analysis.

Characterisation of droplets and microcapsules

Droplets were imaged at the junction with a high speed optical microscope capable of capturing both still images and videos. Samples of emulsion and microcapsules were collected before and after polymerisation and imaged using offline optical microscopy. Typically, droplets and microcapsules in the 10–100 µm range are characterised by image analysis, either manually or using image processing software48. This analysis is normally limited to 50–100 particles per sample. Laser scattering methods can be unreliable in this size regime, particularly for core-shell particles, as several assumptions about density, refractive index, particle shape, and stability under measurement conditions must be made that do not generally hold for such materials49. We therefore decided to explore video processing as an alternative method that would allow the analysis of many more droplets per sample, taking advantage of the continuous production and inline video monitoring of droplets. Still images of droplets and microcapsule were analysed using ImageJ. Videos of droplet production were processed using custom Python code; methodology and limitations are discussed in the SI. Version 1.0 of this code is available under https://github.com/fsimkovic/droplet-assessment.

Results and Discussion

Homogenized emulsions were found to contain droplets from 1–16 µm, with a broad, bimodal distribution of droplet sizes (Fig. 1a,c), as typical for droplets produced by this method43. Larger or smaller average droplet sizes can be generated by changing the stirring speed, but high polydispersity always results owing to the variable shear forces experienced in batch processes.

By contrast, droplets produced in the microfluidic chip were characterised by narrow dispersity (Fig. 1b,d). Relative flow rates that produced single streams of droplets were targeted to avoid the production of aggregated particles in the polymerisation step; however, smaller or larger droplet sizes could readily be produced by widening the range of flow rates used (Fig. 2a–c). Average droplet diameters between 20–26 µm were measured via video analysis when Qd was varied from 1–5 µL min−1 (Fig. 2d,e); an increase in droplet diameter was observed with increased Qd.

Size control of limonene droplets produced in a microfluidic chip (a–c) Optical microscope images of o/w emulsions produced at Qc and Qd of (a) Qc = 100 µL min−1, Qd = 5 µL min−1; (b) Qc = 100 µL min−1, Qd = 10 µL min−1; (c) Qc = 20 µL min−1, Qd = 5 µL min−1. (d) example of still from microscope video that has undergone processing to detect and measure droplet diameter via Python code (Qc = 100 µL min−1, Qd = 1 µL min−1 - see SI for full details); (e) plot of Qd/Qc vs. mean emulsion droplet diameter analysed by video processing of >20000 droplets per video. Qc is fixed at 100 µL min−1. Error bars represent standard deviation.

Narrow dispersity was also observed in the microcapsules produced via subsequent polymerisation of the droplets (Fig. 3a–c). Again, we observed an increase in PUMC size with an increase of Qd, allowing rapid access to ‘learning sets’ of size-controlled microcapsules. Average PUMC diameters of 27, 30, 32, 34, and 35 µm produced at Qc = 100 µL min−1 and Qd of 1, 2, 3, 4, and 5 µL min−1 respectively were measured by still image analysis.

Production of size-controlled limonene microcapsules: (a) Optical microscope image of PUMC from an emulsion produced at Qc = 100 µL min−1, Qd = 5 µL min−1; (b) plot of Qd/Qc vs. mean PUMC diameter analysed by image processing of ~50 capsules. Qc is fixed at 100 µL min−1. (c) histogram of PUMC diameter analysed by image processing of ~50 PUMCs per optical microscope image. Qd = 1 µL min–1 (black solid lines); 2 µL min–1 (dark grey dashed line); 3 µL min–1 (light grey dotted line); 4 µL min–1 (blue solid line); 5 µL min–1 (magenta dashed line). Qc is fixed at 100 µL min−1. Error bars represent standard deviation.

Although it is tempting to compare the sizes of the droplets (20–26 µm, Fig. 2e) and the resultant PUMCs (27–35 µm Fig. 3b), these sets of results are not directly comparable due to the different image processing techniques, and conditions under which the images were obtained (through a glass chip vs. on a glass slide – see SI for detailed discussion). The clear advantage of automated video processing is in enabling the easy processing of tens of thousands of droplets; in this iteration, we sacrifice some accuracy to enable rapid processing (see SI for detailed discussion of the origin of this inaccuracy). In future, a more sophisticated approach, such as a supervised Machine Learning algorithm, could be trained to detect droplets; we anticipate this approach would greatly improve accuracy and enable high quality, automated measurement of droplet sizes as they are generated50.

Microcapsules were characterised by SEM (Fig. 4a,b); both intact and burst particles were observed after exposure to the high vacuum conditions required for SEM imaging, confirming their hollow nature. The microcapsules were observed to have poor stability under the electron beam, eroding during extended exposure and therefore making it difficult to accurately assess shell thickness. From the images obtained, we estimate a shell thickness of ~100 nm.

