Abstract

Tungsten Disulfide (WS2) is considered to be a promising Hydrogen Evolution Reaction (HER) catalyst to replace noble metals (such as Pt and Pd). However, progress in WS2 research has been impeded by the inertness of the in-plane atoms during HER. Although it is known that microstructure and defects strongly affect the electrocatalytic performance of catalysts, the understanding of such related catalytic origin still remains a challenge. Here, we combined a one-pot synthesis method with wet chemical etching to realize controlled cobalt doping and tunable morphology in WS2. The etched products, which composed of porous WS2, CoS2 and a spot of WOx, show a low overpotential and small Tafel slope in 0.5 M H2SO4 solution. The overpotential could be optimized to −134 mV (at 10 mA/cm2) with a Tafel slope of 76 mV/dec at high loadings (5.1 mg/cm2). Under N2 adsorption analysis, the treated WS2 sample shows an increase in macropore (>50 nm) distributions, which may explain the increase inefficiency of HER activity. We applied electron holography to analyze the catalytic origin and found a low surface electrostatic potential in Co-doped region. This work may provide further understanding of the HER mechanism at the nanometer scale, and open up new avenues for designing catalysts based on other transition metal dichalcogenides for highly efficient HER.

Similar content being viewed by others

Introduction

Hydrogen has been considered as a promising clean energy source to remedy the shortage of fossil fuel supply and pollution problems. As such, emerging non-noble catalysts for water splitting are in urgent need. Tungsten Disulfide (WS2), one of the two-dimensional transition metal dichalcogenides (TMDCs), has attracted much attention in the catalysis field due to the presence of active sites located along the edges1,2,3,4, and is expected to replace rare and expensive noble metal catalysts. However, apart from the edges, the majority of the basal surfaces are catalytically inert, which is the main limitation of bare TMDCs compared with noble metal catalysts. The design of the microstructures of such catalyst microstructures thus becomes important, the key directions being the exploration of the influence of pore size distributions, and even electrostatic potential distribution at the surface. There are several approaches reported to overcome the above-mentioned limitation and to enhance the catalytic performance of TMDCs. First, heteroatom doping can significantly modulate the catalytic activity of in-plane TMDC atoms; Deng et al. has systematically reported correlations between dopants and the catalytic activity of in-plane atoms of 2D MoS25. Second, multiscale structures may help to promote the liquid-to-gas electrochemical conversion at the interface of catalysts. These mesoporous foams6, arrays7,8, nanodots9,10, and other nanostructures11,12,13 are commonly employed in catalytic researches. Especially for TMDCs, mesopores help to increase the number of edges, thus increasing the number of active sites. Third, high-conducting carbon-based materials including carbon nanotubes14,15, graphene16,17,18 and carbon cloth19,20 have been mixed with WS2 to improve its electrochemical properties. In addition, WS2 or MoS2 in the metallic 1T phase contains a higher density of exposed active sites, better conductivity and catalytic performance21,22, which can be obtained by chemical exfoliation from sample in the semiconducting 2H phase23. However, clear understanding of the effect of microstructure design on catalytic performance is still limited.

Herein, we combined pore size distribution analysis and electron holography for the first time to solve the above issue. A specific catalyst composed of Cobalt-doped and surface-etched WS2 was synthesized, showing efficient HER activity. We expect that Cobalt-doping will activate the inert in-plane atoms of WS2. Cobalt (Co) is demonstrated to be a good candidate to tune the free energy of hydrogen adsorption of WS2 and some other catalyst candidates19,24. Etching by H2O2 treatment with ultrasonication was applied to modify the morphology of WS225, and also remove the redundant self-nucleated CoS2. The optimized sample displayed efficient HER performance, with an overpotential of −134 mV with a small Tafel slope of 76 mV/dec at a current density of 10 mA/cm2. The dependence of HER performance on sample microstructures was discussed; the nitrogen absorption test showed a better activity along with increasing macropore (>50 nm) distributions. An electron hologram has been taken to study the surface electrostatic potential, especially in Co-doped regions, bringing a new viewpoint into HER activity.

