Abstract

Negative refraction has generated much interest recently with its unprecedented optical phenomenon. However, a broadband negative refraction has been challenging because they mainly involve optical resonances. This paper reports the realization of broadband negative refraction in the visible spectrum by using vertically-stacked metal-dielectric multilayer structures. Such structure exploits the characteristics of the constituent metal and dielectric materials, and does not require resonance to achieve negative refraction. Broadband negative refraction (wavelength 270–1300 nm) is numerically demonstrated. Compared to conventional horizontally-stacked multilayer structures, the vertically-stacked multilayer structure has a broader range of working wavelength in the visible range, with higher transmittance. We also report a variety of material combinations with broad working wavelength. The broadband negative refraction metamaterial provides an effective way to manipulate light and may have applications in super-resolution imaging, and invisibility cloaks.

Similar content being viewed by others

Introduction

Metamaterials composed of nanostructures of artificial atoms have shown many extraordinary properties that cannot be found in natural materials1,2. Super-resolution imaging3,4, negative index materials (NIMs)5,6,7, invisibility cloak8,9, perfect absorbers10,11,12, artificial chirality13,14, and electromagnetically induced transparency15 are examples of metamaterial applications that have properties beyond the limits of natural materials. Hyperbolic metamaterials (HMMs) show distinctive characteristics such as negative refraction16,17, sub-wavelength imaging18,19,20, confining the electromagnetic field21, and thermal emission22,23.

In natural materials, permittivity ε and permeability μ cannot be negative simultaneously, but if a certain material has negative values of both ε and μ24, the refractive index n becomes negative. The conventional materials with positive refractive index n have a positive value of the angle of refraction θ2 according to Snell’s law:

In contrast, NIMs show a negative θ2; i.e., negative refraction. The first NIM was achieved using split-ring resonators (SRRs), which have both negative ε and negative μ25. The negative ε is obtained by conducting wires below the plasma frequency ωP, and negative μ occurs near the resonance frequency ωSRR of SRRs. If ωP > ωSRR, then ε and μ are simultaneously negative in a certain region. Multilayered fishnet structure7, chiral structure26,27,28, and asymmetry nanorings structure29 have been studied to achieve negative n. NIMs have provided the possibility of applications such as super-resolution imaging and invisibility cloaks.

Conventional metamaterials for NIMs30,31 have some drawbacks. The materials require optical resonance to obtain a negative μ; this requirement restricts the range of working wavelength ΔλW to a narrow region near the resonance and causes high resistive loss. As a consequence, development of practical applications has been obstructed. However, electrostatic and magnetostatic fields can be decoupled in electrostatic limits, in which a system has smaller dimensions than the wavelength6. Therefore, under transverse magnetic (TM) polarized light, the electromagnetic behaviors in such system are only relevant to the permittivity. The HMMs consist of constituents with sub-wavelength dimensions, so negative refraction under TM polarized light can be achieved in HMMs by simply manipulating ε even if they do not have negative n.

So far, the negative refraction obtained from HMMs has mainly been shown with horizontally stacked metal-dielectric multilayer structures7,32,33,34 (horizontal HMMs). Such structure use an optical resonance to attain negative refraction; this requirement narrows ΔλW and causes high resistive losses. However, realization of a broad ΔλW and low-loss requires that resonance be avoided. Therefore, in this paper, we present vertically-stacked metal-dielectric multilayer structures (vertical HMMs) to achieve broadband negative refraction. This structure does not require any resonance to realize negative refraction and therefore it has a broad ΔλW that includes the visible range without additional losses due to resonance. The dispersion relation of HMMs was derived using effective medium theory35,36 (EMT) and using this relation, the ΔλW of negative refraction and transmittance of the vertical HMMs and horizontal HMMs are compared. We also suggest various vertical HMMs composed of different metal and dielectric materials. Plots of working wavelength and filling ratio of several metals with fixed dielectric show broadband ΔλW in the vertical HMMs.

