Abstract

Actually, MgB2 is the lightest superconducting compound. Its connection with lightweight metals like Ti (as barrier) and Al (as outer sheath) would result in a superconducting wire with the minimal mass. However, pure Al is mechanically soft metal to be used in drawn or rolled composite wires, especially if applied for the outer sheath, where it cannot provide the required densification of the boron powder inside. This study reports on a lightweight MgB2 wire sheathed with aluminum stabilized by nano-sized γ-Al2O3 particles (named HITEMAL) and protected against the reaction with magnesium by Ti diffusion barrier. Electrical and mechanical properties of single-core MgB2/Ti/HITEMAL wire made by internal magnesium diffusion (IMD) into boron were studied at low temperatures. It was found that the ultra-lightweight MgB2 wire exhibited high critical current densities and also tolerances to mechanical stress. This predetermines the potential use of such lightweight superconducting wires for aviation and space applications, and for powerful offshore wind generators, where reducing the mass of the system is required.

Similar content being viewed by others

Introduction

Although many superconducting elements and compounds have been discovered1, only few of them can be used for thermally and mechanically stabilized long length wires with high current densities. Instead of high power cables and high field magnets, superconducting wires make possible the design of powerful and lightweight superconducting stators and rotors for aircraft engines and generators2,3. Lightweight superconducting wires are also attractive in other specific areas, where the total mass is extremely important, e.g. powerful wind turbines4,5,6 or any space applications7,8. Since the discovery of superconductivity in the lightest superconductive compound MgB29, extensive efforts have been expended in the development of practical composite wires made mostly by powder-in-tube (PIT) processes and in the enhancement of their superconductive properties, particularly the critical current density (Jc) and the upper critical field (Bc). Low cost MgB2 superconductor wires operated at 4–25 K can lower the upfront and ongoing operational costs of superconducting systems. It was found that sheath materials play an important role in the determination of transport properties of the wires made by powder in tube (PIT) technique10. Cu is an ideal thermally stabilizing metal for low-Tc superconducting wires. In the case of MgB2 wires, the Cu reaction with MgB2 has to be inhibited due to a possible radical reduction of the transport current density. Therefore, a protective (i.e. diffusion) barrier has to be used (e.g. Fe, Nb or Ta) in order to avoid any reaction, namely the one between Cu and Mg11. Ti sheathed MgB2 wires were tested initially by Allessadrini12, and Ti barriers were then successfully applied for multicore MgB2 wires stabilized by Cu13,14. Al may also be an appropriate sheath material for MgB2 superconductor due to its high electrical and thermal conductivity, low cost, magnetism, and good formability. However, pure Al is mechanically soft metal to be used in drawn or rolled composite wires, especially if applied for the outer sheath, where it cannot provide the required densification of the boron powder. While Al alloys can offer improved mechanical properties, the conductivities and formability are markedly deteriorated. Furthermore, the solidus temperatures of Al alloys are much lower compared with the melting point of pure Al, which makes even more difficult the formation of MgB2 by the heat treatment of Mg and B components at ≈650 °C. The first experiment with MgB2/Al tape superconductor was made by an ex-situ PIT method without final heat treatment, but it does not allow reaching high critical current density15. Several other experiments to stabilize MgB2 wire with pure Al were also performed16,17, but the stabilization was not effective enough. Also, another solution with Al bonding on the Ti sheathed wire was not successful due to intensively oxidized surfaces of both Al and Ti18. Thermally stable ultrafine-grained Al stabilized by a small content of nano-scale Al2O3 formed in situ in Al matrix, named HITEMAL (high temperature aluminum), was produced by a powder metallurgy approach19,20. HITEMAL shows attractive mechanical and recently also electrical properties at low temperatures21. The first attempt to make an Al-stabilized MgB2 wire was made using Ta diffusion barrier and HITEMAL outer sheath22, which demonstrated the possible production of Al-sheathed MgB2 wires. It allowed to verify the utilization of Al + Al2O3 outer sheath for MgB2 wire and to show what superconducting properties, especially current densities, can be reached in medium magnetic fields. Ta barrier is really heavy material (16.69 g/cm3) for lightweight composite wire, but it has been used due to minimal reaction with Al + Al2O3 during the final heat treatment.