Experimental

Materials

All chemicals used in this work are of analytical grade and applied as received without further purification. Tungsten hexachloride (WCl6, 99.9%), thioacetamide (TAA, 99%), N-methylpyrrolidone (NMP, 99%) and Nafion solution (5%) were purchased from Sigma-Aldrich. Cobalt nitrate hexahydrate (Co(NO3)2·6H2O, 98.5%), and sulfuric acid (H2SO4, 98%) were supplied from Sinopharm Chemical Reagent Co. Ltd. Hydrogen peroxide (H2O2, 30%) was purchased from Nanjing Chemical Reagent Co. Ltd.

Synthesis

In a typical synthesis of Co-doped WS2 (Co-WS2), WCl6 (0.8923 g), Co(NO3)2·6H2O (0.6341 g) and TAA (1.6904 g) were slowly added to deionized (DI) water (30 mL) and stirred at room temperature for 1 h. The solution was then transferred to a polyphenylene (PPL) reaction kettle and maintained at 265 °C for 24 h. The products were cooled to room temperature, centrifuged, washed several times with DI water and ethyl alcohol, and dried at 60 °C. WS2 was synthesized without Co(NO3)2·6H2O as a control.

For the preparation of H2O2-treated Co-WS2, 100 mg of Co-WS2 sample was dispersed in 20 mL of NMP with 2.5 vol% of H2O2 and then sonicated for 2 h. The products were centrifuged at 8000 rpm, washed several times, and dried at 60 °C. For comparation, Co-WS2 treated by H2O2 of different concentrations were prepared.

The products were annealed at 450 °C for 4 h under an Ar atmosphere before HER tests. We also studied the influence of different annealing conditions and passivation by 4-nitrobenzene-diazonium (4-NBD) on HER capability and stability, which can be seen in Supplementary Material (Fig. S1).

Characterization

Field emission scanning electron microscopy (FE-SEM; JSM-7000F) was used to investigate the morphology of the samples. Transmission electron microscopy (TEM) and electron holography observations were obtained using a JEOL model JEM2100 instrument at an accelerating voltage of 200 kV. Energy dispersive spectrometer (EDS; inca x-stream 034A0) was used to confirm the stoichiometry of samples. The crystal phase properties of the samples were analyzed with a Bruker D8 Advance X-ray diffractometer (XRD) using Ni-filtered Cu Kα radiation at 40 kV and 40 mA at 2θ ranging from 10° to 70° with a scan rate of 0.02° per second. Raman spectra were obtained on a Raman spectrometer (LabRam HR800) excited by the 514.5 nm line of an Ar+ laser under 5 mW. X-ray photoelectron spectroscopy (XPS) analysis (PHI5000 Versaprobe) was used to determine the chemical composition of the products. Brunauer-Emmett-Teller (BET) specific surface area tests were carried out on a Thermo Fisher Surfer at 200 °C.

Electrochemical Measurements

A typical three-electrode set-up was utilized for electrochemical measurement with CHI760D potentiostat (CH Instruments, China). All measurements of the HER activity were conducted using a 0.5 M H2SO4 (pH = 0.3) electrolyte after continuous purging with N2 gas. A glassy carbon electrode (GCE) with a diameter of 3 mm covered by a thin catalyst film was used as the working electrode. Typically, 6 mg catalyst was suspended in 1 ml water-ethanol mixed solution (volume ratio of 4:1) containing 20 μl Nafion solution to form a homogeneous ink assisted by ultrasonication. Then 20 ml of the ink was dropped onto the surface of glassy carbon by a micropipette and dried under room temperature. Saturated calomel electrode (SCE) and graphite rod (Pt anodes may dissolve in the electrolyte and contaminate the cathode) were used as reference electrode and counter electrode respectively. The electrocatalytic activities were examined by polarization curves using linear sweep voltammetry (LSV) at a scan rate of 5 mV/s with IR compensation, at room temperature. Before measurements, the samples were repeatedly swept from −0.5 to 0 V (versus SCE) in the electrolyte until a steady voltammogram curve was obtained. Potentials were referenced to a reversible hydrogen electrode (RHE) by adding a value of 0.262 V (0.244 + 0.0591 × pH).

