Abstract

Tungsten disulfide (WS2) as one of transition metal dichalcogenides exhibits excellent catalytic activity. However, its catalytic performances in aqueous phase reactions are limited by its hydrophobicity. Here, the natural hydrophilic two-dimensional clay was used to enhance the dispersibility of WS2 in aqueous phase. WS2/montmorillonite (WS2/MMT) composite nanosheets were prepared via hydrothermal synthesis of WS2 on the surface of montmorillonite from WCl6 and CH3CSNH2. The microstructure and morphology show that WS2 nanosheets are assembled parallelly on the montmorillonite with the interface interaction. Through the support of montmorillonite, WS2/MMT possesses higher photocatalytic ability for aqueous phase reactions than WS2, which could be due to the synergistic effect of higher adsorption property, higher hydrophilicity, dispersibility and more catalytic reaction site. The strategy could provide new ideas for obtaining novel hydrophilic photocatalyst with excellent performance.

Similar content being viewed by others

Introduction

Since the discovery of graphene, two dimensional (2D) materials have pioneered a new field for nanomaterials. Due to their specific structure and unconventional physicochemical property, 2D nanomaterials have received world-wide of attention for energy storage and conversion1, electronics2 and catalysis3,4. In addition to graphene, many novel 2D nanomaterials have been found and researched heavily in recent years5, such as transition metal dichalcogenide (TMD)6,7, layered double hydroxides (LDHs)8 and graphene analogues9,10. Various 2D composite nanosheets were designed and fabricated via multifarious methods11, which exhibit exceptional properties and play important roles in many high-tech fields.

Recently, TMD has attracted a lot of attention due to peculiar electrical and optical characteristics and intrinsic semiconducting properties12. Interestingly, their electronic band gap transform into direct band gap from indirect band gap, with thickness decreasing to monolayer or few layers from bulk13. Tungsten disulfide (WS2) with sandwich structure is a kind of TMD composed of multilayered nanosheets14,15. WS2 sheets possess high absorption for the visible light and excellent photocatalytic activity16, which could be used in hydrogen evolution17, degradation of dyes18 and reduction of nitrophenol19. The photocatalytic ability of WS2 nanosheets might mainly originate from unsaturated atoms on the surfaces and edges20,21. It is reported that the theoretical conduction band and valance band of WS2 are −0.06 and 2.27 eV22, and WS2 has photocatalytic hydrogen production performance21. Conventional methods to obtain few-layered WS2 sheets include mechanical exfoliation and chemical vapor deposition. Hydrothermal synthesis using precursor of sodium molybdate could obtain fullerene-like WS2 nanoparticles, 1D nanotubes and rods, but 2D nanosheets is hard to get in this way. Jieun Yang and co-workers23 first report the synthesis of WS2/graphene nanosheets by hydrothermal method from tungsten chloride at 265 °C. The WS2 nanosheets easily aggregate to reduce catalytic activity, and assembling them on the support materials is one of effective solutions. WS2 and most WS2 composites are hydrophobicity and poor dispersibility in aqueous phase. Therefore, design of hydrophilic WS2 composites is significant for their catalytic ability in aqueous phase.

Montmorillonite (MMT) is one of natural sheet-like clay mineral with excellent hydrophobicity. Its layer structure consists of a central Al-O octahedral sheet and two Si-O tetrahedral sheets, and the unit layer stacks with cation in the interlayer. MMT possesses large special surface area, excellent adsorptive capacity and hydrophobicity, which make it a promising material for pollutants adsorption, catalyst supports24,25,26,27, wastewater treatment28,29, energy storage matrix30,31 and drug delivery systems32. Based on the special structure and property of MMT, hydrophilic composite nanosheets might be constructed through MMT supporting WS2 nanosheets, which could be used as an efficient photocatalyst for aqueous phase reactions. Hazardous wastewaters with organic dye are greatly harmful to the environment33,34,35,36,37. Photocatalysis technology is a potential approach to treat these waste waters38, and design of the efficient photocatalyst is one of the key procedures39,40.

