Abstract

Vanadium dioxide (VO2) is an archetypal metal-insulator transition (MIT) material, which has been known for decades to show an orders-of-magnitude change in resistivity across the critical temperature of approximately 340 K. In recent years, VO2 has attracted increasing interest for electronic and photonic applications, along with advancement in thin film growth techniques. Previously, thin films of VO2 were commonly grown on rigid substrates such as crystalline oxides and bulk semiconductors, but the use of transferrable materials as the growth substrates can provide versatility in applications, including transparent and flexible devices. Here, we employ single-crystalline hexagonal boron nitride (hBN), which is an insulating layered material, as a substrate for VO2 thin film growth. VO2 thin films in the polycrystalline form are grown onto hBN thin flakes exfoliated onto silicon (Si) with a thermal oxide, with grains reaching up-to a micrometer in size. The VO2 grains on hBN are orientated preferentially with the (110) surface of the rutile structure, which is the most energetically favorable. The VO2 film on hBN shows a MIT at approximately 340 K, across which the resistivity changes by nearly three orders of magnitude, comparable to VO2 films grown on common substrates such as sapphire and titanium dioxide. The VO2/hBN stack can be picked up from the supporting Si and transferred onto arbitrary substrates, onto which VO2 thin films cannot be grown directly. Our results pave the way for new possibilities for practical and versatile applications of VO2 thin films in electronics and photonics.

Similar content being viewed by others

Introduction

In recent decades, transition metal oxides that undergo metal-insulator transitions (MITs) have attracted much attention as components for electronic and photonic devices. In particular, vanadium dioxide (VO2) has been of great interest for practical applications because the MIT for VO2 is induced near room temperature (~340 K)1. Additionally, the MIT leads to dramatic changes in the electrical resistivity (up-to five orders of magnitude in a single crystal)2 as well as optical transmittance (more than 50% in the infrared range)3. More importantly, thanks to advancements in thin film growth techniques, VO2 can be prepared consistently in thin film form, with properties comparable to those of the bulk counterpart4. In fact, the growth of high-quality VO2 thin films has been demonstrated even on the wafer scale, which is promising for practical use in electronics and photonics5.

Commonly, thin films of VO2 have been prepared on oxide substrates because a high-temperature oxygen (O2) treatment is often necessary for crystallization. Some of the most common substrates include aluminum oxide (Al2O3)6 and titanium dioxide (TiO2)7, on which VO2 films show a MIT with resistivity changing by up-to four orders of magnitude. Additionally, non-oxide materials have been employed as substrates for VO2 growth, such as silicon (Si)8, germanium9, and gallium nitride10. Even on such semiconducting compounds, VO2 films show reasonable MIT properties, opening the possibility for the realization of electronic and photonic VO2 devices compatible with existing semiconductor technology. On these rigid substrates, the fabrication of devices is, in principle, based on the top-down integration of other components onto VO2. However, if VO2 thin films can be prepared on thin transferable supports, the range of device applications is expected to be extended further, including for example, flexible devices.

Recently, with the progress of research on two-dimensional (2D) layered materials, layered materials have attracted interest as transferable substrates for growth of VO2 thin films. Recent studies have reported that VO2 thin films can be grown on chemical vapor deposited graphene on copper and that a VO2/graphene stack can be transferred onto a plastic film for use in flexible thermochromic windows11,12. Additionally, growth of VO2 on muscovite has been reported13,14. Thin films of muscovite could be peeled off from the bulk with the covering VO214, hence promising flexible device applications. Although these results suggest the utility of layered materials for the VO2 growth substrate, their potential applications may be limited in number because graphene shows an extremely high electrical conductivity, while muscovite is mechanically relatively fragile. Therefore, the search for alternative layered materials with insulating properties as well as mechanical strength is necessary for realizing more versatile applications.

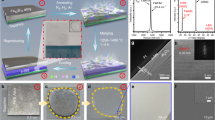

Here, we demonstrate the growth of VO2 thin films on crystalline hexagonal boron nitride (hBN), which is a layered material consisting of honeycomb lattices with nitrogen and boron atoms arranged at the inequivalent triangular sites. Hexagonal BN is electrically insulating even at nanometer thicknesses15,16, due to a wide bandgap energy close to 6 eV17,18. Ultrathin hBN has a large Young’s modulus of ~0.86 TPa and a fracture strength of ~70 GPa19, comparable to those of diamond. In addition to these exceptional electronic and mechanical properties, hBN is inert to O2 exposure even at 500 °C20,21, making it a promising choice for use as an oxide growth substrate. We observed that VO2 thin films could be grown on hBN with crystallinity and that such films underwent a MIT at approximately 340 K. Across the MIT, the resistivity was observed to change by nearly three orders of magnitude, which is comparable to that found for VO2 thin films grown on common substrates6,7,8,9,10. More importantly, we found that the stack of VO2 and hBN could be picked up from an original substrate, and, then, transferred onto another target substrate of any material and geometry, as schematically depicted in Fig. 1. These results have important implications for the realization of a variety of electronic and photonic devices based on VO2/hBN stacks.

