Abstract

Texture affects liking or rejection of many foods for clinically relevant populations and the general public. Phenotypic differences in chemosensation are well documented and influence food choices, but oral touch perception is less understood. Here, we used chocolate as a model food to explore texture perception, specifically grittiness perception. In Experiment 1, the Just Noticeable Difference (JND) for particle size in melted chocolate was ~5 μm in a particle size range commonly found in commercial chocolates; as expected, the JND increased with particle size, with a Weber Fraction of ~0.17. In Experiment 2, individual differences in touch perception were explored: detection and discrimination thresholds for oral point pressure were determined with Von Frey Hairs. Discrimination thresholds varied across individuals, allowing us to separate participants into high and low sensitivity groups. Across all participants, two solid commercial chocolates (with particle sizes of 19 and 26 μm; i.e., just above the JND) were successfully discriminated in a forced-choice task. However, this was driven entirely by individuals with better oral acuity: 17 of 20 of more acute individuals correctly identified the grittier chocolate versus 12 of 24 less acute individuals. This suggests phenotypic differences in oral somatosensation can influence texture perception of foods.

Similar content being viewed by others

Introduction

Food texture is a perception1, arising from the interaction of a food with mechanoreceptors in the oral cavity; it depends not only on the physical structure of the stimulus, but also the neural impulses carried by multiple afferent nerves2. Despite being a key driver of the acceptance or rejection of foods3, oral texture perception remains poorly understood relative to taste and smell, two other sensory inputs critical for flavor perception. It has been argued that texture is not typically noticed when it is within an acceptable range, but that it is a major factor in rejection if an adverse texture is present4. For chocolate specifically, oral texture is a critical quality attribute, with grittiness often being used to differentiate premium chocolates from bulk chocolate.

Chocolate is a semi-solid suspension of fine particles from cocoa and sugar dispersed in a continuous fat phase, making it an ideal food for the study of texture. Of the three types of chocolate — dark, milk, and white — dark leads the global market in total sales5. Increased consumer interest and consumption of dark chocolate is presumably due to the putative health benefits and properties of dark chocolate that have been widely reported in mass media. For example, various reports suggest bioactive components in cocoa may have a beneficial effect on cognitive function and cognitive decline6, may help increase HDL cholesterol levels7 and may have anti-inflammatory activity8. By definition, dark chocolate does not contain dairy fat, making it a slightly simpler system than milk chocolate for the study of texture; given this, as well as its global commercial relevance, we used dark chocolate as our model system.

The chocolate making process requires numerous steps to convert cocoa beans and sugar into finished chocolate. In particular, the refining step is especially critical for the production of the desired smooth texture9,10. During refining, physical force is applied to the cocoa paste to break down the cocoa and sugar particles into smaller sizes. However, this step is also a common bottleneck in production, as finer particle sizes require more processing time and higher energy inputs11. Roll refining is the most common means to reduce particle sizes in commercial chocolate manufacturing9, although hammer or ball mills are also used. Because chocolate production is energy intensive, manufacturers wish to reduce refining time to minimize cost. However, such concerns need to be balanced against product acceptability.

In chocolate, the particle size distribution (PSD) is a fundamental characteristic which has a large influence on both rheology and texture9,10,11. Unsurprisingly, the largest particles have the most influence on mouthfeel and grittiness. Accordingly, one widely-used measure of particle size in chocolate manufacturing is the D90 value, which indicates the size of particles at the 90th percentile of the distribution by volume – that is, 90% of the particles within the sample are finer than the D90 size. When measured via laser diffraction, this value correlates with the sensory perception of the largest particles9. Another widely used parameter is the D(4,3) value, which refers to the volume or mass moment mean (i.e., the De Brouckere mean diameter). A stylized example of a particle size distribution found in chocolate is shown in Fig. 1. Here, different chocolates were quantified using the D90 and D(4,3) values. It is widely claimed that chocolate is perceived as sandy or gritty when particles are larger than ~25–35 μm11,12. Critically however, we have been unable to identify the original source for this value. The closest we have been able to find is a 1967 report by Rostagno, who reported that chocolate was unacceptably coarse when 20% of the particles exceed 22 μm13.

When two products are perceived to have the same grittiness, the products may not be identical in physical composition and particle size distribution; rather, the difference in grittiness may be too small to be perceived as different. In psychophysics, the Just Noticeable Difference (JND) is defined as the smallest change that can be detected between two stimuli (e.g.14). Using JND values measured empirically for stimuli across a range of values, the Weber Fraction can then be calculated. The Weber Fraction (K) is an index of the sensitivity of a sensory system to detect changes in product attributes15. Despite the use of particle size as a control point in the chocolate industry (e.g.16), there is no work in the open literature using relevant psychophysical methods17 to quantify the JND for particle size in chocolate.

The mechanisms for perception of texture in the mouth remain relatively poorly understood relative to research on touch for other body parts like the hands18,19,20,21 and eyes22. Measurement of tactile point pressure sensitivity is widely employed in neurology and other disciplines as a measure of peripheral nerve function through the use of Von Frey Hairs (VFH), sometimes called Semmes-Weinstein monofilaments23. VFH are small calibrated monofilaments which deliver a specific amount of pressure. They are low cost, noninvasive, relatively easy to use and provide a fast way of estimating somatosensation24. VFH have been used to measure mechanical sensitivity in both infants, adults and even animals25 on the hands, feet (e.g.26,27,28) and face (e.g.28). Although prior work using VFH suggests pressure sensitivity on the tongue varies across people29, research on differences in tactile perception in the oral cavity are relatively limited30. Other previous studies have reported mechanical detection thresholds in the oral cavity, but these have focused on normative values rather than individual differences on the tongue (e.g.31), or comparisons between patients and healthy controls on the inner cheek32. Thus, one objective of the current research was to measure and quantify differences in pressure point sensitivity on the tongue in nominally healthy adults.

