Abstract

The grain boundaries in superconducting MgB2 are known to form effective magnetic flux pinning sites and, consequently, bulk MgB2 containing a fine-grain microstructure fabricated from nanoscale Mg and B precursor powders exhibits good magnetic field-trapping performance below 20 K. We report here that the trapped field of MgB2 bulk superconductors fabricated by an infiltration and growth process to yield a dense, pore-free microstructure, can be enhanced significantly by carbon-doping, which increases intra-band scattering within the superconducting grains. A maximum trapped field of 4.15 T has been measured at 7.5 K at the centre of a five-sample stack of Mg(B1−xiCxi)2 bulk superconductors processed by infiltration and growth, which not only represents a ~40% increase in trapped field observed compared to undoped bulk MgB2, but also is the highest trapped field reported to date in MgB2 samples processed under ambient pressure. The trapped field is observed to decay at a rate of <2%/day at 10 K, which suggests that bulk MgB2 superconductors fabricated using the infiltration and growth technique can be used potentially to generate stable, high magnetic fields for a variety of engineering applications.

Similar content being viewed by others

Introduction

A bulk superconductor can act effectively as a quasi-permanent magnet when magnetized by an applied magnetic field below its superconducting transition temperature, Tc. Concentric supercurrents, induced typically throughout the bulk sample during the magnetisation process by the applied magnetic field, persist even when the external field is reduced to zero. The resulting, so-called trapped, magnetic field associated with these currents (the bulk material acts effectively as a thick, single-turn solenoid) decays extremely slowly, giving rise to a relatively stable magnetic field. Significantly, the magnitude of this trapped field is potentially much greater than that obtained typically using conventional Nd-Fe-B-based permanent magnets, which are limited generally to less than 2 T. Such compact superconducting bulk magnets are therefore excellent candidates for engineering applications where a high magnetic field is desired, such as desktop nuclear magnetic resonance (NMR), magnetic resonance imaging (MRI), motors and particle accelerators1,2,3.

MgB2 has been demonstrated to be a promising candidate for stable, high magnetic field applications. The key attributes from the perspective of practical applications are a combination of its high Tc, which exceeds the predictions of BCS theory due to its peculiar two band nature4, and its tendency to form strongly linked grain boundaries, which allows the fabrication of polycrystals without the loss of inter-grain supercurrent5,6. As a result, a variety of methods have been developed and optimised to obtain dense, high performance MgB2 bulk superconductors, such as high pressure sintering7,8,9,10, spark plasma sintering11 and techniques based on infiltration12,13. In particular, infiltration and growth (IG), impregnation or reactive liquid infiltration (RLI) processes have been developed specifically to address challenges associated with conventional sintering routes, such as porosity and poor sinterability. In this approach, B powder is packed initially to form a green body, followed by infiltration with liquid Mg. The vapour infiltration route, used initially for processing MgB2 fibres of diameter 160 μm, was initially reported by Canfield et al.14 and later by Dunand et al. for the synthesis of Mg-MgB2 composites by infiltrating liquid Mg under pressure at 800 °C into a B preform15. The key advantages of this technique were demonstrated subsequently by Giunchi et al. (RLI) for the fabrication of state-of-the art bulk MgB2 artefacts12,13. Such a relatively simple, ambient pressure process not only results in the formation of hard, dense structures but can also be applied to fabricate complex geometries that are not achieved easily using conventional sintering techniques. Bulk MgB2 of relatively high density obtained by IG and RLI techniques is characterised typically by a high effective current carrying cross-sectional area, which translates directly to a higher critical current density (Jc). Although Jc in self-field as high as 106 A/cm2 has been measured in bulk samples, the performance of MgB2 tends to drop-off rapidly with applied magnetic field16. It is, therefore, essential that the in-field performance of bulk MgB2 is enhanced if Nb based low temperature superconducting materials used widely in existing practical applications and which typically require expensive liquid helium (LHe) as a coolant during operation, are to be replaced.

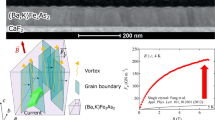

It is well understood that the performance of MgB2 can be enhanced by maximising the density of grain boundaries, which form effective pinning sites in the microstructure17,18,19,20,21. This has been achieved by employing nano-scale Mg and B precursor powders for the synthesis of MgB2, which results ultimately in the formation of fine-grained MgB2. Irradiation via the bombardment of neutrons, γ rays or heavy ions (Ag, Au) at sufficiently high velocities, which induces both large scale and small scale defects in the MgB2 lattice, is another effective approach for improving current carrying performance of bulk MgB222,23,24. Large scale lattice defects, such as dislocations or stacking faults, act as effective pinning centres over a range of applied magnetic field and thereby improve the irreversibility field (Hirr) of the superconductor (i.e. an extension of its ability to generate magnetic fields for practical applications at a given temperature). Small scale lattice defects, such as point defects, on the other hand, tend to reduce the mean free path of the superconducting charge carriers, which, in turn, reduces the coherence length and results in an increased upper critical field (Hc2)25. Alternatively, a superconductor can be made “dirtier”, for example, by alloying to increase charge carrier scattering. Carbon doping (C-doping), in particular, has been shown to be a promising technique for enhancing Jc/Hc2 in bulk MgB2. Increased intra-band scattering (particularly in the σ band26), degradation of crystallinity27,28,29, enhanced vortex and △k pinning30, reduced anisotropy in critical fields31, strengthened grain boundary pinning32 are some of the mechanisms that have led to much improved Jc(B) performance in C-doped MgB2 bulk superconductors. In addition, formation of defects in the microstructure such as stacking faults and nano-inclusions further contribute to pinning33,34. Since C in graphite allotropic form is difficult to dope into bulk MgB235, it is often introduced in other forms that include SiC33, C-nanotube36, nano-diamond37 and organic compounds38.