Results

Multilayer structures are uniaxial media, in which permittivity tensors consist of only diagonal components. Among the components, the permittivity along the layers is the same (\({\varepsilon }_{xx}={\varepsilon }_{yy}\)). Therefore, the dispersion relation for TM polarized light (\(\overrightarrow{k}\cdot \overrightarrow{H}=0\)) for multilayer structure is described as

where kx, ky, kz are directional wavevectors in the medium, k0 is a wavevector in vacuum, ω is the frequency of the wave, c is the velocity of light in vacuum, \({\varepsilon }_{\parallel }\) is permittivity along the layers (\({\varepsilon }_{xx}={\varepsilon }_{yy}\)), and \({\varepsilon }_{\perp }\) is permittivity perpendicular to the layers (εzz). An isotropic medium with the same permittivity in all direction has a spherical isofrequency surface, which shows the isotropic behavior of propagating waves (Fig. 1a). In contrast, in an anisotropic medium, \({\varepsilon }_{\parallel }\) and \({\varepsilon }_{\perp }\) are different, so the isofrequency surface of is not spherical37. In the multilayer structure, each directional permittivity can be replaced by an effective permittivity, which is calculated using effective medium theory36. This theory considers an anisotropic composite as a homogeneous medium with effective parameters.

Diagram of the isofrequency surface of each material. (a) Isotropic materials, in which the permittivity is the same along all directions, have spherical isofrequency. (b) Isofrequency surface of a type-I HMM, which has positive permittivity along the layers (εxx, εyy) and negative permittivity in the vertical direction (εzz). (c) Isofrequency surface of a type-II HMM, which has negative permittivity along the layers (\({{\boldsymbol{\varepsilon }}}_{{\boldsymbol{xx}}},\,{{\boldsymbol{\varepsilon }}}_{{\boldsymbol{yy}}}\)) and positive permittivity in the vertical direction (εzz). Red arrow: wavevector \(\overrightarrow{{\boldsymbol{k}}}\); yellow arrow: Poynting vector \(\overrightarrow{{\boldsymbol{S}}}\) that denotes energy flow. In isotropic materials, \(\overrightarrow{{\boldsymbol{k}}}\) and \(\overrightarrow{{\boldsymbol{S}}}\) point in the same direction; in type-I (b) and type-II (c) HMMs the vectors point in different directions.

If a multilayer structure consists of alternating metal and dielectric layers that have thickness much smaller than the wavelength, this structure can be regarded as a homogeneous medium. Effective permittivities differ according to the direction (Supplementary Note 1):

where f is the filling ratio of the dielectric (f = 1 means that the medium is made entirely of a dielectric; f = 0 means that the medium is made entirely of a metal), εd is the permittivity of dielectric, and εm is the permittivity of the metal. With the effective permittivity, Eq. (2) becomes an elliptic or a hyperbolic equation. Eq. (2) describes a hyperbolic isofrequency surface if the signs of the \({\varepsilon }_{\parallel }\) and \({\varepsilon }_{\perp }\) are different, where multilayer structure shows a dielectric or a metallic behavior according to the direction. If \({\varepsilon }_{\perp }\) is the negative permittivity, the HMM is classified as type-I; if \({\varepsilon }_{\parallel }\) is negative, the HMM is classified as type-II (Fig. 1b,c). Therefore, HMMs are considered as extremely anisotropic materials that have hyperbolic isofrequency surfaces38.

Conventional HMMs are usually made by horizontally stacking metal and dielectric, and are of type-I HMMs. However, this structure uses resonance to realize negative refraction, and therefore has limitations such as narrow ΔλW. To overcome this limitation, we suggest a structure in which metal and dielectric are vertically stacked alternately. This structure has a negative parallel effective permittivity and a positive perpendicular effective permittivity, and is therefore classified as a type-II HMM. The cause of each negative permittivity should be understood. \({\varepsilon }_{\parallel }\) and \({\varepsilon }_{\perp }\) reach negative values by distinct mechanisms. The permittivity εm of metal can be described by the Drude model39,40,41 and the permittivity εd of the dielectric can be considered to be constant regardless of ω.

