Abstract

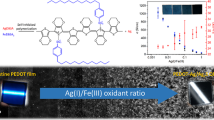

Bi2Se3 nanofilm has exhibited many promising potentials application in the field of photo-to-heat conversion. A highly-efficient photo-to-heat conversion system of Ag/Bi2Se3 composite nanofilm is successfully fabricated through laser direct writing (LDW) technique. The localized heat induced by laser simultaneously achieve Ag particles synthesis, transfer and patterning in a single processing step. The thermal reaction process includes the forming of nanoparticles based on the process of the thermal reduction, laser ablation, sputtering deposition and so on. The thermal storage capability and photothermal conversion stability have been greatly improved through preventing the heat from loss and efficient LSPR enhancing. The photothermal conversion mechanism of composition film is discussed in detail. This work suggests that the laser-assisted transfer technique give rise to a new expectation of functional composite nanofilm application for energy conversion.

Similar content being viewed by others

Introduction

Photo-to-heat conversion performance of nanomaterials has been in the spotlight for new energy applications due to the basic demand for energy harvesting1,2. Photothermal conversion in the UV-visible-NIR range is well reported in nanomaterial dispersions in various solvents or polymer matrices, upon exposure to a laser source3. The effect of heat generation offered by these nanoheaters has been applied in a variety of researching areas such as biological imaging, hyperthermal cancer therapy, drug delivery, photocatalysis, study of phase transitions and water evaporation4,5,6,7,8,9,10.

The photothermal conversion coefficient plays a critical role in efficient use of the photo-to-heat energy11,12. The narrow bandgap semiconducting materials13, especially for topological insulator Bi2Se3 with rhombohedral crystal structure, has intrinsic fundamental simple band structure near the Dirac point and exhibit very high light absorption coefficients for a broad range of wavelengths14,15,16. Owing to the unique electronic structures, resulting in a great deal of potential applications including photonics, spintronic and photothermal15,17,18,19,20. Currently, a great deal of investigations have been reported on combining Bi2Se3 nanostructure with other nanomaterials, such as CdSe/Bi2Se3 quantum dots prepared by action exchange reaction12, the photothermal conversion ability can be extremely improved due to the transport path of carriers changed based on the energy band theory. Likewise, surface-bound collective excitations of free carriers existing in noble metals can be excited by light, which can cause resonance phenomenon in the driving electromagnetic field. Because of the enhanced near-surface electric fields, so-called localized surface plasmon resonances (LSPR), the nanocrystals show intense light absorption and scattering21. These properties can contribute to an extensive application, including pyroelectricity and photothermal conversion.

Ag nanoparticles (NPs) as an important LSPR material is with foreground application in various fields due to large scattering cross-sections and relatively large molar extinction coefficients22,23. Many studies have shown that incorporation of Ag atom into the Bi2Se3 films plays a significant role in optical and optoelectronics aspect via the theory and experiments investigation24,25. A variety of techniques have been reported to prepare Ag-doped nanomaterials thin films in the literature such as thermal evaporation, photochemical synthesis and photocatalytic activity, it can be still necessary to develop another method to prepare the composition structure materials for further applications. The LDW transferring nanotechnology has been of great interest for the fabrication of nanomaterials electronic devices for potential applications including sensors, transparent electrodes and so on26,27. The technique exhibits high through-put and parallel processes to design flexibility at a low cost. The most prominent characteristic is that the laser cannot cause significant problems for gradually phase converted by heat and light over time. The nanomaterials without being acted by laser can be removed, while laser acting pattern area can be transferred to the receiving substrate.

Here, we put forward the idea of creating Ag/Bi2Se3 nanocomposites based on the silver nanocrystal synthesizing, transfer and pattern technology simultaneously. The composite materials are successfully achieved via LDW technology28,29. The method can transfer and pattern different nanomaterials to the various substrate through a single-step process. The photothermal characteristic experiments manifest Ag/Bi2Se3 nanocomposites possess strong photothermal conversion capacity and excellent heat stability. This research provides a new path to prepare the composition nanofilms in the aspect of photo-to-heat application by LDW technology.