In the present work, high quality Mg(B1−xiCxi)2 (where xi is C occupancy on boron sites in MgB2 lattice) bulk superconductors were fabricated using an IG process, with B4C and SiC compounds as a source of C. Changes in the lattice parameters induced by carbon substitution were studied in these samples and their effects on the superconducting properties of the bulk material have been analysed in detail in an attempt to identify the level of C addition that yield optimum critical current density. The modified IG process (MPIG) was then adopted in order to facilitate uniform liquid Mg infiltration, which is necessary to produce homogeneous bulk MgB2 superconductors for practical applications. Finally, trapped field measurements were performed on the doped bulk samples and the results discussed.

Experimental Methods

Sample Preparation

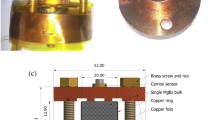

Crystalline β-boron (98% pure, <40 μm) and B4C (99% pure, ~2 µm) powders were mixed using a mortar and pestle to obtain (100-x)% B - x% B4C (hereafter referred to as x% (B4C) precursor compositions with x varying in weight % as 0, 10, 20, 60 and 100 (Table 1). Sixth powder mixture containing β-boron and 10 wt% SiC (~30 nm) [referred to hereafter as 10% (SiC)], was also prepared, given that SiC addition had been demonstrated previously to yield effective C-doping in bulk MgB233. Six precursor pellets of diameter 32 mm and thickness 6 mm, each weighing 7.5 g, were pressed uniaxially from these powder mixtures under a load of 35 MPa. The porous precursors were then subject to the IG process and reacted at 850 °C for 4 h, as described in refs39,40.

Fabrication of High Performance, Homogeneous C-doped samples

The presence of continuous Mg channels in bulk MgB2 processed by IG has been known40. These non-superconducting channels, which form during the IG process, are typically several cm in size and obstruct the flow of supercurrent in the bulk microstructure, which, in turn, limits the field trapping ability of the sample. Therefore, in order to realize the advantages offered by C-doping on a larger scale, Mg channel free MgB2 bulk superconductors were fabricated by combining C-doping and a Modified Precursor Infiltration and Growth (MPIG) technique, as described in ref.40. The Addition of pre-reacted MgB2 phase powder to the boron precursor has been shown previously to facilitate uniform in-flux of Mg, which results in the formation of homogeneous, Mg-channel free microstructure in the bulk MgB2. As a result, appropriate mixtures of B, B4C and MgB2 powders were used as precursors in the MPIG process, as summarised in Table 1. 7.5 g of each precursor composition was pressed under a load of 35 MPa to obtain a pellet of diameter 32 mm and thickness 6 mm. Such C-doped bulk superconductors prepared using this method are referred to subsequently as x% B4C (MPIG), where x is the nominal weight % of B4C in the pellet prior to infiltration. Three bulk superconductors were fabricated by MPIG technique, one with x = 5, and two with x = 10, as described in Table 1.

Characterization

XRD analysis (CuKα = 1.5408 Å) was carried out in order to identify the phases present in the sample microstructure and to enable calculation of the crystallographic lattice parameters of the fully reacted compound. The non-uniform strain/distortion in the MgB2 lattice induced as a result of C substitution was quantified by Williamson-Hall (W-H) analysis41. The critical current density (Jc) of these samples was calculated from the measured magnetic moment hysteresis loops using the extended Bean model for a rectangular cross-section (Sample dimensions ~ 3 × 3 × 1 mm3) in the presence of a magnetic field applied perpendicularly to the surface of the sample42.

Trapped Field Measurements

The field-cooled (FC) method was used to magnetize the C-doped MgB2 bulk superconductors prior to the measurement of trapped magnetic field. This involved cooling down the sample, or sample arrangement, to 5 K in the presence of an external magnetic field of 5 T/6 T applied perpendicular to the top surface of the sample/samples using a Gifford–McMahon (GM) cryocooler (CRTHE05-CSFM, Iwatani Gas). The external magnetic field was then reduced to zero at a rate of 1.8 T/h to minimise any loss of trapped flux from the sample during the magnetization process (as shown in Supplementary Fig. 1). The sample was then heated slowly at a rate of 0.1 K/min and the trapped magnetic flux density measured at temperatures up to 40 K by cryogenic Hall sensors (HGCT-3020, Lake Shore).

Additional data related to this publication is available at the Brunel University London data repository (https://doi.org/10.17633/rd.brunel.5395564).

Results and Discussion

Effect on Tc

Figure 1(a) shows the normalised magnetization as a function of temperature for samples 10% (SiC), x = 10%, 20%, 60%, 100% (B4C) and an undoped sample. Both 10% (SiC) and 10% (B4C) resulted in a reduction of Tc (defined by onset of superconducting transition) from 37.9 K (undoped) to 36.2 K, arising from σ band filling by electron doping43. Electron doping reduces simultaneously the number of holes at the top of the σ bands and the electronic density of states44. Moreover, 10% (B4C) exhibited a relatively sharp superconducting transition, whereas 10% (SiC) showed a very broad transition, suggesting that C-doping is much less uniform in the sample containing SiC compared to that containing B4C. This can be explained by a homogeneous distribution of C at the atomic scale in the case of B4C. All the samples containing varying amounts of B4C exhibited a reasonably sharp superconducting transition with Tc reducing from 37.9 K (Undoped) to 25.9 K [100% (B4C)] as a result of C-doping in MgB2. Moreover, the addition of B4C with x ≥ 20 produced two distinct transition temperatures, suggesting possible presence of two types of Mg(B1−xiCxi)2 phases. The normalised magnetization as a function of temperature for MPIG samples is shown in Fig. 1(b). The MPIG samples, 5% B4C (MPIG) and 10% B4C (MPIG), exhibited a second transition at 34.8 K and 33.8 K respectively, below the onset Tc (37.8 K). Such high Tc onset of 37.8 K in MPIG samples suggests that C-doping has not taken place in the pre-reacted MgB2. The presence of the second transition at lower temperature (34.8 K and 33.8 K), however, suggests that higher levels of C doping into MgB2 that forms during the reaction of B with liquid Mg in the MPIG process.