where ωp is a plasma frequency and γ is damping ratio. The effective permittivity \({\varepsilon }_{\parallel }\) along the layers is the arithmetic mean of permittivities of constituents (Eq. 3); this is similar to the permittivity equation from the Drude model42. In contrast, the effective permittivity \({\varepsilon }_{\perp }\) perpendicular to the layers is the harmonic mean of permittivities of each component (Eq. 4); the form is similar to the permittivity equation from the Lorentz model.

where χ is a susceptibility, N is the number of atoms per unit volume, e is the magnitude of the electric charge of the electron, m0 is the mass of the electron, and ω0 is resonance frequency. As a result, \({\varepsilon }_{\parallel }\) and \({\varepsilon }_{\perp }\) vary with ω. Analysis of the models reveals that the real value of \({\varepsilon }_{\parallel }\) does not require resonance to be negative if the wavelength of incident light is larger than the wavelength that corresponds to the effective ωP of metal (\({\rm{\lambda }} > {{\rm{\lambda }}}_{{\rm{ep}}}\)), whereas the real value of \({\varepsilon }_{\perp }\) is negative when the wavelength is near Lorentz resonance (\({\rm{\lambda }}\simeq {{\rm{\lambda }}}_{res}\)). Therefore, horizontal HMMs that need negative \({\varepsilon }_{\perp }\) use resonance to realize negative refraction43 whereas vertical HMMs that need negative \({\varepsilon }_{\parallel }\) achieve negative refraction without using resonance.

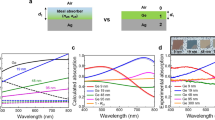

The horizontal and vertical HMM composed of Al and SiO2 are used as an example to compare ΔλW for negative refraction. The calculated effective permittivities (Fig. 2a) of Al and SiO2 multilayer structures have ranges of wavelength and filling ratio in which \({{\rm{\varepsilon }}}_{\parallel }\) is positive (red) and \({{\rm{\varepsilon }}}_{\perp }\) is negative (blue); this is ΔλW for negative refraction in horizontal HMMs (Fig. 2b, yellow). These ranges also show an area in which \({{\rm{\varepsilon }}}_{\parallel }\) is negative (blue) and \({{\rm{\varepsilon }}}_{\perp }\) is positive (red); this is ΔλW for negative refraction in vertical HMMs (Fig. 2b, purple). Compared to horizontal HMMs, the vertical HMMs have a broader ΔλW that includes the visible range.

Diagrams of effective permittivity and the working wavelength ΔλW of a vertical HHM composed of Al and SiO2. Effective permittivity (a, upper) \({{\rm{\varepsilon }}}_{\parallel }\) along the layer and (b, lower) \({{\rm{\varepsilon }}}_{\perp }\) perpendicular to the layer. Red regions: positive effective permittivity; blue regions: negative effective permittivity. (b) Effective permittivity (yellow) in type-I (horizontal) HMMs, which have narrow ΔλW; and (purple) in type-II (vertical) HMMs, which have a broad ΔλW that includes the visible range.

The negative refraction of an HMMs gives it a unique ability to manipulate light. In air, the wavevector \(\overrightarrow{{\boldsymbol{k}}}\) and the Poynting vector \(\overrightarrow{{\boldsymbol{S}}}\) of a TM wave are parallel, but when the TM wave meets the interface between the air and the HMM, \(\overrightarrow{{\boldsymbol{k}}}\) and \(\overrightarrow{{\boldsymbol{S}}}\) are not parallel. Consider a type-II HMM (i.e., \({\varepsilon }_{\parallel } < 0\) and \({\varepsilon }_{\perp } > 0\)) and a wave that is propagating from air to HMM in the x-z plane; i.e., k is in the x-z plane (Fig. 3a). According to the continuity of tangential component (kz,air = kz,HMM) and the causality theorem (\({S}_{x} > 0\))24,44, only one solution exists (Fig. 3b, arrow B). The tangential component Sz of \(\overrightarrow{{\boldsymbol{S}}}\) is in the opposite direction of that of \(\overrightarrow{{\boldsymbol{k}}}\), so the HMM shows negative refraction. The exact direction of \(\overrightarrow{{\boldsymbol{S}}}\) can be obtained using the Maxwell equations and some calculations (Supplementary Note 2).