In this work we present original manufacturing method and properties of ultra-lightweight superconducting wire prepared by internal Mg diffusion process (IMD) into the B, which utilizes the lightest superconducting compound (MgB2 with 2.5 gcm−3) combined with the lightweight composite sheath (Al + 1.37 vol.% Al2O3 with a density of ~2.7 gcm−3) and light metallic barrier material (Ti with a density of 4.5 gcm−3). Due to lowered melting point of Al + 1.37 vol.% Al2O3 (∼ 652 °C)22 in comparison to pure Al (660 °C) and close to melting of Mg (650 °C), really specific heat treatment is needed for MgB2/Ti/HITEMAL wire. It should allow: (i) the fast formation of dense MgB2 phase23, (ii) limited Ti/Al interaction and (iii) keeping the mechanical strength of Al + Al2O3 sheath.

Results

It was shown that the melting point of Al + 1.37 vol.% Al2O3 sheath is relatively low ~652 °C22 while the temperature close to 650 °C is required for the fast formation of a dense MgB2 phase23. This could cause undesirable changes (e.g., melting or recrystallization) of the Al2O3 stabilized Al sheath. Therefore, fast ramp heat treatments (~25 °C/min) with the setting temperature 628–635 °C and overshoot up to 640–646.5 °C were applied for as-deformed Mg/B/Ti/HITEMAL wires named as wA, wB and wC, see Table 1 and Fig. 1. A transversal cross-section image of the wB wire is shown in Fig. 2(a), where the central hole (at the place of the original Mg core) and formed MgB2 layer of thickness ∼100 µm are well visible. It correlates with the kinetic of MgB2 layer formation presented by Li at al. who have calculated the time needed for the for Mg + B reaction24. Our previous experiments have confirmed this model and showed the optimal time of 8 minutes for HT at 635 °C and overshoot 654 °C23. Figure 2(b) shows a thin intermetallic reaction layer with a thickness of ∼1 µm at the Ti/Al interface of the wB wire subjected to heat treatment (HT) temperature 628 °C/10 min.

The local EDS analysis confirmed Al3Ti phase, which is in good agreement with other studies25. A comparable Al3Ti layer of a similar thickness was observed for the wA and wB wires that were heat treated for 10 min, while for the wC wire that was annealed for 30 min, the layer increased to ∼4 µm (see Table 1). Formation of the Al3Ti phase at the Ti/Al interface may significantly decrease thermal and electrical transport between the MgB2 core and outer Al + Al2O3 sheath. To minimize the Al3Ti phase formation, a short heat treatment regime with a very fast initial ramp is preferred.

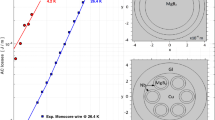

The critical current densities of the compared wires wA-wC were determined from the magnetic loops by using Bean’s critical state model to establish a relationship between the width of the hysteresis loop Δm and the critical current density. Assuming a full penetration of the measured sample by a magnetic field, the particular form of the formulae relating Δm to Jc can be derived with regard to the current flow geometry. In the case of a cylindrical MgB2 core, the critical current density is obtained according to:

where ΔM is the width of the hysteresis loop divided by the volume of the MgB2 core, and d is the core diameter. For the wires made by the IMD process resulting in an annular MgB2 core shown in Fig. 1(a), all formulae must be multiplied by a factor considering the hollow core geometry26. The factor is \((1-\frac{{d}_{I}^{2}}{{d}_{O}^{2}})/(1-\frac{{d}_{I}^{3}}{{d}_{O}^{3}})\), where dI and do is the inner and outer diameter of the MgB2 core and the formula for Jc is:

Filament dimensions dI and do in wB wire are 0.00423 and 0.00625 cm, respectively. Figure 3(a) shows the critical current densities of the wB wire measured by a vibrating sample magnetometer at external magnetic fields 1–9 T (in B|| and B⊥) and temperatures 5–25 K. Jc(B, T) values of the wire in the perpendicular field are identical with Jc of a single core MgB2/Ti/Cu wire made by the IMD process and annealed at 640 °C/60 min27, which is a result of a sufficiently dense boron powder deformed inside the Al + Al2O3 sheath. The dotted lines present Jc values at a parallel field, which are very similar to the perpendicular one for temperatures 5–15 K, and only slightly lowered at temperatures above 20 K. A small Jc difference between the perpendicular field direction (with currents flowing along the tubular core) and parallel one reflects an excellent homogeneity of the MgB2 compound created by the IMD process. An opposite behavior with large Jc differences between B|| and B⊥ was observed in MgB2 made by in-situ PIT process, which was attributed primarily to a texture caused by wire deformation and resulting to different ‘porosity’ or ‘connectivity’ in longitudinal and transversal direction28. Figure 3(b) shows the transport engineering current densities (calculated to the whole cross-section of the wire) at 4.2 K for wA, wB and wC samples. The highest Je is measured for the wA due to the Tmax = 646.5 °C, which is close to the melting point of Mg22. The mechanism of presented IMD process at temperatures below 650 °C considers fast Mg diffusion into boron powder and subsequent creation of MgB2 phase23,24. The resistive transitions of compared MgB2 layers are similar (see the insert in Fig. 1), but the systematic decrease of critical temperature (Tc = 37.00 K - wA, 36.89 K - wB and 36.87 K - wC) and small widening of R(T) transition (ΔTc = 1.90 K - wA, 2.03 K - wB and 2.15 K - wC) can be observed. It reflects the composition and purity of created MgB2 phase and correlates with Je values shown by Fig. 3(b).