Phase analysis

Figure 2(a) compares the XRD patterns obtained for B4C containing samples [x% (B4C)] with an undoped sample. The undoped sample shows the presence of familiar phases: MgB2, residual Mg and a small amount of metastable Mg2B25. On the other hand, the samples containing B4C are composed predominantly of C-doped, superconducting Mg(B1−xi,Cxi)2. The equilibrium MgB2C2 phase and a small amount of unreacted B4C were detected for higher nominal B4C content of x ≥ 60%. Figure 2(b) provides insight into nature and extent of C-doping in MgB2. The peaks for the B4C containing samples exhibit a component of a plane normal to the crystallographic a-b plane, and show a consistent and significant shift towards higher angles with considerable peak broadening. In addition, the peak positions corresponding to planes parallel to the basal (001) plane remain almost unchanged. This clearly suggests, and is in good agreement with previously observed studies33,35, that C-doping induces strain in the crystallographic a-b plane only.

(a) XRD patterns for an undoped sample and B4C containing samples [x% (B4C)] revealing the presence of a majority Mg(B1−xi,Cxi)2 phase along with minor concentrations of Mg, B4C and MgB2C2. (b) A significant shift observed in the (110) reflection while the (002) reflection remains almost unchanged. (c) Variation of the calculated lattice parameters a/c with C-doping. Data for sintered SiC/B4C containing and single crystal samples are also shown. (d) Measured values of Tc in C-doped samples carbon substitution (xi) as a function of nominal B4C content (x).

Figure 2(c) shows the calculated in-plane lattice parameter for MgB2 as a function of B4C addition [x% (B4C)]. The data obtained are compared with those for C-doped MgB2 single crystals and for C-doped samples produced by B4C and SiC via a sintering route under similar reaction conditions44. It is apparent from the change in lattice parameter ‘a’ that B4C is a more efficient dopant than SiC. Also, the C-doping level for IG samples with 10% (B4C) and 20% (B4C) appears to be higher than that observed in C-doped single crystals. This could be due to the fact that about 15% boron is present in the form of the intermediate boride phase, Mg2B25, which is not transformed fully into superconducting MgB239. This possibly results in an apparent increase in carbon concentration in MgB2. Expectedly, A small change in lattice parameter ‘c’ was observed from 3.518 to 3.524 Å from the undoped sample to 100% (B4C) sample. Figure 2(d) compares Tc observed in C-doped samples with nominal B4C addition [x% (B4C)]. The actual carbon substitution produced by B4C addition, which is estimated by comparing the lattice parameter ‘a’ obtained for the present samples with that for the single crystals of Mg(B1−xiCxi)2 shown in Fig. 2(c), is also presented. The maximum carbon substitution on the B site of up to xi = 0.088 was obtained for the samples containing B4C. The effective carbon substitution (xi) in 5% (B4C) MPIG and 10% (B4C) MPIG samples was estimated to be 0.022 and 0.033 respectively.

The reaction of B4C with Mg is known to result in the formation of MgB2 via the following chemical reactions:

Detailed analysis by Wilke et al.45 suggests that an equilibrium MgB2C2 phase begins to appear when carbon saturation is reached, i.e. when C can no longer be accommodated in the MgB2 lattice, which is precipitated subsequently in the form of MgB2C2. Analysis of C-doped MgB2 single crystals shows that C saturation occurs at about xi = 0.1544. In the present study, the presence of MgB2C2 was detected for a B4C content of x ≥ 60 (xi = 0.07), despite the fact that the actual substitution xi was <0.15. This suggests that carbon saturation probably occurred locally within the microstructure. Moreover, the presence of residual B4C indicates that not all the carbon within the precursor composition doped into the MgB2 lattice.

The mechanism of C-doping in MgB2 from B4C in the IG process can be understood from Figs 1 and 2, and is summarised in Fig. 3(a). Bulk Mg(l) infiltration occurs after 20–40 minutes from the beginning of the IG process39. This is followed by the start of the transformation of B and B4C particles into MgB2 and C-doped MgB2 (Reaction II), respectively. The excess carbon in B4C, which cannot be accommodated in the Mg(B0.85C0.15)2 lattice, precipitates in the form of MgB2C2. The carbon then diffuses into neighbouring undoped MgB2 grains. Figure 3(b) shows the expected carbon concentration gradient from C-sources the B4C and SiC, respectively, assuming that both are added separately to B to achieve the same target xi in the Mg(B1-xiCxi)2 phase when all the C is doped in Mg(B1−xiCxi)2 for an infinite reaction time. In this case, a steeper C-concentration gradient is expected since the atomic % of C is higher in SiC (0.5) than it is in B4C (0.2). This results conceivably in a wider spread in ΔC and a resulting broader Tc (Fig. 1). Furthermore, it is noted that the number of C-sources with SiC addition is significantly lower than those associated with B4C addition when the B4C and SiC particle sizes are comparable. This is because number of moles of SiC required to achieve a target xi is fewer than the number of moles of B4C required to achieve the same level of doping, coupled with the smaller molar volume of SiC relative to B4C. This is likely to result in higher composition fluctuations of xi in the SiC containing sample [Fig. 3(c)] compared to that containing B4C [Fig. 3(d)].

(a) Schematic illustration of C-doped MgB2 bulk superconductor processed by infiltrating liquid Mg into Boron precursor containing 10% B4C at 850 °C. The illustrations shown from left to right represent the various stages of reaction with time. The xi value for 10% (B4C) is calculated to be 0.033. (b) Expected carbon concentration gradients originating from two different carbon sources. The relatively large difference in ΔC is due to a large variation in C at% between the two dissimilar SiC and B4C chemical phases. A higher degree of C variation within the Mg(B1-xiCxi)2 grain associated with (c) B4C addition relative to (d) SiC addition is observed. Carbon sources are represented by the dashed regions. Note that the intermediate boride formation during the transformation of B to Mg2B25 is not shown.