Herein, we first designed and prepared the WS2/montmorillonite (WS2/MMT) composite nanosheets as a hydrophilic photocatalyst for aqueous phase reactions. WS2/MMT was successfully fabricated through facile in-situ hydrothermal synthesis of WS2 on MMT. The microstructure and morphology were characterized, and the photocatalytic ability for aqueous phase reactions was evaluated by degradation of organic dye. The effect of MMT on catalytic ability was studied, and the possible catalysis mechanism for photocatalytic degradation of RhB were explored and illustrated in detail.

Results

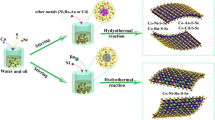

As schematically depicted in Fig. 1, the WS2/montmorillonite (WS2/MMT) composite nanosheets were hydrothermally synthesized with tungsten chloride and thioacetamide at 220 °C for 24 h. Firstly, the montmorillonite (MMT) was added in water solution of WCl6 and CH3CSNH2. The surface of MMT is negatively charged for the Si4+ lattice replaced by Al3+. Conventional tungstate precursors such as Na2WO4 and (NH4)10W12O41 are unable to adsorb on of MMT. Therefore, WCl6 was employed as a precursor of tungsten, and W6+ was adsorbed on MMT by electrostatic interaction. In hydrothermal conditions, the thioacetamide was pyrolyzed and released H2S, and WCl6 was reduced to form WS2 by sulfurization. Finally, the WS2 nanosheets were nucleated and grown, and the as-prepared WS2 was assembled on MMT to prepare WS2/MMT nanosheets.

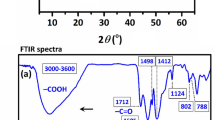

The crystallographic structure was inspected by XRD measurements, and the patterns of MMT, WS2, WS2/MMT, WS2/MMT-0.5 and WS2/MMT-2 are presented in Fig. 2a. In the pattern of MMT, the reflection at 7.2° (2θ) is attributed to the (001) reflection of Na-montmorillonite, indicating that the d001 basal spacing is 1.22 nm. The diffraction peaks at 19.7° and 34.7° (2θ) are corresponding to (100) and (110) planes of MMT. The diffraction peaks in the pattern of hydrothermally synthesized WS2 can be attributed to 2H-WS2 phase (JCPDS#08-0237). The reflection at 14.2° due to the (002) diffraction shows the distance of lattice plane along (002) is 0.62 nm for WS2 multilayer. The reflections assigned to (100) and (110) planes of WS2 are found at 32.7° and 58.4°, respectively. The main reflections of MMT and WS2 were observed in XRD pattern of WS2/MMT. Compared with WS2/MMT, the intensity of the reflections of WS2 is relatively lower in the pattern of WS2/MMT-0.5, indicating the lower content of WS2. The reflection assigned to (100) plane of WS2 has higher intensity in the WS2/MMT-2, while the diffraction peak corresponding to (002) plane is broader and lower, which could be attributed to lower stacking of WS2 layers.

The interface interaction was studied by FTIR analysis. In the FTIR spectrum of MMT (Fig. 2b), the bands due to vibration of Si–O is found at 471 and 1022 cm−1, indicating that a silicon-oxygen tetrahedron exists in the layered structure of MMT. The broad band at 3620 cm−1 is due to the aluminum hydroxy stretching vibration. The hydroxy bending vibration and H–O–H stretching vibration corresponding to hydrogen bonding water could be observed at 1637 and 3453 cm−1. The bands at 1401, 1613 and 3125 cm−1 in the FTIR spectrum of WS2 are associated with the W–S bending vibration and stretching vibration41. For WS2/MMT, the bands corresponding to hydroxy decrease significantly, and the band of Si–O shifts to 1037 cm−1 from 1022 cm−1, which suggests the interface interaction between WS2 and MMT.

