Abstract

Two-dimensional (2D) layered Platinum Ditelluride (PtTe2), a novel candidate of group 10 transition-metal dichalcogenides (TMDs), which provides enormous potential for pulsed laser applications due to its highly stable and strong nonlinear optical absorption (NOA) properties. PtTe2 saturable absorber (SA) is successfully fabricated with firstly demonstrated the passively Q-switched laser operation within a Yb-doped fiber laser cavity at 1066 nm. Few layered PtTe2 is produced by uncomplicated and cost-efficient ultrasonic liquid exfoliation and follow by incorporating into polyvinyl alcohol (PVA) polymer to form a PtTe2-PVA composite thin film saturable absorber. The highest achieved single pulse energy is 74.0 nJ corresponding to pulse duration, repetition rate and average output power of 5.2 μs, 33.5 kHz and 2.48 mW, respectively. This work has further exploited the immeasurable utilization potential of the air stable and broadband group 10 TMDs for ultrafast photonic applications.

Similar content being viewed by others

Introduction

Q-switching, a useful and very important technique, has been widely studied and applied in pulsed laser development over the past decades1,2,3,4. Contributed by the remarkable high pulse peak power, Q-switched laser can be employed in vast applications, for instance, industrial laser engraving, nonlinear optics, skin treatment, and eyes surgery5,6,7. Q-switched laser pulses can be produced by using Acousto-optical or Electro-optical modulators (AOM/EOM)8 to actively modify the Quality factor within the cavity. However, AOM/EOM consists of bulky and expensive components, as well as the control driver. It will lead to high cost of production and complexity of the Q-switching laser system9. In contrast, modulates the cavity Q-factor passively by utilizing the nonlinear optical absorption (NOA) properties of some novel nano-materials may serve as an advanced alternative solution for Q-switched laser pulse generation.

Typically, doped crystals, e.g. Co: MALO10 and V: YAG11, and semiconductor saturable absorber mirror (SESAM), e.g. InGaAs12 are used to induce passively Q-switched laser operation among various commercial laser systems. However, the synthesis process of these commercial saturable absorbers usually involve expensive and complicated doped crystal growth and metal oxide chemical vapor deposition (MOCVD) techniques. Additionally, the narrow operation wavelength band of doped crystals and SESAMs also reduced the corresponding flexibility and applicability13. As a result, tremendous research effort has been devoted to searching novel saturable absorber materials which accompany with high operation performance and simple SA fabrication method. The carbon-based nano-materials e.g. graphene14, graphene-oxide15,16, and carbon nanotube17 have attracted great research interests for its demonstrated exceptional nonlinear optical responses. However, these carbon-based materials have their own limitations e.g. lower modulation depth for graphene, diameter control needed for carbon nanotube. The study works on carbon-based materials have inspired the research interests of other layered 2D materials for pulsed laser and nonlinear optical applications.

