Abstract

Most studies on CO2 emissions reduction strategies that address the ‘two-degree scenario’ (2DS) recognize a significant role for CCS. For CCS to be effective, it must be deployed globally on both existing and emerging energy systems. For nations with large-scale emissions, offshore geologic CO2 storage provides an attractive and efficient long-term strategy. While some nations are already developing CCS projects using offshore CO2 storage resources, most geographic regions have yet to begin. This paper demonstrates the geologic significance of global continental margins for providing broadly-equitable, geographically-relevant, and high-quality CO2 storage resources. We then use principles of pore-space utilization and subsurface pressure constraints together with analogs of historic industry well deployment rates to demonstrate how the required storage capacity can be developed as a function of time and technical maturity to enable the global deployment of offshore storage for facilitating 2DS. Our analysis indicates that 10–14 thousand CO2 injection wells will be needed globally by 2050 to achieve this goal.

Similar content being viewed by others

Introduction

The Role of CCS in the Energy Transition

A major societal challenge is achieving globally significant reductions in greenhouse gas emissions to the atmosphere. There is growing clarity from numerous studies1,2,3 that large-scale geologic disposal of CO2 from industrial emissions will be essential to achieve this objective. The ‘wedge model’ analysis for identifying opportunities for CO2 atmospheric reductions4 remains useful for anticipating contributions from different sectors – essentially a blend of growth in renewable energy use, improved energy efficiency, and various means of decarbonization of energy production and consumption. In this construct, CO2 Capture and Storage (CCS) is anticipated to support approximately 13% of total cumulative emissions reductions through 2050, requiring around 120,000 million tones (Mt) of cumulative CO2 reduction by 2050. Annual storage rates in 2050 are expected to be 6–7,000 Mtpa5. Furthermore, the IPCC argue that emissions reduction costs without CCS deployment could be as much as 29% to 297% higher by 21006. Lastly, many sectors of the modern economy, such as cement and steel production, are dependent on CCS alone to achieve significant decarbonization.

Despite this widespread recognition of the important role of CCS, fundamental doubts seem to remain among communities and policy makers about the viability and effectiveness of CCS deployment. There is certainly a significant economic hurdle, but active projects do exist and costs are decreasing with technology maturation, such that full-chain (capture, transport, storage) CCS can currently be considered as technically demonstrated and available as an integrated decarbonization technology (Norway, Japan, and Brazil have active offshore CO2 injection projects and the UK, USA, Australia and China have projects in the planning stages).

A recent assessment of the long-term performance and security of CO2 storage indicates a high degree of confidence in retention7. Despite some skepticism about project deployment, there are currently 19 CO2 injection projects globally8, of which 4 large-scale projects are dedicated to geologic storage in saline formations (Sleipner, Snøhvit, Quest, IBDP) which together inject nearly 4 million tonnes CO2 per annum (Mtpa). The 19 large-scale CCS facilities in operation together with a further 4 under construction, have an installed capture capacity of 36 Mtpa8. Additional experience in handling, transport, and injection of CO2 has been gained from almost fifty years of enhanced oil recovery (CO2 EOR). CCS is therefore demonstrated and underway at industrial scales globally; however, an order of magnitude increase is needed to meet the long-term expectations for CCS and to realize the 2DS goals.

In this paper we reinforce the overall viability of CCS and propose a meaningful timeline by using the historic perspective of the utilization of hydrocarbon resources in sedimentary basins as an analog to demonstrate the future utilization of the same basin geologic resources for CO2 disposal. Our conclusions offer decision makers a rational perspective for further support to allow CCS to deliver on stated emissions reduction goals. As our focus is on deep subsurface geological storage of captured CO2 (GCS), we will refer to GCS as the principal objective, assuming that significant global CO2 capture activities emerge in parallel.

Gigatonne-Scale CO2 Storage in Offshore Basins

Our analysis is based on the broad similarities in the stratigraphic and tectonic histories of passive continental margins and clarifies the primary factors affecting basin-wide and global storage potential (capacity), emphasizing typical subsurface fluid pressure profiles. Important local and regional differences in the tectonic histories of the continental margins are discussed in the Appendix (See Appendix: Methods used in supporting the main paper). Our approach departs from extensive prior regional volumetric quantification techniques9 that rely on a subsurface volumetric efficiency factor (ε). Rather, we develop concepts that emphasize regional stratigraphic pressure constraints that will matter at the Gigatonne (Gt) storage scale, referred to here as the ‘basin ΔP’ approach. We then demonstrate, using historic industry hydrocarbon well development data at three different regional scales, combined with rational average injection rates informed by the stratigraphic pressure analysis and practical experience, that accessing this storage resource is possible on the required timeframes and within pressure constraints that allow GCS to deliver the expected emissions mitigation role. We also argue that the history of technology development in extracting oil and gas resources over the last century (termed the primary, secondary and tertiary recovery methods) can to some extent be applied for evaluating similar future phases of CO2 disposal technology, each employing more advanced pressure management methods. Our aim is to provide the first-order technical basis and confidence that various nations need to effectively and simultaneously develop their offshore geology for GCS on a timeline that is relevant for 2DS10.