Results

The morphology and composition structure of the as-prepared samples are analyzed by TEM, SEM and XRD, as showed in Fig. 1. Figure 1(a) illustrates XRD patterns of Bi2Se3 determine the composition and structure of the sample synthesized by microwave-assisted method. The main diffraction peaks can be readily indexed into the rhombohedral phase of Bi2Se3, which is well agreement with the JCPDS Card No. 33–0214. The well-defined peaks in XRD pattern indicate the forming of high quality Bi2Se3. The microstructure characteristics of the as-prepared Bi2Se3 samples are analysed by transmission electron microscopy (TEM), which shows that Bi2Se3 nanosheets have several hundred nanometers in lateral size in Fig. 1(b). High-resolution TEM (HRTEM) images show that the nanosheets are consisted of numerous Bi2Se3 nanocrystals with a high-quality crystal. The morphology of the as-prepared Bi2Se3 is characterized by SEM and is shown in Fig. 1(d,e), the results indicate that the sample consisted of well-defined hexagonal nanosheets with smooth surfaces. And, from the insert Fig. 1(e), it is clearly seen that the ethanol solution of Bi2Se3 nanosheets is pretty stable owing to the low interfacial energy between ethanol solvent and Bi2Se3 nanosheets30,31.

Preparing and patterns of Ag/Bi2Se3 composition film by LDW is shown in Fig. 2. Figure 2(a) illustrates the schematic of the fabrication process for Bi2Se3 pattern on various substrates by the laser direct writing technique. Under the circumstances, transfer proceeded, by the laser-induced, resembling ejection of a “flyer” that is projected away from the donor film and toward the receiving substrate, where it landed, causing the formation of a voxel. Laser-treated Bi2Se3 film (square pattern) located between before. Digital images of Bi2Se3 pattern on the silicon substrate, glass substrate, Si/SiO2 substrate, and Polyimide film are shown in Fig. 2(b,e), respectively. These results indicate the transferring and pattern can be achieved simultaneously by LDW technology. It can be necessary to point out that phase change of the donor material has not been appeared during the process of transferring. The transfer method also can be used to transfer stacks of different materials, especially interesting for the fabrication of multi-layered devices32.

(a) Schematicdiagram of the laser direct-writing selective area transfer patterning of Bi2Se3. (b) Images of Bi2Se3 pattern on the silicon substrate (A square pattern consisting of dots). (c) Laser-treated Bi2Se3 film (square pattern) located between glass substrate before. (d) Bi2Se3 pattern on the Si/SiO2 substrate. (e) The images of Bi2Se3 patterns on Polyimide (PI) film.

As for the preparing of Ag/Bi2Se3 composition nanofilm, the glass loaded AgNO3 film and Bi2Se3 film is placed in the way of face-to-face and assure to contact closely. The laser beam pass the glass substrate loaded AgNO3, AgNO3 film, and Bi2Se3 film in order, and then throughout from the glass substrate loaded Bi2Se3. AgNO3 film absorbs laser energy and transforms into localized heat, leading to the formation of Ag NPs. At the same time, Ag NPs can be sputtered and deposited on the surface of Bi2Se3 film due to the instantaneous high temperature under the laser action, which gives rise to formation of Ag/Bi2Se3 composite film. It can be necessary to point out that the intensity of laser and scan rate have great impact on patterning integrality of Ag NPs transferred to the glass loaded Bi2Se3 film. When the intensities of laser beam is lower than a certain value or the scan speed is too fast, which can result in nanomaterials not transferred or incompletely transferred, even glass substrate can be damaged.