Transition metal dichalcogenide (TMD), a new class of the 2D family, had gained explosive grow of advertence in the past few years. TMDs provided a wide choice of materials with various favorable properties18,19,20 and which derived extensive applications, for example, photodetectors21, biosensors22 and energy storage23. Layered TMD is composed of stacked planar crystal accompany with a stoichiometry of MX2, where M and X stand for the group 4 to 10 transition metal and chalcogen atoms (S, Se, Te), respectively. Remarkably, the modification of NOA properties of TMDs nanosheet can be simply achieved by controlling the corresponding size, thickness24,25,26 and concentration27 which provided advance merit for utilizing in nonlinear optical (NLO) devices. In the recent years, the study of Q-switcher application is mainly focusing on the group 6 TMDs materials, such as MoS228, MoSe229, WS230 and WSe231, but barely extend to the group 10 TMDs 2D materials. Reported by Zhou et al.32,33, PtS2 had shown a strong interlayer interaction with a bandgap modulated from 0.25 eV to 1.6 eV, which even wider than that of black phosphorus (BP). Meanwhile, the air stability and electron carrier mobility (exceed 1000 cm2V−1s−1)32 of group 10 TMDs also had shown superior result. The merits of the Pt-based 2D materials enable some new applications in different fields, e.g. photocatalyst34, FETs33 and photodetectors35,36,37,38. Additionally, the Q-switched or mode-locked laser pulses generation have been successfully demonstrated by using PtS239,40 and PtSe241,42,43 based saturable absorber. For the infrared pulsed laser and optical communication application, the functional 2D material with a relatively small bandgap is more suitable for the mainstream laser photonic system41. Group 6 TMDs (e.g. monolayer WS2: 2.1 eV, 590 nm24; monolayer MoS2: 1.78 eV, 696 nm41) have relatively large bandgap and leads to the resonant absorption wavelength located in visible range. Although its bandgap energy can be further modified by changing the layer number, nanosheet size and lattice structure, however, it could further increase the optical loss and reduce stability of the system41. Previous studies had shown that monolayer and bilayer PtSe2 are indirect bandgap of 1.18 eV and 0.21 eV44, respectively (semi-metallic as from 3 layers to bulk form). Remarkably, PtTe2 shows the smallest monolayer indirect bandgap of 0.40 eV (~3 µm) among the Pt based TMDs family (it also exhibits semi-metallic as from bilayer to bulk form)44. These unique electronic structures of group 10 TMDs allow direct excitation of valence electrons to the conduction band, which it do not require the assistant of intermediate energy state (induced by lattice defect doping) in the band gap41. Hence it provided efficient and broadband saturable absorption within the infrared range covering the operational wavelengths of mainstream laser systems. Besides, compared with other 2D material based SAs with near or zero bandgap, such as WTe245 or MXene (Ti3CN)46, PtTe2 also shows advancing merits as mentioned previously. WTe2 is very susceptible to oxidation in an ambient condition45,47, especially during the dispersion process. Usually, an additional protective coating or incorporated within host materials could curb the oxygen corrosion, but it requires additional surface treatment and passivation on the 2D material48 which inevitably intervened the nonlinear optical properties of the SA. MXenes materials have the metal atoms that highly exposed on the surfaces49. In aqueous solutions of delaminated-MXene, literatures had shown that both the multilayered Ti3C2Tx MXene and monolayer flakes50 degrade gradually either in humid air51 or water52. Meanwhile, to delaminate the MXene, a selective wet etching process is utilized to remove the “A” layer from the MXene MAX phase with followed by intercalation of the guest molecules (e.g. dimethyl sulfoxide -DMSO) and sonication, which highly hazardous Hydrofluoric acid (HF) is used as the wet etchant of the MXene MAX phase46. These complicated pre-SA preparation process and degradation problem will taper off the pragmatic application of MXene as a saturable absorber. Combined with the merits of high air stability and electron carrier mobility, group 10 TMDs are able to produce fast and stable nonlinear response to the incident light and generate narrower pulse width for the ultrafast operation43, therefore it provided a great potential for various nonlinear optics, pulsed laser and photonic applications.

In this work, we have firstly demonstrated the pulsed laser operation by using our homemade Platinum Ditelluride, PtTe2 based saturable absorber. The 3D lattice structure of PtTe2 is shown in Fig. 1. This newly developed Pt-based TMDs material has strong interlayer interaction53 and air stability54,55. Contrast to the complicated and expensive CVD fabrication method53,56,57, the PtTe2 nanosheets used for this experiment are produced by an uncomplicated and cost-effective ultrasonic liquid exfoliation technique and followed by incorporating within the polyvinyl alcohol (PVA) polymer to form a larger-scale PtTe2-PVA saturable absorber. The fabrication method employed here is well suitable for making commercial products.