Results and Discussions

The morphology and chemical composition of as-synthesized Co-WS2 are shown in Fig. 1. The XRD pattern in Fig. 1a shows the differences between Co-doped WS2 and pure CoS2. The diffraction peaks of both pure CoS2 and Co-doped WS2 correspond to CoS2 (JCPDS card no. 41–1471). However, the doped Co has a stronger (111) diffraction (27.9°), while pure CoS2 has stronger (200) and (311) diffractions, corresponding to peaks at 32.3° and 54.9° respectively. There are two peaks at 14.4° and 33.6°, assigned to diffractions of the (002) and (101) planes of WS2 (JCPDS card no. 08-0237) respectively. It is worth mentioning that the Co-doping also oxidizes WS2, with observed diffraction peaks at around 25°26. Though the mechanism of oxidation is still under investigation, tungsten oxides (WOx) have higher electrical conductivities than the metallic phase 1T-WS2, and may bring additional benefits to HER27,28,29. The typical three-dimensional nanosheet structures of WS2 can be observed in SEM (Fig. 1b), while massive self-nucleated CoS2 also exists (Fig. S2). EDS mapping (Fig. 1c) indicates a homogeneous distribution of Co element, instead of dissociative CoS2 shown in Fig. S2. Figure 1d shows a HRTEM image of Co-WS2, detailing the crystal structure of the product. The lattice plane (002) of WS2 with a spacing distance of about 6.2 Å can be observed, as well as the lattice plane (100) of WS2 with a shorter spacing distance of 2.7 Å. Another plane of middle spacing distance of 3.3 Å can be also found, which corresponds to the lattice plane (111) of CoS2, which corroborates with the XRD results.

After etching of WS2 by H2O2, the intensity of CoS2 peaks decreased (Fig. 2a), corresponding to the notable decrease of Co content found in EDS mapping (Fig. 2c). However, the (002) diffraction peak of WS2 became broader, which is caused by poor crystallinity. The Co-WS2 samples became smaller after H2O2 etching and ultrasonication, while pieces of WS2 were still observed as displayed in Fig. 2b. Such a porous nanosheet structure is propitious for HER. Raman spectroscopy was conducted for WS2, Co-WS2 and H2O2 treated Co-WS2. As shown in Fig. 2d, the peaks observed at 353 cm−1 and 418 cm−1 correspond to the \({{\rm{E}}}_{2{\rm{g}}}^{1}\) and \({{\rm{A}}}_{1{\rm{g}}}\) modes of WS2, respectively. \({{\rm{E}}}_{2{\rm{g}}}^{1}\) is an in-plane optical mode, while \({{\rm{A}}}_{1{\rm{g}}}\) corresponds to out-of plane vibrations of the sulfur atoms30,31. However, both the two bands of Co-WS2 and H2O2 treated Co-WS2 show an obvious shift to 330 cm−1 and 404 cm−1 respectively, as compared to pure WS2. This change of red shift should be ascribed to the influence of small amounts of doping to the host materials32.

X-ray photoelectron spectroscopy (XPS) spectra are shown in Fig. 3 to confirm the elemental composition of the products. Figure 3a shows the typical survey spectrum of WS2, Co-doped WS2 and H2O2 treated Co-WS2. Here, the presence of C 1s, W 4f, S 2p, and O 1 s regions may be observed in both samples. Specifically, Co 2p regions can be seen in Co-doped samples. In Fig. 3b, compared to bare WS2, two peaks of 4f-level W atoms shift to higher binding energy, which is probably caused by Co-doping. It is found that the W-O bond at 36.5 eV shows a relative increase in Co-doping samples, demonstrating oxidation along with Co-doping. Meanwhile, the conversion of W valence state from +4 (WS2) to +6 (WO3) could also result in the increase of binding energy26. In Fig. 3c, the S 2p3/2 and 2p1/2 peaks at 162.6 and 163.8 eV suggest the −2 valence state for S. Co-doping leads to the formation of S-O bond, shown as the peak at around 169 eV. This decreases the binding energy for S 2p bonds. Two peaks shown in Fig. 3d at binding energy of 780.6 and 798.0 eV corresponding to Co 2p3/2 and 2p1/2, are almost consistent with the results reported for CoS233.