Only slightly lowered peak temperature of 642.5 °C for the wB wire resulted in around 10% lower Je compared with that of the wA wire, but Je of wC wire is lowered by 37% at field 6 T in comparison to wA. Figure 3(b) shows also the relation between the transport and magnetic Je (from VSM), for the wB wire, where a falling off of the magnetic Je from the transport one was observed. It can be rationalized considering a different current flow combined with no fully identical connectivity along and across the core axis.

Changes in the critical currents of present wires subjected to axial tension at 4.2 K are shown in Fig. 4. Due to a larger thermal contraction of Ti and Al compared with that of MgB2, cooling down to 4.2 K results in compression stress which acts on the MgB2 layer and reduces the critical temperature and current1,29. Applied axial tension partially compensates the pressure stress and consequently critical current increases up to a level of irreversible strain (εirr), where the breaking of brittle MgB2 leads to a radical degradation. The εirr value defines the maximum strain at which the current still remains reversible29. One can see a considerable effect of applied heat treatment on the irreversible strain in Figure 4. The wA wire with the highest peak temperature of 646.5 °C behaves mechanically as the weakest, and consequently the lowest εirr = 0.166% is measured due to the apparent softening of the outer sheath.

However, the wC wire annealed at the peak temperature of 640 °C has the highest εirr = 0.342%, which is even comparable with the strain limit of a single-core IMD wire reinforced with a GlidCop sheath, see the filled circles in Fig. 4. GlidCop is dispersion strengthened copper which was already effectively used for some MgB2 wires23. Table 1 shows the irreversible strain εirr and irreversible stress σirr measured for wA-wC, which are correlating well with the sheath microhardness HV0.005 – the lowest for wA ∼ 43 GPa and the highest for wC ∼ 68 GPa. It was already shown that strain and stress tolerances (σirr and εirr) of MgB2 wires are dominantly affected by mechanical strength of the outer sheath30. Therefore, structural changes in outer sheath of wires wA-wC were examined by transmission electron microscopy.

The as-deformed Al + Al2O3 consists of Al grains intensively elongated in the wire drawing direction and transversal structure shows a randomly distributed nanometric Al2O3 dispersoids, see Fig. 5(a). The nano-dispersoids stemmed from native amorphous (am)-Al2O3 layers on as-atomised Al powders20. The induced shear deformation broke up the Al2O3 layers into am-Al2O3 platelets during the cold working steps21, and some remnants of the fractured am-Al2O3 platelets remained at high angle grain boundaries, see the white arrow in Fig. 5(a). However, a majority of the am-Al2O3 platelets transformed into nanometric crystalline Al2O3 dispersoids during the cold working were found at both, the Al grain boundaries and within the Al grain interiors, see the black arrow in Fig. 5(a). During the final heat treatment Al grains coarsening is observed. High angle grain boundaries are preferentially eliminated with increasing temperature, but low angle grain boundaries are still stabilized by Al2O3 dispersoids and are sustained even higher annealing temperatures, see Fig. 5(b). The black arrows show co-localization of low angle grain boundaries with Al2O3 dispersoids in the wA wire sheath.