(a) Schematic of light propagation (red arrows) in vertical HMM. (b) 2D isofrequency surface for TM waves (blue curves) and isofrequency surface in the air (red circle) at 600 nm. Yellow arrows: wavevectors A1 in air and B1 in the HMM; green arrows: Poynting vector A2 in air and B2 in the HMM. When light is incident at a certain angle from air to the vertical HMM, the tangential component kz of \(\overrightarrow{{\boldsymbol{k}}}\) should be continuous at the boundary and the causality theorem must be satisfied, so only one solution is physically correct. B1 and B2 have different directions in z direction; this relationship means that vertical HMMs have negative refraction.

Loss and transmittance of HMMs are related to resonance, which make a difference in performance between two types of HMMs. Horizontal HMMs that use resonance suffer high losses from it, so they have a narrow ΔλW in which refraction is negative. In contrast, vertical HMMs do not use resonance, so they have wide ΔλW and show no losses due to resonance2. Moreover, transmission is higher in vertical HMMs than in horizontal HMMs. Even though the transmission varies depending on wavelength, the combinations of metal and dielectric and the filling ratio, it can be represented roughly by the imaginary part of effective permittivity. As the imaginary part increases, the losses also increase11:

where ε0 is the permittivity of the vacuum, ω is the angular frequency, \({\varepsilon ^{\prime\prime} }_{r}\) is the imaginary part of the relative permittivity of the medium, and E is the electric field. Near the resonance frequency, the permittivity of material has a high imaginary part that induces a high absorption and thereby high resistive loss. On the other hand, the loss of the vertical HMMs is rarely affected by resonance because the vertical HMMs do not use the resonance for negative refraction; the loss of vertical HMMs is only related to constituent materials.

The horizontal HMM has a large imaginary part which leads to high losses because \({\varepsilon }_{\perp }\) of this HMM uses resonance to attain a negative real value. Therefore, high losses due to the resonance are inevitable in horizontal HMMs. However, each permittivity of vertical HMM has a small imaginary part because this HMM is not related to any resonance. In Ag-SiO2 multilayer structures, \({\varepsilon }_{\perp }\) in the horizontal HMM has a large imaginary part (\({\varepsilon }_{\perp }\): −15.546 + 24.227i at 356 nm), whereas \({\varepsilon }_{\parallel }\,\)in the vertical HMM has a small value (\({\varepsilon }_{\parallel }\): −6.589 + 0.219i at 600 nm). Therefore, the vertical HMM shows a broader ΔλW for negative refraction and higher transmittance than the horizontal type or conventional NIMs that use resonance.

We also compared two types of HMMs in terms of transmittance and intensity profiles (Fig. 4). Al and SiO2 multilayered structure with 0.5 filling ratio is used in each simulation because it has a wide ΔλW that includes the whole visible range. According to the ΔλW, the horizontal HMM was simulated at 135 nm and the vertical structure was simulated at 600 nm in which it shows negative refraction. The layer thickness was 6.75 nm in the horizontal HMM and 30 nm in the vertical HMM. The total height of each structure was determined by how many times the wave proceeds, so thickness of ~2.5λ was used for each simulation. The light is incident at an angle of 40°. In the simulation results, the transmittance is 0.01 in the horizontal HMM and 0.18 in the vertical HMM. The results clearly show that the vertical HMM has a higher transmittance than the horizontal one. Although the absolute value of transmittance by vertical HMMs is not high, it is enough to allow utilization of negative refraction.