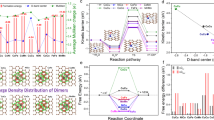

We tested the electrocatalytic HER performance using a simple three-electrode set-up in 0.5 M H2SO4 solution. Figure 4a shows the polarization curves measured by Linear-sweep voltammetry (LSV) at a scan rate 0.5 mV/s. Bare WS2 and bare CoS2 both showed poor HER performances, and CoS2 even showed a reduction peak during cathodic polarization that disappeared after hundreds of scans. The Co-doped WS2 sample showed a good HER performance with an overpotential of −255 mV at the current density of −10 mA/cm2. The influence of Co-doping with different amounts has been discussed, as shown in Fig. S3. Considering the self-nucleation of CoS2 at the surface of WS2, we have tried another method to realize Co-doping. The results are still under study, as displayed in Fig. S4.

The H2O2 treated Co-WS2 reached a much smaller overpotential of −160 mV at −10 mA/cm2, showing a better HER performance that approaches that of the commercial 20% Pt/C catalyst (−21 mV @ −10 mA/cm2). By fitting linear regions of the LSV plots to the Tafel equation η = a + b log j, where j is the current density and b is the Tafel slope34, the corresponding Tafel plots of each sample were shown in Fig. 4b. Tafel slopes of 20% Pt/C, H2O2-treated Co-WS2, Co-WS2, bare CoS2 and bare WS2 were extracted as 32, 76, 79, 60, and 150 mV/dec, respectively. The Co-doped WS2 samples showed smaller Tafel slopes than that of WS2, indicating a faster gain of HER velocity with increasing potential. Also, even though the HER activity of CoS2 is relatively low, the Tafel slope is similar to that of a Pt/C catalyst, which may reflect the effect of Co doping. Electrochemical impedance spectroscopy (EIS) was used to investigate the electrode kinetics under the HER test conditions, confirming the facile kinetics of H2O2-treated Co-WS2 toward HER (Fig. S5).

We then investigated the HER performance of the best sample (H2O2 treated Co-WS2) under different loadings, as shown in Fig. 4c. It was found that the catalytic performance got even better with heavier loading, and the overpotential could reach −134 mV when the loading on GCE was 5.1 mg/cm2. However, when the loading was further increased (by increasing the concentration of dispersion ink or enhancing the dropped amount on GCE), the dry film of catalyst on GCE became fragile and fell off easily, causing poor electrical conductivity and HER stability. Durability measurement of H2O2-treated Co-WS2 was carried out with a small loading of 0.85 mg/cm2 (Fig. S6).

Characterizations indicated that the Co-doping caused oxidation in the final products. Compared to bare WS2, Co-doped WS2 consists of W, Co, S, and O elements. We applied H2O2 in order to etch the surface of WS2, but also caused a massive loss of Co. Considering the better HER performance of H2O2 treated Co-WS2, we speculate that appropriate H2O2 etching could remove redundant self-nucleated CoS2 covering or mixed with WS2, which possesses poor HER activity. The remaining Co content plays a role in tuning the free energy of hydrogen adsorption of WS2 atoms, especially inert in-plane atoms. The above-mentioned lead to a highly efficient HER performance, manifested as good electrical conductivities of tungsten oxide (WOx).