Due to the importance of texture in food products like chocolate and the potential for substantial individual differences in oral touch across the population, there is a need to assess oral tactile function in consumers and determine how this may relate to specific food products. As far as we know, no prior work has reported associations between pressure point sensitivity in the oral cavity in relation to the perception of texture attributes such as particle size in a food product. Accordingly, the aims of the present study were to (a) test the ability of consumers to discriminate between different particle sizes in chocolate around the widely claimed critical value of ~25 μm, (b) to quantify oral pressure point detection and discrimination threshold estimates in healthy consumers, and (c) measure the relationship between oral pressure point threshold estimates with the discrimination of particle size in commercial dark chocolate.

Materials and Methods

Study overview and participants

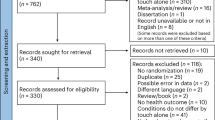

A total of 111 volunteers were recruited for two experiments. An online screening questionnaire was completed by 500+ individuals in State College, Pennsylvania, USA, and the surrounding area: regular chocolate consumers who were not pregnant and did not have food allergies, or any history of facial injury, recent dental work, any known smell or taste defects, or any mouth piercings, were invited to participate. Fifty individuals (13 men, 37 women) completed Experiment 1a, a taste test with experimentally manipulated chocolates produced in our pilot plant (details below). These 50 individuals were later invited back to evaluate a second set of experimental chocolates; 10 newly qualified respondents were also invited, resulting in a total of 60 participants (18 men, 42 women) for Experiment 1b. In a separate study (Experiment 2), oral touch sensitivity was measured one-on-one with a trained experimenter in 51 new participants (10 men, 41 women); no one from Experiment 1a or b participated in Experiment 2. Of the 51 participants who had their oral touch sensitivity quantified in Experiment 2, 44 participants (7 men, 37 women) later returned to our laboratory to evaluate two commercially produced chocolates.

All experiments were performed in accordance with relevant guidelines and regulations for research with human participants. For Experiment 1, all procedures were exempted from full IRB review by the Penn State Office of Research Protections under the consumer testing exemption in 45 CFR 46.101(b)(6). For Experiment 2, the protocol was reviewed and approved by Penn State Institutional Review Board (Protocol #00006365). All participants provided informed consent; implied consent was obtained via a click through question on the computer for Experiment 1, and written consent was provided for Experiment 2. Participants received a small cash incentive for their time, and all testing was conducted in the Erickson Food Science Building at the Pennsylvania State University.

Production of experimental chocolates for experiment 1a & 1b

For Experiment 1a, West African chocolate liquor (sourced from Cargill Cocoa & Chocolate, Mount Joy, PA) was combined with extra fine granulated cane sugar (Golden Barrel, Honey Brook, PA) in small white plastic buckets (10-inch diameter) and thoroughly mixed. Six batches of liquor and sugar were created and run through a Lehmann model 5.B 3-roll refiner set to different particle sizes. The refiner was set to D90 particle size values of approximately 30, 35, 40, 50, 60, and 80 micrometers (microns; μm) and each batch was refined. These values represent a very large range of particle sizes for chocolate, as the majority of commercial products produced fall below 30 μm in D90 size9. After refining, the refiner flake (sugar + cocoa liquor) for each particle size was conched in a Hobart A200 table top conch with an attached water bath. Each sample was conched for 7.5 hours with the water bath set to 55 °C. At the 7.5-hour point, deodorized cocoa butter and soy lecithin (Bioscience Food Solutions GmbH, Siegburg, Germany) were added and the batch was conched for an additional 30 minutes. The final formulation for all samples was: 48.9% sucrose, 43.7% cocoa liquor, 6.86% cocoa butter and 0.5% soy lecithin (by mass). The final chocolate sample formulations were at a fat content of ~32%. (This level was selected because the fat content of chocolate can affect rheological properties like viscosity; however, above ~30%, the effect of fat on viscosity is negligible33). After conching was completed, samples were removed from the conch and were stored in their original buckets until sensory testing. Final particle sizes for the two series of stimuli created with the roll refiner are shown in Table 1.

Due to limitations of the roll refiner used in Experiment 1a, a Union Process Attritor grinding ball mill was used to produce chocolates with D90 particle sizes smaller than 30 μm for Experiment 1b. An attached water bath (set to ~37.8 °C/100 °F) was used to cool the sample during production. As above, chocolate liquor was combined with granulated cane sugar in round buckets and mixed in the same formulation. Six batches of chocolate at different particle sizes were refined using the ball mill. The ball mill was run at 1750 rpm with 5 millimeter (mm) diameter stainless steel balls for differing times to create samples with varying particle sizes. Final particle sizes for each of six batches are shown in Table 1. After grinding in the ball mill, finished chocolate was separated from the stainless-steel balls using a colander and shake table. Samples were then stored until sensory testing.

Particle size analysis

Particle size analysis of all samples was conducted using a Malvern Mastersizer® 3000 laser diffraction particle size analyzer. Chocolate samples were prepared using a standardized procedure developed in conjunction with the Penn State Materials Characterization Laboratory and Malvern Instruments34. Representative output from this protocol can be found in the Supplementary Materials.