Strain analysis

Figure 4(a) shows the full width at half maximum (FWHM) data for various XRD reflections as a function of nominal B4C content [x% (B4C)]. It is apparent that C-doping has induced a large amount of lattice strain/distortion and degradation of the crystallinity in MgB2, but mostly in the a-b direction, as evidenced by the increase in FWHM for the (100) and (110) reflections. In comparison, the FWHM of the (002) reflection appears rather small. The non-uniform strain/distortion in the MgB2 lattice can be quantified by a Williamson-Hall (W-H) plot according to following equation41:

where βObserved and βInstrumental are the observed and instrumental broadening in radian respectively, K is the Scherrer constant determined by crystallite size (~1), λ and L are the X-ray wavelength and size of diffracting domain in Å, respectively, and εN is the non-uniform strain. Here, βinstrumental is approximated to be the FWHM of an undoped sample, which is assumed to be strain-free. Also, since strain is present only in the a-b plane, only the (100) and (110) reflections are considered for the purposes of strain analysis. A W-H plot is shown for nominal B4C content in Fig. 4(a). The C-doping was found to induce strain of up to 0.46% in the lattice, as shown in Fig. 4(b). In addition, semi-coherent precipitates (MgB2-Mg) were detected in TEM analysis (Supplementary Fig. 2). Such a formation of semi-coherent interface further leads to localized strain in the interface region.

Jc and Pinning Force

Figure 5(a) compares Jc at 5 and 20 K as a function of external field for 10% (SiC), 10% (B4C) and the undoped sample. It can be seen that the C-doped samples exhibit a much weaker dependence of Jc on external field, and particularly at 5 K. The sample containing B4C, 10% (B4C) in particular, shows a significantly enhanced self-field Jc of 600 kA/cm2 (5 K) and 350 kA/cm2 (20 K), which represents an increase of 50% and 36% with respect to the Jc measured in the undoped sample.

Measured Jc as a function of external field for samples (a) 10% (SiC), 10% (B4C) (b) and x% (B4C) from x = 0 to x = 100 and (c) Jc as a function of external fields at 5 K for MPIG samples. (d) Pinning force (JcxB) at 20 K, as a function of reduced field (µ0H/µ0Hirr) for undoped and doped MgB2 samples processed by IG.

In addition, an in-field Jc (5 T, 5 K) as high as 50 kA/cm2 was observed for this sample, which is nearly 10 times that observed for the undoped sample. The enhanced flux pinning, (at higher external fields, in particular) and Hirr is clearly a result of induced strain in the lattice, or degradation in the crystallinity of MgB2. Such lattice imperfections enhance the intra-band scattering and reduce the electron mean free path l and coherence length ξ according to the following equation46:

A shortening of ξ allows more flux to be accommodated in the sample, which results in an increased Hc2. On the other hand, the sample containing SiC did not exhibit a similar improvement in Jc due to intrinsic, inhomogeneous C-doping [Fig. 1(a)]. Moreover, the reaction of SiC with Mg is known to lead to the formation of non-superconducting Mg2Si inclusions in the bulk microstructure, which reduces the effective current carrying cross section of the sample33,47. Previous studies of C-doped MgB2 bulk samples have also reported improved Jc-B behaviour. Nominal composition of MgB1.8(SiC)0.1 exhibited a two-fold increase in Jc (100 kA/cm2 at 3 T, 20 K) compared to undoped sample. Similarly, Jc in MgB1.5(B4C)0.1 exhibited a five-fold increase (50 kA/cm2 at 5 T, 5 K) compared to Jc in undoped sample33. Serquis et al. further reported high in-field Jc of up to 50 kA/cm2 (5 T, 5 K) for samples containing C-nanotube36 and a diamond doped sample showed an improved Jc of 10 kA/cm2 (20 K, 4 T), from an undoped reference Jc of 100 A/cm2 37. A novel technique, which involved coating B with malic acid and toluene with B prior to sintering, resulted in an eight-fold increase in Jc to 40 kA/cm2 (20 K, 5 T)38.

In this study, Jc-B was also measured for varying B4C content [x% (B4C)] in order to observe any change in Jc with C-doping, as shown in Fig. 5(b). 100% (B4C) exhibited a relatively high self-field Jc of 250 kA/cm2 at 5 K, despite having a low Tc (22 K). This, together with the superconducting transitions shown [Fig. 1(a)] and the XRD [Fig. 2(a)] suggests that B4C is not only highly reactive with Mg, but that the superconducting Mg(B1-xiCxi)2 phase is also well connected within the bulk microstructure. 10% (B4C) exhibited optimum Jc(B) performance, with Jc degrading gradually for higher B4C content. This demonstrates a ‘trade-off’ between enhanced flux pinning and a reduction in Tc as a result of C-doping. Undoped MPIG, 5% (B4C) MPIG and 10% (B4C) MPIG samples, on the other hand, exhibited self-field Jc’s of 200, 250 and 440 kA/cm2, respectively at 5 K as shown in Fig. 5(c). It is apparent that the MPIG samples show reduced Jc with respect to IG samples. For instance, 10% (B4C) and 10% B4C (MPIG) samples showed a maximum self-field Jc of 600 and 440 kA/cm2 respectively, at 5 K. This is because the grain boundary areas of such pre-reacted MgB2 particles are of low Jc, due to weaker connectivity and lower Hc2 in such areas, as suggested by the magneto-optical observations of Polyanskii et al.48.