The chemical statuses of the samples were investigated using XPS. Fig. 3a shows the XPS survey spectra of samples in the range 0–700 eV. Compared with the XPS spectrum survey of MMT, the peaks of W and S are observed in the WS2/MMT. The binding energy of Si 2p in WS2/MMT (Fig. 3b) shifts to a little higher energy state compared with that of MMT, indicating electronic interaction between WS2 and MMT. The W 4 f peaks of WS2/MMT (Fig. 3c) are located at the binding energies of 32.2, 34.3, 36.1 and 38.2 eV, respectively. The binding energies of W 4f7/2 and W 4f5/2 peaks at 32.2 and 34.3 eV are correspond to W4+, and the binding energies at 36.1 and 38.2 eV are attributed to W6+ (oxide states), which might be due to the partial oxidation of tungsten on the surface and the interface interaction between WS2 and MMT. In the scans of S 2p electrons of WS2/MMT (Fig. 3d), the binding energies of S 2p3/2 and S 2p1/2 peaks are 161.9 and 163.3 eV, respectively.

The morphologies of samples were characterized with SEM. In the SEM image of MMT (Fig. 4a), the sample presents a lamellar morphology and smooth surface, which is favorable for the supporting of WS2. The WS2 synthesized by hydrothermal method exhibits the agglomerated particles with irregular shapes (Fig. 4c). For WS2/MMT (Fig. 4e), WS2 and MMT exhibit two dimensional morphology and stack with each other to form layer structure. In the WS2/MMT composites, MMT could reduce the agglomeration of WS2. The energy disperse spectrum of WS2/MMT indicates that the mass contents of W and S element are 29.84 Wt% and 10.60 Wt%, which is in accord with the theoretical element ratio of WS2.

Further details of the microstructure could be obtained by TEM and HRTEM. The TEM image of MMT (Fig. 4b) shows dispersed nanosheet. As shown in Fig. 4d, the synthesized WS2 is irregular nanoparticle. The HRTEM image indicates that the (002) plane WS2 nanoparticle is 0.62 nm, in accordance with XRD result. From the TEM and HRTEM of WS2/MMT (Fig. 4f), the microstructure of sample exhibits composite nanosheets, and WS2 nanosheets are assembled parallelly on MMT. The WS2 nanosheets could possess better dispersibility and expose more catalytic reaction edges attributed to support of MMT.

The specific surface area was characterized by nitrogen adsorption-desorption isotherms. In the curves of MMT and WS2/MMT (Fig. 5a), the type IV adsorption branches are corresponding to the mesoporous structure. The specific surface area of WS2/MMT and MMT are calculated to be 16.13 and 38.02 m2∙g−1, respectively. No hysteresis loop is observed in the curve of WS2, and the specific surface area is 6.56 m2∙g−1. Compared with WS2, WS2/MMT has relatively higher specific surface area, and it might be because MMT could reduce the stack and inhibit the agglomeration of WS2 nanosheets. The pore size distributions are shown in Fig. 5b. The average pore size of MMT is about 3 nm, while those of WS2 and WS2/MMT are around 40 nm. Due to the support of MMT, WS2/MMT composite nanosheets possess larger special surface area than WS2, which might provide more reactive sites to enhance photocatalytic activity.

The UV–vis diffuse reflectance spectra of samples are shown in Fig. 6a. The visible light absorption of MMT is very weak. WS2 and WS2/MMT exhibit considerable visible absorption, which is consistent with the black color of the samples. It is of great significance for visible light photocatalytic application42. The band gap energies of MMT, WS2 and WS2/MMT (Fig. 6b) are 3.86, 1.37 and 1.51 eV, respectively. Compared with WS2, WS2/MMT possesses larger band gap energy, which could be due to the effects of the few layered WS2 and MMT.

Compared with the PL peak of WS2 (Fig. S1), the peak shape and position of WS2/MMT are similar, while the peak intensity is higher. It might be related to luminescence-inactive multilayer structure in WS2. In the PL spectrum of MMT, the peak at 354 and 398 nm could be due to the intrinsic defects of surplus oxygen on the surface and intrinsic diamagnetic defect center, respectively. The PL peak intensity of WS2/MMT is weaker than that of MMT, which is attributed to the less recombination of photo-generated carriers.