Schematic illustration of the growth of the VO2 thin film on a hBN flake supported on a substrate (left). Due to the weak van der Waals (vdW) interaction between hBN and the substrate, the stack of VO2 and hBN is expected to be transferred from the original substrate onto a target substrate of any material and geometry (right).

Results and Discussion

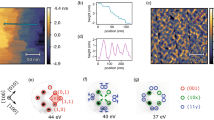

For the VO2 growth substrates, we used thin flakes of high-purity hBN single crystals, which were synthesized by the method described in ref.22. Using adhesive tape, thin flakes of hBN were mechanically exfoliated from bulk single crystals onto Si substrates with 285 nm-thick silicon dioxide (SiO2) layers, leading to the (0001) surface facing upward. The exfoliated hBN flakes have atomically flat surfaces with few defects15,16. Following an O2 treatment at 500 °C in ambient pressure for 3.5 hours to remove the adhesive tape residue20, thin films of VO2 were grown onto hBN by pulsed laser deposition (PLD, see Methods for more details). Figure 2a is a typical optical image of the hBN flakes supported on SiO2/Si after the growth of a VO2 thin film. The lateral sizes of the hBN flakes exfoliated on SiO2 range up-to hundreds of micrometers in length. By measuring the height difference between the region covered with VO2 and the substrate by using atomic force microscopy (AFM), the thickness of the deposited film was determined to be ~26.9 nm. Below, by using cross-sectional scanning transmission electron microscopy (STEM), we find that the thicknesses of films supported on SiO2 and hBN are comparable to each other. First, the crystallinity of VO2 on hBN was characterized using Raman spectroscopy. Figure 2b is a Raman spectrum obtained for VO2 grown on a 226 nm-thick hBN flake at 300 K (see the inset for the optical image of the VO2/hBN stack). In addition to the peaks for Si and hBN at 520 and 1367 cm−1 23,24, prominent Raman peaks from the vibration modes of monoclinic VO2 were observed at 192, 222, 307, 389, and 614 cm−1 25, indicating the growth of the VO2 crystal on hBN.

(a) Optical image of hBN flakes exfoliated onto a SiO2/Si substrate after the growth of VO2. The left purple region shows the SiO2/Si surface, which was masked during the growth, while the deposited region is colored in gray. The scale bar is 250 μm. (b) Raman spectrum measured for the VO2 thin film grown on hBN on SiO2/Si at 300 K. The inset shows the optical image of the VO2/hBN stack. The scale bar is 50 μm. (c) Temperature-dependent Raman spectra measured at VO2 on hBN. The measurement temperature was increased from 300 to 370 K and, subsequently, decreased from 370 to 300 K with a 10 K step. (d) The area ratio of the VO2 peak at 614 or 644 cm−1 to the Si peak at 520 cm−1 as a function of temperature in the heating (red square dot) and cooling (blue circular dot) processes.

Additionally, we investigated the phase transition properties of the VO2 films grown on hBN from temperature-dependent Raman spectroscopy measurements. As shown in Fig. 2c, the Raman peaks for VO2 on a hBN flake were diminished above 340 K when heated up from 300 K but appeared when cooled down from 370 K below 330 K. The observations imply that VO2 on hBN undergoes a structural phase transition between the monoclinic (which is commonly called the “M1” phase) and tetragonal structures at a temperature of approximately 340 K26. We note that the Raman peaks for VO2 with a tetragonal structure are absent, as reported previously25,26. Noteworthy, near the transition temperature, strong peaks were observed at 199 and 644 cm−1, rather than 192 and 614 cm−1 (see Fig. 2c). The Raman peaks are characteristics of the monoclinic “M2” phase of VO2, which is the metastable transient structure between the monoclinic M1 and tetragonal structures and can be stabilized by doping27,28 or applying strain along the [110] direction of the rutile structure29,30. Although we cannot completely exclude the possibility of unintentional doping in VO2 without a detailed chemical analysis, since no dopants were added during growth, the stabilization of the M2 phase in VO2 on hBN is most likely due to strain along the [110] direction. Below, from cross-sectional STEM measurements, the VO2 thin film is observed to be grown preferentially with the (110) orientation. Therefore, VO2 is supposed to be compressively strained isotropically in the in-plane direction on hBN, leading to tensile strain along the [110] direction. Such interfacial strains have been observed in thin films grown on layered materials and are explained to be due to the dipole-dipole interactions31. Further detailed measurements with, for example, synchrotron X-ray diffraction spectroscopy will be needed to identify the cause of the stabilization of the M2 phase in VO2 grown on hBN.