The variation of normalised pinning force Fp/Fp(max) with reduced field (h = H/Hirr) is shown in Fig. 5(d) for undoped and C-doped samples. Hirr is defined as the field at which Jc = 102 A/cm2. Dew-Hughes proposed the following equation characterising pinning forces in type II superconductors that originate from various sources49:

where the parameters p and q are material constants. Dew-Hughes suggested six different pinning mechanisms based on equation (3): (1) p = 0, q = 2: normal core pinning, volume pins; (2) p = 1, q = 1: Δk-pinning, volume pins (3) p = 1/2, q = 2: normal core pinning, surface pins; (4) p = 3/2, q = 1: Δk-pinning, surface pins; (5) p = 1, q = 2: normal core pinning, point pins; and (6) p = 2, q = 1: Δk-pinning, point pins.

The maximum of the normalized pinning force is expected at h = 0.2 for samples where surface pinning is dominant, such as that observed for undoped MgB2 in Fig. 5(d). Such pinning is also observed in Nb-based superconductors where grain boundaries form dominant pinning sites50. The apparent deviation of pinning force from Dew-Hughes model results probably from anisotropy in Hc2, which is origin of Hirr in MgB2 rather than thermally activated depinning51. The normalised pinning force maxima in the samples containing B4C are shifted to lower fields at both 5 K and 20 K. For instance, 10% (B4C) and 20% (B4C) exhibit maxima at h = 0.18 and 0.15, respectively at 20 K. Such behaviour has also been reported by Matsushita et al.52, Cheng et al. in C-doped samples36 and Shcherbakova et al. in bulk MgB2 containing sugar53. This suggests the possible presence of other, non-surface, flux pinning centres in C-doped samples, such as volume pinning. Recently, Yang et al. also observed such shift for MgB2 containing Dy2O354. Dy based nano-inclusions were considered to form additional pinning sites and the origin of the observed shift. In the present study, fine precipitates in the sample microstructure, such as MgB2C2 or unreacted B4C could contribute towards volume pinning. Such a contribution to pinning from inclusions was reported by Dou et al. in sintered Mg(B1−xiCxi)2 containing SiC33. Alternatively, such a shift in pinning force maxima towards lower field could also result from inhomogeneous C-doping, and a resultant distribution of HC2, within the bulk microstructure.

High Performance homogeneous C-doped samples

Long range microstructural homogeneity and uniformity in the level and extent of carbon doping in the MgB2 bulk matrix plays a critical role in determining the flux trapping potential of this material, although Jc measured in a sample of dimensions of several mm gives a good indication of this at a more local level. As a result, homogeneous, defect free C-doped MgB2 bulk superconductors were fabricated by a MPIG process (Section 2.2). 5% B4C (MPIG) and 10% B4C (MPIG) samples were prepared in order to study the trapped field performance of bulk samples given that optimum Jc(B) behaviour was obtained for 10% (B4C) [Fig. 5(b)].

Trapped Field Measurements

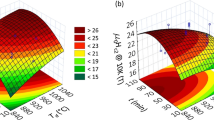

Three sets of measurements were performed as follows - (i) 5% B4C (MPIG) [Fig. 6(a)], (ii) a two-sample stack of 10% B4C (MPIG) [Fig. 6(b)] and (iii) a five-sample stack [Fig. 6(c)], referred to subsequently as Stack-5. The arrangement of bulk superconductors and the location of hall probes are shown in the respective insets in Fig. 6. For the purpose of comparison, the trapped field at the centre and surface of a single, undoped bulk is shown in Fig. 6(a), whereas the trapped field at the centre and surface of a two-sample-stack of undoped bulks is shown in Fig. 6(b)40. A trapped magnetic flux density of 2.47 T and 2.44 T was recorded at 5 K at the centre of the top and bottom surfaces of the 5% B4C (MPIG) bulk superconductor, respectively, confirming a high degree of uniformity in the sample microstructure [Fig. 6(a)]. This value of trapped field represents an increase of 16% over the one measured for the undoped MPIG sample, which decreases with temperature, reaching 0 T at 36.2 K. The two-sample stack of 10% B4C (MPIG) bulk superconductors trapped 3.75 T and 2.7 T at the centre and top surface at 5 K, respectively, which represents a 25% increase over the trapped field observed in an undoped MPIG bulk of same geometrical configuration [Fig. 6(b)], which decreased relatively rapidly to reach 0 T at 34.6 K. It can be concluded, therefore, that the rate of change of trapped field with temperature (−dB/dT) decreases with C-doping. The observed increase in trapped field from the undoped MPIG to 10% B4C (MPIG) correlates, clearly, with higher Jc at lower temperature and vice versa, and is due directly to increased C-doping in the bulk composition [Fig. 5(b)].

Maximum trapped field as a function of normalised temperature for (a) 5% B4C (MPIG) (b) 10% B4C (MPIG) bulk MgB2 superconducting discs. Data for undoped MPIG bulk samples measured in the same configuration are also shown (c) Trapped field dependence with normalised temperature for a stack arrangement (Stack-5). The location of the hall probe(s) is shown in the insets and an image of representative bulk shown in (a). H1 was placed in the middle of gap (1.6 mm) between the two bulks.

To date, much of the enhancement in trapped field in MgB2 has been achieved by grain refinement. For instance, Fuchs et al. and Sugino et al. used nano-scale Mg and B powders produced by high energy ball milling to synthesize MgB2 in an attempt to maximise grain boundary density19,55. These samples trapped maximum fields of 5.4 T (12 K) and 3.72 T (5 K) respectively. Similarly, Naito et al. observed that the addition of Ti (nominal composition Mg1−xiTixiB2) resulted in the formation of a thin layer of TiB2 on the MgB2 crystal that pinned the grain boundaries of MgB2 and inhibited grain growth56. Such a TiB2 layer was also thought to form a vortex point pinning site. On the contrary, the increase in trapped field of Mg(B1−xiCxi)2 bulk superconductors observed in the present study originates from atomic level intra-band scattering associated directly with C-doping. In addition, the increase has been achieved by the simple addition and mixing of B4C with B powder, and without the use of expensive techniques such as high energy ball milling. This demonstrates that C-doping via B4C in the IG process is an effective way of fabricating high performance MgB2 bulk superconductors that can potentially generate high magnetic fields.