Release of limonene from PUMC: (a,b) SEM images of (a) intact and (b) burst PUMCs produced by microfluidics; (c,d) confocal fluorescence microscopy images of (c) intact PUMCs produced by microfluidics after 24 h drying; (d) the same microcapsules after application of finger-pressure onto the glass slide.

To visualise the liquid core of the microcapsules, an emulsion containing fluorescent dye (Hostasol yellow 3 G) was generated in the microfluidic chip and subjected to encapsulation via IFP using the protocols described above. The resultant microcapsules were dried on a glass slide for 24 h before imaging with confocal fluorescence microscopy (Fig. 4c). To release the fluorescent payload, a gentle pressure was then applied via a second glass slide (Fig. 4d), indicating that these microcapsules may have utility in applications where pressure-sensitive release is desirable – for example, fragrance release in deodorants.

Conclusions

A series of monodisperse polymer microcapsules was produced using microfluidic methods and using sustainable materials. By using video processing to analyse the size distributions of the droplets produced, we can rapidly and automatically establish narrow dispersity, and measure changing droplet size when using different flow rates. Such straightforward and adaptable methodologies are readily extendable to other chemistries, different particle sizes, and new payloads for diverse applications. It has been previously demonstrated that shell thickness and permeability can be tuned by careful choice of surfactant and polymerisation chemistry24,38,39,40. By exploiting this tunability in combination with the size control demonstrated in this work, we anticipate the production of bespoke sustainable microcapsules for commercial formulations, healthcare, and energy and sustainability applications. Such control over microcapsule production will enable new applications and products as well as facilitating greater understanding of the impact of particle size on function.

Supporting data statement

Details of image and video processing methods are available in the Supporting Information. Please contact the corresponding author regarding requests for data. Version 1.0 of the source code used in this study is available under https://github.com/fsimkovic/droplet-assessment.

References

Esser-Kahn, A. P., Odom, S. A., Sottos, N. R., White, S. R. & Moore, J. S. Triggered Release from Polymer Capsules. Macromolecules 44, 5539–5553, https://doi.org/10.1021/ma201014n (2011).

Yow, H. N. & Routh, A. F. Formation of liquid core-polymer shell microcapsules. Soft Matter 2, 940–949, https://doi.org/10.1039/b606965g (2006).

Sliwka, W. Microencapsulation. Angew Chem Int Edit 14, 539–550, https://doi.org/10.1002/anie.197505391 (1975).

Zhang, Y. F. & Rochefort, D. Characterisation and applications of microcapsules obtained by interfacial polycondensation. Journal of Microencapsulation 29, 636–649, https://doi.org/10.3109/02652048.2012.676092 (2012).

Brown, E. N., White, S. R. & Sottos, N. R. Microcapsule induced toughening in a self-healing polymer composite. J Mater Sci 39, 1703–1710, https://doi.org/10.1023/B:JMSC.0000016173.73733.dc (2004).

Liang, K. et al. Charge-shifting click capsules with dual-responsive cargo release mechanisms. Adv Mater 23, H273–277, https://doi.org/10.1002/adma.201101690 (2011).

Broaders, K. E., Pastine, S. J., Grandhe, S. & Frechet, J. M. Acid-degradable solid-walled microcapsules for pH-responsive burst-release drug delivery. Chem Commun (Camb) 47, 665–667, https://doi.org/10.1039/c0cc04190d (2011).

De Koker, S., Hoogenboom, R. & De Geest, B. G. Polymeric multilayer capsules for drug delivery. Chem Soc Rev 41, 2867–2884, https://doi.org/10.1039/c2cs15296g (2012).

Madene, A., Jacquot, M., Scher, J. & Desobry, S. Flavour encapsulation and controlled release - a review. Int J Food Sci Tech 41, 1–21 (2006).

Huang, M. X. & Yang, J. L. Facile microencapsulation of HDI for self-healing anticorrosion coatings. J Mater Chem 21, 11123–11130, https://doi.org/10.1039/c1jm10794a (2011).

Wu, G. et al. Robust microcapsules with polyurea/silica hybrid shell for one-part self-healing anticorrosion coatings. J Mater Chem A 2, 11614–11620, https://doi.org/10.1039/c4ta01312c (2014).

Su, J. F. et al. Preparation and physicochemical properties of microcapsules containing phase-change material with graphene/organic hybrid structure shells. J Mater Chem A 5, 23937–23951, https://doi.org/10.1039/c7ta06980d (2017).

Sun, N. & Xiao, Z. G. Synthesis and Performances of Phase Change Materials Microcapsules with a Polymer/BN/TiO2 Hybrid Shell for Thermal Energy Storage. Energ Fuel 31, 10186–10195, https://doi.org/10.1021/acs.energyfuels.7b01271 (2017).