The transition temperature estimated from the Raman spectroscopy measurements in Fig. 2c is supposed to be lower than the exact transition temperature because the actual temperature of VO2 is higher than the set value due to laser heating during the measurements. To further explore the critical temperature for the structural phase transition, we collected the Raman spectra for VO2 using a much smaller laser intensity than that used in Fig. 2c (see Methods). Figure 2d shows the area ratio for the VO2 peak at 614 or 644 cm−1 to the Si peak at 520 cm−1 as a function of temperature for the heating and cooling processes. We found that the Raman peak area ratio was reduced abruptly at 344 K in the heating process, but, in the cooling process, increased largely at 340 K. We note that the actual critical temperature for the structural phase transition of VO2 could be still higher than the obtained values because the influence of laser heating cannot be completely ruled out. The observations suggest that the structural phase transition is induced with hysteresis. The magnitude of hysteresis is as small as that reported in the Raman spectroscopy measurement for single-crystalline VO232, implying that the VO2 film on hBN is a single crystal or polycrystalline with grain sizes comparable to the laser spot size of the Raman spectroscopy measurement of ~1 μm.

Next, we investigated the morphology of VO2 thin films grown on hBN using AFM. Figure 3a shows an AFM image of a VO2 thin film grown on a hBN flake collected at room temperature. The VO2 thin film on hBN was observed to be composed of grains with meandering boundaries, thus suggesting a polycrystalline nature, at least, in the in-plane direction. To estimate the characteristic grain size of VO2 on hBN, we measured the spacing between grain boundaries over the AFM image. Figure 3b shows the distribution of the VO2 grain sizes on hBN. As often seen in polycrystalline films33, the grain size distribution can be well fitted with a logarithmic-normal function, with the mean size determined to be 490 ± 60 nm in length. Although we cannot be certain that each grain is single-crystalline, the observed grain size as large as micrometers is consistent with the expectation from the Raman spectroscopy measurements. The grain size of VO2 on hBN is one order of magnitude larger than that of polycrystalline VO2 on Al2O3(0001)34, where small grains are formed as a result of the ease of the large lattice mismatch strain (see Supplementary Information for the AFM image). Therefore, compared with the VO2 films grown on Al2O3, VO2 on hBN is supposed to be strained slightly during growth. While the grains of VO2 on hBN were found to upheave by ~10 nm near the boundaries, which is likely due to the effect of grain boundary grooving35, each grain has a relatively flat surface in the middle, with a roughness of <0.4 nm, as shown in the AFM image and the height distribution in Fig. 3c,d. The observation of an atomically flat surface may imply single crystallinity for each VO2 grains on hBN.

(a) AFM topographic image of VO2 grown on hBN. The scale bar is 1 μm. (b) The distribution of the grain size of VO2 (black square dots). The red curve is a logarithmic-normal fit. (c) Magnified AFM image of VO2 on hBN. The scale bar is 200 nm. (d) The height histogram for the area surrounded by the dashed light blue line in (c). The red solid curve is a Gaussian fit with a standard deviation of 0.4 nm.