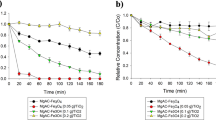

Photodegradation of organic dyes was applied to evaluate the photocatalytic abilities of samples for aqueous phase reactions. The variation of decoloration rate with MMT, WS2, WS2/MMT, WS2/MMT-0.5 and WS2/MMT-2 as catalysts is shown in Fig. 7a. The RhB aqueous solution is stable with visible light irradiation during 1 h, and the decoloration rate has hardly the change without catalyst. Adsorption equilibrium was reached without light irradiation for 15 min, and physical adsorption of samples was recorded. MMT has the highest adsorption capacity up to 17.0%, and the adsorption rate of WS2 is lowest. The WS2/MMT has higher adsorption rate than WS2, and the adsorption rate has an increase tendency with the increasing of MMT content. It might be because the special structure of MMT, and the high specific surface area and abundant surface hydroxyl groups are in favor of the adsorption for RhB43,44. WS2/MMT has the highest degradation speed, and the overall decoloration rate of RhB is up to 99.8% after visible light irradiation for 45 min. The degradation speeds of WS2/MMT-0.5 and WS2/MMT-2 are higher than that of WS2, but lower than WS2/MMT. Photocatalytic ability of WS2/MMT composite nanosheets is enhanced via the support of MMT. It might be because the MMT sheets prevent WS2 nanosheets aggregation, and improve the hydrophilicity and dispersibility of aqueous phase, which could supply composites more reactive sites. As shown in Fig. S4, the photocatalytic ability of WS2/MMT does not show obvious change after four cycles, indicating the high stability of WS2/MMT in the aqueous phase photocatalytic reaction process. WS2/MMT also shows excellent photodegradation performance for Methylene blue (MB), Methyl orange (MO) and Congo red (CR) in the aqueous phase (Fig. S5). The photodegradation of RhB was observed to follow pseudo-first-order kinetics21 according to the formula (ln(C/C0 = −kt)), where C and C0 is the homologous and initial concentration, and k is apparent reaction rate constant. The apparent reaction rate constants of WS2/MMT and WS2 are 0.16 and 0.09 min−1 (Fig. S6), indicating the higher photocatalytic ability of WS2/MMT.

In Fig. 7b, WS2/MMT composite nanosheets uniformly disperse in water, while WS2 almost floated on the aqueous phase, which could be attributed to the hydrophobicity of hydrothermally synthesized WS2. Contact angles of MMT, WS2/MMT and WS2 (Fig. S2) are 18.7°, 32.3° and 54.5°, respectively. With the supporting of MMT, WS2/MMT has better hydrophilicity than WS2.

Discussion

As shown in Fig. S3, the UV–vis absorption peak of RhB is located at 554 nm, while no obvious absorption peak is observed after RhB is photodegraded. The possible photocatalysis mechanism for the degradation of RhB is shown in Fig. 7c. With the excitation of visible light, the photoinduced electrons (e–) and holes (h+) are generated in WS2, respectively45. hydroxyl groups could capture h+ to form hydroxyl radicals (OH·), which could restrain recombination and improve the photocatalytic ability46. The photoexcited e– electrons might induce the O2– with O2, and these h+, OH· and O2– could photo-oxidize organic molecules RhB.

In conclusion, WS2/MMT nanosheets were prepared by the hydrothermal method, which were utilized as an efficient hydrophilic photocatalyst for aqueous phase reactions. Few-layered WS2 nanosheets are grown parallelly on MMT, and MMT could reduce the stack and inhibit the agglomeration of WS2 nanosheets, which supply composites more catalytic reaction sites. With WS2/MMT as photocatalyst, the overall decoloration capacity of RhB was up to 99.8%. Through the support of MMT, WS2/MMT possesses high hydrophilicity and dispersibility of aqueous phase, which is conducive to the enhancement of catalytic ability. The WS2/MMT composite nanosheets have potential to treat organic waste water. The strategy could provide insights for construction of efficient hydrophilic photocatalyst with excellent activity for environmental treatment.