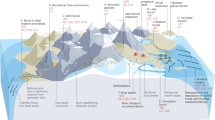

The global offshore continental shelves (Fig. 1) represent the most significant Gt-scale storage resource for GCS. Onshore basins are also important, but the offshore settings offer both significant volumes and practical deployment benefits at scale. Offshore continental margins, dominated by thick Cenozoic-age sediments provide vast subsurface rock volumes broadly prospective for storage due to their suitable subsurface depth range and relatively young age (low compaction, limited diagenesis, and high porosity). This volumetrically-significant resource can adequately and efficiently match the global objective of Gt-scale CO2 disposal. Furthermore, this resource benefits from lower technical and societal risks related to regionally-limited access to suitable onshore geology (e.g. EU, Atlantic US, China and India), issues related to protection of potable groundwater resources, and avoidance of population centers. The existence and historic exploitation of numerous giant hydrocarbon accumulations in offshore basin settings (Fig. 1, yellow symbols) can also be taken as evidence for appropriate subsurface conditions for retention of large volumes of buoyant non-wetting fluids over geologic time scales, giving an excellent precedent for successful deployment of GCS. Regional comparison of the overall similarity of geographic extent of available storage resources for select regions is provided in Fig. 2, illustrating a broadly equitable storage and geographically relevant resource potential.

Map of global distribution and thickness of sediment accumulations on continental margins52,53 with the thickest stratigraphy indicated in red. Yellow dots represent the largest offshore hydrocarbon fields (i.e. suitable large-scale subsurface hydrocarbon containment demonstrated54, and blue lines are the largest continental river systems, often leading to extensive and thick offshore Cenozoic stratigraphy.

Comparison of prospective storage resource regions for selected global localities at the same map scale (1:15,000,000). The footprint of the Utsira sandstone formation (North Sea) utilized for GCS since 1996 is indicated in the solid black outline and represents the size of a typical regional geologic storage target. Currently active (Sleipner, Snøhvit, Tomakomai, Lula), completed (K12B) and proposed (Goldeneye) offshore CO2 injection projects are indicated with white stars. Cross-hatched regions have water depths >1,000 m. Major hydrocarbon fields (Fig. 1) are shown in black cross symbols, indicating favorable conditions for large-scale subsurface retention of buoyant fluids.

Many offshore continental margin basins (Figs. 1 and 2) have comparable geologic evolution that has resulted in broadly similar stratigraphic and structural elements: typically, a phase of continental rifting and subsidence followed by a period of passive margin coastal progradation11,12. Decades of investigation indicate that these margins exhibit a deeper rift sequence with some variability in structural style13, typically Mesozoic in age (often representing the rifting of the Pangaea supercontinent around 175 million years ago), with advanced diagenesis (cementation and porosity reduction due to burial and interaction with hot fluids). These deeper rift sequences are typically overlain by net-progradational and aggradational Cenozoic sediments composed of fluvial, deltaic, shelf, and slope deposits. Where large continental-draining river systems enter these settings (Fig. 1, blue lines), clastic accumulations may exceed many kilometers thickness. Other margins may have extensive carbonate development14, also suitable for GCS. These Cenozoic-age passive margin deposits are also characterized by lower levels of diagenesis (porosity reduction) and less pervasive faulting than the underlying Mesozoic stratigraphy. Arguably, the deeper rift sequences are less well-suited for the first phase of GCS, while the upper Cenozoic sequences offer some of the best regional saline aquifer storage targets (such as the Utsira sandstone offshore Norway; Fig. 2). In all cases, the essential storage requirement is to find thick high-porosity sediment reservoir units overlain by sealing units (usually thick shales), ideally with open hydrologic systems for dissipating induced pressure increases. Shallower projects also have reduced drilling costs. The deeper rift sequence often includes many large-scale faults that often propagate upwards and generate additional subsequent faulting in the overlying stratigraphy. The fault architecture is also a critical element for storage site characterization, since faults can both transmit and retain buoyant fluids15,16. In a global petroleum assessment, 71% of the known hydrocarbon reserves occurred in structural (i.e. faulted) traps, as opposed to stratigraphic or other trap types17, suggesting faults are commonly involved in high-saturation subsurface buoyant fluid retention.

Basin-Fluid Pressure Analysis Approach

Two of the three largest global hydrocarbon (oil and gas) producing regions are the North Sea and the Gulf of Mexico – the largest being the Middle East/Persian Gulf region, which is mainly onshore and partly offshore. We will therefore consider these two basins as representative of a mature state of subsurface knowledge for the highly prospective offshore basins available for large-scale CO2 disposal. One of the most significant common features in geologic development of the continental margins is the subsurface fluid pressure distribution18. Typically, these geologic basins have a shallow interval (<2–3 km) with hydrostatic (normal) pressures that develop with depth into naturally over-pressured systems, a common feature which can be deduced from the initial reservoir pressure data from decades of hydrocarbon exploration in different basins19,20,21,22,23. This behaviour is essentially controlled by a natural balance between the rate of compaction and the rate of fluid pressure dissipation24, where a loss of balance is usually termed ‘disequilibrium compaction’, although other processes are also involved in generating overpressure25.