To examine the crystallinity of the VO2 grains on hBN at the atomic scale, we employed high-angle annular dark-field STEM (HAADF-STEM. See Methods for the details)36. The specimens for the STEM measurements were prepared by cutting a VO2/hBN stack by focused ion beam milling. Figure 4a is a cross-sectional STEM image of the VO2/hBN stack obtained at room temperature. While the crystal structure of hBN cannot be well resolved from this viewing angle, the lattice fringe is clearly seen for the VO2 region over the sample. The inset in Fig. 4a shows the atomically resolved STEM image of hBN obtained from a different viewing angle. The darker regions imply that other VO2 grains with different orientations are present along the projection direction in the specimen. The crystallinity of the VO2 grain is confirmed from the sharp spots observed in the fast Fourier transformation (FFT) image extracted from the area surrounded by the dashed light blue line in Fig. 4a (see Fig. 4b for the FFT image; the assignments for the spots will be discussed in the following). To determine the crystallographic orientation of the grain, we obtained a high-resolution STEM image of VO2, as shown in Fig. 4c. Vanadium atoms are observed to be arranged with an out-of-plane spacing of 0.325 nm, with an in-plane spacing of 0.167 nm. We note that the out-of-plane lattice spacing of VO2 is determined by calibration with a known interlayer spacing of hBN of 0.333 nm (see the inset of Fig. 4a). Since the monoclinic and rutile VO2 show <1% difference in the spacing between neighboring vanadium atoms, we characterize the crystallographic orientation of the VO2 grain based on the rutile structure, for simplicity. The out-of-plane lattice spacing of 0.325 nm could be assigned as the spacing between the (110) plane of the rutile VO2, which is 0.322 nm for the bulk. Therefore, the VO2 crystal on hBN is strained by 1% along the [110] direction of the rutile structure, while the in-plane strain is estimated to be 0.3% by assuming the Poisson’s ratio to be 0.337. Such magnitude of tensile strain along the [110] direction is large enough to stabilize the M2 phase in VO2 near the transition temperature29. Given the observed in-plane spacing, the projection direction can be, therefore, identified along the [1\(\bar{1}\)3] direction of the rutile structure (see Fig. 4d for a schematic illustration). In the presence of four crystallographic variants, there are four candidate directions in the monoclinic VO2 (i.e., [61\(\bar{2}\)], [6 \(\bar{1}\bar{2}\)], [6 \(\bar{1}\bar{4}\)], and [61\(\bar{4}\)]) to which the rutile [1\(\bar{1}\)3] direction can be transformed. Therefore, among the variants taking the [61\(\bar{4}\)] orientation for the projection, for example, the spots in the FFT image can be assigned, as shown in Fig. 4b.

(a) Cross-sectional STEM image of the VO2/hBN stack. The orange dashed line indicates the interface between VO2 and hBN. The inset shows an atomically resolved STEM image of hBN. The scale bar in the inset is 1 nm. (b) FFT image of the VO2 region surrounded by the dashed light blue line in (a). The Miller indices of the spots are indicated by choosing the [61\(\bar{4}\)] of the monoclinic structure as the projection direction. (c) Atomically resolved STEM image of VO2. (d) Schematic illustration of VO2 grown on hBN with the orientation of the [110] direction of the rutile structure. The relative atomic position of VO2 compared to hBN and the atomic structure of VO2 at the interface do not necessary reflect the actual configuration.

From the STEM image of the other specimen, we observed that the VO2 grain is, again, orientated along the [110] direction of the rutile structure (see Supplementary Information). Therefore, VO2 is presumably grown on hBN, most preferentially with the (110) orientation of the rutile structure. We note that VO2 is grown in the rutile structure since the growth temperature is 450 °C4. A density functional theory calculation has shown that the (110) surface is the most energetically favorable among the low Miller index planes of VO238, and, indeed, growth of polycrystalline VO2 films with the (110) orientation has been observed on Si and quartz30. Therefore, the preferential growth of the VO2 film with the (110) orientation on hBN is legitimate because the hBN surface has no dangling bonds, and hence, only weak van der Waals interactions are expected to act at the interface (see Fig. 4d). Such so called “van der Waal epitaxy” of VO2 has been reported previously on a muscovite(0001) substrate, but the growth orientation is not [110] but in the [010] direction14. This difference might be because the layers of muscovite are negatively charged39 in contrast with hBN, and the electrostatic interactions, in addition to the van der Waals interactions, play a role at the growth interface. As shown in Supplementary Fig. S2, we also observed Moiré patterns in the STEM images of VO2, which are most likely produced by superposition in the multiple grains and/or the monoclinic variants in the VO2 film (see Fig. 3c for the AFM image of the VO2 film with grains). To settle the growth orientations, therefore, further detailed analysis for the Moiré patterns as well as plan-view TEM measurements will be necessary.