Result and Discussion

After successful ultrasonic liquid exfoliation, the morphology, crystal lattice structure and chemical composition of the obtained PtTe2 nanosheets were characterized. Figure 2(a–c) show that the most frequently observed dimension along the short-axis, long-axis and thickness are around 88 nm, 120 nm, and 25 nm, respectively. Topology graph of two randomly selected flakes and their corresponding height profiles along the marked lines are shown in Fig. 3. The lateral dimensions for long-axis of both flake A and flake B are around 125 nm, which within the statistic result and indicated the successful exfoliation of the PtTe2 sample.

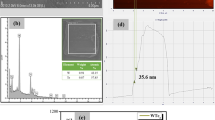

From the TEM image (Fig. 4(a)), it shows that the lateral size of a randomly selected PtTe2 flake well match with the AFM statistical results. The relevant high-resolution FETEM image is inserted in Fig. 4(a) and shows an inter-plane distance of 0.29 nm corresponding to the (011) plane of PtTe258. The Transmission spectra of the PtTe2-PVA composite and a reference PVA film are presented in Fig. 4(b) which shows that the type-II Dirac semimetal57 PtTe2 has no characteristic absorption peak from 500 nm to 2000 nm wavelength range, as similar to graphene-SA59. For the chemical composition of PtTe2 sample, Fig. 5(a) shows only characteristic peaks from Pt or Te and no other observable impurities is found (Cu peak is induced from the copper mesh support for TEM measurement). Meanwhile, as shown in Fig. 5(b), the Raman-active modes Eg and A1g were positioned at 110.7 cm−1 and 154.8 cm−1, respectively, and which agree well with the previous report57. The Eg mode is representing the in-plane vibration mode of Platinum and Ditelluride atoms. Meanwhile, the A1g is standing for the out-plane vibration modes of Ditelluride atoms. These strong characteristic Raman peaks reveal that the fabricated PtTe2 nanosheets possess with good crystallinity.

For the laser test, a pure Polyvinyl alcohol (PVA) film, which possess of identical thickness as the PtTe2-PVA SA film, was first inserted between the connector junction of the ring cavity as shown in Fig. 6 to act as a control experiment set. No Q-switched laser pulses were observed by modifying the polarization direction of the polarization controller (PC) and pumping power. It confirms Q-switching operation cannot be obtained by using pure PVA polymer or cavity phase self-modulation. Further on, the fabricated PtTe2-SA was cut with a size in approximately 1 mm × 1 mm, and was introduced into the laser system by sandwiching between two fiber connectors. The parasitic reflection could be eliminated by using FC/APC connector and thus improved the stability of the Q-switching system.

Stable Q-switched pulse train was observed as the pump power elevated to the starting threshold of 118 mW. However, when the pump power raised beyond 146.5 mW, the Q-switched output was vanished due to the over saturation of the absorber at high input fluence26,60. The average output power was measured as from 1.03 mW to 2.48 mW with respect to the pump power from 118 mW to 146.5 mW as shown in Fig. 7(a). The modulation ranges of the pulse width (Full width at half maximum) and the repetition rate are 13.6 μs to 5.2 μs and 23.0 kHz to 33.5 kHz, respectively as shown in Fig. 7(b). The fluctuation of repetition rate and output power of the Q-switched laser are less than 5% within the test time of about 30 to 45 minutes during the measurement. The minimum pulse duration can be further shortened by either enhancing the modulation depth of the SA or reducing the total length of ring cavity61. The maximum recorded single pulse energy is about 74.0 nJ which is comparable to previous literature of passive Q-switching Yb-doped fiber laser with utilizing another TMDs based SA, for instance, MoSe2 (116 nJ)29, MoS2 (126 nJ)28, WS2 (13.6 nJ)30, and even the group 10 PtS2 (45.6 nJ) Q-switched laser operated in 1569 nm39. Meanwhile, the correlated pulse train, single laser pulse profile, radio-frequency (RF) (resolution bandwidth: 20 Hz) and wavelength spectra has shown in Fig. 7(c–f) corresponding to the maximum output single pulse energy of 74.0 nJ.