In order to quantitatively analyze the dependence of HER performance on sample microstructures, we carried out independent N2 adsorption measurements based on Brunauer-Emmett-Teller (BET) models on these powder samples. The BET surface area and HER overpotential (at 10 mA/cm2) of each sample were compared in Fig. 5a. Based on our understanding, bigger surface areas of catalyst should be associated with more active sites. Especially for WS2, the mesopores may increase the number of edges as the active sites and increase the accessibility of the catalyst surface. That is the reason why we chose H2O2 to etch WS2 into ultrathin and porous nanosheets. The BET measurement confirmed the influences of etching on WS2, and the surface area of WS2 was enhanced from 82.9 to 99.0 m2/g. The BET surface area of Co-doped WS2 is slightly smaller than that of WS2, due to the Co-doping into the interspace of WS2 and the self-nucleation of CoS2. However, the relation between HER performance and surface area of WS2 samples is unexpected. The higher surface area of H2O2-treated WS2 led to a worse HER performance than that of bare WS2, and the lowest surface area of H2O2-treated Co-WS2 corresponds to the best HER efficiency. For better understanding, pore size distributions were calculated from adsorption branches of isotherms by the Barrett-Joyner-Halenda (BJH) method, as shown in Fig. 5b. The detailed pore size distributions suggest that serial WS2 samples contain a mixture of macropores (>50 nm), mesopores (2–50 nm), and a small amount of micropores (<2 nm). Compared to bare WS2, the H2O2 etching caused an increase in mesopore distribution ranging from 10 to 50 nm, as well as micropores of 0.8 nm and macropores of 90 nm. The increased mesopores caused a larger BET surface area, but had no impact on the HER. The Co-doped WS2 also possesses a broad mesopore distribution, which is probably contributed by CoS2. The subsequent H2O2 treatment resulted in macropore distributions at 50 nm and 73 nm. The influence of H2O2 concentrations is discussed in supplementary materials (Fig. S7). Considering the above results, we speculate that both Co doping and H2O2 etching almost could not influence the pore (<10 nm) distribution of WS2. Thus the macropores etched by H2O2 associated with Co-doping may account for the enhanced HER performance.

To understand the effect of doped Co content in the improvement of HER activity of WS2, electron holographic imaging has been taken to study the inner electrostatic potential of our samples. The amount of phase shift can provide a direct measure of the variation in electrostatic potential at the surface of nonmagnetic specimens with uniform thickness35,36. We selected a thin specimen containing CoS2 and WS2, as shown in Fig. 6(a). The corresponding hologram was taken using a transmission electron microscope equipped with an electron biprism and processed by two dimensional Fourier transformation to obtain the side-bands. The phase was reconstructed from the side-bands by inverse Fourier transformation, shown in Fig. 6(b). Figure 6(c) displayed the potential step along the dashed box in Fig. 6(b), showing a lower inner electrostatic potential in Co-doped regions of the sample.The Gibbs free energy of WS2 or MoS2 is too strong, leading to the poisoning of the active sites, especially in inner planes. Electronic states of in plane atoms would be significantly modulated by Co doping, thus leading to a moderate hydrogen adsorption free energy with a Gibbs free energy close to 0 for highly efficient HER6,37. The hologram may explain the modulation of electronic states. This is the first use of electrostatic potential measured by hologram to distinguish the activity in a single region of catalysts. DFT calculation is needed for further insights.

Conclusions

In summary, we studied the influence of microstructure on high-performance Co-doped WS2-based HER catalyst. H2O2 etching was used to remove redundant self-nucleated CoS2 and modify the surface morphology of WS2, thus creating macropores. Various characterization results indicated that the products were composed of WS2, CoS2 and a spot of WOx, showing a low HER overpotential of −134 mV (10 mA/cm2 at a loading of 5.1 mg/cm2), with a small Tafel slope of 76 mV/dec. Co-doping associated with H2O2 resulted in an increasing macropore (>50 nm) distributions, which may account for the enhanced HER performance. For the first time, we used electron holographic analysis to study the electrostatic potential in Co-doped region. Further work is required, such as carbon material hybridization and DFT calculation, and we believe our study could bring in better understanding of promising catalysts design to replace noble metal for hydrogen production.

References

Jaramillo, T. F. et al. Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts. Science 317, 100–102 (2007).

Lukowski, M. A. et al. Highly active hydrogen evolution catalysis from metallic WS2 nanosheets. Energy Environ. Sci. 7, 2608–2613 (2014).

Gholamvand, Z., McAteer, D., Harvey, A., Backes, C. & Coleman, J. N. Electrochemical applications of two-dimensional nanosheets: The effect of nanosheet length and thickness. Chem. Mater. 28, 2641–2651 (2016).

Yin, Y. et al. Contributions of phase, sulfur vacancies, and edges to the hydrogen evolution reaction catalytic activity of porous molybdenum disulfide nanosheets. J. Am. Chem. Soc. 138, 7965–7972 (2016).

Deng, J. et al. Triggering the electrocatalytic hydrogen evolution activity of the inert two-dimensional MoS2 surface via single-atom metal doping. Energy Environ. Sci. 8, 1594–1601 (2015).