Intensity profile in horizontal and vertical HMM composed of Al and SiO2. Surface color represents normalized electric field [V/m]; green arrows: Poynting vector that indicates the direction of energy flow. The height of each HMM was ~2.5 times the wavelength used in the simulations. (a) Horizontal HMM. Light with wavelength 135 nm is incident with an angle of 40° to the horizontal HMM; the filling ratio is 0.5, each layer is 6.75 nm thick, and the total height is 330 nm. (b) Vertical HMM. Light with wavelength 600 nm is incident with an angle of 40°; the filling ratio is 0.5, each layer is 30 nm thick, and the total height is 1,500 nm.

Various material combinations of the vertical HMMs with Ag, Al, Au, and Cu as a metal and SiO2 as a dielectric were also analyzed (Fig. 5). Each combination is plotted by wavelength and filling ratio to compare the working wavelength, which is denoted by yellow and purple regions. The yellow and purple regions represent the working range for negative refraction in the type-I HMMs and the type-II HMMs, respectively. It is noteworthy that aAll combinations of the materials has much broader ΔλW in the vertical HMMs than in horizontal HMMs, and that some combinations can realize negative refraction only in vertical HMMs. (transmittances in Supplementary Note 3). Therefore, various vertical HMMs which use type-II region have a potential to realize negative refraction over the visible wavelength range.

Effects of filling ratio f and wavelength. Various metals are used with same dielectric SiO2. When a medium is made entirely of dielectric, f = 1, when the medium is made entirely of metal, f = 0. Yellow region: ΔλW for negative refraction in type-I HMMs; purple regions: ΔλW for negative refraction in type-II HMMs. When f = 0.5, (a) Al is type-I at 85 ≤ λ ≤ 155 nm and type-II at λ > 155 nm. (b) Ag was type-I at 330 ≤ λ ≤ 360 nm and type-II at λ > 360 nm, (c) Au only type-II at λ> 500 nm, and (d) Cu is only type-II at λ > 350 nm. Type-II region of HMMs of all combination shows a larger ΔλW that includes the visible range.

This paper has demonstrated a broadband negative refraction that was realized by vertically stacked metal-dielectric multilayer structures. These vertical HMMs do not use resonance to realize negative refraction, so they do not suffer from losses due to this resonance. Therefore, vertical HMMs have higher transmittance and ΔλW that covers the entire visible range and extends into the mid-infrared without additional losses. We also provide several material combinations for broadband negative refraction that includes the visible range. Because of these advantages, vertical HMMs can manipulate light by exploiting negative refraction so they can be widely used in light-controlling devices such as invisibility cloaks and super-resolution imaging.

Method

We used COMSOL Multiphysics 5.3 for numerical simulation and RCWA (in-house code) to calculate transmittance.

References

Shekhar, P., Atkinson, J. & Jacob, Z. Hyperbolic metamaterials: fundamentals and applications. Nano Convergence 1, 14 (2014).

Cortes, C. L., Newman, W., Molesky, S. & Jacob, Z. Quantum nanophotonics using hyperbolic metamaterials. J. Opt. 14, 063001 (2012).

Lee, D. et al. Realization of Wafer-Scale Hyperlens Device for Sub-diffractional Biomolecular Imaging. ACS Photonics 5, 2549–2554 (2018).

Rho, J. et al. Spherical hyperlens for two-dimensional sub-diffractional imaging at visible frequencies. Nat. Commun. 1, 143 (2010).

Smith, D. R., Pendry, J. B. & Wiltshire, M. C. K. Metamaterials and Negative Refractive Index. Science 305, 788–792 (2004).

Pendry, J. B. Negative Refraction Makes a Perfect Lens. Phys. Rev. Lett. 85, 3966–3969 (2000).

Valentine, J. et al. Three-dimensional optical metamaterial with a negative refractive index. Nature 455, 376–379 (2008).

Leonhardt, U. & Tyc, T. Broadband Invisibility by Non-Euclidean Cloaking. Science 323, 110 (2009).

Schurig, D. et al. Metamaterial Electromagnetic Cloak at Microwave Frequencies. Science 314, 977 (2006).

Nguyen, D. M., Lee, D. & Rho, J. Control of light absorbance using plasmonic grating based perfect absorber at visible and near-infrared wavelengths. Sci. Rep. 7, 2611 (2017).