Q-switched laser performance: (a) The average output power and (b) Repetition rate and Pulse duration variation with respect to the different pump power. (c) Pulse train, (d) Single pulse profile, (e) Radio frequency spectrum, and (f) Wavelength spectrum corresponding to the maximum output single pulse energy of 74.0 nJ.

The passively Q-switched Yb-doped fiber laser based on PtTe2 saturable absorber was first demonstrated. A stable Q-switched operation was illustrated from 1066 nm fiber ring cavity. The achieved pulse duration and repetition rate range are 13.6 μs to 5.2 μs and 23.0 kHz to 33.5 kHz, respectively, with correlated to the average output power from 1.03 mW to 2.48 mW. The highest achieved single pulse energy is 74.0 nJ which is well comparable with the output achieved by using other group 6 or 10 TMDs saturable absorber within the fiber laser system. This first demonstration proves the novel photonic applications of the newly developed 2D PtTe2 material.

Methods

PtTe2 nanosheets preparation

The PtTe2 nanosheets were prepared by using ultrasonic liquid exfoliation to break the interlayer bonding. Isopropyl Alcohol (IPA) was selected as the exfoliation solvent in order to prevent flakes aggregation because of its well surface energy compatibility with the TMDs substances. First, 175 mg PtTe2 powder, which purchased from Six Carbon Inc., was mixed with 175 ml IPA solvent. Then, the mixture was probe sonicated for (SCIENTZ-1200E, Ningbo Scientz Biotechnology Co., Ltd) over 15 hours. The probe sonication operated at the frequency of 20 kHz and power of 1500 W. Then the PtTe2 suspension was centrifuged at 3000 rpm speed for 5 minutes and only the supernatant was extracted to remove large flakes and impurities.

Sample characterizations

The statistic measurement of the size and thickness distribution among 150 flakes were obtained by utilizing an atomic force microscope (Bruker Nanoscope 8). The Ultrahigh magnification image and chemical ingredient of the PtTe2 flakes were obtained by using field emission transmission electron microscopy (FETEM. JEM-2100F) with an accessory of energy-dispersive X-ray spectroscopy (EDS). Raman spectra was measured by a LabRAM HR 8000 Raman Spectrometer.

PtTe2 saturable absorber preparation

In order to synthesize PtTe2-SA, firstly, PVA solution with 15% weight percentage was prepared by mixing the pure PVA powders with deionized water. Then the fabricated PtTe2 suspension was added into the PVA solution by a weight ratio of 1: 6 and further stirred for 30 minutes. Afterward, the mixture was dried under 60 °C for 48 hours in the oven to form a PtTe2-PVA composite thin film and it serves as a transmission type saturable absorber for the Q-switching experiment.

Experimental setup

A ring cavity of Ytterbium-doped fiber laser was built as the schematic diagram shown in Fig. 6 for testing the performance of PtTe2-SA. The cavity was constituted with a 980/1064 wavelength division multiplexer (WDM), a 0.68 m long Yb-doped single mode fiber (LIEKKI Yb1200-4/125), a polarization-independent isolator (PI-ISO), a polarization controller (PC), and an output coupler with 90:10 coupling ratio. The total cavity length is about 12 meters. The fabricated PtTe2-SA was cut with a size in approximately 1 mm × 1 mm, and was introduced into the cavity by sandwiching between two fiber connectors.

References

Degnan, J. J. Theory of the Optimally Coupled Q-Switched Laser. IEEE J Quant Electron 25, 214–220, https://doi.org/10.1109/3.16265 (1989).

Wagner, W. G. & Lengyel, B. A. Evolution of the Giant Pulse in a Laser. J Appl Phys 34, 2040–2046, https://doi.org/10.1063/1.1729732 (1963).

Szabo, A. & Stein, R. A. Theory of Laser Giant Pulsing by a Saturable Absorber. J Appl Phys 36, 1562–1566, https://doi.org/10.1063/1.1703087 (1965).