As the fluid pressure increases with depth it begins to approach the lithostatic pressure gradient, and a limiting pressure is reached – the rock fracture pressure – such that subsurface reservoirs rarely exhibit pressures greater than 80–90% of the lithostatic pressure (often taken to be 22.6 kPa/m or 1 psi/ft). This general behavior is characterized in the depth plot shown in Fig. 3, based on a generalized Norwegian North Sea basin case. For comparison, average initial-reservoir pressure trends for all Miocene reservoirs on the inner shelf of Texas26 are shown to be hydrostatic to approximately 2,750 meters27, consistent with regional GoM data28. Three depth zones are identified in this generic plot: (1) a normally pressured zone between 1 and 3 km depth, (2) a weakly over-pressured zone between 3 and 4 km depth, and (3) a high over-pressured zone between 4 and 5 km depth. The actual depths of these zones and style of vertical transition will be basin dependent, but the trend with depth is commonly observed. Referring to the stratigraphic summary above, the Cenozoic sequences are typically in the normally-pressured zone, while the deeper Mesozoic rift-sequences are commonly found in the deeper over-pressured zones (with many exceptions to that simplification).

Pressure depth functions for a generalised Norwegian North Sea basin case illustrating the shallow normally pressured region (1), and the progressively deeper and more overpressured regions (with excess initial pressure P2 and P3). P-hydro is the hydrostatic gradient, sigma-V is the vertical principal stress, and the maximum reservoir pressure is described by the formation fracture pressure P_frac (See Appendix: Methods used in supporting the main paper).

Appreciation of this common fluid pressure trend with depth (Fig. 3) is arguably the single most significant consideration for offshore global GCS deployment at the Gt-scale in a reasonable timeframe (assuming that the basic reservoir and seal characteristics are identified29). This is because large-scale CO2 disposal will require subsurface pressure management, rather than being simply controlled by the available subsurface pore volumes. While pore volume is a static metric, pressure evolution involves time, which is an important consideration for understanding how GCS can meet intended volumetric targets within anticipated timelines through mid-century. This has been described as ‘dynamic capacity’30, and while pressure constraints have been identified and discussed previously as key factors for CCS31,32,33,34, this evaluation has primarily been considered for reservoir-scale performance35 rather than at a stratigraphic scale.

Reservoir pressure mitigation methods involving subsurface brine extraction have also been investigated36, but ultimately include re-injection into another nearby stratigraphic interval, which does not overcome the large-scale stratigraphic pressure limitations that are considered here. So, while brine extraction and re-injection may enable single projects to be optimized, the strategy is not necessarily favorable for long-term Gt-scale storage in a basin employing multiple projects throughout the stratigraphy and may not be required. However, pressure management among multiple projects may be useful in the later stages of storage resource development (as argued below).

Thus, while CO2 storage trapping mechanisms37 (structural trapping, residual-phase trapping, dissolution and mineralization) are essential to GCS, it is the subsurface reservoir pressure that ultimately limits CO2 injection and the total storage capacity at the Gt-scale at operational timescales. Pressure propagates in the subsurface far more effectively and pervasively than injected fluids, and the pressure footprint can be assumed to extend outward from an injection well by a factor of 10 to 100 compared to the dimensions of the CO2 plume38. The importance of pressure limitations was encountered at the Snøhvit project in the Barents Sea (a Mesozoic injection target), where the initial injection well had to be modified to allow access to stratigraphic units with better pressure communication39,40. As a corollary, the Sleipner project (Cenozoic) has not encountered any pressure limitations, being connected to a large open aquifer system. Here, we develop the concept of the ‘available pressure resource’ for global deployment of offshore GCS, using the cases of the North Sea and the Gulf of Mexico as a reference.

Our proposed generic approach, the ‘basin ΔP’ approach, is based on integration of the injectivity equation over the project lifetime, where pressure limits are defined by basin pressure. We obtain the following function (See Appendix: Methods used in supporting the main paper):

where,

Vproject is the estimated volume stored

Ic is the injectivity

Pwell is the injection well pressure

Pinit is the initial reservoir pressure

ApD(tD) is a characteristic pressure function

Fb is a volume flux boundary condition.

The characteristic pressure function, the integral of reservoir pressure with time, is a function of the formation properties and the dimensions of the storage unit, represented graphically in Fig. 4. The integration is between the limits Pinit and Pfinal, where Pfinal may be defined with reference to pfrac as a limiting condition. For a closed saline aquifer unit with no-flow boundary conditions (such as a sealed fault block), Fb = 0; while for the case of some pressure dissipation from the saline aquifer formation, Fb is positive, and for a case with some brine influx into the storage unit Fb is negative. It is generally assumed that Fb is a small factor compared to the injectivity term. However, for the case of an infinite aquifer with no pressure boundary limitation, Fb could be large or even dominant.