Sensory testing with experimental chocolates for experiment 1

Chocolate samples were melted in a warming box set at ~37.8 °C (100 °F) before testing by naïve chocolate consumers. Samples were evaluated as melted chocolate – this was done to minimize any potential variation due to differences in chocolate eating style (i.e., fast chewers, thorough chewers, and suckers)35, and because prior work indicates the perception of particles begins once samples are melted in the mouth36. Samples were served to seated participants in two-inch plastic cups containing ~4 g of melted dark chocolate; each cup was labeled with a random 3-digit blinding code. Participants evaluated pairs of chocolate samples for perceived grittiness in a two-alternative forced choice (2-AFC) task using the method of constant stimuli15. Here, the term task refers to what participants were asked to do (choose the grittier stimulus) while the term method refers to the manner in which stimuli were presented to the participant.

In Experiment 1a, participants were asked to evaluate two series of samples, with four pairs in each series (i.e., a total of 8 chocolates). Following the method of constant stimuli, each series included a fixed reference that was compared against 4 experimental samples (two with particle sizes above the reference, and two below) in a pairwise fashion. In Experiment 1b, participants evaluated a total of five pairs for the two series: samples were similar to those in Experiment 1a (two above, and two below the reference), with the addition of a blind control (i.e., the reference against itself). After evaluating each pair, participants were asked to rinse with water, as prior data indicate water is superior to other palate cleaners37; a 30-second break was enforced between each pair via software. Presentation order was counterbalanced using a balanced Latin squares design. All data were collected using Compusense Cloud software (Guelph, ONT, Canada). Using Microsoft Excel (Microsoft, Redmond, WA), the sum of the number of total pairs correct were calculated, and the percentage of times a stimulus was judged as “grittier than” the reference was determined for each pair. Just Noticeable Differences and Weber fractions were calculated as described by Camacho and colleagues14.

Assessing oral somatosensory function for experiment 2

Prior to testing, participants provided consent and answered standard demographic questions (e.g., age, gender). They were also asked about their general health and average speech use38, health of their lower face24, use of tobacco socially or regularly, if they were diabetic or used insulin, and whether they had a neurologic injury like a stroke or concussion. During testing, participants were seated in a private windowless exam room. Tactile detection and discrimination threshold estimates were obtained using a set of calibrated Von Frey Hairs (VFH) ranging from 0.008 g to 15 g (Aesthesio® Precision Tactile Sensory Evaluators, DanMic Global LLC, San Jose CA). Detection and discrimination assessments were completed bilaterally on the right and left edge of the tongue just lateral to the tongue tip as well as at midline (“center”) on the tongue tip. The order of the testing locations was counterbalanced across participants. Participants were allowed to rinse with water at any point, and a break of 3 minutes was enforced between detection and discrimination threshold assessments. All equipment was cleaned immediately using 70% ethyl alcohol prep pads after testing was finished with a participant, and again prior to testing with a new participant. All question and threshold data were collected and recorded on paper ballots. Data was entered into Microsoft Excel software for analysis.

Detection thresholds using VFH for experiment 2

Tactile detection threshold estimates were determined using a two-alternative forced choice (2-AFC) task39. Participants were required to indicate which of the two sequentially presented observation intervals contained the test stimulus; this is sometimes called a temporal 2-AFC or two-interval-forced-choice (2-IFC) task. Participants heard the researcher say “trial one” and “trial two”, with the stimulus being presented randomly in only one trial. Using one or two fingers, the participant indicated in which trial they felt the stimulus; if participants were unsure, they were told to make their best guess (i.e., a forced choice). All participants started at 1.0 g of nominal pressure. Threshold measurement was conducted with a 3 down/1 up staircase method. The amount of force applied from VFH is discrete and the progression is nonlinear, as the nominal pressure levels (in grams) are predetermined by the manufacturer (i.e., 0.002, 0.02, 0.04, 0.07, 0.16, 0.4, 0.6, 1, 1.4, 2, etc). A new set of filaments was purchased prior to testing, and no attempt was made to verify manufacture provided values. When a participant gave three correct detections at a specific stimulus level, the researcher decreased the VFH filament to the next lower level. If the participant was incorrect, the researcher increased the stimulus to the next level up. Final detection threshold estimates were defined as the mean of 5 reversals (‘crossings’) in the staircase. No feedback was given to participants.

Discrimination thresholds using VFH for experiment 2

Continuing with the Von Frey Hair monofilaments, discrimination threshold estimates were determined using the approach of Etter and colleagues24. In contrast to the detection task described above, for discrimination, participants received stimuli in both trials one and two. They were asked to indicate, using one or two fingers, which trial had the “stronger or harder” pressure. The trial with greater force was counterbalanced. As the monofilament stimulators come in fixed levels of force (see above), discrimination trials started at three levels above their detection threshold. For example, if a participant’s detection threshold was 0.02 grams, they started their discrimination thresholds at 0.16 grams. The same criteria for correct and incorrect responses, and stopping points were used as above.

Discrimination of two commercially available chocolates for experiment 2

Participants received two squares of solid commercially available dark chocolate at ambient temperature in 1-inch diameter cups labeled with random 3-digit blinding codes. The chocolates were served solid at room temperature (in contrast to Experiment 1), both for simple logistics of one-on-one testing, and to further increase the ecological validity of these data. Participants were asked to identify the grittier sample in a 2-AFC task. The two chocolates were Scharffen Berger Bittersweet Dark and ChocoLove Strong Dark, both with 70% cocoa, purchased locally. Participants rinsed with water before tasting and were allowed to rinse at any other point during tasting. Testing ended after the chocolate tasting was complete.