Xu, D., Wang, Y., Li, H., Yao, J. & Tsang, Y. H. 104 W high stability green laser generation by using diode laser pumped intracavity frequency-doubling Q-switched composite ceramic Nd: YAG laser. Opt Express 15, 3991–3997, https://doi.org/10.1364/OE.15.003991 (2007).

Watanabe, S. & Takahashi, H. Treatment of Nevus of Ota with the Q-switched Ruby Laser. New England J. Medicine 331, 1745–1750, https://doi.org/10.1056/NEJM199412293312604 (1994).

Qi, J., Wang, K. L. & Zhu, Y. M. A study on the laser marking process of stainless steel. J Mater Proc Techno 139, 273–276, https://doi.org/10.1016/S0924-0136(03)00234-6 (2003).

Latina, M. A., Sibayan, S. A., Shin, D. H., Noecker, R. J. & Marcellino, G. Q-switched 532-nm Nd: YAG laser trabeculoplasty (selective laser trabeculoplasty): A multicenter, pilot, clinical study. Ophthalmology 105, 2082–2090, https://doi.org/10.1016/S0161-6420(98)91129-0 (1998).

Tsang, Y. H., Qamar, F., King, T. A., Ko, D. K. & Lee, J. Nanosecond Q-switched operation of coupled Yb and Tm fibre lasers. J Phys D: Appl Phys 38, 1365 (2005).

Leigh, M., Shi, W., Zong, J., Wang, J. & Jiang, S. Compact, single-frequency all-fiber Q-switched laser at 1 μm. Opt Lett 32, 897–899, https://doi.org/10.1364/OL.32.000897 (2007).

Yumashev, K. V., Denisov, I. A., Posnov, N. N., Kuleshov, N. V. & Moncorge, R. Excited state absorption and passive Q-switch performance of Co2+doped oxide crystals. J Alloys and Comp 341, 366–370, https://doi.org/10.1016/S0925-8388(02)00039-7 (2002).

Grabtchikov, S. et al. Passively Q-switched 1.35 μm diode pumped Nd: KGW laser with V: YAG saturable absorber. Opt Mater 16, 349–352, https://doi.org/10.1016/S0925-3467(00)00099-9 (2001).

Spühler, G. J. et al. Experimentally confirmed design guidelines for passively Q-switched microchip lasers using semiconductor saturable absorbers. J Opt Soc Am B 16, 376–388, https://doi.org/10.1364/JOSAB.16.000376 (1999).

Tang, C. Y. et al. Passively Q-Switched Nd: YVO4 Laser Using WS2 Saturable Absorber Fabricated by Radio Frequency Magnetron Sputtering Deposition. J Lightwave Techno 35, 4120–4124, https://doi.org/10.1109/JLT.2017.2726138 (2017).

Luo, Z. et al. Graphene-based passively Q-switched dual-wavelength erbium-doped fiber laser. Opt lett 35, 3709–3711, https://doi.org/10.1364/OL.35.003709 (2010).

Zhao, J. Q. et al. Graphene-oxide-based Q-switched fiber laser with stable five-wavelength operation. Chin Phys Lett 29, 114206 (2012).

Zhao, J. et al. An Ytterbium-doped fiber laser with dark and Q-switched pulse generation using graphene-oxide as saturable absorber. Opt Commun 312, 227–232, https://doi.org/10.1016/j.optcom.2013.09.038 (2014).

Yu, H. et al. Sub-100 ns solid-state laser Q-switched with double wall carbon nanotubes. Opt Commun 306, 128–130, https://doi.org/10.1016/j.optcom.2013.05.010 (2013).

Mak, K. F. & Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat Photon 10, 216, https://doi.org/10.1038/nphoton.2015.282 (2016).

Chhowalla, M., Liu, Z. & Zhang, H. Two-dimensional transition metal dichalcogenide (TMD) nanosheets. Chem Soc Rev 44, 2584–2586, https://doi.org/10.1039/C5CS90037A (2015).