Figure 6 shows TEM bright field images of transversal sections of the Al + Al2O3 sheath in the heat-treated wires wA - wC (a-c) in comparison to as-deformed one shown by Fig. 6(d). The TEM micrographs demonstrate the different microstructure upon annealing with the peak temperature between 640 °C and 646.5 °C. While Al grains of as-deformed wire have generally equiangular shape of averaged size dav ∼ 470 nm, enlarged and/or elongated (not equiangular) grains are visible in wB and wC wires due to grains coarsening. High angle grain boundaries of Al + Al2O3 sheaths are yet well stabilized by Al2O3 dispersoids at heat treatment temperature Tmax = 640 °C, see Fig. 6(c), where nearly doubled grain size dav ∼ 950 nm in comparison to as-deformed sheath is found. The outer sheath of wC wire stays polycrystalline with the structure similar to the as-deformed one, see Fig. 6(d). The grain size structure of wB sheath shown by Fig. 6(b) is more affected by annealing only ∼10 °C below the melting of Al + Al2O3 and dav ∼ 1380 nm was estimated for Tmax = 642.5 °C. Figure 6(a) shows that grain boundaries in wA (5.5 °C bellow the melting of Al + Al2O3) are not more stabilized and a big Al grains with sub-grains and low angle grain boundaries with localized Al2O3 dispersoids are present. Consequently, the correct estimation of dav for wA wire is not possible. Observed structural changes and grains coarsening leads to mechanical softening of heat treated Al + Al2O3 sheaths, which is accompanied by the decreased sheath micro-hardness (see Table 1) in comparison to not annealed Al + Al2O3 wire with HV0.005 ∼ 70 GPa22.

Discussion

The presented microstructural study clearly illustrates that the different Al grain structure of the Al + Al2O3 sheaths strongly affects the wire responses to axial tension. The Al + Al2O3 is a suitable material for a sufficiently strong superconducting wire, but conditions of the final heat treatment have to be controlled very precisely. Figure 4 shows the different strain tolerances, which are strongly affected by the applied annealing influencing the sheath microstructure (see Figs 5 and 6). While the apparent critical current degradation in the wA wire occurred at the tensile stress of 141 MPa due to not more stabilized grain boundaries by Al2O3 dispersoids, the wC wire is able to withstand much higher stress of 214 MPa. Due to polycrystalline structure and grain size dav ∼ 950 nm, the mechanical strength of the wC wire was by ~25% higher than determined for the wA wire, which is characterized by big grains with sub-grains and low angle grain boundaries. The averaged grain size of wB sheath (Tmax = 642.5 °C) is ∼1380 nm, which is larger than for wC and consequently σirr = 172 MPa is measured, see Table 1. Similar correlation (sheath softening) is observed by the micro-hardness (HV0.005) data, which decreased from HV0.005 = 68 to 43 as the peak temperature increased from 640 to 646.5 °C, respectively (see Table 1). Nevertheless, the achieved HV0.005 = 43 for the Al-Al2O3 sheath of the wA wire remains still much higher than that of pure Al (HV0.005 = 27)21 due to a dense net of low angle grain boundaries effectively stabilized by Al2O3 dispersoids. The observed differences are attributed only to structural changes in the Al + Al2O3 material (and formation of thicker Al3Ti layer) subjected to different heat treatment. Therefore, precisely chosen heat treatment has to be applied to form a high current density MgB2 core along with a high strength Al + Al2O3 sheath and Ti diffusion barrier with a limited interfacial reaction at the sheath interface.

Calculation of conductor mass based on the MgB2/Ti/Al + Al2O3 can lead to at least 2.5 times weight reduction when compared with a typical MgB2/Nb/Cu wire of the same cross-sectional dimensions. This clearly outlines the potential of the lightest MgB2/Ti/Al + Al2O3 superconducting wire, when compared with any other metallic or ceramic superconductors. Consequently, presented MgB2 wire meets demanding requirements on electrical and mechanical properties of superconductors for efficient superconductive and light-weight applications.