Data analysis

Pressure-point detection and discrimination threshold estimates were calculated for the right, center and left tongue tip. Significant differences in participant detection and discrimination threshold estimates by location (Right, Center & Left) were determined using paired t-tests. Linear regression was used to test for a possible relationship between a participant’s detection and discrimination threshold estimate. No subgroup analyses on the basis of gender were performed: we did not have any such a priori hypotheses, and the unequal gender split in our participants would make any such analysis underpowered and potentially misleading.

Because the discrimination thresholds were clearly bimodal (see below), participants were dichotomized into high and low sensitivity groups using the antimodal value (0.6 g) as the cutoff. Potential relationships between the groups were assessed via chi-square analysis. Similarly, relationships between chocolate discrimination ability and oral touch phenotype (high/low groups for point pressure) were assessed via chi-square tests.

As D90 and D(4,3) represent different summary parameters drawn from the same particle size distribution function for an individual batch of chocolate, the results below focus on the D90 values both for simplicity and clarity, and because these values have greater industrial relevance. Interested readers can find D(4,3) data in the Supplemental Materials.

Results

Just noticeable differences and weber fractions

For experiments 1a and 1b, the D90 particle sizes for the experimentally produced chocolates are shown above in Table 1. Figure 2 shows the percentage of times each chocolate was identified as being grittier than the constant reference. For additional context, dots labeled with lower case letters are also shown: these represent particle size values from commercially available chocolates using the same measurement procedure. These commercial products were not evaluated by participants in Experiment 1 and are shown for context. The D90 particle size of commercial samples ranged from 19.2 µm to 31.1 µm, which largely overlaps with the range of values obtained for the experimentally produced chocolates in series 4 and 3. Linear fits were plotted for each series, and were used to calculate the JND values and corresponding Weber Fractions (K).

Proportion of times each experimentally produced chocolate was judged “grittier than the reference stimulus”. The D90 particle size of the reference for each series is shown in the legend. For context, the gray shaded box indicates the range of particle size for commercially available dark chocolates analyzed via laser diffraction. The commercial products were: (a) Lindt Dark; (b) ChocoLove Strong Dark; (c) Wegmans Supermarkets Dark; (d) Ghirardelli Dark 72%; (e) Cacao Godiva Dark; (f) Hershey’s Special Dark; (g) Ghirardelli Dark 60% Cacao; (h) Scharffen Berger Bittersweet Dark; (i) Cavalier Dark.

For three smaller series (i.e., those with references of 26.5 µm, 29.3 µm and 41.3 µm D90 values), the JND values were relatively constant, around ~5 µm. Under Weber’s Law, the JND should be proportional to the size of the stimulus, so unsurprisingly, the JND for the largest series (i.e., a reference stimulus of 52.4 µm) was substantially larger than the other series, with a JND value of 10.5 µm. However, given this, we would have also expected the JND for Series 3 to be slightly greater; the reason for this small discrepancy is unknown. Table 2 details the values for the JND and reference D90 particle size for each series. The empirically determined Weber Fractions (K) for series 4, 3, 2 and 1 were 0.20, 0.12, 0.15, and 0.19, respectively, with an overall mean of 0.17. When D(4,3) particle sizes were used to calculate JND’s (see Table S2 in Supplemental Materials), the JNDs increased as the particle size of the reference stimulus increased, and the Weber Fraction ranged from 0.07 to 0.14 (see Table S3).

Pressure point sensitivity via VFH in experiment 2

Pressure point detection threshold estimates were obtained for the left and right anterior lateral edge and midline (“center”) of the tongue tip in 51 participants. Pressure point discrimination thresholds were only obtained from 47 of these participants due to a testing error.

Threshold estimates for detection and discrimination at each tongue location are shown in Fig. 3 and Table 3. The detection threshold estimates showed evidence of a floor effect, as most participants were able to detect stimuli at or below the second lowest stimulus level (0.02 grams of pressure) in the 2-IFC task (i.e., when a stimulus was only presented in one of two temporal intervals). Across tongue regions, the right and left lateral edge of the tongue were not significantly different for detection (p’s > 0.10), but there was some weak evidence that values on the midline of the tongue tip might be different than the left (p = 0.07) and the right edges of the tongue (p = 0.11). Within the same participants, the variance in participants’ discrimination threshold estimates were significantly higher than for detection thresholds at all three tongue loci (F-test; all p’s < 0.004). For the discrimination threshold estimates, there was no evidence of significant differences between the three loci (all p’s > 0.10).

Measures of oral somatosensory function collected from young, nominally healthy adults in Experiment 2. In each panel, the x-axis is the nominal pressure applied, and the y-axis is the number of participants. Detection threshold estimates are shown on the left-hand column for the anterior lateral edge of the tongue on the participant’s right (top row), midline center of the tongue tip (middle row) and the anterior lateral edge of the tongue on the participant’s left (bottom row). Discrimination threshold estimates are shown in the right-hand column, at the same locations. The detection thresholds are from 51 participants while the discrimination thresholds are from 47 of the same individuals.

Although minimal variation was observed for pressure point detection threshold estimates, there was greater variation observed in the ability to discriminate between two different levels of force. Based on the antimodal values apparent in Fig. 3, we split participants into high (PPHigh) and low (PPLow) sensitivity groups for each tongue location tested. Mean values for the groups are shown in Table 4, and as would be expected following classification, the group means were significantly lower for the high point pressure sensitivity group (PPHigh) than the low point pressure sensitivity group (PPLow) at all three loci (all p’s < 0.005).