Equation (1) assumes a constant injection pressure and constant injectivity – simplifying assumptions appropriate for screening prospective projects and evaluating expected GCS performance. With more complex operational variables, numerical reservoir simulation can be used to more accurately assess injection volumes as a function of variable pressure gradients. At the project screening stage, parameters for Eq. (1) can be estimated using regional basin data (See Appendix: Methods used in supporting the main paper) and initial estimates of storage unit geometry and formation permeability. Volumes may be converted to mass using estimates for the mean in situ CO2 density. An illustration of the application of Eq. (1) to a real dataset is given in the Appendix (See Appendix: Methods used in supporting the main paper).

There are essentially two operational criteria for stopping storage projects:

- A.

The storage project fills the available pore-space before the maximum pressure limit is reached (Aquifer geometry A in Fig. 4);

- B.

The storage project reaches the maximum pressure limit before the available pore-space can be fully utilized (Aquifer geometry B in Fig. 4).

The concept outlined in Fig. 4 is scaled to a common set of initial conditions: the initial reservoir pressure, Pinit, the bottom-hole well pressure, Pwell, and the formation fracture pressure Pfrac. Storage geometry A follows a pressure path Pa towards a final pressure Pfa, and likewise for B.

The Sleipner and Quest projects are examples of A, while the early injection history at the Snøhvit project was an example of B. A further situation is also possible where CO2 is injected in an inclined aquifer, with lateral migration gradually being hindered and eventually stopped by processes of structural, residual and solubility trapping41,42. This would be a variant of A, since pressure would not be a limiting factor.

Thus, in general, if all prospective storage formations fall into either of these two categories, the total storage resources will be smaller than the initial static volumetric estimates based on storage efficiency, ε, since the B-category aquifers will be pressure limited. As we argue below, early projects will tend to focus on the best available storage opportunities provided by ‘Class A’ aquifers (and in the offshore basins these will typically be found in the shallower mainly post-rift Cenozoic stratigraphy). As the global need to access storage resources grows, projects will then start to exploit the ‘Class B’ aquifers, having to adjust project designs to cope with the local formation pressure limits. A third class of storage projects, which we will term ‘Class C’ will be the cases where active pressure management is used to further enhance storage availability. This will allow natural pressure limits to be circumvented by active production schemes, including brine production43 the use of the ‘pressure space’ created by oil and gas production44 or direct injection into depleted gas fields45. We argue that this transition from early use of CO2 injection into aquifers without significant pressure limits (Class A), through to CO2 storage in pressure-limited aquifers (Class B) and eventually to pressure management at the basin scale (Class C), represents a global technology development strategy for storage (Table 1), which is analogous to the historic oil and gas production strategy which has moved from primary recovery (pressure depletion modus), to secondary recovery technology (mainly pressure management by water injection), and then to tertiary methods (involving injection of gas, CO2 and other chemicals to further enhance hydrocarbon recovery). We know from historic data that each new phase of oilfield recovery added a factor of 0.5–1 to the previously recoverable oil resources.

It is not simple to predict how successive stages of technology development will work to increase the accessible CO2 storage resources, but as an indicator of this potential we can use the relatively mature storage resource assessments for the Utsira formation offshore Norway46. For the Utsira Fm. structural trapping of free-phase CO2 (a Class-A resource) provides ~0.8 Gt of storage47, while injection up to the natural pressure limits (Class-B resource) could allow up to 8.3 Gt of storage48. Studies of the potential Utsira storage resource when deploying active pressure management (Class-C resource) gave estimates between 42 and 50 Gt of storage47,49. The potential for growth in storage resources as a function of increasing application of technology is therefore significant. This strategy for utilization of the global offshore basin storage resource is captured graphically in Fig. 5.

CO2 storage resource development strategy, illustrated for the case of the mapped Norwegian North Sea resource base. Here we have used the lower-bound resource estimate to identify the Class A resource with a preference for initial deployment in the shallower Cenozoic stratigraphy. The Class B resource approaches the mapped capacity values and utilizes deeper stratigraphy. Class C is used to exploit the upper bound potential in the last phase.

To illustrate the range of likely behaviour of different CO2 injection projects at different stratigraphic depths and contrasting reservoir conditions, we postulate four model scenarios (also shown on Fig. 3):

- (a)

A shallow open-boundary case (SO) with injection at 1000 m depth and with no significant pressure constraint (a Cenozoic Class-A resource);

- (b)

A moderate-depth, partially-closed pressure boundary case (MC) with injection at 1800m depth (a Cenozoic Class-B resource);

- (c)

A deep closed-boundary case (DC) with injection at 2500 m depth (a Mesozoic Class-B resource);

- (d)

A deep open-boundary case (DO) with injection at 2800 m depth and with no significant pressure constraint (a Mesozoic Class-A resource).

These have been modeled using Eq. (1), with the assumptions shown in Table 2, to estimate the storage metrics and have well rates that cover the observed range in historical injection data (See Appendix: Methods used in supporting the main paper). Of course, a wide range of scenarios are possible – these are only intended to portray representative well behaviors. Of these 4 scenarios, the DC case reaches a pressure limit before the end of the expected well life of 25 years, resulting in only 5.1 Mt stored at project closure in year 16. The best case (SO) achieves 23.4 Mt stored after 25 years, and the mean injection rate for all four cases is 0.57 Mtpa, close to the historical mean of 0.53 Mtpa and lower than the historical mean for offshore wells at 0.7 Mtpa (See Appendix: Methods used in supporting the main paper).