From the Raman spectroscopy measurements, we found that VO2 films grown on hBN underwent a structural phase transition at approximately 340 K (see Fig. 2d). Here, we investigate if the structural phase transition in VO2 on hBN accompanies an electronic phase transition. Figure 5a,b show schematic and optical images of the VO2/hBN stack with the platinum (Pt)/chromium (Cr) contact electrodes used for the electrical measurement. See Methods for details of the electrical measurements. The length and width of VO2 between the electrodes was 41 and 37 μm, while the thickness of VO2 and supporting hBN was estimated to be 40 and 90 nm, respectively. The resistance of VO2 was measured in a two-probe configuration at temperatures ranging between 300 and 378 K. Figure 5c shows the resistance-temperature characteristics for VO2 on hBN measured in the heating (red curve) and cooling (blue curve) processes. At 300 K, VO2 shows a resistance of <107 Ω; however, the resistance was observed to be largely reduced with increasing temperature above ~344 K. Ultimately at 378 K, the resistance was decreased down to the order of 103 Ω. Alternatively, when the VO2 film was cooled down, the resistance showed a large increase below ~336 K. These observations clearly indicated that the MIT for VO2 on hBN was thermally induced at approximately 340 K with hysteresis, similar to polycrystalline VO2 films grown on other substrates such as Al2O3(0001)6. The magnitude of the resistance change across the MIT is comparable to that observed in VO2 grown on common substrates6,7,8,9,10, emphasizing the usefulness of hBN as the VO2 growth substrate.

(a) Schematic and (b) optical images of the VO2/hBN stack contacted with the Pt/Cr electrodes for the electrical measurements. The scale bar in the optical image is 10 μm. (c) Resistance-temperature characteristic of the VO2/hBN stack. The electrical resistance of VO2 was measured from 300 to 378 K (red curve) and, subsequently, from 378 to 300 K (blue curve).

We observed several resistance jumps, particularly during the heating process for the resistance-temperature curve in Fig. 5c. Similar behaviors were previously observed for the resistance-temperature characteristics of VO2 thin films grown on Al2O3(10\(\bar{1}\)0)40 and TiO2(001)41, which were explained by the effects of the crystal domain sizes relative to the spacing between the measurement electrodes. Thin films of VO2 commonly consist of crystal domains, with each domain having a slightly different critical temperature for the MIT. As a result, when the temperature-dependent electrical measurement is conducted for a VO2 thin film, the resistance does not change thoroughly at a unique temperature, but gradually with temperature in a percolating manner. However, if the spacing between the measurement electrodes is narrowed down to the scale of the domain size, the formation of single percolation paths between the electrodes becomes marked in the resistance change, resulting in step-like behaviors in the resistance-temperature characteristics. The typical domain size for polycrystalline VO2 on Al2O3 was measured to be tens of nanometers, and, hence, a nanometer-scale electrode spacing was necessary to observe such resistance jumps40. For single-crystalline VO2 on TiO2(001), the domain is regulated by the cracks formed in the film, which is as large as micrometers in size41. Therefore, resistance jumps were observed even for an electrode spacing of 50 μm. The resistance jumps in VO2 on hBN were observed with a 41 μm-long electrode spacing, implying that the characteristic domain size is on the order of hundreds of nanometers or even micrometers, which is consistent with the observed grain sizes in Fig. 3. Therefore, with decreasing electrode spacing close to the domain size, the resistance change for VO2 on hBN is expected to be more step-like, and, ultimately, to exhibit a single step across the MIT, as observed in single-crystalline VO22.

Finally, although the actual fabrication of devices is beyond the scope of this paper, we performed a transfer of the VO2/hBN stack for device applications. Figure 6a,b show optical images of the VO2/hBN stack before and after the transfer process. See Methods for details of the pick-up and transfer process. By this process, the stacks were uniformly transferred from the substrate to the polymer film, as can be confirmed from the Raman spectra for VO2 in Fig. 6c. The polymer film has an elastomeric property and has been previously commonly used for stretchable electronics42. Therefore, the VO2/hBN stacks supported on the polymer could form the basis of electronic and optical switching devices with flexibility, bendability, and stretchability. To further validate the transferability of the VO2/hBN stacks, we transferred the stacks from the polymer films to other substrates such as gold, glass slide and paper, where the direct growth of a high-quality VO2 thin film is challenging (see Supplementary Information for optical images of VO2/hBN transferred onto these substrates). The Raman spectroscopy measurements confirmed uniform crystallinity for the transferred VO2, suggesting the utility of hBN as a transferrable substrate.

Optical images of the VO2/hBN stack on (a) the SiO2/Si substrate and (b) transferred onto the polymer film. The scale bars are 50 μm. The insets in (a,b) show schematic illustrations of the stacking structure. (c) Raman spectra for the VO2/hBN stack before (black curve) and after (red curve) the transfer process. The prominent peaks due to the vibrational modes of VO2 can be seen even after the transfer.