Texture discrimination in commercial chocolates

After all one-on-one somatosensory testing was complete, participants evaluated two commercial chocolates in a 2-AFC task. Across all participants, two-thirds were able to discriminate between the two commercial chocolates. They systematically identified the Scharffen Berger sample as being ‘more gritty’ than the Chocolove sample: 44 of 67 responses (p = 0.0093, one tail). This is consistent with laser diffraction analysis, as the Scharffen Berger had a D90 particle size of 25.20 μm versus 19.70 μm for the Chocolove sample. The significant difference between samples was anticipated, as the difference in particle sizes between the two commercial samples was greater than the JND estimates determined in Experiment 1.

Possible relationships between point pressure discrimination thresholds and discrimination of commercial chocolates were tested; we did not test similar relationships with the detection threshold estimates, given the minimal variation observed in this young, nominally healthy cohort. As above, participants were grouped into PPLow and PPHigh groups for pressure point sensitivity for the right, center and left tongue. In chi-square analysis, there was no significant relationship between pressure point discrimination ability on the right and left lateral edges of the tongue and perception of grittiness in the commercial dark chocolates tested (p’s > 0.20). In contrast, there was evidence of a relationship between pressure point discrimination ability at the midline of the tongue tip, and perception of particles in chocolate (chi-square = 0.0246). That is, 85% (17/20) of the individuals in the PPHigh group correctly identified the chocolate with the larger particle size as being grittier, while the individuals in the PPLow group performed exactly at the level expected by chance (50%; 12 of 24 correct).

Discussion

Here, we describe two novel experiments on the ability of naïve chocolate consumers to discriminate between different particle sizes in dark chocolate. Individual differences in oral point-pressure sensitivity were assessed as measures of oral somatosensory function, and a significant relationship was observed between differences in clinical measures of oral somatosensory function at the tongue tip and texture perception of dark chocolate. These data advance our understanding of texture perception in the oral cavity, by suggesting that, as with smell and taste, phenotypic differences in oral somatosensory can generalize to real foods.

For experimentally produced dark chocolates with D90 particle size from 19 to 33 µm and 22 to 36 µm respectively – that is, in a range comparable of commercially available dark chocolates – the Just Noticeable Differences (JNDs) were 5.04 and 4.44 µm. This suggests that naïve chocolate consumers (i.e., non-experts) are able to perceive differences in chocolate particle size when they differ by only ~5 micrometers (microns). The JND was greater when the size of the reference increased, as would be expected from Weber’s Law. While the larger stimuli with correspondingly bigger JNDs were above the range normally found in chocolates intended for eating, these data still have some industrial relevance. This is because much of the chocolate produced commercially is intended for use in products such as cookies, biscuits, caramel or nuts, and these ‘inclusions’ are frequently manufactured with larger particle sizes. Indeed, the grittiness of the chocolate is partially masked by the texture of the food itself12. Present findings may also help reduce energy use in the chocolate industry (reducing both environmental impact and production cost), as chocolates with smaller D90 particle sizes take longer to refine and require substantially more energy in manufacturing9. These data also speak to quality control efforts vis-à-vis critical limits: as a matter of definition, variation below the JND will presumably not be noticed by consumers.

Calculations of the Weber Fractions (K) for the four series of melted stimuli in Experiment 1 were roughly constant, with a mean of 0.17 for the D90 particle size. As would be expected, the JND for larger particle sizes was larger, similar to many other studies in food and non-food products14,40,41. The Weber Fractions determined here in melted chocolate for particle size perception are comparable to those reported for various taste qualities such as sweetness (K = 0.13), saltiness (K = 0.15) and sourness (K = 0.22)41. In contrast, chemesthetic stimuli (like the perception of pungency from chilies) show much higher Weber Fractions (K = 0.59–0.64)40 than those observed here. Although the psychophysics of particle size perception have not been formally tested previously, present data are also aligned with Weber Fractions reported previously for other textural properties, including viscosity of model beverages (K = 0.26)14, creaminess of added fat in beverages (K = 0.16)42 and the firmness of edible fats (K = 0.20)43. Given that values reported previously for textural attributes like creaminess perception and firmness are similar to those observed here for particle size in chocolate, this suggesting that there may be shared mechanisms for oral texture perception in humans.

Regarding individual differences in oral somatosensory function on the tongue, minimal variation was observed in pressure point detection, regardless of locus, as their appears to be a floor effect, as the lightest Von-Frey Hairs (VFHs) were clearly perceptible to young nominally healthy adults without oral pathology. Similar effects have been reported in other work on healthy young adults, regardless of whether thresholds were determined with an adaptive staircase (like the one used here)24 or the method of limits with ascending and descending series31. Despite the minimal variation seen across participants, there was also some evidence here that detection thresholds may be lower on the midline of the tongue as compared to the lateral edge on the right and left near the tip. Thus, present data bring new empirical support to the idea that the tip of the tongue is the more sensitive than the sides44. We believe this is a novel finding: prior work with VFH suggests the tongue tip is more sensitive than the face (right cheek) or upper gums31, but we cannot find any prior data comparing tongue regions. Increased sensitivity at tongue midline may be due, in part, to the fungiform papillae (FP) present on the tongue tip, as other work suggests those with higher FP density have higher lingual tactile sensitivity in a letter recognition task45. Yackinous reported that those who perceived more bitterness from 6-n-propylthiouracil (i.e., so-called supertasters) were more sensitive to point-pressure stimulation with VFH on the center tongue29, and that supertasters had higher fungiform papillae counts on the anterior tongue46. However, those studies did not directly assess potential relationships between pressure point sensitivity and FP density, and we did not collect data on FP density here, so additional work is needed to explore possible relationships between papillae density and oral somatosensory function.