Kim, I., So, S., Rana, A. S., Mehmood, M. Q. & Rho, J. Thermally robust ring-shaped chromium perfect absorber of visible light. Nanophotonics 7 (2018).

Guclu, C., Campione, S. & Capolino, F. Hyperbolic metamaterial as super absorber for scattered fields generated at its surface. Phys. Rev. B 86, 205130 (2012).

Lee, H.-E. et al. Amino-acid- and peptide-directed synthesis of chiral plasmonic gold nanoparticles. Nature 556, 360–365 (2018).

Zhang, S. et al. Photoinduced handedness switching in terahertz chiral metamolecules. Nat. Commun. 3, 942 (2012).

Zhang, S., Genov, D. A., Wang, Y., Liu, M. & Zhang, X. Plasmon-Induced Transparency in Metamaterials. Phys. Rev. Lett. 101, 047401 (2008).

Argyropoulos, C., Estakhri, N. M., Monticone, F. & Alù, A. Negative refraction, gain and nonlinear effects in hyperbolic metamaterials. Opt. Express 21, 15037–15047 (2013).

Poddubny, A., Iorsh, I., Belov, P. & Kivshar, Y. Hyperbolic metamaterials. Nat. Photonics 7, 948–957 (2013).

Kim, M., So, S., Yao, K., Liu, Y. & Rho, J. Deep sub-wavelength nanofocusing of UV-visible light by hyperbolic metamaterials. Sci. Rep. 6, 38645 (2016).

Byun, M. et al. Demonstration of nanoimprinted hyperlens array for high-throughput sub-diffraction imaging. Sci. Rep. 7, 46314 (2017).

Lee, D. et al. Demonstration of a Hyperlens-integrated Microscope and Super-resolution Imaging. J. Vis. Exp., e55968 (2017).

Yang, X., Yao, J., Rho, J., Yin, X. & Zhang, X. Experimental realization of three-dimensional indefinite cavities at the nanoscale with anomalous scaling laws. Nat. Photonics 6, 450–454 (2012).

Dyachenko, P. N. et al. Controlling thermal emission with refractory epsilon-near-zero metamaterials via topological transitions. Nat. Commun. 7, 11809 (2016).

Guo, Y., Cortes, C. L., Molesky, S. & Jacob, Z. Broadband super-Planckian thermal emission from hyperbolic metamaterials. Appl. Phys. Lett. 101, 131106 (2012).

Viktor, G. V. The electrodynamics of substances with simultaneously negative values of ε and μ. Sov. Phys. Usp. 10, 509 (1968).

Shelby, R. A., Smith, D. R., Nemat-Nasser, S. C. & Schultz, S. Microwave transmission through a two-dimensional, isotropic, left-handed metamaterial. Appl. Phys. Lett. 78, 489–491 (2001).

Zhang, S. et al. Negative Refractive Index in Chiral Metamaterials. Phys. Rev. Lett. 102, 023901 (2009).

Pendry, J. B. A Chiral Route to Negative Refraction. Science 306, 1353–1355 (2004).

Liu, Y. & Zhang, X. Metamaterials: a new frontier of science and technology. Chem. Soc. Rev. 40, 2494 (2011).

Kanté, B. et al. Symmetry breaking and optical negative index of closed nanorings. Nat. Commun. 3, 1180 (2012).

Fan, X., Wang, G. P., Lee, J. C. W. & Chan, C. T. All-Angle Broadband Negative Refraction of Metal Waveguide Arrays in the Visible Range: Theoretical Analysis and Numerical Demonstration. Phys. Rev. Lett. 97, 073901 (2006).

Scalora, M. et al. Negative refraction and sub-wavelength focusing in the visible range using transparent metallo-dielectric stacks. Opt. Express 15, 508–523 (2007).

Orlov, A. A., Zhukovsky, S. V., Iorsh, I. V. & Belov, P. A. Controlling light with plasmonic multilayers. Photonics Nanostructures: Fundam. Appl. 12, 213–230 (2014).