To demonstrate formation of the composite structure and photothermal characteristic of the sample, measurement results of optical and thermal properties are shown in Fig. 3. The UV-vis-NIR absorbance spectra of Ag/Bi2Se3 nanocomposite film are shown in Fig. 3(a). It can be clearly seen that there is a broadened absorbance from 500 nm to 800 nm. The UV absorption of the films can be caused by the excitation of electrons from the band-to-band or band-defect transitions33,34. The weak absorption near 808 nm is caused by the LSPR in the near infrared band, which is in good agreement with recent theoretical work for Bi2Se3 nanosheets based on tight-binding theory35. An apparent absorption from 350 nm to 400 nm appears for Ag/Bi2Se3 nanocomposite owing to the surface plasma excitation of spatially confined electrons in nano-sized Ag0 particles36. The absorption band is considerable broad and red-shifted owing to the different Ag particle size37, which can result in large shifts of the emission peak excited by the different wavelengths light. It is also inferred that the Ag nanoparticles indeed grow on the surface of Bi2Se3 nanosheets. Meanwhile, Ag NPs existing on the surface of Bi2Se3 can account for the high electrical conductivity, proving by resistance value of multimeter in Fig. 3(b), while none is displayed in Bi2Se3 film. The result further demonstrates that Ag can grow on the surface of Bi2Se3 film by LDW technology.

(a) UV-vis absorption spectrum of Bi2Se3 and Ag/Bi2Se3 films. (b) The conductive performance of the Ag NPs based Ag/Bi2Se3 films. (c) Optical properties of Ag/Bi2Se3 film in the wavelength range of 250−2200 nm, dashed lines represent the spectral solar irradiance density of air mass 1.5 global (AM 1.5 G) tilt solar spectrum. (d) Photothermal conversion effect of Ag, Bi2Se3 and Ag/Bi2Se3 films.

In order to further illuminate the light absorption ability, the experimental measurement of transmission, reflection and absorption spectra for Ag/Bi2Se3 film is investigated by using a spectrophotometer system with an integrating sphere. As shown in Fig. 3(c), the film exhibits a considerable negligible transmission and low reflection within the limits of spectrum of 400–2200 nm, while corresponding to strong absorption, which can be ascribed to the combined characteristic between broads absorption of the Ag NPs, Bi2Se3 layer as well as the light scattering of Ag NPs surface, increasing the optical path length in the composite film38. It is worth mentioning, the improved surface roughness can enhance the multi-scattering of incident light, benefiting for the effective absorption. In generally, the strong spectrum absorption ability indicates that the Ag/Bi2Se3 film is a promising photothermal conversion material. Ag/Bi2Se3 has been proven to be effective in the aspect of photothermal conversion. Figure 3(d) is curves of variances films in temperature including Ag, Bi2Se3 and Ag/Bi2Se3 film. It is clearly seen that temperature of Ag/Bi2Se3 film exhibits rather higher than the other films (Bi2Se3 and Ag) under irradiation of 1 W laser. The infrared thermometer with accuracy of ±0.1 °C is applied to test the temperature, recording one time per 1 s. The temperature of Ag/Bi2Se3 composite film rises to balance rapidly within 120 s, while Bi2Se3 film is in 180 s. And, the temperature of Ag film only increases by 4 °C in Fig. 3(d), it can resist rapid heat dissipation.

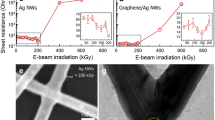

As shown in Fig. 4, it is clearly seen that pattern of Bi2Se3 and Ag/Bi2Se3 is preform by optical microscope image. Figure 4(a) is optical microscope image of Bi2Se3 film prepared on a glass slice via the evaporation-induced self-assembly process in Bi2Se3 nanosheets alcohol solution. The image shows that the highly uniform Bi2Se3 film can be fabricated based on the self-deposition method. Figure 4(b) show the optical microscope image of Ag pattern on the glass substrate after AgNO3 film is acted by the laser. It can be clearly seen that the Ag NPs are formed continually along the track of laser. The interval in Ag pattern transferred to the surface of Bi2Se3 film is 0.01 mm (Fig. 4(c)), which is well agreement with the set value of laser path in computer (in Fig. 4(d)).