Finally, a five-sample stack arrangement was constructed in order to investigate the effect of thickness on the trapped field, as shown in the inset to Fig. 6(c), which is significant given the potential of bulk MgB2 for application as a coaxial cylindrical superconducting magnet (which is consistent with this geometrical sample arrangement). A Hall sensor was placed on top of the 5-sample stack (H2) and another was sandwiched between the bulk superconductors (H1). A maximum trapped flux density of 4.15 T and 2.2 T was measured on H1 and H2 at 7.5 K, of which the former is the highest trapped field observed to date in MgB2 bulk samples fabricated under ambient pressure. Measurement (ii) was repeated with an external field of 6 T, which was observed to have very little effect on the magnetic flux density measured at both in the centre and surface of the two-sample stack (not shown here). The trapped field of 2.32 T (H2 extrapolated to 5 K) represents a ~10% increase in the magnetic field compared to that observed in a single bulk sample. Interestingly, 4.3 T (H1 extrapolated to 5 K) represents a ~15% increase with respect to trapped field at the centre of 10% B4C (MPIG) at 5 K. This suggests that such a stack arrangement could be used to generate high trapped fields in bulk MgB2. Simulation studies, such as that reported in ref.57, could be very useful to understand the distribution of magnetic flux within such a sample arrangement.

Flux Creep

Loss of flux from the superconductor occurs when the Lorentz force exceeds the flux pinning force, in which case when J > Jc. In addition, flux also ‘leaks’ at J < Jc due to thermally activated flux motion. MgB2, in particular, exhibits a low field decay rate compared to its high temperature superconductor counterparts at a given normalised temperature58. This is important from application perspective, since high temporal stability is desired in devices for Magnetic Resonance Imaging/Nuclear Magnetic Resonance, for example. Yamamoto et al. measured a low decay of 1.7%59 in peak trapped field after 3 days, while Naito et al. noted a small decay of 2% after 40 hrs of field removal56. The stability of peak trapped magnetic field at the centre in the MgB2 bulk samples was investigated by measuring the magnetic field relaxation at 10 K and 20 K after removal of the magnetizing field (Shown in Supplementary Figs 3 and 4). The time dependence of normalised trapped field at 10 K and 20 K for various samples is shown in Fig. 7(a,b), respectively. All the curves exhibit typical logarithmic decay (with the relevant equations given in the insets) with time (t > 100 s), although the variation in flux creep was observed to be non-logarithmic for t < 100 s. The decrease in normalised trapped field after one day at 20 K was observed to be significant greater than that observed at 10 K. For example, 5% B4C (MPIG) showed a 2.3% and 3.8% reduction in trapped flux at 10 K and 20 K, respectively after 1 day. This can be explained by following equation from the Anderson-Kim model60:

where ν is the jump attempt frequency from one pinning site to another, Uo is the activation energy (i.e. height of the potential well) for the de-pinning of flux line and kB is Boltzmann’s constant. The trapped field is expected to decay with time since the flux jump frequency increases with temperature. Interestingly, the creep rate was also found to increase with C-doping, although stronger grain boundary pinning is expected for these samples.

Conclusion

C-doped MgB2 samples were prepared by IG technique using B4C and SiC as sources of C. Samples fabricated using B4C showed a more homogeneous C distribution compared to those containing SiC. This is attributed to the higher reactivity of B4C with Mg and an atomically uniform distribution of C in the bulk microstructure. Various Mg(B1-xiCxi)2 phases in the B4C containing samples were identified using XRD and their lattice parameters were calculated. These samples showed significant enhancement in Jc, particularly at lower temperature and higher fields. We account for this as being due to the generation of lattice strains and a loss of crystallinity in the MgB2 phase accompanied by the effects of C-doping. Analysis of the pinning force also suggested the possibility of a contribution to enhanced Jc from point pinning. A significant increase in trapped field was observed in C-doped MgB2 bulk superconductors. The trapped field obtained (4.15 T) in a stack of five stacked of bulk samples is the highest reported to date for MgB2 bulk superconductors synthesized under ambient pressure conditions. Finally, we note that the finer particle size of B4C is likely to yield more efficient and uniform C-doping, without the formation of MgB2C2 and leaving residual B4C. This, together with nano-sized boron powder, would potentially yield an optimum combination of enhanced grain boundary pinning and increased Hc2, which could extend significantly the performance boundaries of bulk MgB2.

References

Iwasa, Y., Hahn, S. Y., Tomita, M., Lee, H. & Bascunan, J. A persistent-mode” magnet comprised of YBCO annuli. IEEE Trans. Appl. Supercond. 15, 2352–2355 (2005).

Nakamura, T., Itoh, Y., Yoshikawa, M., Oka, T. & Uzawa, J. Development of a superconducting magnet for nuclear magnetic resonance using bulk high-temperature superconducting materials Concepts Magn. Reson., Part B 31B, 65–70 (2007).

Kii, T. et al. Low-temperature operation of a bulk HTSC staggered array undulator. IEEE Trans. Appl. Supercond. 22, 4100904 (2012).

Giubileo, F. et al. Two-gap state density in MgB2: a true bulk property or a proximity effect? Physical review letters 87, 177008–177008 (2001).

Kambara, M. et al. High intergranular critical currents in metallic MgB2 superconductor. Supercond. Sci. Technol. 14, L5–L7 (2001).

Larbalestier, D. C. et al. Strongly linked current flow in polycrystalline forms of the superconductor MgB2. Nature 410, 186–189 (2001).

Dancer, C. E. J. et al. A study of the sintering behaviour of magnesium diboride. J. Europ. Cer. Soc. 29, 1817–1824 (2009).