Conclusion

We demonstrated growth of VO2 crystals on an insulating layered material, hBN. The VO2 film is polycrystalline, but the mean grain size was observed to reach up-to micrometers. The VO2 thin film is grown preferentially with the (110) orientation, which is predicted by the DFT calculation to be the most energetically stable38. Thin films of VO2 on hBN undergo a MIT at approximately 340 K, with the electrical resistance changing by nearly three orders of magnitude, showing high quality comparable to those of VO2 films grown on common substrates6,7,8,9,10. Most importantly, VO2 thin films could be transferred onto arbitrary surfaces with the supporting hBN; therefore, a broad spectrum of applications in electronics and photonics can be envisioned. For example, by transfer of the VO2/hBN stack onto an elastomer, flexible and stretchable devices could be fabricated. Thin flakes of hBN show good insulating and dielectric properties and also show atomically flat surfaces43. Therefore, the VO2/hBN heterostructure could form the basis of a “Mott transistor”44, where the MIT is controlled by gating. Additionally, the VO2/hBN heterostructure could behave as a reconfigurable hyperbolic metasurface45, with great potential for applications in nanophotonic devices. Moreover, due to an inert surface with no dangling bonds, hBN is expected to have a wide degree of freedom as a substrate for oxide thin film growth.

Methods

Growth of VO2 thin films on hBN flakes

Thin films of VO2 were grown onto hBN flakes by PLD using an argon fluoride excimer laser with a wavelength of 193 nm under an oxygen pressure of 0.95 Pa at a substrate temperature of 450 °C. The repetition rate was 2 Hz and the growth time was 5 h. A vanadium pentoxide pellet was used for the target.

Characterization

The Raman spectroscopy measurements were conducted using a commercial system (Raman Touch, Nanophoton) with a solid state laser operating at a wavelength of 532 nm at 300–380 K. The temperature was controlled by placing a sample onto a thermally conductive plate connected to a Peltier heating/cooling device. The grating size was 1200 lines/cm. The laser spot size was ~ 1 μm and the laser power was set to be either 0.2 or 1 mW. The AFM measurements were conducted at room temperature in the ambient with the dynamic force mode using Si cantilevers (SPA-300HV, Hitachi High-Tech Science). The HAADF-STEM measurements were performed using a JEOL JEM-ARM200F ACCELARM operated at an acceleration voltage of 200 kV. The probe semi-angle was 18 mrad. The probe current was 9 pA. The angular detection range of the HAADF detector for the scattered electrons was 50–150 mrad.

Electrical measurements

The stacks of VO2/hBN were etched into microwires by photolithography and reactive ion etching (RIE) under a mixture of O2 and sulfur hexafluoride gases. The contacting electrodes were prepared by photolithography and sputtering deposition of Cr (5 nm) and Pt (200 nm). Electrical measurements were conducted in air using a source measurement unit (2635A, Keithley) at temperatures ranging from 300 to 378 K, which was controlled by the Peltier heating/cooling system.

Pick-up and transfer process

To pick-up the stack of VO2 and hBN, we used commercially available polymer films (PF Gel-Film, Gel-Pak)46 treated with water vapor, which show enhanced adhesion47. The polymer film covered with a thin water layer was placed onto the SiO2/Si substrate with the VO2/hBN stacks, and, then, was slowly peeled off from the substrate. The polymer films with the stacks were placed onto the target substrates using a transfer system (IZU-NNHA, Izumi-Tech), which was equipped with an optical microscope and micromanipulator.

Data Availability

All data generated or analyzed during this study are included in this published article and its Supplementary Information file.

References

Liu, K., Lee, S., Yang, S., Delaire, O. & Wu, J. Recent progresses on physics and applications of vanadium dioxide. Mater. Today 21, 875–896 (2018).

Mun, B. S. et al. Nonpercolative metal-insulator transition in VO2 single crystals. Phys. Rev. B - Condens. Matter Mater. Phys. 84, 3–6 (2011).

Chain, E. E. Optical properties of vanadium dioxide and vanadium pentoxide thin films. Appl. Opt. 30, 2782–2787 (1991).

Nag, J. & Haglund, R. F. Synthesis of vanadium dioxide thin films and nanoparticles. J. Phys. Condens. Matter 20, 1–14 (2008).

Zhang, H.-T. et al. Wafer-scale growth of VO2 thin films using a combinatorial approach. Nat. Commun. 6, 8475 (2015).