Manzeli, S., Ovchinnikov, D., Pasquier, D., Yazyev, O. V. & Kis, A. 2D transition metal dichalcogenides. Nat Rev Mater 2, 17033, https://doi.org/10.1038/natrevmats.2017.33 (2017).

Zeng, L. H. et al. High-responsivity UV-vis photodetector based on transferable WS2 film deposited by magnetron sputtering. Sci Rep 6, 20343, https://doi.org/10.1038/srep20343 (2016).

Gan, X., Zhao, H. & Quan, X. Two-dimensional MoS2: A promising building block for biosensors. Biosens Bioelectron 89, 56–71, https://doi.org/10.1016/j.bios.2016.03.042 (2017).

Jariwala, D., Sangwan, V. K., Lauhon, L. J., Marks, T. J. & Hersam, M. C. Emerging device applications for semiconducting two-dimensional transition metal dichalcogenides. ACS nano 8, 1102–1120, https://doi.org/10.1021/nn500064s (2014).

Long, H. et al. Tuning nonlinear optical absorption properties of WS2 nanosheets. Nanoscale 7, 17771–17777, https://doi.org/10.1039/C5NR04389A (2015).

Liang, G. et al. Technique and model for modifying the saturable absorption (SA) properties of 2D nanofilms by considering interband exciton recombination. J. Mater. Chem. C 6, 7501–7511, https://doi.org/10.1039/C8TC00498F (2018).

Chen, Y. et al. Mechanically exfoliated black phosphorus as a new saturable absorber for both Q-switching and Mode-locking laser operation. Opt. Express 23, 12823–12833, https://doi.org/10.1364/OE.23.012823 (2015).

Tao, L. et al. Fabrication of covalently functionalized graphene oxide incorporated solid-state hybrid silica gel glasses and their improved nonlinear optical response. J. Phys. Chem. C 117, 23108–23116, https://doi.org/10.1021/jp404463g (2013).

Woodward, R. I. et al. Tunable Q-switched fiber laser based on saturable edge-state absorption in few-layer molybdenum disulfide (MoS2). Opt. Express 22, 31113–31122, https://doi.org/10.1364/OE.22.031113 (2014).

Woodard, R. I. et al. Wideband saturable absorption in few-layer molybdenum diselenide (MoSe2) for Q-switching Yb-, Er- and Tm-doped fiber lasers. Opt. Express 23, 20051–20061, https://doi.org/10.1364/OE.23.020051 (2015).

Zhang, M. et al. Yb- and Er-doped fiber laser Q-switched with an optically uniform, broadband WS2 saturable absorber. Sci Rep 5, 17482–17491, https://doi.org/10.1038/srep17482 (2015).

Chen, B. et al. Q-switched fiber laser based on transition metal dichalcogenides MoS2, MoSe2, WS2, and WSe2. Opt Express 23, 26723–26737, https://doi.org/10.1364/OE.23.026723 (2015).

Zhao, Y. et al. Extraordinarily strong interlayer interaction in 2D layered PtS2. Adv Mater 28, 2399–2407, https://doi.org/10.1002/adma.201504572 (2016).

Zhao, Y. et al. High‐Electron‐Mobility and Air‐Stable 2D Layered PtSe2 FETs. Adv Mater 29, 1604230, https://doi.org/10.1002/adma.201604230 (2017).

Zhuang, H. L. & Henning, R. G. Computational Search for Single-Layer Transition-Metal Dichalcogenide Photocatalysts. J. Phys. Chem. C. 117, 20440–20445, https://doi.org/10.1021/jp405808a (2013).

Zeng, L. H. et al. Fast, Self-Driven, Air-Stable, and Broadband Photodetector Based on Vertically Aligned PtSe2/GaAs Heterojunction. Adv. Funct. Mater. 28, 1705970, https://doi.org/10.1002/adfm.201705970 (2018).