Deng, J. et al. Multiscale structural and electronic control of molybdenum disulfide foam for highly efficient hydrogen production. Nat. Commun. 8, 14430 (2017).

Peng, S. et al. Engineering Co9S8/WS2 array films as bifunctional electrocatalysts for efficient water splitting. J. Mater. Chem. A 5, 23361–23368 (2017).

Yang, H., Zhang, Y., Hu, F. & Wang, Q. Urchin-like CoP nanocrystals as hydrogen evolution reaction and oxygen reduction reaction dual-electrocatalyst with superior stability. Nano Lett. 15, 7616–7620 (2015).

Tan, C. et al. Preparation of High-Percentage 1T-Phase Transition Metal Dichalcogenide Nanodots for Electrochemical Hydrogen Evolution. Adv. Mater. 30, 1705509 (2018).

Xu, S., Li, D. & Wu, P. One-pot, facile, and versatile synthesis of monolayer MoS2/WS2 quantum dots as bioimaging probes and efficient electrocatalysts for hydrogen evolution reaction. Adv. Funct. Mater. 25, 1127–1136 (2015).

Xie, J. et al. Intralayered Ostwald Ripening to Ultrathin Nanomesh Catalyst with Robust Oxygen-Evolving Performance. Adv. Mater. 29, 1604765 (2017).

Li, H. et al. Atomic-Sized Pores Enhanced Electrocatalysis of TaS2 Nanosheets for Hydrogen Evolution. Adv. Mater. 28, 8945–8949 (2016).

Wu, A. et al. Hierarchical MoS2@ MoP core–shell heterojunction electrocatalysts for efficient hydrogen evolution reaction over a broad pH range. Nanoscale 8, 11052–11059 (2016).

Yu, S. et al. Rational design of efficient electrocatalysts for hydrogen evolution reaction: single layers of WS2 nanoplates anchored to hollow nitrogen-doped carbon nanofibers. ACS Appl. Mater. Inter. 7, 28116–28121 (2015).

He, Q. et al. In situ growth of metallic 1T-WS2 nanoislands on single-walled carbon nanotube films for improved electrochemical performance. RSC Adv. 6, 87919–87925 (2016).

Yang, J. et al. Two-dimensional hybrid nanosheets of tungsten disulfide and reduced graphene oxide as catalysts for enhanced hydrogen evolution. Angew. Chem. Int. Ed. 52, 13751–13754 (2013).

Luxa, J., Fawdon, J., Sofer, Z., Mazánek, V. & Pumera, M. MoS2/WS2-Graphene Composites through Thermal Decomposition of Tetrathiomolybdate/Tetrathiotungstate for Proton/Oxygen Electroreduction. Chemphyschem 17, 2890–2896 (2016).

He, H.-Y. One-step assembly of 2H-1T MoS2: Cu/reduced graphene oxide nanosheets for highly efficient hydrogen evolution. Sci. Rep. 7, 45608 (2017).

Zhou, X. et al. Symmetric synergy of hybrid CoS2–WS2 electrocatalysts for the hydrogen evolution reaction. J. Mater. Chem. A 5, 15552–15558 (2017).

Shifa, T. A. et al. Efficient Catalysis of Hydrogen Evolution Reaction from WS2(1−x)P2x Nanoribbons. Small 13 (2017).

Geng, X. et al. Pure and stable metallic phase molybdenum disulfide nanosheets for hydrogen evolution reaction. Nat. Commun. 7, 10672 (2016).

Li, H. et al. Amorphous nickel-cobalt complexes hybridized with 1T-phase molybdenum disulfide via hydrazine-induced phase transformation for water splitting. Nat. Commun. 8, 15377 (2017).

Leong, S. X. et al. 2H → 1T Phase Change in Direct Synthesis of WS2 Nanosheets via Solution-Based Electrochemical Exfoliation and Their Catalytic Properties. ACS Appl. Mater. Inter. 9, 26350–26356 (2017).

Wang, D.-Y. et al. Highly active and stable hybrid catalyst of cobalt-doped FeS2 nanosheets–carbon nanotubes for hydrogen evolution reaction. J. Am. Chem. Soc. 137, 1587–1592 (2015).