Methods

Materials

The montmorillonite (MMT) used was obtained from Zhejiang Sanding Technology Co. Ltd. (Zhejiang, China). It consisted primarily of MMT (>97%) with minor impurity of quartz. The chemical compositions of MMT were as follows: SiO2 61.5 Wt%, Al2O3 19.3 Wt%, MgO 3.5 Wt%, Fe2O3 1.4 Wt%, Na2O 2.8 Wt%, CaO 2.5 Wt%, K2O 0.6 Wt%, and the loss on ignition was approximately 8.4 Wt%. Tungsten chloride (WCl6), thioacetamide (CH3CSNH2) and Rhodamine B were purchased from Sinopharm Chemical Reagent Co. Ltd. All reagents were analytical grade and used without further purification46.

Preparation

The WS2/montmorillonite (WS2/MMT) composite nanosheets were synthesized by a facile hydrothermal method. In a typical experiment, 1.785 g of tungsten chloride and 3.415 g of thioacetamide were dissolved in 60 mL of deionized water and mechanically stirred for 30 min at room temperature. 1.000 g of MMT was added in the solution, and the mixture suspension was stirred for another 30 min and sonicated for 10 min at room temperature. Then, the suspension was transferred into a 100 mL Teflon-lined stainless steel autoclave, heated up to 220 °C, and kept for 24 h11. After cooling naturally, the precipitates were collected by centrifugation, and subsequently washed several times with deionized water. The final products were obtained after drying at 60 °C for 24 h. For comparison, pure WS2 samples were synthesized by a similar process, without MMT. Other samples were similarly prepared with different additive amounts of tungsten chloride and thioacetamide. A sample prepared with 0.893 g of tungsten chloride and 1.708 g of thioacetamide was labeled as WS2/MMT-0.5. A sample with 3.570 g of tungsten chloride and 6.830 g of thioacetamide was labeled as WS2/MMT-26.

Characterization

Powder X-ray diffraction (XRD) patterns of the samples were obtained on a RIGAKU D/max-2550 PC X-ray diffractometer with Cu Kα radiation (λ = 0.15406 nm) at a scan rate of 0.02°/s32. Fourier transform infrared (FTIR) spectra of the samples were obtained between 4000 and 400 cm−1 on a Nicolet Nexus 670 FTIR spectrophotometer using KBr pellets. Scanning electron microscopy (SEM) images were obtained with a JEOL JSM-6360LV scanning electron microscope at an accelerating voltage of 5 kV, which equipped with energy dispersive spectrometer (EDS). Transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) were operated with a JEOL JEM-2100F transmission electron microscope at an acceleration voltage of 200 kV42. The N2 adsorption-desorption isotherms were record at 77 K and analyzed using an ASAP 2020 surface area analyzer. X-ray photoelectron spectroscopy (XPS) measurements were performed using an ESCALAB 250 spectrometer. The UV-vis diffuse reflectance spectra (UV-vis DRS) were obtained with a Shimadzu UV2450 UV-vis spectrophotometer, and barium sulfate was used as reference. The photoluminescence (PL) experiment were conducted on a Hitachi F-4500 fluorescence spectrometer using an excitation wavelength of 254 nm3. The contact angles of the samples were measured using the sessile-drop technique using a goniometer (GBX, France).

Photocatalytic activity evaluation

Photodegradation of Rhodamine B (RhB) was selected as a typical reaction to evaluate the photocatalytic activity of samples for aqueous phase reactions. The light source was a 150 W high pressure mercury lamp with wave length λ > 400 nm. In a typical photocatalytic experiment, 100 mg of catalyst was added in 100 mL RhB aqueous solution (0.02 mmol/L). Firstly, the mixture suspension was magnetically stirred in the dark for 15 min to ensure the establishment of an adsorption-desorption equilibrium between the catalyst and RhB aqueous solution. Then, the reaction vessel was positioned with light irradiation, and 1 mL of 3% H2O2 was added as oxidant to initiate the reaction. About 3 mL of analytical sample was withdrawn from the reaction suspension every 5 min, and the catalyst was removed by a centrifuge. The concentration of the photodegradable compound was monitored by recording the absorbance (A) of the clarified solution at 554 nm with an UV-visible spectrophotometer. The decoloration rate (%) was calculated from the formula: decoloration rate (%) = (A0 − A)/A0 × 100%, where A0 was the initial absorbance, and A was the absorbance at homologous times25. The catalyst was centrifuged for the next cycle. Photocatalytic degradation of Methylene blue (MB), Methyl orange (MO) and Congo red (CR) were performed under the similar condition.