Global CO2 Injection Development well Rate and Timeline

Given the reservoir performance concepts developed above, and the constraint of expected average injection rates, how then could a strategy for systematic use of this subsurface offshore continental margin stratigraphic storage resource be implemented? We address this by considering the history of hydrocarbon industry development in the selected regions to provide a template for a credible deployment timescale for CCS as an analog for achieving global emissions reduction targets.

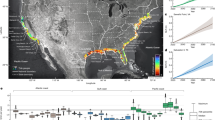

Figure 6 presents future well-development based on historical well performance for the Texas inner shelf of the Gulf of Mexico, the entire Gulf of Mexico, and the Norwegian North Sea (well count data from Texas Railroad Commission, U.S. Bureau of Safety and Environmental Enforcement, and the Norwegian Petroleum Directorate). The primary data provided are the annual and total cumulative number of wells drilled in each region. The historical curves have each been shifted such that the initial year for the first well is 2020 (although a few offshore CO2 injection wells existed globally before that time). The cumulative number of historic hydrocarbon wells has been translated to storage volumes assuming a 25-year well life for each CO2 injection well, a reasonable assumption given the experience with enhanced oil recovery using CO2 injection wells in the Permian Basin of west Texas. This results in some fall-off of active well numbers in the years after 2050. The number of wells active in 2050 in these scenarios are 17,155 for the Gulf of Mexico case, 2,083 for Norway and 345 for Texas.

Projected growth of the number of CO2 injection wells and the cumulative CO2 injected, based on historical hydrocarbon well development for three different geologic regions. Historic datasets have been replotted beginning in 2020 to provide a perspective on potential future regional CCS well deployment. The lower slope of the data in late years is a result of hydrocarbon production maturation (resource depletion, creaming concepts), which might also occur with CO2 storage when resource limits are eventually reached (volume or pressure). Thin dashed lines represent high (P10) and low (P90) bounds (See Appendix: Methods used in supporting the main paper) based on injection rates of 0.33 and 1.06 Mta.

The mean CO2 injection rate per well is assumed to be 0.7 Mtpa (or 17.5Mt per well over the 25-year lifetime), based on the available data for injection rates to date (See Appendix: Methods used in supporting the main paper) and consistent with pressure-sensitive results derived in Table 2. Using available historic data from industrial-scale storage projects in operation (See Appendix: Methods used in supporting the main paper) we obtain rate estimates of 0.532 ± 0.271 Mtpa for all wells and 0.695 ± 0.222 Mtpa for the offshore wells only. Using the offshore wells statistics (See Appendix: Methods used in supporting the main paper) we then obtained values for a 90% confidence interval: P90 = 0.33, P50 = 0.70, P10 = 1.06 (where P90 indicates 90% probability of exceedance). We recall that the IEA5 envision global CCS deployment capable of capturing and storing up to 7 Gt of CO2 emissions per year in 2050, with total cumulative mitigation of 120 Gt at that time50. Using the assumed mean injection rate of 0.7 Mtpa per well, this implies that over 10,000 CO2 injection wells (delivering 7,000 Mt per year total) may need to be in operation by 2050. Is this plausible? Essentially yes, considering historic well development rates. For example, by converting the historical well development trajectories into future CO2 injection wells (Fig. 6) and assuming 0.7 Mtpa average injection rates, we can infer that:

A single ‘Gulf-of-Mexico well development’ CO2 injection model could achieve the 7 Gtpa storage by 2043 and 12 Gtpa by 2050. Cumulative storage in 2050 would be 116 Gt.

Alternatively, five ‘Norway offshore well development’ models could achieve the 7 Gtpa storage by 2050. Cumulative storage in 2050 would be 73 Gt.

Cumulative storage of >100 Gt by 2050 is most efficiently achieved with 5–7 regions pursuing a Norwegian-scale offshore well development model using individual well injection rates between 0.5–1 Mta, although it could be achieved with a single GoM model with 0.7 Mtpa injection rates.

The point of this extrapolation is to demonstrate that it will only take a fraction of the historic worldwide offshore petroleum well development rate to achieve the global requirements for GCS. While offshore CCS is suitable many places (recall Figs. 1 and 2), it does not have to be deployed everywhere to achieve global benefit, and focus can be on the most prospective and economic regions. In practice, these developments would likely occur in multiple offshore basins close to the main locations of onshore capture; however, our selected basin development curves constrain the total well rate required to achieve the incremental and cumulative 2DS emissions reduction goal for 2050. Further discussion of the assumptions made in this evaluation and alternative injection wells scenarios are given in the Appendix (See Appendix: Methods used in supporting the main paper).

To obtain a preliminary cost estimate for this potential global offshore drilling programme, we note that offshore injection well costs are of order ~50–100 M€ (55–110 MUSD) per well, assuming a 2015 reference case51. The offshore drilling costs in terms of emissions avoided are therefore of order 2.9–5.5 €/tonne (3.2–6.3US$/tonne) for our mean well rate of 17.5Mt per well. This does not include the costs of capture, transport or platform infrastructure, but indicates that offshore saline aquifer storage can be a cost-effective emissions-mitigation measure in a world where the cost/penalty of emitting to atmosphere rises above the current level of 20–60 US$/tCO2e (carbonpricingdashboard. worldbank.org).