Discussion

The photothermal conversion image of Ag/Bi2Se3 composite films are further investigated in near infrared region (Fig. 5). The temperatures of the composite film show remarkable increase within 120 s under irradiation of 808 nm laser. The temperature of Ag/Bi2Se3 composite film rises rapidly with the increasing of the laser power, eventually reach to 47 °C within 120 s at the laser power in 1.2w, as shown in Fig. 5(a). The final equilibrium temperatures of Ag/Bi2Se3 nanofilm is increased by around 34.7 °C at 0.6w, 38.2 °C at 0.8w, 42.6 °C at 1.0w and 45.6 °C at 1.2w, respectively. Presently, many thin films, such as Zinc oxide (ZnO), Titanium dioxide (TiO2), and aluminum-doped zinc oxide are investigated in the application of photothermal conversion39,40,41,42. Although they have performed an excellent photothermal conversion effect, which is still essential to improve photothermal conversion capacity. Compared with the previous researching results, the final equilibrium temperature of Ag/Bi2Se3 nanofilm of is previously higher the reported value. These appearances clearly indicate that Ag/Bi2Se3 composite film possesses the outstanding capacity of photothermal conversion, which can be considered as a promising photothermal material. The thermal equilibrium time constant can effectively evaluate the heat storage capacity, and can be determined by heat transfer equation43. The thermal equilibrium time constants of Ag/Bi2Se3 composite film with different laser power are obtained for thermal equilibration with the surroundings via conductive and irradiative heat transfer11. Figure 5(b) shows a time constant for heat transfer time determined as the negative reciprocal slope of ln (θ) vs. t using temperature versus time data recorded during cooling of the solution. The thermal equilibrium time constant of the samples are calculated to be 20.67, 28.40, 28.07 and 28.10 s for the laser powers 0.6, 0.8, 1.0 and 1.2 s, respectively. It can clearly be seen that these heat transfer time constants remain basically stable with increasing of laser power. The result is attributed to the equilibrium of heat generation and transfer to environment and demonstrating an excellent heat storage capacity of Ag/Bi2Se3 composite film. Figure 5(c) reveals the temperature elevation cycle performance of Ag/Bi2Se3 composite film over four laser ON/OFF cycles of laser irradiation. No significant decrease for the temperature elevation is observed for these samples, indicating excellent thermal stability of the Ag/Bi2Se3 composite film. It can be demonstrated that Ag/Bi2Se3 composite film are dominant heat sources. Transmissivity of Ag/Bi2Se3 composite film with various laser powers is presented in Fig. 5(d) It can clearly be seen that transmissivity of various laser powers for Ag/Bi2Se3 composite film is a horizontal line, revealing the high stability of the film.

Mechanism of Ag/Bi2Se3 film photothermal conversion is essential to analysis in Fig. 6. Ag/Bi2Se3 composite film exhibits better photothermal conversion performance than Bi2Se3 film. The synergistic effect between the Ag NPs with the Bi2Se3 nanosheets can play an important role in the process of Ag/Bi2Se3 composite film photothermal conversion. The changing of the Ag/Bi2Se3 film steady-state temperature is collected as a function of intensity of the light-source (laser power 0.6, 0.8, 1.0 and 1.2w, respectively), and is shown in Fig. 6(a). The intensity vs temperature increases in a linear manner y(x) = 19.9*x + 22.49, indicating that the photothermal effect in the Ag/Bi2Se3 composite film is intrinsic. This result indicates the photothermal conversion should arise from material itself rather than due to any other factors. The strong absorption of Ag/Bi2Se3 composite film becomes potential candidates for application of photothermal conversion. It has already been demonstrated that a metal-island film can enhance the absorption, which support LSPR that efficiently couple incident light into the waveguide modes39. The guided modes trap the incident light in the active region, enhancing the absorption in a manner analogous to light trapping by surface texturing44.

In this case, the incident photon trapped into the Bi2Se3 film with the help of Ag NPs and enhanced the light absorption. The increasing optical path length and photon coupling process inside the Bi2Se3 in consequence of Ag NPs plasmonic oscillation, which can lead to the intensive absorption of Bi2Se3 in visible region. In addition, Ag NPs existing in Bi2Se3 film cause synergetic effect of multi-scattering induced light trapping, the reflection in interface and the optimal trade-off between light absorption and phonon emission. The process can result in sufficient absorption of incident light. Furthermore, it is worth noting that Ag/Bi2Se3 film will undergo multiple laser absorption, and a great deal of photons generated under the condition of 808 nm laser irradiation due to LSPR effect. Electrons can be motivated into conduction band while holes still retain in the valence band. The above-bandgap electrons and holes relax to the band edges. The behaviour is called thermalization process, which can convert the excess energy into heat (Fig. 6(b))43. The surplus band edge energy is responsible for heat generation and the heat can be absorbed by the vibration of crystal lattice.