Data availability

The data that support the findings of this study are available from the corresponding author on reasonable request.

References

Woods, J. M. et al. One-step synthesis of MoS2/WS2 layered heterostructures and catalytic activity of defective transition metal dichalcogenide films. ACS Nano 10, 2004–2009 (2016).

Fu, Q. et al. Synthesis and enhanced electrochemical catalytic performance of monolayer WS2(1-x)Se2x with a tunable band gap. Adv. Mater. 27, 4732–4738 (2015).

Zhong, Y. et al. Band-gap-matched CdSe QD/WS2 nanosheet composite: Size-controlled photocatalyst for high-efficiency water splitting. Nano Energy 31, 84–89 (2017).

Cao, Y. et al. Defect-induced efficient dry reforming of methane over two-dimensional Ni/h-boron nitride nanosheet catalysts. Appl. Catal. B-Environ. 238, 51–60 (2018).

Han, X., Yu, Y., Huang, Y., Liu, D. & Zhang, B. Photogenerated carriers boost water splitting activity over transition-metal/semiconducting metal oxide bifunctional electrocatalysts. ACS Catal. 7, 6464–6470 (2017).

Peng, K., Fu, L., Yang, H., Ouyang, J. & Tang, A. Hierarchical MoS2 intercalated clay hybrid nanosheets with enhanced catalytic activity. Nano Res. 10, 570–583 (2016).

Li, N. et al. Stable multiphasic 1T/2H MoSe2 nanosheets integrated with 1D sulfide semiconductor for drastically enhanced visible-light photocatalytic hydrogen evolution. Appl. Catal. B-Environ. 238, 27–37 (2018).

Zhao, Y. et al. Defect-rich ultrathin ZnAl-layered double hydroxide nanosheets for efficient photoreduction of CO2 to CO with water. Adv. Mater. 27, 7824–7831 (2015).

Pumera, M. & Sofer, Z. Towards stoichiometric analogues of graphene: graphane, fluorographene, graphol, graphene acid and others. Chem. Soc. Rev. 46, 4450–4463 (2017).

Liu, H., Chen, D., Wang, Z., Jing, H. & Zhang, R. Microwave-assisted molten-salt rapid synthesis of isotype triazine-/heptazine based g-C3N4 heterojunctions with highly enhanced photocatalytic hydrogen evolution performance. Appl. Catal. B-Environ. 203, 300–313 (2017).

Peng, K., Fu, L., Ouyang, J. & Yang, H. Emerging parallel dual 2D composites: natural clay mineral hybridizing MoS2 and interfacial structure. Adv. Funct. Mater. 26, 2666–2675 (2016).

Shi, J. et al. Temperature-mediated selective growth of MoS2/WS2 and WS2/MoS2 vertical stacks on au foils for direct photocatalytic applications. Adv. Mater. 28, 10664–10672 (2016).

Sang, Y. et al. From UV to near-infrared, WS2 nanosheet: A novel photocatalyst for full solar light spectrum photodegradation. Adv. Mater. 27, 363–369 (2015).

Su, D., Dou, S. & Wang, G. WS2@graphene nanocomposites as anode materials for Na-ion batteries with enhanced electrochemical performances. Chem. Commun. 50, 4192 (2014).

Zhong, Y., Zhao, G., Ma, F., Wu, Y. & Hao, X. Utilizing photocorrosion-recrystallization to prepare a highly stable and efficient CdS/WS2 nanocomposite photocatalyst for hydrogen evolution. Appl. Catal. B-Environ. 199, 466–472 (2016).

Raza, F. et al. Structuring Pd nanoparticles on 2H-WS2 nanosheets induces excellent photocatalytic activity for cross-coupling reactions under visible light. J. Am. Chem. Soc. 139, 14767–14774 (2017).

Zhao, X., Ma, X., Sun, J., Li, D. & Yang, X. Enhanced catalytic activities of surfactant-assisted exfoliated WS2 nanodots for hydrogen evolution. ACS Nano 10, 2159–2166 (2016).