García-Meca, C. et al. Low-Loss Multilayered Metamaterial Exhibiting a Negative Index of Refraction at Visible Wavelengths. Phys. Rev. Lett. 106, 067402 (2011).

Zhang, J. et al. Towards -1 effective index with one-dimensional metal-dielectric metamaterial: a quantitative analysis of the role of absorption losses. Opt. Express 15, 7720–7729 (2007).

Elser, J., Wangberg, R., Podolskiy, V. A. & Narimanov, E. E. Nanowire metamaterials with extreme optical anisotropy. Appl. Phys. Lett. 89, 261102 (2006).

Tang, S. et al. Effective-medium theory for one-dimensional gratings. Phys. Rev. B 91, 174201 (2015).

Liu, Y., Bartal, G. & Zhang, X. All-angle negative refraction and imaging in a bulk medium made of metallic nanowires in the visible region. Opt. Express 16, 15439–15448 (2008).

Xiong, Y., Liu, Z., Sun, C. & Zhang, X. Two-Dimensional Imaging by Far-Field Superlens at Visible Wavelengths. Nano Lett. 7, 3360–3365 (2007).

Vial, A., Grimault, A.-S., Macías, D., Barchiesi, D. & de la Chapelle, M. L. Improved analytical fit of gold dispersion: Application to the modeling of extinction spectra with a finite-difference time-domain method. Phys. Rev. B 71, 085416 (2005).

Vial, A., Laroche, T., Dridi, M. & Le Cunff, L. A new model of dispersion for metals leading to a more accurate modeling of plasmonic structures using the FDTD method. Appl. Phys. A 103, 849–853 (2011).

Cai, W., Genov, D. A. & Shalaev, V. M. Superlens based on metal-dielectric composites. Phys. Rev. B 72, 193101 (2005).

Sun, J., Shalaev, M. I. & Litchinitser, N. M. Experimental demonstration of a non-resonant hyperlens in the visible spectral range. Nat. Commun. 6, 7201 (2015).

Hoffman, A. J. et al. Negative refraction in semiconductor metamaterials. Nat. Mater. 6, 946–950 (2007).

Jacob, Z., Alekseyev, L. V. & Narimanov, E. Optical Hyperlens: Far-field imaging beyond the diffraction limit. Opt. Express 14, 8247–8256 (2006).

Acknowledgements

This work is financially supported by the national Research Foundation grants (NRF-2019R1A2C3003129, CAMM-2019M3A6B3030637, NRF-2018M3D1A1058998, NRF-2017R1E1A2A01076613, and NRF-2015R1A5A1037668) funded by the Ministry of Science and ICT, Korea. S.S. acknowledges the global Ph.D fellowship (NRF-2017H1A2A1043322) from the NRF-MSIT, Korea. Authors acknowledge Gwanho Yoon (POSTECH) for RCWA simulation.

Author information

Authors and Affiliations

Contributions

J.R. conceived the idea and guided the research. S.B. and S.S. did numerical simulations. S.S. suggested the idea of materials characterizations. S.B., S.S. and J.R. prepared the manuscript. All authors participated in the discussion and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bang, S., So, S. & Rho, J. Realization of broadband negative refraction in visible range using vertically stacked hyperbolic metamaterials. Sci Rep 9, 14093 (2019). https://doi.org/10.1038/s41598-019-50434-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-50434-3

This article is cited by

-

Nonlocal response of planar plasmonic layers

Optical and Quantum Electronics (2023)

-

Hyperbolic metamaterials: fusing artificial structures to natural 2D materials

eLight (2022)

-

Broadband and Efficiency Reflective Polarization Converter in X and Ku Bands Based on an Asymmetric Rod-Shaped Ring with a Hole-Shaped Metasurface

Journal of Electronic Materials (2022)

-

Double defects-induced elastic wave coupling and energy localization in a phononic crystal

Nano Convergence (2021)

-

Nanoimprint lithography for high-throughput fabrication of metasurfaces

Frontiers of Optoelectronics (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.