In summary, Bi2Se3 can be transferred on different material substrates by LDW technology, and a composite structure Ag/Bi2Se3 nanofilm can also be fabricated. The localized heat induced by laser direct achieve simultaneously material synthesis, transfer and patterning in a single processing step. The thermal reaction process includes the forming of nanoparticles based on the process of the thermal reduction, laser ablation, and sputtering deposition and so on. The photothermal measurement experiments show that the composite film possess excellent heat storage capacity and heat stability. The strong absorption can mainly originate from broad absorption of the Ag/Bi2Se3 layer and the LSPR enhancing of Ag nanoparticles, which can be main factor to result in Ag/Bi2Se3 composite film owning the excellent photothermal conversion properties.

Methods

All chemicals were analytical grade and used without further purification. In a typical synthesis of Bi2Se3 nanosheets, Bi2Se3 nanosheets are prepared by a one-pot microwave-assisted method. In brief, the synthesis process of Bi2Se3 is described as follow, 1.1 mmol Na2SeO3 powder (0.2014g), 4 mmol PVP powers (0.4666 g), 0.8 mmol Bi(NO3)3·5H2O (0.3970 g) and 6.2 mmol NaOH (0.2495 g) are added into ethylene glycol (60 mL), with well-distributed mixing. The mixing solution is heated by the microwave means for 60 min. Then, the solution is cooled down to the room temperature and centrifuged at the speed of 8000 rpm for 30 min, washed three times with deionized water and alcohol, respectively. The powder is collected and dried overnight for further research.

LDW treatment

As-prepared Bi2Se3 powder is dispersed in 50 ml alcohol. A uniform Bi2Se3 thin film can be prepared on the glass substrate by evaporating self-assembling process45. The intrinsic glass substrate has been carefully cleaned in a sonicating bath warm acetone (50 °C) for an hour to remove the organic pollutant. The glass slice with self-assembling Bi2Se3 film is placed face-to-face on the different substrates including silicon, glass, Si/SiO2 and Polyimide (PI) and so on. The laser beam with an output power 1100 mW, a wavelength of 470 nm and light spot diameter 100 μm, is focused on Bi2Se3 films and is scanned at a speed of 1.6 mm/sec. Following laser treatment, the vacant part for Bi2Se3 films is transferring to various substrates.

The preparing process of AgNO3 solution is illustrated as follow. 0.05 mmol AgNO3 (0.01 g) power and 0.2 mmol PVP (0.02 g) are dissolved in 0.5 mL alcohol; the mixture is stirred for 10 min. The mixture deposits onto glass substrate to formation of AgNO3 film by evaporating self-assembling process, which is similar to the preparing of Bi2Se3 thin film. The surface of AgNO3 film closely contact surface of the as-prepared Bi2Se3 film, and the laser beam is focused on the AgNO3 film and move along the path according to the computer designing. Subsequently, patterning of Ag is carefully transferred to Bi2Se3 film, resulting in the formation of Ag/Bi2Se3 composite structure.

Characterization

UV-vis absorption spectrum is obtained using a Perkin Lambda UV-vis-NIR spectrophotometer. The transparency and reflectance are recorded using a UV-via NIR spectrometer with an integrating sphere unit. X-ray diffraction (XRD) is recorded using a Shimadzu XRD-7000 with Cu-Kradiation. The morphology and characterizations of the obtained samples is assessed on a field emission scanning electron microscope (FESEM, FEI Quanta 200 F) and with transmission electron microscopy (TEM, FEI Tecnai G2 S-Twin) with an operating voltage of 300 kV. Electrical conductivity is measured by multimeter. Optical microscope image is recorded on Leica DM500. All optical measurements are performed at room temperature.

The external adjustable power 808 nm NIR laser with a spot size of 0.6 cm2 is used to measure the photothermal conversion performance of nanofilm. The output power is independently calibrated using a handy optical power meter. The in-situ temperature is recorded by an infrared thermometer with accuracy of ±0.1 °C tilted 45°relative to the path of the laser.