In contrast to the detection threshold data, substantially more variability was observed in discrimination threshold estimates across individuals. We did not find evidence of any significant differences in terms of discrimination ability across loci; however, discrimination threshold estimates did seem to show the same pattern as the detection thresholds, with the tongue tip having slightly lower threshold estimates. Additional work seems warranted. In direct comparison with other recent data24, the discrimination threshold estimates for the right and left lateral edge of the tongue were slightly higher here; the reason for this is unknown. Conversely, discrimination threshold estimates for pressure point sensitivity for the tongue tip have not been reported previously, so we are unable to make any comparisons.

Critically, the ability to detect a stimulus and to discriminate between stimuli are subtly different cognitive tasks. However, for oral touch, it has not been reported whether these might covary within an individual – i.e. does high detection ability correspond with high discrimination ability? Here, no relationship was observed between a participant’s detection and discrimination ability for pressure point sensitivity, with the caveat that a potential relationship cannot be ruled out entirely, given the restricted range of responses for the detection thresholds in this nominally healthy cohort. Alternatively, the apparent lack of a relationship may also be due to the fact that detection and discrimination procedures are different cognitive tasks39. In a detection threshold, the stimulus must be stronger than some critical amount in order to be consciously observed47, whereas in a discrimination threshold, participants are required to distinguish differences in intensity between two stimuli.

In experiment 2, we asked participants to evaluate two commercially available dark chocolates that differed in particle size, and critically, this difference was just above the JND determined with experimentally produced chocolates in Experiment 1. Indeed, the two commercial chocolates were roughly the same particle sizes (19 μm and 26 μm) as two of the experimentally produced chocolates (samples A and the blind reference from Series 1): this allows for a direct comparison across the two experiments. In both, the groups were able to discriminate between the samples (80% correct, and 66% correct, respectively). The slightly better performance for the experimental chocolates may be explained by the slightly larger difference in particle size (7.2 um versus 5.5 um for the pair of commercial chocolates, although both were above the estimated JND of ~5 micrometers (microns).

Limitations of this work should be noted. Chocolate is a convenient model food that is both self-stable and highly acceptable to participants, as well as being amenable to experimental manipulation in terms of particle size. However, it is somewhat unique in that most foods are not a semi-solid suspensions of fine particles in a continuous fat phase. As such, present findings may not generalize to other foods, or to textural properties beyond grittiness. For example, in a recent pilot study, we failed to find any evidence to support a relationship between differences in point pressure sensitivity and viscosity discrimination in maltodextrin solutions (Alcala, Etter, & Hayes, unpublished data). Also, sample presentation differed between Experiments 1 and 2 (melted versus solid chocolate). Melted chocolate was used in the JND experiment to minimize possible effects of eating styles (see35). Whether such differences could modify the relationships seen in Experiment 2 remains unknown; while unlikely, additional work would be needed to formally test this. Last, we did not test for any sex or gender effects here. While sex effects are common in taste research (e.g.48,49), touch research on non-oral surfaces either fails to find sex effects on the face28 or tongue31, or suggests that apparent sex differences may be artifacts due to size differences50. Additional work on the role of sex and oral cavity size is needed.

Here, we tested whether there was a relationship between oral touch sensitivity and the perception of particle size. In Experiment 2, there were two distinct groups of participants in terms of discrimination thresholds, and they showed substantial variation in their ability to discriminate between different amounts of force applied to the tongue. When participants were split into groups based on pressure point sensitivity – high (PPHigh) and low (PPLow) acuity – there was a significant relationship between chocolate discrimination and pressure point sensitivity for the PPHigh group on the center tongue. However, a similar relationship was not seen for data from the lateral edge of the tongue. These findings are novel, as we are unaware of previous work showing a relationship between oral pressure sensitivity and ability to detect differences in particle size in a food product. Collectively, these findings suggest that texture detection mechanisms which underpin point pressure sensitivity likely contribute to the detection of particle size in food like dark chocolate.

References

Szczesniak, A. S. Texture is a sensory property. Food Qual Prefer 13, 215–225 (2002).

Hudspeth, A. J., Jessell, T. M., Kandel, E. R., Schwartz, J. H. & Siegelbaum, S. A. Principles of neural science. (McGraw-Hill, Health Professions Division, 2013).

Jeltema, M., Beckley, J. & Vahalik, J. Model for understanding consumer textural food choice. Food Sci Nutr 3, 202–212, https://doi.org/10.1002/fsn3.205 (2015).

Bourne, M. Food Texture and Viscosity: Concept and Measurement. 2nd edn, (Academic Press, 2002).

Watt, A. Report: Dark Chocolate leads global market. (Candy Industry, 2015).

Crichton, G. E., Elias, M. F. & Alkerwi, A. Chocolate intake is associated with better cognitive function: The Maine-Syracuse Longitudinal Study. Appetite 100, 126–132, https://doi.org/10.1016/j.appet.2016.02.010 (2016).

Mursu, J. et al. Dark chocolate consumption increases HDL cholesterol concentration and chocolate fatty acids may inhibit lipid peroxidation in healthy humans. Free Radic Biol Med 37, 1351–1359, https://doi.org/10.1016/j.freeradbiomed.2004.06.002 (2004).