Zou, J.-P. et al. Fabrication of novel heterostructured few layered WS2-Bi2WO6/Bi3.84W0.16O6.24 composites with enhanced photocatalytic performance. Appl. Catal. B-Environ. 179, 220–228 (2015).

Wen, Y., Zhang, H. & Zhang, S. One-step gas–solid reaction synthesis of W@WS2 nanorattles and their novel catalytic activity. Nanoscale 6, 13090–13096 (2014).

Vattikuti, S. V. P., Byon, C. & Reddy, C. V. Preparation and improved photocatalytic activity of mesoporous WS2 using combined hydrothermal-evaporation induced self-assembly method. Mater. Res. Bull. 75, 193–203 (2016).

Koyyada, G. et al. Enhanced solar light-driven photocatalytic degradation of pollutants and hydrogen evolution over exfoliated hexagonal WS2 platelets. Mater. Res. Bull. 109, 246–254 (2019).

Ma, X. et al. Evidence of direct Z-scheme g-C3N4/WS2 nanocomposite under interfacial coupling: First-principles study. J. Alloy. Comp. 788, 1–9 (2019).

Yang, J. et al. Two-dimensional hybrid nanosheets of tungsten disulfide and reduced graphene oxide as catalysts for enhanced hydrogen evolution. Angew. Chem.-Int. Edit. 52, 13751–13754 (2013).

Peng, K. et al. One-step hydrothermal growth of MoS2 nanosheets/CdS nanoparticles heterostructures on montmorillonite for enhanced visible light photocatalytic activity. Appl. Clay Sci. 175, 86–93 (2019).

Peng, K., Fu, L., Yang, H. & Ouyang, J. Perovskite LaFeO3/montmorillonite nanocomposites: synthesis, interface characteristics and enhanced photocatalytic activity. Sci. Rep. 6, 19723 (2016).

Li, X. & Tang, A. Pd modified kaolinite nanocomposite as a hydrogenation catalyst. RSC Adv. 6, 15585–15591 (2016).

Yan, Z., Yang, H., Ouyang, J. & Tang, A. In situ loading of highly-dispersed CuO nanoparticles on hydroxyl-group-rich SiO2-AlOOH composite nanosheets for CO catalytic oxidation. Chem. Eng. J. 316, 1035–1046 (2017).

Li, X., Ouyang, J., Zhou, Y. & Yang, H. Assembling strategy to synthesize palladium modified kaolin nanocomposites with different morphologies. Sci. Rep. 5, 13763 (2015).

Yan, Z., Fu, L., Yang, H. & Ouyang, J. Amino-functionalized hierarchical porous SiO2-AlOOH composite nanosheets with enhanced adsorption performance. J. Hazard. Mater. 344, 1090–1100 (2018).

Peng, K., Fu, L., Li, X., Ouyang, J. & Yang, H. Stearic acid modified montmorillonite as emerging microcapsules for thermal energy storage. Appl. Clay Sci. 138, 100–106 (2017).

Peng, K., Zhang, J., Yang, H. & Ouyang, J. Acid-hybridized expanded perlite as a composite phase-change material in wallboards. RSC Adv. 5, 66134–66140 (2015).

Li, X., QianYang, Ouyang, J., Yang, H. & Chang, S. Chitosan modified halloysite nanotubes as emerging porous microspheres for drug carrier. Appl. Clay Sci. 126, 306–312 (2016).

Peng, K., Yang, H. & Ouyang, J. Tungsten tailing powders activated for use as cementitious material. Powder Technol. 286, 678–683 (2015).

Peng, K., Lv, C. & Yang, H. Novel preparation of glass ceramics from amorphized tungsten tailings. Ceram. Int. 40, 10291–10296 (2014).

Gao, S. et al. Triboelectric nanogenerator powered electrochemical degradation of organic pollutant using Pt-free carbon materials. ACS Nano 11, 3965–3972 (2017).

Li, X. et al. Facile synthesis of wormhole-like mesoporous tin oxide via evaporation-induced self-assembly and the enhanced gas-sensing properties. Nanoscale Res. Lett. 13, 14 (2018).