Methods

A single-core MgB2 wire was fabricated by internal magnesium diffusion (IMD) into a boron process. Pure Mg99.99% rod 2.9 mm in diameter was precisely positioned in the central axis of a Ti99.99% tube with 5.5 mm inner diameter and 7.2 mm outer diameter. The free volume between the Ti tube and Mg rod was filled by a B99.8% powder (<1 µm size) in a glove-box under pure Argon atmosphere. The Mg/B/Ti composite was rotary swaged down to 6.2 mm diameter, cleaned, and inserted into a HITEMAL tube with 6.3 mm inner diameter and 9.1 mm outer diameter, that was machined from an as-extruded Al + 1.37 vol.% Al2O3 rod21. The Mg/B/Ti/Al + Al2O3 composite rod was rotary swaged down to 7.5 mm and then groove rolled to a rectangular wire with a cross-section of 1.02 × 1.02 mm2. A heat treatment process was applied at 300 oC for 30 min during the groove rolling process each time after reaching around 50% area reduction. The volume composition of the as-deformed wires corresponded to around 11% Mg, 12% B, 27% Ti, and 50% Al + Al2O3 outer sheath. The following final heat treatment was applied under Ar atmosphere at: (i) 632 °C for 10 min (wA wire); (ii) 628 °C for 10 min (wB wire); and (iii) 635 °C for 30 min (wC wire), with the peak temperatures of 646.5, 641.5 and 640 °C, respectively, see Fig. 1 and Table 1.

Hysteresis loops measured by a vibrating sample magnetometer (VSM) option in PPMS of Quantum Design system were recorded between −2 and +9 T with a constant field sweep of 6.3 mT/s in a temperature range of 5–25 K (at 5 K steps), and the field directed perpendicular and parallel to the wire axis. Using Bean’s critical state model, the critical current density Jc-mag was determined. Resistive transitions were measured by a standard four-probe method with DC current magnitude of 100 mA. Critical temperature (Tc) and the width of transition (ΔTc) were determined from R(T) dependences shown by the insert in Fig. 1. Transport critical currents were measured at liquid He temperature and an external magnetic field from 4.0 to 8.0 T using standard DC measurement with 1 μVcm−1 criterion for Ic values. A free-standing short sample (∼50 mm) configuration was used for the tensile load tests of the wires at 4.2 K29. The electro-mechanical characteristics: Ic versus the tensile strain (ε) and the stress-strain curves σ(ε) were measured at a constant external magnetic field of 6 T. Scanning electron microscopy (SEM, JOEL 7600 F) with energy dispersive spectrometry (EDS, Oxford Instruments X-Max 50) was used to characterize polished transversal-sections of the heat-treated wires. Transmission electron microscopy (TEM) observations were made using JEOL JEM 1200FX microscope. TEM specimens were prepared by mechanical grinding and polishing followed by Ar beam ion milling using GATAN PIPS II. The transversal Al grain size (dav) was determined by image analyse of multiple bright filed TEM micrographs.

References

Buzea, C. & Yamashita, T. Review of the superconducting properties of MgB2. Sup. Sci. and Technology 14, R115 (2001).

Masson, P. J., Brown, G. V., Soban, D. S. & Luongo, C. A. HTS machines as enabling technology for all-electric airborne vehicles. Sup. Sci. and Technology 20, 748–756 (2007).

Masson, P. J. et al. Superconducting Ducted Fan Design for Reduced Emissions Aero propulsion. IEEE Trans. Appl. Supercond. 19, 1662–1668 (2009).

Abrahamsen, A. B. et al. Superconducting wind turbine generators. Sup. Sci. and Technology. 23, 034019 (2010).

Park, D. H., Choi, Kim, S. W. & Lee, J. H. J. M. Cryogenic mechanical behavior of 5000- and 6000-series aluminum alloys: Issues on application to offshore plants. Cryogenics 68, 44–58 (2015).

Marino, I. et al. Lightweight MgB2 superconducting 10 MW wind generator. Sup. Sci. and Technology 29, 024005 (2016).

Spillantini, P. Active shielding for long duration interplanetary manned missions. Adv. Space Res. 45, 900–916 (2010).

Calvelli, V., Musenich, R., Tunesi, F. & Battiston, R. A Novel Configuration for Superconducting Space Radiation Shields. IEEE Trans. Appl. Supercond. 27, 0500604 (2017).

Nagamatsu, J., Nagakawa, N., Muranaka, T., Zenitani, Y. & Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 410, 63–64 (2001).

Schlachter, S. I. et al. Suitability of sheath materials for MgB2 powder-in-tube superconductors. Physica C 445–448, 777–783 (2006).

Kováč, P., Hušek, I., Melišek, T., Kulich, M. & Štrbík, V. MgB2 composite wires with Fe, Nb and Ta sheaths. Sup. Sci. and Technology 19, 600–605 (2006).

Alessandrini, M. et al. High critical current of Ti-sheathed MgB2 wires for AC and weight-critical applications. Sup. Sci. and Technology 19, 129–132 (2006).

Kováč, P., Hušek, I., Melišek, T. & Holúbek, T. Properties of stabilized MgB2 composite wire with Ti barrier. Sup. Sci. and Technology 20, 771–776 (2007).