Zeng, L. H. et al. Ultrafast and sensitive photodetector based on a PtSe2/silicon nanowire array heterojunction with a multiband spectral response from 200 to 1550 nm. NPG Asia Mater 10, 352–362, https://doi.org/10.1038/s41427-018-0035-4 (2018).

Wu, D. et al. Design of 2D layered PtSe2 heterojunction for the high-performance room-temperature broadband infrared photodetector. ACS Photon 5, 3820–3827, https://doi.org/10.1021/acsphotonics.8b00853 (2018).

Zeng, L. H. et al. Controlled Synthesis of Two-dimensional Palladium Diselenide for Sensitive Photodetectors Application. Adv Funct Mater 29, 1806878, https://doi.org/10.1002/adfm.201806878 (2018).

Wang, X. et al. Laser Q-switching with PtS2 microflakes saturable absorber. Opt. Express 26, 13055–13060, https://doi.org/10.1364/OE.26.013055 (2018).

Long, H. et al. Ultrafast laser pulses generation by using 2D layered PtS2 as a saturable absorber. J Lightwave Techno 37, 1174–1179, https://doi.org/10.1109/JLT.2018.2889289 (2018).

Yuan, J. et al. Few-Layer Platinum Diselenide as a New Saturable Absorber for Ultrafast Fiber Lasers. ACS Appl. Mater. Interfaces 10, 21534–21540, https://doi.org/10.1021/acsami.8b03045 (2018).

Tao, L. et al. Vertically standing PtSe2 film: a saturable absorber for a passively mode-locked Nd: LuVO4 Laser. Photon Res 6, 750–755, https://doi.org/10.1364/PRJ.6.000750 (2018).

Zhang, k. et al. Q-switched and mode-locked Er-doped fiber laser using PtSe2 as a saturable absorber. Photon Res 6, 893–900, https://doi.org/10.1364/PRJ.6.000893 (2018).

Villaos, R. A. B. et al. Thickness dependent electronic properties of Pt dichalcogenides. npj 2D Materials and Applications 3, https://doi.org/10.1038/s41699-018-0085-z (2019)

Koo, J. et al. Near‐Infrared Saturable Absorption of Defective Bulk‐Structured WTe2 for Femtosecond Laser Mode‐Locking. Adv Functl Mater 26, 7454–7461, https://doi.org/10.1002/adfm.201602664 (2016).

Jhon, Y. I. et al. Metallic MXene Saturable Absorber for Femtosecond Mode‐Locked Lasers. Adv Mater 29, 1702496, https://doi.org/10.1002/adma.201702496 (2017).

Lee, C. H. et al. Tungsten Ditelluride: a layered semimetal. Sci. Rep. 5, 10013, https://doi.org/10.1038/srep10013 (2015).

Kopf, D. et al. All-in-one dispersion-compensating saturable absorber mirror for compact femtosecond laser sources. Opt. Lett. 21, 486–488, https://doi.org/10.1364/OL.21.000486 (1996).

Zhao, T., Zhang, S., Guo, Y. & Wang, Q. TiC2: a new two-dimensional sheet beyond MXenes. Nanoscale 8, 233–242, https://doi.org/10.1039/C5NR04472C (2016).

Zhang, C. J. et al. Oxidation Stability of Colloidal Two-Dimensional Titanium Carbides (MXenes). Chem. Mater. 29, 4848–4856, https://doi.org/10.1021/acs.chemmater.7b00745 (2017).

Lipatov, A. et al. Effect of Synthesis on Quality, Electronic Propertiesand Environmental Stability of Individual Monolayer Ti3C2 MXene Flakes. Adv. Electron. Mater 2, 1600255, https://doi.org/10.1002/aelm.201600255 (2016).

Mashtalir, O. et al. Dye Adsorption and Decomposition on Two-Dimensional Titanium Carbide in Aqueous Media. J. Mater.Chem. A 2, 14334–14338, https://doi.org/10.1039/C4TA02638A (2014).