Liu, W. et al. Kinetic and mechanism studies on pyrolysis of printed circuit boards in the absence and presence of copper. ACS Sustainable Chem. & Eng. 7, 1879–1889 (2018).

Li, X. & Peng, K. Synthesis of 3D mesoporous alumina from natural clays for confining CdS nanoparticles and enhanced photocatalytic performances. Appl. Clay Sci. 165, 188–196 (2018).

Sun, M., Zhao, Q., Du, C. & Liu, Z. Enhanced visible light photocatalytic activity in BiOCl/SnO2: heterojunction of two wide band-gap semiconductors. RSC Adv. 5, 22740–22752 (2015).

Liu, X., Su, Y., Zhao, Q., Du, C. & Liu, Z. Constructing Bi24O31Cl10/BiOCl heterojunction via a simple thermal annealing route for achieving enhanced photocatalytic activity and selectivity. Sci. Rep. 6, 28689 (2016).

Wu, J. et al. Glucose aided preparation of tungsten sulfide/multi-wall carbon nanotube hybrid and use as counter electrode in dye-sensitized solar cells. ACS Appl. Mater. Interfaces 4, 6530–6536 (2012).

Li, X. & Peng, K. Hydrothermal synthesis of MoS2 nanosheet/palygorskite nanofiber hybrid nanostructures for enhanced catalytic activity. Appl. Clay Sci. 162, 175–181 (2018).

Peng, K. & Yang, H. Carbon hybridized montmorillonite nanosheets: preparation, structural evolution and enhanced adsorption performance. Chem. Commun. 53, 6085–6088 (2017).

Yan, Z., Fu, L., Zuo, X. & Yang, H. Green assembly of stable and uniform silver nanoparticles on 2D silica nanosheets for catalytic reduction of 4-nitrophenol. Appl. Catal. B-Environ. 226, 23–30 (2018).

Li, X., Peng, K., Chen, H. & Wang, Z. TiO2 nanoparticles assembled on kaolinites with different morphologies for efficient photocatalytic performance. Sci. Rep. 8, 11663 (2018).

Li, X. & Peng, K. MoSe2/montmorillonite composite nanosheets: hydrothermal synthesis, structural characteristics, and enhanced photocatalytic activity. Minerals 8, 268 (2018).

Acknowledgements

This work was supported by National Natural Science Foundation of China (51804242, 51772237, 51704030), the China Postdoctoral Science Foundation (2018T111054, 2017M623182, 2017M610617) and Natural Science Basic Research Plan in Shaanxi province of China (2018JQ5155). Shaanxi Science & Technology co-ordination & Innovation project (No. 2015KTCL01-13) Shaanxi Innovation Capacity Support Program (2018TD-031).

Author information

Authors and Affiliations

Contributions

K.P. and H.W. conceived the experiment. K.P., X.L. and J.W. performed the experiments. Z.C., L.S. and X.F. were involved in scientific discussion and data analysis. K.P. wrote initial drafts of the work. All authors commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Peng, K., Wang, H., Li, X. et al. Emerging WS2/montmorillonite composite nanosheets as an efficient hydrophilic photocatalyst for aqueous phase reactions. Sci Rep 9, 16325 (2019). https://doi.org/10.1038/s41598-019-52191-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-52191-9

This article is cited by

-

Ultra-efficient MCF-7 cell ablation and chemotherapy-integrated electrothermal therapy with DOX–WS2–PEG–M13 nanostructures

Discover Materials (2024)

-

Photocatalytic degradation of ciprofloxacin by MMT/CuFe2O4 nanocomposite: characteristics, response surface methodology, and toxicity analyses

Environmental Science and Pollution Research (2023)

-

One-step calcination synthesis of 2D/2D g-C3N4/WS2 van der Waals heterojunction for visible light-induced photocatalytic degradation of pharmaceutical pollutants

Environmental Science and Pollution Research (2023)

-

A novel, facile, and efficient two-step hydrothermal route for WS2 nanosheets and its optimistic exposure as competent industrial-level sonocatalyst

Journal of Materials Science: Materials in Electronics (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.