Conclusions

CCS is essential for realizing a global emissions reduction strategy consistent with 2DS aspirations. Globally, it is the continental margin geology that can most rapidly accommodate the large-scale CCS anticipated. There are many well-established global geologic similarities in these basins, and prior petroleum exploration provides an exceptionally well-documented starting point for deploying CCS in these settings. We propose using the characteristic pressure and stress versus depth trends in these basins as a framework for determining the initial and final pressure bounds (the basin ΔP approach) for determining the capacity of prospective storage projects. By utilizing the ‘pressure stratigraphy’ of these basins, early class-A projects can exploit the most accessible storage sites (generally shallower and less constrained by pressure limits), while later projects will exploit the majority of sites (class-B projects) which will have practical pressure limits governed by the basin stress and pressure profiles. Eventually, more advanced technology using pressure management approaches (class-C projects) will allow further resource development. This forward strategy for CCS has a precedent in the historic development of technology in oil and gas projects.

The timeframe of Gigatonne-scale CCS is hard to evaluate using either multiple individual numerical reservoir simulations (too many are needed) or using regional static volumetric assessments (which are likely optimistic as they don’t account for the dynamic pressure conditions). However, by developing a basin-scale pressure model to frame project capacity assessments, we propose a consistent and transparent basis for assessing and developing these resources.

Using historic well development scenarios from mature hydrocarbon basins and applying stratigraphic dynamic pressure constraints, a strategy for accessing the required storage capacity through time is demonstrated, providing a roadmap for global deployment of offshore CO2 storage consistent with the 2DS objective. Using this analysis, it is clear that the required well rate for realizing global CCS in the 2020–2050 timeframe is a manageable fraction of the historical well rate deployed from historic petroleum exploitation activities and is most efficiently achieved with multiple simultaneous regional developments.

Data availability

Methods used are described in the Supplementary Information (Appendix).

References

Stocker, T. F. (Ed.) Climate change 2013 - the physical science basis. Working Group I contribution to the Fifth assessment report of the Intergovernmental Panel on Climate Change (Cambridge University Press, 2014).

IEA, 20 years of carbon capture and storage: Accelerating future deployment, https://www.iea.org/publications (2016).

IEA, Energy Technology Perspectives in 2017 (OECD/IEA. Paris, 2017).

Pacala, S. & Socolow, R. Stabilization Wedges: Solving the Climate Problem for the Next 50 Years with Current Technologies. Science 305(5686), 968–972, https://doi.org/10.1126/science.1100103 (2004).

IEA, Carbon Capture and Storage: The solution for deep emissions reductions (International Energy Agency Publications, Paris, 2015)

Edenhofer, O. et al. (Eds), Mitigation of Climate Change. Working Group III (WG3) of the Fifth Assessment Report (AR5) of the Intergovernmental Panel on Climate Change. (Cambridge University Press, 2014).

Alcalde, J. et al. Estimating geological CO2 storage security to deliver on climate mitigation, Nature Communications, 9, [2201], https://doi.org/10.1038/s41467-018-04423-1 (2018).

GCCSI, Global status of CCS: 2018, www.globalccsinstitute.com/resources/global-status-report/ (Global CCS Institute, 2018).

Van der Meer, L. G. H. The CO2 storage efficiency of aquifers. Energy Conversion and Management 36(6–9), 513–518 (1995).

IEAGHG, CCS Deployment in the context of regional developments in meeting long-term climate change objectives (IEAGHG Technical Report 2017-07, August, 2017).

Schlee, J. S. A comparison of two Atlantic-type continental margins, U.S. Geological Survey, Professional Paper 1167 (United States Government Printing Office, Washington D.C., 1980).

Gibbs, A. D. Structural evolution of extensional basin margins. J. Geol. Soc. London 141, 609–620 (1984).

Lister, G. S., Etheridge, M. A. & Symonds, P. A. Detachment models for the formation of passive continental margins. Tectonics 10(5), 1038–1064 (1991).

Ehrenberg, S. N. & Nadeau, P. H. Sandstone vs. carbonate reservoirs: a global perspective on porosity-depth and porosity-permeability relationships. AAPG Bulletin 89(4), 435–445 (2005).

Smith, D. A. Sealing and non-sealing faults in Louisiana Gulf Coast Basins. AAPG Bulletin, 64, 145–172 (1980).

Manzocchi, T., Childs, C. & Walsh, J. J. Faults and fault properties in hydrocarbon flow models. Geofluids 10(1–2), 94–113 (2010).

U.S. Geological Survey, World Petroleum Assessment 2000, Digital Data Series 60, https://energy.usgs.gov/OilGas/AssessmentsData/WorldPetroleumAssessment.aspx (2000).

Huffman, A. R. & Bowers, G. L. Pressure regimes in sedimentary basins and their prediction. AAPG Memoir 76. https://doi.org/10.1306/M76870 (2001).