References

Volz, S., Shiomi, J., Nomura, M. & Miyazaki, K. Heat conduction in nanostructured materials Journal of Thermal. Sci. Technol. 11, 15–529, https://doi.org/10.1299/jtst.2016jtst0001 (2016).

Juangsa, F. B., Muroya, Y., Ryu, M., Morikawa, J. & Nozaki, T. Comparative study of thermal conductivity in crystalline and amorphous nanocomposite. Appl. Phys. Lett. 110, 253105, https://doi.org/10.1063/1.4986920 (2017).

Sun, Z. B., Xie, H. H. & Tang, S. Y. Ultrasmall Black Phosphorus Quantum Dots: Synthesis and Use as Photothermal Agents. Angew chem int edit 54, 11526–11530, https://doi.org/10.1002/anie.201506154 (2015).

Xing, C., Jing, G. & Liang, X. Graphene oxide/black phosphorus nanoflake aerogels with robust thermo-stability and significantly enhanced photothermal properties in air. Nanoscale. 9, 8096, https://doi.org/10.1039/C7NR00663B (2017).

Zijlstra, P., Chon, J. W. M. & Gu, M. Five-dimensional optical recording mediated by surface plasmons in gold nanorods. Nature. 459, 410–3, https://doi.org/10.1038/nature08053 (2009).

Pustovalov, V. K. Light-to-heat conversion and heating of single nanoparticles, their assemblies, and the surrounding medium under laser pulses. Rsc. Adv. 6, 81266–89, https://doi.org/10.1039/c6ra11130k (2016).

Tao, W., Ji, X. & Xu, X. Inside Cover: Antimonene Quantum Dots: Synthesis and Application as Near‐Infrared Photothermal Agents for Effective Cancer Therapy. Angew Chem Int Ed Engl. 56, 11896, https://doi.org/10.1002/anie.201703657 (2017).

Neumann, O. & Urban, A. S. Solar vapor generation enabled by nanoparticles. Acs Nano. 7, 42–49, https://doi.org/10.1021/nn304948h (2013).

John, S. K., John, D., Bijoy, N., Chathanathodi, R. & Anappara, A. A. Magnesium diboride: An effective light-to-heat conversion material in solid-state. Appl. Phys. Lett. 111, 033901, https://doi.org/10.1063/1.4994154 (2017).

You, C. et al. A strategy for photothermal conversion of polymeric nanoparticles by polyaniline for smart control of targeted drug delivery. Nanotechnol. 28, 165102, https://doi.org/10.1088/1361-6528/aa645f (2017).

Jia, G., Zhang, Y. & Wang, P. Nano-photo-thermal energy drives MoS2/ZnO nanoheterojunctions growing. Opt. Mater. Express. 6, 876–83, https://doi.org/10.1364/OME.6.000876 (2016).

Jia, G. Z. et al. Excellent photothermal conversion of core/shell CdSe/Bi2Se3 quantum dots. Nano Res. 8, 1443–53, https://doi.org/10.1007/s12274-014-0629-2 (2015).

Liu, C. et al. Topological insulator Bi2Se3 nanowire/Si heterostructure photodetectors with ultrahigh responsivity and broadband response. J. Mater. Chem. C. 4, 5648–55, https://doi.org/10.1039/c6tc01083k (2016).

Cao, Y. et al. Mapping the orbital wavefunction of the surface states in three-dimensional topological insulators. Nat. Phys. 9, 499–504, https://doi.org/10.1038/NPHYS2685 (2013).

Xie, H., Li, Z. & Sun, Z. Metabolizable Ultrathin Bi2Se3 Nanosheets in Imaging-Guided Photothermal Therapy. Small. 12, 4136–4145, https://doi.org/10.1002/smll.201601050 (2016).

Xie, H. et al. Near-infrared optical performances of two Bi2Se3 nanosheets. Rsc Advances 7, 50234–50238, https://doi.org/10.1039/C7RA09872C (2017).