Takano, Y., Takeya, H., Fujii, H., Kumakura, H. & Hatano, T. Superconducting properties of MgB2 bulk materials prepared by high-pressure sintering. Appl. Phys. Lett 78, 2914–2916 (2001).

Jung, C. U. et al. Effect of Sintering under high pressure on the superconductivity of MgB2. Appl. Phys. Lett. 78, 4157–4159 (2001).

Liao, X. Z. et al. Defect structures in MgB2 wires introduced by hot isostatic pressing. Supercond. Sci. Technol. 16, 799–803 (2003).

Lee, S. Y., Yoo, S. I., Kim, Y. W., Hwang, N. M. & Kim, D. Y. Preparation of dense MgB2 bulk superconductors by spark plasma sintering 2003. J. Am. Ceram. Soc 86, 1800–1802 (2003).

Giunchi, G. High density MgB2 obtained by reactive liquid Mg infiltration. Inter. J. of Modern Phys. B 17, 453–460 (2003).

Giunchi, G., Ripamonti, G., Cavallin, T. & Bassani, E. The reactive liquid Mg infiltration process to produce large superconducting bulk MgB2 manufacts. Cryogenics 46, 237–242 (2006).

Canfield, P. C. et al. Superconductivity in Dense MgB2 Wires. Phys. Rev. Lett. 86, 2423–2426 (2001).

Dunand, D. C. Synthesis of superconducting Mg-MgB2 composites. Appl. Phys. Lett 79, 4186–4188 (2001).

Prikhna, T. A. et al. Nanostructural in homogeneities acting as pinning centers in bulk MgB2 with low and enhanced grain connectivity. Supercond. Sci. Technol. 27, 044013–044021 (2014).

Hassler, W. et al. Influence of the milling energy transferred to the precursor powder on the microstructure and the superconducting properties of MgB2 wires Supercond. Sci. Technol. 26, 025005–025011 (2013).

Wang, C. et al. Effect of high-energy ball milling time on superconducting properties of MgB2 with low purity boron powder. Supercond. Sci. Technol. 25, 035018–035024 (2012).

Sugino, S., Yamamoto, A., Shimoyama, J. & Kishio, K. Enhanced trapped field in MgB2 bulk magnets by tuning grain boundary pinning through milling. Supercond. Sci. Technol. 28, 055016–055022 (2015).

Fischer, C. et al. Preparation of MgB2 tapes using a nanocrystalline partially reacted precursor. Appl. Phys. Lett. 83, 1803–1805 (2003).

Perner, O. et al. Microstructure and impurity dependence in mechanically alloyed nanocrystalline MgB2 superconductors. Supercond. Sci. Technol. 17, 1148–1153 (2004).

Putti, M., Vaglio, R. & Rowell, J. M. Radiation effects on MgB2: a review and a comparison with A15 superconductors. Supercond. Sci. Technol. 21, 043001–043025 (2008).

Bugoslavsky, Y. et al. Enhancement of the high-magnetic-field critical current density of superconducting MgB2 by proton irradiation. Nature 411, 561–563 (2001).

Eisterer, M. et al. Neutron irradiation of MgB2 bulk superconductors. Supercond. Sci. Technol. 15, L9–L12 (2002).

Putti, M. et al. Neutron irradiation of Mg11B2: From the enhancement to the suppression of superconducting properties. Appl. Phys. Lett. 86, 112503–112505 (2005).

Pallecchi, I. et al. Magnetoresistivity as a probe of disorder in the π and σ bands of MgB2. Phys. Rev. B 72, 184512 (2005).

Pogrebnyakov, A. V. et al. Properties of MgB2 Thin Films with Carbon Doping. Appl. Phys. Lett. 85, 2017–2019 (2004).

Braccini, V. et al. High-field superconductivity in alloyed MgB2 thin films. Phys. Rev. B 71, 012504 (2005).

Senkowicz, B. J. et al. Improved upper critical field in bulk-form magnesium diboride by mechanical alloying with carbon. Appl. Phys. Lett. 86, 202502–202504 (2005).

Xiang, F. S. et al. Evidence for transformation from δT c to δ l pinning in MgB2 by graphene oxide doping with improved low and high field J c and pinning potential. Appl. Phys. Lett. 102, 152601–152605 (2013).

Wisniewski, A. et al. Comparison of the influence of carbon substitution and neutron-induced defects on the upper critical field and flux pinning in MgB2 single crystals. Supercond. Sci. Technol. 20, 256–260 (2007).

Yamamoto, A. et al. Universal relationship between crystallinity and irreversibility field of MgB2. Appl. Phys. Lett. 86, 212502–212504 (2005).

Dou, S. X. et al. Enhancement of the critical current density and flux pinning of MgB2 superconductor by nanoparticle SiC-doping Appl. Phys. Lett. 81, 3419–3421 (2002).

Kim, J. H. et al. Microscopic role of carbon on MgB2 wire for critical current density comparable to NbTi NPG Asia. Materials 4, e3–e6 (2012).

Yamamoto, A. et al. Effects of B4C-doping on critical current properties of MgB2 superconductor. Supercond. Sci. Technol. 18, 1323–1328 (2005).

Serquis, A. et al. Correlated enhancement of H c2 and J c in carbon nanotube doped MgB2 Supercond. Sci. Technol 20, L12–L15 (2007).

Cheng, C. H., Yang, Y., Munroe, P. & Zhao, Y. Comparison between nano-diamond and carbon nanotube doping effects on critical current density and flux pinning in MgB2 Supercond. Sci. Technol. 20, 296–301 (2007).

Hossain, M. S. A. et al. The enhanced J c and B irr of in situ MgB2 wires and tapes alloyed with C4H6O5 (malic acid) after cold high pressure densification. Supercond. Sci. Technol. 22, 095004–095011 (2009).