Harrison, W. J. & Summa, L. L. Paleohydrology of the Gulf of Mexico basin. American Journal of Science 291(2), 109–176 (1991).

Gaarenstroom, L., Tromp, R. A. J., & Brandenburg, A. M. Overpressures in the Central North Sea: implications for trap integrity and drilling safety. In Geological Society, London, Petroleum Geology Conference series, Vol. 4, No. 1: 1305–1313 (1993).

Mello, U. T. & Karner, G. D. Development of sediment overpressure and its effect on thermal maturation: Application to the Gulf of Mexico basin. AAPG bulletin 80(9), 1367–1396 (1996).

Bolås, H. M. N. & Hermanrud, C. Hydrocarbon leakage processes and trap retention capacities offshore Norway. Petroleum Geoscience 9(4), 321–332 (2003).

Ramdhan, A. M. & Goulty, N. R. Overpressure and mudrock compaction in the Lower Kutai Basin, Indonesia: A radical reappraisal. AAPG bulletin 95(10), 1725–1744 (2011).

Muggeridge, A., Abacioglu, Y., England, W. & Smalley, C. The rate of pressure dissipation from abnormally pressured compartments. AAPG Bulletin 89(1), 61–80 (2005).

Osborne, M. J. & Swarbrick, R. E. Mechanisms for generating overpressure in sedimentary basins: A reevaluation. AAPG bulletin 81(6), 1023–1041 (1997).

Seni, S. J. et al. (Eds.) Atlas of Northern Gulf of Mexico Gas and Oil Reservoirs, Volume 1 - Miocene and Older Reservoirs. (Bureau of Economic Geology, The University of Texas at Austin, 1997).

Meckel, T. A., Nicholson A. J. & Treviño, R. H. Capillary aspects of fault-seal capacity for CO2 storage, Lower Miocene, Texas Gulf of Mexico, In: Treviño, R. H. & T. A. Meckel, Eds., Geological CO2 sequestration atlas of Miocene strata, offshore Texas state waters, Bureau of Economic Geology, Report of Investigations No. 283 (The University of Texas at Austin, 2018).

Morris, S. et al. The pore pressure regime of the northern Gulf of Mexico: Geostatistical estimation and regional controls. AAPG Bulletin 99(1), 91–118 (2015).

Birkholzer, J. T., Zhou, Q., Cortis, A. & Finsterle, S. A sensitivity study on regional pressure buildup from large-scale CO2 storage projects. Energy Procedia 4, 4371–4378, https://doi.org/10.1016/j.egypro.2011.02.389. (2011).

Ganjdanesh, R. & Hosseini, S. A. Development of an analytical simulation tool for storage capacity estimation of saline aquifers. Int. J. Greenhouse Gas Control 74, 142–154 (2018).

Rutqvist, J., Birkholzer, J. T. & Tsang, C.-F. Coupled reservoir-geomechanical analysis of the potential for tensile and shear failure associated with CO2 injection in multilayered reservoir–caprock systems. International Journal of Rock Mechanics and Mining Sciences 45(2), 132–143, https://doi.org/10.1016/j.ijrmms.2007.04.006. (2008).

Mathias, S. A., Miguel de, G. J. G. M., Thatcher, K. E. & Zimmerman, R. W. Pressure buildup during CO2 injection into a closed brine aquifer. Transport Porous Media 89, 383–397, https://doi.org/10.1007/s11242-011-9776-z. (2011).

Ehlig-Economides, M. J. & Economides, C. A. Sequestering Carbon Dioxide in a Closed Underground Volume. Journal of Petroleum Science and Engineering 70, 123–130 (2009).

Cavanagh, A. J., Haszeldine, R. S. & Blunt, M. Open or Closed: A Discussion of the Mistaken Assumptions in the Economides Analysis of Carbon Sequestration. Journal of Petroleum Science and Engineering 74(1-2), 107–110 (2010).

Babaei, M. et al. Calculation of pressure- and migration-constrained dynamic CO2 storage capacity of the North Sea Forties and Nelson dome structures. International Journal of Greenhouse Gas Control 53, 127–140 (2016).

Goudarzi, A., Hosseini, S. A., Sava, D. & Nicot, J.-P. Simulation and 4D seismic studies of pressure management and CO2 plume control by means of brine extraction and monitoring at the Devine Test Site, South Texas, USA. Greenhouse Gas Sci. Technol. 8, 185–204 (2017).

Metz, B., Davidson, O., De Coninck, H., Loos, M. & Meyer, L. Carbon dioxide capture and storage: Working Group III of the Intergovernmental Panel on Climate Change (Cambridge, University Press, United Kingdom and New York, USA (2005).

Birkholzer, J. T., Zhou, Q. & Tsang, C. F. Large-scale impact of CO2 storage in deep saline aquifers: A sensitivity study on pressure response in stratified systems. International Journal of Greenhouse Gas Control 3(2), 181–194 (2009).

Hansen, O. et al. Snøhvit: The history of injecting and storing 1 Mt CO2 in the fluvial Tubåen Fm. Energy Procedia 37, 3565–3573 (2013).

Pawar, R. J. et al. Recent advances in risk assessment and risk management of geologic CO2 storage. International Journal of Greenhouse Gas Control 40, 292–311 (2015).