Gu, Y., Yu, S., Park, J. Y., Harvatine, K. & Lambert, J. D. Dietary cocoa reduces metabolic endotoxemia and adipose tissue inflammation in high-fat fed mice. J Nutr Biochem 25, 439–445, https://doi.org/10.1016/j.jnutbio.2013.12.004 (2014).

Afoakwa, E. O. Chocolate Science and Technology. (Wiley-Blackwell, 2010).

Beckett, S. T., Fowler, M. S. & Ziegler, G. R. Beckett’s industrial chocolate manufacture and use. (John Wiley & Sons, 2017).

Adriaenssens, M., Greiner M. & Depypere, F. The Complexity of Controlling Particle Size in Chocolate The Manufacturing Confectioner. 97(4), 85 (2017).

Do, T. A., Hargreaves, J. M., Wolf, B., Hort, J. & Mitchell, J. R. Impact of particle size distribution on rheological and textural properties of chocolate models with reduced fat content. J Food Sci 72, E541–552, https://doi.org/10.1111/j.1750-3841.2007.00572.x (2007).

Rostagno, W. Chocolate Particle Size and Its Organoleptic Influence (1967).

Camacho, S., Dop, M., de Graaf, C. & Stieger, M. Just Noticeable Differences and Weber Fraction of Oral Thickness Perception of Model Beverages. J Food Sci 80, S1583–1588, https://doi.org/10.1111/1750-3841.12922 (2015).

Lawless, H. T. & Heymann, H. Sensory evaluation of food: principles and practices [2nd ed]. 2nd edn, (Springer, 2010).

Adriaenssens, M., Greiner, M. & Depypere, F. D. R. The Complexity of Controlling Particle Size in Chocolate. 71st PMCA Production Conference (2017).

Prescott, J., Hayes, J. E. & Byrnes, N. K. In Encyclopedia of Agriculture and Food Systems (ed. Van Alfen, N. K.) 80–101 (Elsevier, 2014).

Brisben, A. J., Hsiao, S. S. & Johnson, K. O. Detection of vibration transmitted through an object grasped in the hand. J Neurophysiol 81, 1548–1558 (1999).

Miyaoka, T., Mano, T. & Ohka, M. Mechanisms of fine-surface-texture discrimination in human tactile sensation. J Acoust Soc Am 105, 2485–2492, https://doi.org/10.1121/1.426852 (1999).

Skedung, L. et al. Feeling Small: Exploring the Tactile Perception Limits. Sci Rep-Uk 3, https://doi.org/10.1038/srep02617 (2013).

Wandersman, E., Candelier, R., Debregeas, G. & Prevost, A. Texture-Induced Modulations of Friction Force: The Fingerprint Effect. Phys Rev Lett 107, https://doi.org/10.1103/PhysRevLett.107.164301 (2011).

Gupta, P. K., Jensen, P. S. & de Juan, E. Surgical forces and tactile perception during retinal microsurgery. Lect Notes Comput Sc 1679, 1218–1225 (1999).

Tracey, E. H., Greene, A. J. & Doty, R. L. Optimizing reliability and sensitivity of Semmes-Weinstein monofilaments for establishing point tactile thresholds. Physiol Behav 105, 982–986, https://doi.org/10.1016/j.physbeh.2011.11.002 (2012).

Etter, N. M., Miller, O. M. & Ballard, K. J. Clinically Available Assessment Measures for Lingual and Labial Somatosensation in Healthy Adults: Normative Data and Test Reliability. Am J Speech Lang Pathol 26, 982–990, https://doi.org/10.1044/2017_AJSLP-16-0151 (2017).

Bradman, M. J., Ferrini, F., Salio, C. & Merighi, A. Practical mechanical threshold estimation in rodents using von Frey hairs/Semmes-Weinstein monofilaments: Towards a rational method. J Neurosci Methods 255, 92–103, https://doi.org/10.1016/j.jneumeth.2015.08.010 (2015).

Slater, R. et al. Cortical pain responses in human infants. J Neurosci 26, 3662–3666, https://doi.org/10.1523/JNEUROSCI.0348-06.2006 (2006).

Johansson, R. S., Vallbo, A. B. & Westling, G. Thresholds of Mechanosensitive afferents in the Human Hand as measured with Von Frey Hairs. Brain research 184, 343–351 (1980).

Rolke, R. et al. Quantitative sensory testing in the German Research Network on Neuropathic Pain (DFNS): standardized protocol and reference values. Pain 123, 231–243, https://doi.org/10.1016/j.pain.2006.01.041 (2006).

Yackinous, C. & Guinard, J. X. Relation between PROP taster status and fat perception, touch, and olfaction. Physiology & Behavior 72, 427–437 (2001).

Kravchuk, O., Torley, P. & Stokes, J. R. In Food Materials Science and Engineering (eds Bandari, B. & Roos, Y. H.) 349–372 (Blackwell Publishing, 2012).

Pigg, M., Baad-Hansen, L., Svensson, P., Drangsholt, M. & List, T. Reliability of intraoral quantitative sensory testing (QST). Pain 148, 220–226, https://doi.org/10.1016/j.pain.2009.10.024 (2010).

Costa, Y. M. et al. Trigeminal nociceptive function and oral somatosensory functional and structural assessment in patients with diabetic peripheral neuropathy. Sci Rep 9, 169, https://doi.org/10.1038/s41598-018-37041-4 (2019).

Afoakwa, E. O., Paterson, A. & Fowler, M. Effects of particle size distribution and composition on rheological properties of dark chocolate. European Food Research and Technology 226, 1259–1268, https://doi.org/10.1007/s00217-007-0652-6 (2007).