Kim, D. H. & Kwok, H. S. Pulsed laser deposition of VO2 thin films. Appl. Phys. Lett. 65, 3188–3190 (1994).

Muraoka, Y. & Hiroi, Z. Metal–insulator transition of VO2 thin films grown on TiO2 (001) and (110) substrates. Appl. Phys. Lett. 80, 583–585 (2002).

Okimura, K. & Kubo, N. Preparation of VO2 films with metal-insulator transition on sapphire and silicon substrates by inductively coupled plasma-assisted sputtering. Jpn. J. Appl. Phys. 44, 1150–1153 (2005).

Yang, Z., Ko, C. & Ramanathan, S. Metal-insulator transition characteristics of VO2 thin films grown on Ge(100) single crystals. J. Appl. Phys. 108, 073708 (2010).

Zhou, Y. & Ramanathan, S. Heteroepitaxial VO2 thin films on GaN: Structure and metal-insulator transition characteristics. J. Appl. Phys. 112, 074114 (2012).

Kim, H. et al. Flexible thermochromic window based on hybridized VO2/graphene. ACS Nano 7, 5769–5776 (2013).

Kim, H. et al. Enhanced optical response of hybridized VO2/graphene films. Nanoscale 5, 2632–2636 (2013).

Yan, J., Huang, W., Zhang, Y., Liu, X. & Tu, M. Characterization of preferred orientated vanadium dioxide film on muscovite (001) substrate. Phys. Stat. Sol. (a) 205, 2409–2412 (2008).

Li, C.-I. et al. van der Waal epitaxy of flexible and transparent VO2 film on muscovite. Chem. Mater. 28, 3914–3919 (2016).

Britnell, L. et al. Electron tunneling through ultrathin boron nitride crystalline barriers. Nano Lett. 12, 1707–1710 (2012).

Lee, G.-H. et al. Electron tunneling through atomically flat and ultrathin hexagonal boron nitride. Appl. Phys. Lett. 99, 243114 (2011).

Watanabe, K., Taniguchi, T. & Kanda, H. Direct-bandgap properties and evidence for ultraviolet lasing of hexagonal boron nitride single crystal. Nat. Mater. 3, 404–409 (2004).

Cassabois, G., Valvin, P. & Gil, B. Hexagonal boron nitride is an indirect bandgap semiconductor. Nat. Photon. 10, 262–266 (2016).

Falin, A. et al. Mechanical properties of atomically thin boron nitride and the role of interlayer interactions. Nat. Commun. 8, 15815 (2017).

Garcia, A. G. F. et al. Effective cleaning of hexagonal boron nitride for graphene devices. Nano Lett. 12, 4449–4454 (2012).

Li, L. H., Cervenka, J., Watanabe, K., Taniguchi, T. & Chen, Y. Strong oxidation resistance of atomically thin boron nitride nanosheets. ACS Nano 8, 1457–1462 (2014).

Taniguchi, T. & Watanabe, K. Synthesis of high-purity boron nitride single crystals under high pressure by using Ba-BN solvent. J. Cryst. Growth 303, 525–529 (2007).

Parker, J. H. Jr., Feldman, D. W. & Ashkin, M. Raman scattering by silicon and germanium. Phys. Rev. 155, 712–714 (1967).

Geick, R., Perry, C. & Rupprecht, G. Normal modes in hexagonal boron nitride. Phys. Rev. 146, 543–547 (1966).

Pan, M. et al. Raman study of the phase transition in VO2 thin films. J. Cryst. Growth 268, 178–183 (2004).

Okimura, K. et al. Temperature-dependent Raman and ultraviolet photoelectron spectroscopy studies on phase transition behavior of VO2 films with M1 and M2 phases. J. Appl. Phys. 115, 153501 (2014).

Marezio, M., McWhan, D. B., Remeika, J. P. & Dernier, P. D. Structural aspects of the metal-insulator transitions in Cr-doped VO2. Phys. Rev. B 5, 2541–2551 (1972).

Strelcov, E. et al. Doping-based stabilization of the M2 phase in free-standing VO2 nanostructures at room temperature. Nano Lett. 12, 6198–6205 (2012).

Atkin, J. M. et al. Strain and temperature dependence of the insulating phases of VO2 near the metal-insulator transition. Phys. Rev. B - Condens. Matter Mater. Phys. 85, 020101(R) (2012).