Liu, M. et al. Dual-Wavelength Harmonically Mode-Locked Fiber Laser With Topological Insulator Saturable Absorbe. IEEE Photonic tech l. 26, 983–986, https://doi.org/10.1109/LPT.2014.2311101 (2014).

Pesin, D. & MacDonald, A. H. Spintronics and pseudospintronics in graphene and topological insulators. Nat mater. 11, 409–416, https://doi.org/10.1038/nmat3305 (2012).

Wang, Z. T. et al. Switchable Dual-Wavelength Synchronously Q-Switched Erbium-Doped Fiber Laser Based on Graphene Saturable Absorber. IEEE Photonics J 4, 869–876, https://doi.org/10.1109/JPHOT.2012.2199102 (2012).

Ying, Y., Yang, Y. & Ying, W. Two-dimensional materials for novel liquid separation membranes. Nanotech. 27, 332001, https://doi.org/10.1088/0957-4484/27/33/332001 (2016).

Pathak, T. K., Swart, H. C. & Kroon, R. E. Structural and plasmonic properties of noble metal doped ZnO nanomaterials. Physica B. 535, 114–8, https://doi.org/10.1016/j.physb.2017.06.074 (2018).

McFarland, A. D. & Van Duyne, R. P. Single silver nanoparticles as real-time optical sensors with zeptomole sensitivity. Nano Lett. 3, 1057–62, https://doi.org/10.1021/nl034372s (2003).

Shi, J. et al. A tumor-targeting near-infrared laser-triggered drug delivery system based on GO@Ag nanoparticles for chemo-photothermal therapy and X-ray imaging. Biomater. 35, 5847–61, https://doi.org/10.1016/j.biomaterials.2014.03.042 (2014).

Sakr, G. B., Yahia, I. S., El-Komy, G. M. & Salem, A. M. Optical properties of thermally evaporated Bi2Se3 thin films treated with AgNO3 solution. Surf. Coat. Technol. 205, 3553–8, https://doi.org/10.1016/j.surfcoat.2010.12.013 (2011).

Yang, J. Y., Chen, R. G., Fan, X. A., Bao, S. Q. & Zhu, W. Thermoelectric properties of silver-doped n-type Bi2Te3-based material prepared by mechanical alloying and subsequent hot pressing. J. Alloys Compd. 407, 330–3, https://doi.org/10.1016/j.jallcom.2005.06.041 (2006).

Zacharatos, F., Karvounis, P. & Theodorakos, I. Single Step Laser Transfer and Laser Curing of Ag NanoWires: A Digital Process for the Fabrication of Flexible and Transparent, Microelectrodesm. Mater. 11, 1036, https://doi.org/10.3390/ma11061036 (2018).

Rigoni, F. et al. Transfer of CVD-grown graphene for room temperature gas sensors. Nanotechnol. 28, 414001, https://doi.org/10.1088/1361-6528/aa8611 (2017).

Oh, J.-S. et al. Laser-Assisted Simultaneous Patterning and Transferring of Graphene. J. Phys. Chem. C. 117, 663–8, https://doi.org/10.1021/jp309382w (2013).

In, J. B., Lee, D., Fornasiero, F., Noy, A. & Grigoropoulos, C. P. Laser-Assisted Simultaneous Transfer and Patterning of Vertically Aligned Carbon Nanotube Arrays on Polymer Substrates for Flexible Devices. Acs Nano. 6, 7858–66, https://doi.org/10.1021/nn302192y (2012).

Zhang, Y. et al. Size effect on near infrared photothermal conversion properties of liquid-exfoliated MoS2 and MoSe2. Superlattices Microstruct 105, 22–7, https://doi.org/10.1016/j.spmi.2016.11.058 (2017).

Zhou, K.-G., Mao, N.-N., Wang, H.-X., Peng, Y. & Zhang, H.-L. A Mixed-Solvent Strategy for Efficient Exfoliation of Inorganic Graphene, Analogues Angew. Chem.-Int. Edit. 50, 10839–42, https://doi.org/10.1002/anie.201105364, (2011).

Stewart, J. S., Lippert, T., Nagel, M., Nuesch, F. & Wokaun, A. Red-green-blue polymer light-emitting diode pixels printed by optimized laser-induced forward transfer. Appl. Phys. Lett. 100, 203303, https://doi.org/10.1063/1.4717463 (2012).