Lei, Z., Xu, S. & Wu, P. Ultra-thin and porous MoSe2 nanosheets: facile preparation and enhanced electrocatalytic activity towards the hydrogen evolution reaction. Phys. Chem. Chem. Phys. 18, 70–74 (2016).

Wang, X. et al. Noble-Metal-Free Hybrid Membranes for Highly Efficient Hydrogen Evolution. Adv. Mater. 29 (2017).

Liu, F. et al. A catalyzed-growth route to directly form micropatterned WO2 and WO3 nanowire arrays with excellent field emission behaviors at low temperature. Cryst. Growth Des. 10, 5193–5199 (2010).

Zheng, T. et al. Conductive Tungsten Oxide Nanosheets for Highly Efficient Hydrogen Evolution. Nano Lett. 17, 7968–7973 (2017).

Chen, J. et al. WO3–x Nanoplates Grown on Carbon Nanofibers for an Efficient Electrocatalytic Hydrogen Evolution Reaction. ACS Appl. Mater. Inter. 8, 18132–18139 (2016).

Morrish, R., Haak, T. & Wolden, C. A. Low-temperature synthesis of n-type WS2 thin films via H2S plasma sulfurization of WO3. Chem. Mater. 26, 3986–3992 (2014).

Huo, N. et al. Novel and Enhanced Optoelectronic Performances of Multilayer MoS2-WS2 Heterostructure Transistors. Adv. Funct. Mater. 24, 7025–7031, https://doi.org/10.1002/adfm.201401504 (2014).

Shifa, T. A. et al. Engineering the Electronic Structure of 2D WS2 Nanosheets Using Co Incorporation as CoxW(1-x)S2 for Conspicuously Enhanced Hydrogen Generation. Small 12, 3802–3809, https://doi.org/10.1002/smll.201601168 (2016).

Zhang, J. et al. Copper dopants improved the hydrogen evolution activity of earth-abundant cobalt pyrite catalysts by activating the electrocatalytically inert sulfur sites. J. Mater. Chem. A 5, 17601–17608, https://doi.org/10.1039/c7ta05433e (2017).

Li, Y. et al. MoS2 Nanoparticles Grown on Graphene: An Advanced Catalyst for the Hydrogen Evolution Reaction. J. Am. Chem. Soc. 133, 7296–7299, https://doi.org/10.1021/ja201269b (2011).

Drisko, G. L. et al. Air-Stable Anisotropic Monocrystalline Nickel Nanowires Characterized Using Electron Holography. Nano Lett., https://doi.org/10.1021/acs.nanolett.7b04791 (2018).

Li, L., Hu, X. & Gao, Y. Electron Holographic Study of Semiconductor Light-Emitting Diodes. Small 14, https://doi.org/10.1002/smll.201701996 (2018).

Cao, Y. et al. Atomic-Level Insight into Optimizing the Hydrogen Evolution Pathway over a Co-1-N-4 Single-Site Photocatalyst. Angew. Chem. Int. Ed. 56, 12191–12196, https://doi.org/10.1002/anie.201706467 (2017).

Acknowledgements

This work was financially supported by the National Basic Research Program of China (2018YFA0209100), the National Science Foundations of China (61205057 and 11574136).

Author information

Authors and Affiliations

Contributions

The experiments and characterizations were carried out by L.Y.Z. with the assistence of H.Z.S. and H.W. under the guidance of S.C.Y. and Y.S. L.Y.Z. and S.C.Y. wrote the manuscript and prepared all figures. Y.S. and S.C.Y. supervised and coordinated all the work.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, L., Yan, S., Song, H. et al. Multivariate Control of Effective Cobalt Doping in Tungsten Disulfide for Highly Efficient Hydrogen Evolution Reaction. Sci Rep 9, 1357 (2019). https://doi.org/10.1038/s41598-018-37598-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-37598-0

This article is cited by

-

Molybdenum Disulfide Nanosheets Decorated with Platinum Nanoparticle as a High Active Electrocatalyst in Hydrogen Evolution Reaction

Nanoscale Research Letters (2022)

-

Field controllable electronic properties of MnPSe3/WS2 heterojunction for photocatalysis

Journal of Central South University (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.