Okimura, K., Watanabe, T. & Sakai, J. Stress-induced VO2 films with M2 monoclinic phase stable at room temperature grown by inductively coupled plasma-assisted reactive sputtering. J. Appl. Phys. 111, 073514 (2012).

Sun, X., Shi, J., Washington, M. A. & Lu, T.-M. Probing the interface strain in a 3D-2D van der Waals heterostructure. Appl. Phys. Lett. 111, 151603 (2017).

Petrov, G. I., Yakovlev, V. V. & Squier, J. Raman microscopy analysis of phase transformation mechanisms in vanadium dioxide. Appl. Phys. Lett. 81, 1023–1025 (2002).

Mendelson, M. I. Average grain size in polycrystalline ceramics. J. Am. Ceram. Soc. 52, 443–446 (1969).

Xu, G., Jin, P., Tazawa, M. & Yoshimura, K. Thickness dependence of optical properties of VO2 thin films epitaxially grown on sapphire (0001). Appl. Surf. Sci. 244, 449–452 (2005).

Amram, D., Klinger, L., Gazit, N., Gluska, H. & Rabkin, E. Grain boundary grooving in thin films revisited: The role of interface diffusion. Acta Mater. 69, 386–396 (2014).

Cho, Y. et al. Morphology of phase-separated VO2 films deposited on TiO2-(001) substrate. Mater. Res. Bull. 102, 289–293 (2018).

Gu, Y., Cao, J., Wu, J. & Chen, L.-Q. Thermodynamics of strained vanadium dioxide single crystals. J. Appl. Phys. 108, 083517 (2010).

Mellan, T. A. & Grau-Crespo, R. Density functional theory study of rutile VO2 surfaces. J. Chem. Phys. 137, 154706 (2012).

Christenson, H. K. & Thomson, N. H. The nature of the air-cleaved mica surface. Surf. Sci. Rep. 71, 367–390 (2016).

Sharoni, A., Ramírez, J. G. & Schuller, I. K. Multiple avalanches across the metal-insulator transition of vanadium oxide nanoscaled junctions. Phys. Rev. Lett. 101, 4–7 (2008).

Kawatani, K., Takami, H., Kanki, T. & Tanaka, H. Metal-insulator transition with multiple micro-scaled avalanches in VO2 thin film on TiO2(001) substrates. Appl. Phys. Lett. 100, 173112 (2012).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Yang, Z., Ko, C. & Ramanathan, S. Oxide electronics utilizing utrafast metal-insulator transitions. Annu. Rev. Mater. Res. 41, 337–367 (2011).

Folland, T. G. et al. Reconfigurable infrared hyperbolic metasurfaces using phase change materials. Nat. Commun. 9, 4371 (2018).

Castellanos-Gomez, A. et al. Deterministic transfer of two-dimensional materials by all-dry viscoelastic stamping. 2D Mater. 1, 011002 (2014).

Ma, X. et al. Capillary-force-assisted clean-stamp transfer of two-dimensional materials. Nano Lett. 17, 6961–6967 (2017).

Acknowledgements

The authors would like to thank S. Sakakihara for carrying out the RIE process. This work was partly supported by JSPS KAKENHI Grant Numbers 17K14658, 16H03871, 26248061, and 17H01054, the Yazaki Memorial Foundation for Science and Technology, the Research Program of “Five-star Alliance” in “NJRC Mater. & Dev.”, and the Nanotechnology Platform Project (Nanotechnology Open Facilities in Osaka University) of the MEXT, Japan (Nos F-16-OS-0012 and F-16-OS-0016).

Author information

Authors and Affiliations

Contributions

M.Y. and H.T. conceived the experiment. H.T. directed the project. S.G. performed the PLD growth of VO2 on hBN and conducted the AFM, Raman spectroscopy, and electrical measurements. M.Y. and T.K. assisted the experiments. S.G. and M.Y. analyzed the experimental data. K.S., S.A. and Y.M. performed the STEM measurements. K.S., S.A., Y.M., S.G., M.Y. and H.T. analyzed the STEM results. S.G., M.Y. and R.N. conducted the transfer process. K.W. and T.T. synthesized the high-purity hBN crystals. M.Y. and S.G. prepared the manuscript using substantial inputs from the other authors. All the authors discussed the experimental results.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Genchi, S., Yamamoto, M., Shigematsu, K. et al. Growth of vanadium dioxide thin films on hexagonal boron nitride flakes as transferrable substrates. Sci Rep 9, 2857 (2019). https://doi.org/10.1038/s41598-019-39091-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-39091-8

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.