Mason, B. P., Bogdan, A. R., Goswami, A. & McQuade, D. T. A general approach to creating soluble catalytic polymers heterogenized in microcapsules. Org Lett 9, 3449–3451, https://doi.org/10.1021/ol071360v (2007).

Ciriminna, R. & Pagliaro, M. Sol-gel microencapsulation of odorants and flavors: opening the route to sustainable fragrances and aromas. Chem Soc Rev 42, 9243–9250 (2013).

Lee, H. et al. Encapsulation and Enhanced Retention of Fragrance in Polymer Microcapsules. ACS Appl Mater Interfaces 8, 4007–4013 (2016).

Ravanfar, R., Celli, G. B. & Abbaspourrad, A. Controlling the Release from Enzyme-Responsive Microcapsules with a Smart Natural Shell. Acs Appl Mater Inter 10, 6046–6053 (2018).

Geng, J. L., Li, W. L., Smaga, L. P., Sottos, N. R. & Chan, J. Damage-Responsive Microcapsules for Amplified Photoacoustic Detection of Microcracks in Polymers. Chem Mater 30, 2198–2202, https://doi.org/10.1021/acs.chemmater.8b00457 (2018).

Paret, N., Trachsel, A., Berthier, D. L. & Herrmann, A. Controlled Release of Encapsulated Bioactive Volatiles by Rupture of the Capsule Wall through the Light-Induced Generation of a Gas. Angewandte Chemie-International Edition 54, 2275–2279, https://doi.org/10.1002/anie.201410778 (2015).

Intentionally added microplastics in products, E. C. R., Doc Ref 39168, retrieved from, http://ec.europa.eu/environment/chemicals/reach/pdf/39168%20Intentionally%20added%20microplastics%20-%20Final%20report%2020171020.pdf on 23/05/2018.

Cogliano, V. J. et al. Meeting report: summary of IARC monographs on formaldehyde, 2-butoxyethanol, and 1-tert-butoxy-2-propanol. Environ Health Persp 113, 1205–1208 (2005).

Salthammer, T. Formaldehyde in the Ambient Atmosphere: From an Indoor Pollutant to an Outdoor Pollutant? Angewandte Chemie-International Edition 52, 3320–3327 (2013).

Rule, J. D., Sottos, N. R. & White, S. R. Effect of microcapsule size on the performance of selfhealing polymers. Polymer 48, 3520–3529, https://doi.org/10.1016/j.polymer.2007.04.008 (2007).

Perignon, C., Ongmayeb, G., Neufeld, R., Frere, Y. & Poncelet, D. Microencapsulation by interfacial polymerisation: membrane formation and structure. J Microencapsul 32, 1–15, https://doi.org/10.3109/02652048.2014.950711 (2015).

Berchane, N. S., Jebrail, F. F. & Andrews, M. J. Optimization of PLG microspheres for tailored drug release. Int J Pharmaceut 383, 81–88, https://doi.org/10.1016/j.ijpharm.2009.09.010 (2010).

Poncelet, D., Desmet, B. P. & Neufeld, R. J. Nylon Membrane Formation in Biocatalyst Microencapsulation - Physicochemical Modeling. J Membrane Sci 50, 249–267, https://doi.org/10.1016/S0376-7388(00)80624-9 (1990).

Whitesides, G. M. The origins and the future of microfluidics. Nature 442, 368–373 (2006).

Zhang, J. et al. One-step fabrication of supramolecular microcapsules from microfluidic droplets. Science 335, 690–694 (2012).

Wang, J.-T., Wang, J. & Han, J.-J. Fabrication of advanced particles and particle-based materials assisted by droplet-based microfluidics. Small 7, 1728–1754 (2011).

Teh, S.-Y., Lin, R., Hung, L.-H. & Lee, A. P. Droplet microfluidics. Lab Chip 8, 198–220, https://doi.org/10.1039/b715524g (2008).

Lignel, S., Salsac, A. V., Drelich, A., Leclerc, E. & Pezron, I. Water-in-oil droplet formation in a flow-focusing microsystem using pressure- and flow rate-driven pumps. Colloid Surface A 531, 164–172, https://doi.org/10.1016/j.colsurfa.2017.07.065 (2017).

Yang, C. H. et al. Microfluidic assisted synthesis of multi-functional polycaprolactone microcapsules: incorporation of CdTe quantum dots, Fe3O4 superparamagnetic nanoparticles and tamoxifen anticancer drugs. Lab Chip 9, 961–965 (2009).

Steinbacher, J. L. et al. Rapid Self-Assembly of Core-Shell Organosilicon Microcapsules within a Microfluidic Device. J. Am. Chem. Soc. 128, 9442–9447, https://doi.org/10.1021/ja0612403 (2006).

Zhang, H. et al. Microfluidic production of biopolymer microcapsules with controlled morphology. J Am Chem Soc 128, 12205–12210 (2006).