Bhagurkar, A. G. Microstructural evolution in infiltration-growth processed MgB2 bulk superconductors. J Am Ceram Soc. 100, 2451–2460 (2017).

Bhagurkar, A. G. A trapped magnetic field of 3 T in homogeneous, bulk MgB2 superconductors fabricated by a modified precursor infiltration and growth process. Supercond. Sci. Technol. 29, 035008–035015 (2016).

Williamson, G. K. & Hall, W. H. X-ray line broadening from filed aluminium and wolfram. Acta metallurgica 1, 22–31 (1953).

Chen, D. X. & Goldfarb, R. B. Kim model for magnetization of type‐II superconductors. J. Appl. Phys. 66, 2489–2500 (1989).

Kortus, J., Dolgov, O. V., Kremer, R. K. & Golubov, A. A. Band Filling and interband scattering effects in MgB2: carbon versus aluminum Doping. Phys. Rev. Lett 94, 027002–027005 (2005).

Lee, S., Masui, T., Yamamoto, A., Uchiyama, H. & Tajima, S. Carbon substituted MgB2 single crystals. Physica C 397, 7–13 (2003).

Wilke, R. H. T., Budko, S. L., Canfield, P. C., Finnemore, D. K. & Hannahs, S. T. Synthesis of Mg(B1−xCx)2 powders. Physica C 432, 193–205 (2005).

Tinkham, M. Introduction to Superconductivity, New York, NY: McGraw-Hill (1996).

Wang, X. L. et al. Significant enhancement of critical current density and flux pinning in MgB2 with nano-SiC, Si, and C-doping. Physica C 408, 63–67 (2004).

Polyanskii, A. A. et al. Magneto-optical studies on polycrystalline MgB2 bulks manufactured by different processes. IEEE Trans. Appl. Supercond. 17, 2746–2749 (2007).

Dew-Hughes, D. Flux pinning mechanisms in type II superconductors. Philos. Mag. 30, 293–305 (1974).

Dew-Hughes, D. The role of grain boundaries in determining J c in high-field high-current superconductors Philos. Mag 55, 459–479 (1987).

Eisterer, M., Zehetmayer, M. & Weber, H. W. Current percolation and anisotropy in polycrystalline MgB2 Phys. Rev. Lett. 90, 247002–247006 (2003).

Matsushita, T. Flux Pinning in Superconductors 2nd edn, Ch. 9.2, 384–386 (Springer, 2014).

Shcherbakova, O. V. et al. Sugar as an optimal carbon source for the enhanced performance of MgB2 superconductors at high magnetic fields. Supercond. Sci. Technol. 21, 015005–015011 (2008).

Yang, Y., Sumption, M. D. & Collings, E. W. Influence of metal diboride Dy2O3 additions on microstructure and properties of MgB2 fabricated at high temperature and under pressure. Sci. Rep. 6, 29306–29316 (2016).

Fuchs, G. High trapped fields in bulk MgB2 prepared by hot-pressing of ball-milled precursor powder. Supercond. Sci. Technol. 26, 122002–122006 (2013).

Naito, T., Yoshida, T. & Fujishiro, H. Ti-doping effects on magnetic properties of dense MgB2 bulk superconductors. Supercond. Sci. Technol. 28, 095009–095016 (2015).

Zou, J. et al. Numerical modelling and comparison of MgB2 bulks fabricated by HIP and infiltration growth. Supercond. Sci. Technol. 28, 075009–075017 (2015).

Eley, S., Miura, M., Maiorov, B. & Civale, L. Universal lower limit on vortex creep in superconductors Nature Materials 16 409–413 (2017)

Yamamoto, A., Ishihara, A., Tomita, M. & Kishio, K. Permanent magnet with MgB2 bulk superconductor Appl. Phys. Lett. 105, 032601–032604 (2014).

Anderson, P. W. Theory of flux creep in hard superconductors. Phys. Rev. Lett. 9, 309 (1962).

Acknowledgements

The authors acknowledge financial support from the KACST-Cambridge Joint Centre of Excellence in Advanced Materials and Manufacturing (CAMM) based at the University of Cambridge, UK. Partial financial support from Engineering and Physical Sciences Research Council, UK (Grant: EP/K031422/1) is gratefully acknowledged. The work at Tokyo University of Agriculture and Technology was supported by MEXT Elements Strategy Initiative to Form Core Research Center and by JSPS KAKENHI Grant No. JP15H05519.

Author information

Authors and Affiliations

Contributions

N.H.B., J.D. and D.C. developed this study. A.B. conducted the experimental work and wrote the manuscript. L.W. and M.X. carried out transmission electron microscopy and analysed the results. A.D. and A.Y. performed measurements on SQUID and trapped field measurements respectively. T.A., D.C, J.D., A.Y. and N.H.B. reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bhagurkar, A.G., Yamamoto, A., Wang, L. et al. High Trapped Fields in C-doped MgB2 Bulk Superconductors Fabricated by Infiltration and Growth Process. Sci Rep 8, 13320 (2018). https://doi.org/10.1038/s41598-018-31416-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-31416-3

This article is cited by

-

Green-light p-n junction particle inhomogeneous phase enhancement of MgB2 smart meta-superconductors

Journal of Materials Science: Materials in Electronics (2024)

-

Maximum reduction of energy losses in multicore MgB2 wires by metastructured soft-ferromagnetic coatings

Scientific Reports (2022)

-

BaZrO3 dopant interactions during MgB2 wire formation by modified internal magnesium diffusion process

Applied Physics A (2021)

-

Comparing of the Magnetic Force Parameters of Superconducting Maglev System Using Horizontal and Vertical PMG Geometry in Multi-Surface HTS-PMG Arrangement

Journal of Superconductivity and Novel Magnetism (2021)

-

Reproducibility of small Ge2C6H10O7-added MgB2 bulks fabricated by ex situ Spark Plasma Sintering used in compound bulk magnets with a trapped magnetic field above 5 T

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.