Li, G. et al. Preparation and photoelectrochemical performance of Ag/graphene/TiO2 composite film. Appl. Surf. Sci. 257, 6568–72, https://doi.org/10.1016/j.apsusc.2011.02.078 (2011).

Liu, B. S. et al. Photocatalytic mechanism of TiO2-CeO2 films prepared by magnetron sputtering under UV and visible light. Surf. Sci. 595, 203–11, https://doi.org/10.1016/j.susc.2005.08.016 (2005).

Vargas, A. et al. The Changing Colors of a Quantum-Confined Topological Insulator. Acs Nano. 8, 1222–30, https://doi.org/10.1021/nn404013d (2014).

Ko, S., Banerjee, C. K. & Sankar, J. Photochemical synthesis and photocatalytic activity in simulated solar light of nanosized Ag doped TiO2 nanoparticle compositeComposites. Part B. 42, 579–83, https://doi.org/10.1016/j.compositesb.2010.09.007 (2011).

Yu, B., Leung, K. M., Guo, Q., Lau, W. M. & Yang, J. Synthesis of Ag-TiO2 composite nano thin film for antimicrobial application. Nanotechnol. 22, 115603, https://doi.org/10.1088/0957-4484/22/11/115603 (2011).

Ganguly, A., Mondal, A., Dhar, J. C., Singh, N. K. & Choudhury, S. Enhanced visible light absorption by TiO2 film patterned with Ag nanoparticles arrays. Physica E. 54, 326–30, https://doi.org/10.1016/j.physe.2013.07.019 (2013).

Sahu, D. R., Lin, S.-Y. & Huang, J.-L. ZnO/Ag/ZnO multilayer films for the application of a very low resistance transparent electrode. Appl Surf Sci. 252, 7509–14, https://doi.org/10.1016/j.apsusc.2005.09.021 (2006).

Wang, J. & Shi, D. Spectral selective and photothermal nano structured thin films for energy efficient windows. Applied Energy. 208, 83–96, https://doi.org/10.1016/j.apenergy.2017.10.066 (2017).

Kulczyk-Malecka, J. et al. Investigation of silver diffusion in TiO2/Ag/TiO2 coatings. Acta Mater. 66, 396–404, https://doi.org/10.1016/j.actamat.2013.11.030 (2014).

Ando, E. & Miyazaki, M. Durability of doped zinc oxide/silver/doped zinc oxide low emissivity coatings in humid environment. Thin Solid Films. 516, 4574–7, https://doi.org/10.1016/j.tsf.2007.06.028 (2008).

Wang, J. et al. High-Performance Photothermal Conversion of Narrow-Bandgap Ti2O3 Nanoparticles. Adv. Mater. 29, 1603730, https://doi.org/10.1002/adma.201603730 (2017).

Jeong, S. et al. Hybrid Silicon Nanocone-Polymer Solar Cells. Nano Lett. 12, 2971–6, https://doi.org/10.1021/nl300713x (2012).

Jia, G., Wu, Z., Wang, P., Yao, J. & Chang, K. Morphological evolution of self-deposition Bi2Se3 nanosheets by oxygen plasma treatment. Sci. Rep. 6, 22191, https://doi.org/10.1038/srep22191 (2016).

Acknowledgements

This work has been partly supported by National Natural Science Foundation of China grant (11674240, 11504261).

Author information

Authors and Affiliations

Contributions

Jia Guozhi and Zhao Zejia wrote the main manuscript text, experimental work, and data analysis. Zhang Qiurui and Zhou Yaoyao experimental work. Liu Yanling data analysis. Jia Guozhi project planning, data analysis.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, Z., Jia, G., Liu, Y. et al. In-situ synthesized and pattern Ag/Bi2Se3 composite structure by LDW and photothermal conversion. Sci Rep 9, 1781 (2019). https://doi.org/10.1038/s41598-019-38496-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-38496-9

This article is cited by

-

Growth kinetics and photothermal conversion of Cu2O–Ag nanocomposites

Applied Physics A (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.