Casanova, F. & Santos, L. Encapsulation of cosmetic active ingredients for topical application-a review. J Microencapsul 33, 1–17, https://doi.org/10.3109/02652048.2015.1115900 (2016).

Yoshida, J.-i, Kim, H. & Nagaki, A. Green and Sustainable Chemical Synthesis Using Flow Microreactors. Chemsuschem 4, 331–340, https://doi.org/10.1002/cssc.201000271 (2011).

Vaccaro, L., Lanari, D., Marrocchi, A. & Strappaveccia, G. Flow approaches towards sustainability. Green Chem 16, 3680–3704 (2014).

Polenz, I., Datta, S. S. & Weitz, D. A. Controlling the Morphology of Polyurea Microcapsules Using Microfluidics. Langmuir 30, 13405–13410, https://doi.org/10.1021/la503234z (2014).

Polenz, I., Weitz, D. A. & Baret, J. C. Polyurea Microcapsules in Microfluidics: Surfactant Control of Soft Membranes. Langmuir 31, 1127–1134, https://doi.org/10.1021/la5040189 (2015).

Chen, P. W., Erb, R. M. & Studart, A. R. Designer polymer-based microcapsules made using microfluidics. Langmuir 28, 144–152 (2012).

Li, J., Mazumder, M. A. J., Stoever, H. D. H., Hitchcock, A. P. & Shirley, I. M. Polyurea microcapsules: Surface modification and capsule size control. J. Polym. Sci., Part A: Polym. Chem. 49, 3038–3047, https://doi.org/10.1002/pola.24740 (2011).

Ciriminna, R., Lomeli-Rodriguez, M., Cara, P. D., Lopez-Sanchez, J. A. & Pagliaro, M. Limonene: a versatile chemical of the bioeconomy. Chemical Communications 50, 15288–15296 (2014).

Rodrigues, S. N. et al. Scentfashion (R): Microencapsulated perfumes for textile application. Chem Eng J 149, 463–472, https://doi.org/10.1016/j.cej.2009.02.021 (2009).

Jafari, S. M., He, Y. H. & Bhandari, B. Nano-emulsion production by sonication and microfluidization - A comparison. Int J Food Prop 9, 475–485, https://doi.org/10.1080/10942910600596464 (2006).

Donsi, F., Annunziata, M., Sessa, M. & Ferrari, G. Nanoencapsulation of essential oils to enhance their antimicrobial activity in foods. Lwt-Food Sci Technol 44, 1908–1914, https://doi.org/10.1016/j.lwt.2011.03.003 (2011).

Cabral, J. T. & Hudson, S. D. Microfluidic approach for rapid multicomponent interfacial tensiometry. Lab Chip 6, 427–436, https://doi.org/10.1039/b511976f (2006).

Watanabe, T., Lopez, C. G., Douglas, J. F., Ono, T. & Cabral, J. T. Microfluidic Approach to the Formation of Internally Porous Polymer Particles by Solvent Extraction. Langmuir 30, 2470–2479, https://doi.org/10.1021/la404506b (2014).

Rosinski, S. et al. Characterization of microcapsules: recommended methods based on round-robin testing. Journal of Microencapsulation 19, 641–659 (2002).

Stojanović, Z. & Marković, S. Determination of Particle Size Distributions by Laser Diffraction. Technics - New Materials 21, 11–20 (2012).

Hamzeloo, E., Massinaei, M. & Mehrshad, N. Estimation of particle size distribution on an industrial conveyor belt using image analysis and neural networks. Powder Technol 261, 185–190 (2014).

Acknowledgements

The authors thank Dr. Alex Ciupa and Dr. Casper Kunstmann-Olsen for assistance with analytical measurements and useful discussions. AGS thanks the Royal Society and Engineering and Physical Sciences Research Council for a Royal Society-EPSRC Dorothy Hodgkin Fellowship. This work made use of shared equipment located at the Materials Innovation Factory; created as part of the UK Research Partnership Innovation Fund (Research England) and co-funded by the Sir Henry Royce Institute. The authors also thank Dr Robert Treharne and HiPy (www.hipy.uk) for useful discussions and facilitating the collaborative Python work in this manuscript.

Author information

Authors and Affiliations

Contributions

A.G.S. and M.T. conceived and designed the work. M.T. acquired the data. M.T. and A.G.S. interpreted the data. F.S. wrote the Python code and interpreted the outputs relating to it. All authors contributed to drafting the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thorne, M.F., Simkovic, F. & Slater, A.G. Production of monodisperse polyurea microcapsules using microfluidics. Sci Rep 9, 17983 (2019). https://doi.org/10.1038/s41598-019-54512-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-54512-4

This article is cited by

-

Dendritic polyurea microcapsule: a slow release nitrogenous fertilizer

Iranian Polymer Journal (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.