Hao, S. et al. Low‐Temperature Eutectic Synthesis of PtTe2 with Weak Antilocalization and Controlled Layer Thinning. Adv Functl Mater 28, 1803746, https://doi.org/10.1002/adfm.201803746 (2018).

Ghosh, B. et al. Broadband excitation spectrum of bulk crystals and thin layers of PtTe2. Phys. Rev. B 99, 045414, https://doi.org/10.1103/PhysRevB.99.045414 (2019).

Politano, G. et al. Tailoring the Surface Chemical Reactivity of Transition-Metal Dichalcogenide PtTe2 Crystals. Adv Funct Mater 28, 1706504–1706511, https://doi.org/10.1002/adfm.201706504 (2018).

Fu, L. et al. Highly Organized Epitaxy of Dirac Semi-metallic PtTe2 Crystals with Extra High Conductivity and Visible Surface Plasmons at Edges. ACS Nano 12, 9405–9411, https://doi.org/10.1021/acsnano.8b04540 (2018).

Ma, H. et al. Thickness-Tunable Synthesis of Ultrathin Type-II Dirac Semimetal PtTe2 Single Crystals and Their Thickness-Dependent Electronic Properties. ACS Nanolett 18, 3523–3529, https://doi.org/10.1021/acs.nanolett.8b00583 (2018).

Rosli, N. F. et al. Layered PtTe2 Matches Electrocatalytic Performance of Pt/C for Oxygen Reduction Reaction with Significantly Lower Toxicity. ACS Sustainable Chem. Eng. 6, 7432–7441, https://doi.org/10.1021/acssuschemeng.7b04920 (2018).

Sun, Z. et al. Graphene Mode-Locked Ultrafast Laser. ACS Nano 4, 803–810, https://doi.org/10.1021/nn901703e (2010).

Kiran, P. P. et al. Nonlinear absorption properties of ‘axial-bonding’type tin (IV) tetratolylporphyrin based hybrid porphyrin arrays. Opt Commun 252, 150–161, https://doi.org/10.1016/j.optcom.2005.04.008 (2005).

Degnan, J. J. Qptimization of passively Q-switched lasers. IEEE J. Quantum Electron 31, 1890–1901, https://doi.org/10.1109/3.469267 (1995).

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (61575167); Shenzhen Science and Technology Innovation Commission (JCYJ20170303160136888); Shenzhen Science and Technology Innovation Commission (JCYJ20180306173805740); The Research Grants Council of Hong Kong, China (GRF 152109/16E PolyU B-Q52T).

Author information

Authors and Affiliations

Contributions

C.Y.T., P.K.C. and Y.H.T. developed the concept. C.Y.T. and P.K.C. conducted the experiments. P.K.C. and Y.H.T. wrote the paper. C.Y.T., P.K.C. and S.M. performed the laser characterization, A.F.M. and Raman measurement. X.Y.W. and H.L. conducted the TEM measurement. C.Y.T., P.K.C. and Y.H.T. reviewed and edited the manuscript. Y.H.T. directed the overall research. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, P.K., Tang, C.Y., Wang, X.Y. et al. Passively Q-switched Ytterbium-doped fiber laser based on broadband multilayer Platinum Ditelluride (PtTe2) saturable absorber. Sci Rep 9, 10106 (2019). https://doi.org/10.1038/s41598-019-46658-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-46658-y

This article is cited by

-

Two-dimensional noble transition-metal dichalcogenides for nanophotonics and optoelectronics: Status and prospects

Nano Research (2022)

-

Imaging and identification of point defects in PtTe2

npj 2D Materials and Applications (2021)

-

Ytterbium-doped fiber laser as pulsed source of narrowband amplified spontaneous emission

Scientific Reports (2019)

-

Nonlinear photoresponse of metallic graphene-like VSe2 ultrathin nanosheets for pulse laser generation

Science China Information Sciences (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.