Gasda, S. E., Nordbotten, J. M., & Celia, M. A. Vertically averaged approaches for CO2 migration with solubility trapping. Water Resources Research, 47.5 (2011).

Gasda, S. E., Nilsen, H. M. & Dahle, H. K. Impact of structural heterogeneity on upscaled models for large-scale CO2 migration and trapping in saline aquifers. Advances in Water Resources 62, 520–532 (2013).

Buscheck, T. A. et al. Active CO2 reservoir management for carbon storage: Analysis of operational strategies to relieve pressure buildup and improve injectivity. International Journal of Greenhouse Gas Control 6, 230–245 (2012).

Nazarian, B., Thorsen, R. & Ringrose, P. Storing CO2 in a reservoir under continuous pressure depletion – a simulation study, GHGT-14 Conference Proceedings, Melbourne, Australia. Available at SSRN: https://ssrn.com/abstract=3365822 (2019).

Jenkins, C. R. et al. Safe storage and effective monitoring of CO2 in depleted gas fields. Proceedings of the National Academy of Sciences 109(2), E35–E41 (2012).

Thibeau, S., Seldon, L., Masseranoc, F., Canal Vila, J. & Ringrose, P. Revisiting the Utsira Saline Aquifer CO2 Storage Resources using the SRMS Classification Framework. GHGT-14 Conference Proceedings, Melbourne, Australia. Available at SSRN: https://ssrn.com/abstract=3366195 (2019).

Bøe R., Magnus C., Osmundsen P. T., Rindstad B. I. CO2 point sources and subsurface storage capacities for CO2 in aquifers in Norway, Norwegian Geological Survey (NGU) Report 2002.010 (2002).

Gasda, S., Wangen, M., Bjørnara, T. & Elenius, M. Investigation of caprock integrity due to pressure build-up during high-volume injection into the Utsira formation. Energy Procedia 114, 3157–3166 (2017).

Holloway, S. (Ed.) The underground disposal of carbon dioxide, Final report of Joule 2, Project No. CT92-0031, British Geological Survey, Keyworth, Nottingham, UK, 355p (1996).

International Energy Agency Energy: Technology Perspectives 2013: Technology Roadmap for Carbon Capture and Storage (p.23–24; 2013).

Ringrose, P. et al. Developing Optimised and Cost-Effective Solutions for Monitoring CO2 Injection from Subsea Wells. In 14th Greenhouse Gas Control Technologies Conference Melbourne Available at SSRN: https://ssrn.com/abstract=3366156 (2018).

Divins, D. L. Total Sediment Thickness of the World’s Oceans & Marginal Seas, NOAA National Geophysical Data Center, Boulder, CO. (2003).

Whittaker, J. et al. Global sediment thickness data set updated for the Australian-Antarctic Southern Ocean. Geochemistry, Geophysics, Geosystems 14(8), 3297–3305 (2013).

Mann, P., Gahagan, L. & Gordon, M., Tectonic Setting of the World’s Giant Oil Fields, World Oil 222.10 (October): 78–79 (2001).

Acknowledgements

P.R. thanks NTNU and Equinor for financial support and permission to publish and acknowledges useful advice from Bamshad Nazarian (Equinor), Ole Jakob Artnzen (Equinor) and Martin Landrø (NTNU). CO2 storage site data from Equinor operations was kindly released to NTNU as part of the Norwegian CCS Research Centre. T.M. thanks his colleagues at the Gulf Coast Carbon Center for constructive discussions, the Director of the Bureau of Economic Geology, The University of Texas at Austin for authorization to publish, and research funding in part through National Energy Technology Laboratory DOE award number: DE-FE0026083 - Offshore CO2 Storage Resource Assessment of the Northern Gulf of Mexico. The views and opinions of authors expressed herein do not necessarily state or reflect those of our host institutions, or the United States Government or any agency thereof.

Author information

Authors and Affiliations

Contributions

P.R. mainly contributed the work on CO2 injectivity, well rates, basin pressure analysis and the offshore Norway case study. T.M. mainly contributed the work on global offshore basins and hydrocarbon fields and the Gulf of Mexico case study. Well databases were assessed by T.M. and the injection-well model scenarios were mainly developed by P.R. Both authors worked iteratively to develop the arguments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ringrose, P.S., Meckel, T.A. Maturing global CO2 storage resources on offshore continental margins to achieve 2DS emissions reductions. Sci Rep 9, 17944 (2019). https://doi.org/10.1038/s41598-019-54363-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-54363-z

This article is cited by

-

Capillarity-Driven Hydrate Film Formation in Geologic Carbon Storage

Transport in Porous Media (2024)

-

The impact of methane leakage on the role of natural gas in the European energy transition

Nature Communications (2023)

-

Subsurface carbon dioxide and hydrogen storage for a sustainable energy future

Nature Reviews Earth & Environment (2023)

-

An assessment of energy system transformation pathways to achieve net-zero carbon dioxide emissions in Switzerland

Communications Earth & Environment (2023)

-

Towards a process-based understanding of rifted continental margins

Nature Reviews Earth & Environment (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.