Rawle, A. F. The importance of particle sizing to the coatings industry Part 1: Particle size measurement. Advances in Colour Science and Technology. 5(1) (2002).

Carvalho-da-Silva, A. M., Van Damme, I., Wolf, B. & Hort, J. Characterisation of chocolate eating behaviour. Physiology & Behavior 104, 929–933, https://doi.org/10.1016/j.physbeh.2011.06.001 (2011).

Ziegler, G. R., Mongia, G. & Hollender, R. The role of particle size distribution of suspended solids in defining the sensory properties of milk chocolate. International Journal of Food Properties 4, 353–370 (2001).

Lee, C. A. & Vickers, Z. M. Discrimination among astringent samples is affected by choice of palate cleanser. Food Qual Prefer 21, 93–99, https://doi.org/10.1016/J.Foodqual.2009.08.003 (2010).

Baylor, C., Yorkston, K., Eadie, T., Miller, R. & Amtmann, D. Levels of Speech Usage: A Self-Report Scale for Describing How People Use Speech. J Med Speech Lang Pathol 16, 191–198 (2008).

Gescheider, G. A. Psychophysics: the fundamentals. 3rd edn (1997).

Orellana-Escobedo, L. et al. Determination of absolute threshold and just noticeable difference in the sensory perception of pungency. J Food Sci 77, S135–139, https://doi.org/10.1111/j.1750-3841.2011.02589.x (2012).

McBride, R. L. A JND-scale:category-scale convergence in taste. Journal of Perception & Psychophysics 34, 77–83 (1983).

Zahn, S., Hoppert, K., Ullrich, F. & Rohm, H. Dairy-Based Emulsions: Viscosity Affects Fat Difference Thresholds and Sweetness Perception. Foods 2, 521–533, https://doi.org/10.3390/foods2040521 (2013).

Rohm, H. A. & Raaber, S. U. Difference thresholds in texture evaluation of edible fats: Firmness and spreadability. Journal of food science 57, 647–650 (1992).

Rosenthal, A. J. Food Texture: Measurement and Perception. (Aspen Publishers Inc., 1999).

Essick, G., Chopra, A., Guest, S. & McGlone, F. Lingual tactile acuity, taste perception, and the density and diameter of fungiform papillae in female subjects. Physiology & Behavior 80, 289–302, https://doi.org/10.1016/j.physbeh.2003.08.007 (2003).

Yackinous, C. A. & Guinard, J. X. Relation between PROP (6-n-propylthiouracil) taster status, taste anatomy and dietary intake measures for young men and women. Appetite 38, 201–209 (2002).

Lawless, H. T. Quantitative Sensory Analysis: Psychophysics, Models and Intelligent Design. (Wiley, 2013).

Baker, A. N., Miranda, A. M., Garneau, N. L. & Hayes, J. E. Self-reported Smoking Status, TAS2R38 Variants, and Propylthiouracil Phenotype: An Exploratory Crowdsourced Cohort Study. Chem Senses 43, 617–625, https://doi.org/10.1093/chemse/bjy053 (2018).

Garneau, N. L. et al. Crowdsourcing taste research: genetic and phenotypic predictors of bitter taste perception as a model. Front Integr Neurosci 8, 33, https://doi.org/10.3389/fnint.2014.00033 (2014).

Peters, R. M., Hackeman, E. & Goldreich, D. Diminutive digits discern delicate details: fingertip size and the sex difference in tactile spatial acuity. J Neurosci 29, 15756–15761, https://doi.org/10.1523/JNEUROSCI.3684-09.2009 (2009).

Acknowledgements

This manuscript was completed in partial fulfillment of the requirements for a Master of Science degree at the Pennsylvania State University by the first author. The authors would like to thank Ms. Tiffany Murray and the wage payroll staff of the Sensory Evaluation Center for their assistance in data collection, as well as our study participants for their time and participation.

Author information

Authors and Affiliations

Contributions

J.E.H. and S.P.B. conceived of the experiments. N.M.E. and G.R.Z. contributed to the design. S.P.B. produced the chocolate, with guidance from G.R.Z. S.P.B. collected data from participants, analyzed data, and wrote an initial draft of the manuscript. J.E.H. edited and revised the manuscript, with additional input from N.M.E. and G.R.Z.

Corresponding author

Ethics declarations

Competing Interests

N.M.E. has no potential conflicts to report. S.P.B. was a graduate student when the work was performed; he is now employed by Rich Products Corporation, who has no interest or involvement in this work. J.E.H. and G.R.Z. have each received speaking and/or consulting fees from the food industry for work unrelated to this project. Also, the Sensory Evaluation Center at Penn State conducts applied taste tests for the food industry to facilitate experiential learning for students. None of these organizations have had any role in study conception, design or interpretation, or the decision to publish these data.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Breen, S.P., Etter, N.M., Ziegler, G.R. et al. Oral somatosensatory acuity is related to particle size perception in chocolate. Sci Rep 9, 7437 (2019). https://doi.org/10.1038/s41598-019-43944-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-43944-7

This article is cited by

-

Exploring the effects of structure and melting on sweetness in additively manufactured chocolate

Scientific Reports (2024)

-

Production of bioactive and functional frozen yogurt through easy-to-make microspheres incorporation

Journal of Food Science and Technology (2024)

-

Oral somatosensory alterations and salivary dysfunction in head and neck cancer patients

Supportive Care in Cancer (2023)

-

Predicting thickness perception of liquid food products from their non-Newtonian rheology

Nature Communications (2021)

-

Subjective touch sensitivity leads to behavioral shifts in oral food texture sensitivity and awareness

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.