Kováč, P., Hušek, I., Melišek, T., Kopera, L. & Polák, M. J. Supercond. and Novel Magn. 26, 2109–2114 (2013).

Nakane, T., Kitaguchi, H. & Kumakura, H. Ex situ fabrication of MgB2/Al tapes with high critical current density. Sup. Sci. and Technology 19, 528–533 (2006).

Dou, S. X., Collings, E. W. & Shcherbakova, O. & Shcherbakov A. Aluminium-stabilized magnesium diboride - a new light-weight superconductor. Sup. Sci. and Technology 19, 333–337 (2006).

Hušek, I., Kováč, P., Melišek, T. & Kopera, L. Thermally stabilized MgB2 wires with different barriers. Cryogenics 51, 550–554 (2011).

Musenich, R. et al. Ti–MgB 2 Conductor for Superconducting Space Magnets. IEEE Trans. Appl. Supercond. 26, 6200204 (2016).

Balog, M., Nagy, J., Iždinský, K. & Simančík, F. Compaction of ultra-fine Al powders. Int. J. of Mat. and Product Technology. 23, 69–78 (2005).

Balog, M., Simancik, F., Walcher, M., Rajner, W., Poletti, C. Extruded Al-Al2O3 composites formed in situ during consolidation of ultrafine Al powders: Effect of the powder surface area. Materials Science and Engineering A. 529, 131–137 (2011).

Kováč, P. et al. Properties of Al–Al2O3 metal matrix composites aimed for low temperature applications. Cryogenics 87, 58–65 (2017).

Kováč, P. et al. Lightweight Al stabilized MgB2 conductor made by IMD process. Sup. Sci. and Technology 30, 115001 (2017).

Kováč, P., Hušek, I., Melišek, T., Kopera, L. & Kulich, M. Fast creation of dense MgB2 phase in wires made by IMD process. Sup. Sci. and Technology 29, 10LT01 (2016).

Li, G. Z., Sumption, M. D. & Collings, E. W. Kinetic analysis of MgB2 layer formation in advanced internal magnesium infiltration (AIMI) processed MgB2 wires. Acta Mater. 96, 66–71 (2015).

Krizik, P. et al. Ultrafine-grained Al composites reinforced with in-situ Al3Ti filaments. Materials Science and Engineering A. 657, 6–14 (2016).

Brunner, B. et al. Critical Current Density and Pinning Behaviour of Mono-core MgB2 Wires Prepared by Internal Magnesium Diffusion and In-situ Powder-in-Tube Method. Physica C 505, 39–43 (2014).

Kováč, P., Hušek, I., Melišek, T., Kopera, L. & Kováč, J. Critical currents, I c-anisotropy and resistance to stress of MgB2 wires made by internal magnesium diffusion. Sup. Sci. and Technology 27, 065003 (2014).

Shi, Z. X. et al. Sup. Sci. and Technology 23, 045018 (2010).

Kopera, L., Kováč, P. & Melišek, T. Electromechanical characterization of selected superconductors. Sup. Sci. and Technology 21, 115001 (2008).

Kováč, P. et al. Behaviour of filamentary MgB2 wires subjected to tensile stress at 4.2 K. Sup. Sci. and Technology 26, 105028 (2013).

Acknowledgements

This work was supported by the Slovak Scientific Agency under the APVV-14-0522 project and the VEGA 2/0129/16 project.

Author information

Authors and Affiliations

Contributions

P.K. and I.H. participated in technological verification. P.K. prepared the manuscript and Figures 2–3. A.R. performed SEM and TEM microscopy analyses and prepared Figures 1, 4–5. M.K., J.K., T.M. and L.K. performed electrical and mechanical characterization at low temperatures. M.B. and P.Kr. fabricated extruded Al + Al2O3 material for the outer sheath. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kováč, P., Hušek, I., Rosová, A. et al. Ultra-lightweight superconducting wire based on Mg, B, Ti and Al. Sci Rep 8, 11229 (2018). https://doi.org/10.1038/s41598-018-29354-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-29354-1

This article is cited by

-

Maximum reduction of energy losses in multicore MgB2 wires by metastructured soft-ferromagnetic coatings

Scientific Reports (2022)

-

BaZrO3 dopant interactions during MgB2 wire formation by modified internal magnesium diffusion process

Applied Physics A (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.