Abstract

Pulsed Laser Deposition is a commonly used non-equilibrium physical deposition technique for the growth of complex oxide thin films. A wide range of parameters is known to influence the properties of the used samples and thin films, especially the oxygen-vacancy concentration. One parameter has up to this point been neglected due to the challenges of separating its influence from the influence of the impinging species during growth: the UV-radiation of the plasma plume. We here present experiments enabled by a specially designed holder to allow a separation of these two influences. The influence of the UV-irradiation during pulsed laser deposition on the formation of oxygen-vacancies is investigated for the perovskite model material SrTiO3. The carrier concentration of UV-irradiated samples is nearly constant with depth and time. By contrast samples not exposed to the radiation of the plume show a depth dependence and a decrease in concentration over time. We reveal an increase in Ti-vacancy–oxygen-vacancy-complexes for UV irradiated samples, consistent with the different carrier concentrations. We find a UV enhanced oxygen-vacancy incorporation rate as responsible mechanism. We provide a complete picture of another influence parameter to be considered during pulsed laser depositions and unravel the mechanism behind persistent-photo-conductivity in SrTiO3.

Similar content being viewed by others

Introduction

The field of transition metal oxides has opened various research opportunities over the last decade due to their manifold interesting properties (e.g. electronic and magnetic)1,2. As the importance of complex metal oxide research has grown, there has been a commensurate increase in importance of pulsed laser deposition (PLD). PLD has proved a versatile and powerful tool for the deposition and epitaxial growth of this class of multicomponent materials2,3,4.

The properties of these transition metal oxides are highly depended on their stoichiometry and the presence of point defects. Prominent examples are oxygen vacancy induced conduction5,6,7,8, and the suppression of donor doping by cation vacancies9,10,11,12,13,14,15,16. Deposition of high quality epitaxial oxide films is normally enabled by using oxide single crystal substrates. It has been shown that the point defect density of both, the thin film and the substrate, play a crucial role. The substrate can, for example, strongly contribute to the conductivity if a significant amount of oxygen vacancies is generated during growth17,18,19,20.

The point defect densities within thin film and substrate induced during PLD growth generally differ strongly from the expected equilibrium values due to the involved complex non-equilibrium processes. For SrTiO3 (STO), one of the most commonly used transition metal oxide substrates, the influence of various process parameters on the formation of oxygen vacancies has been investigated in great detail20,21,22,23,24,25,26. The formation of oxygen vacancies is especially relevant when working at low deposition pressures. Up to now, several reasons were found for the equilibrium exceeding formation of oxygen vacancies: the oxidization of the oxygen deficient thin film via the substrate resulting in the formation of oxygen vacancies in the substrate21,22,23, impinging species of the plasma plume resulting in an oxygen removal24,25,26, and even an influence of the applied measurement devices20.

While the effect of impinging species from the PLD plasma plume has been recognized and studied24,25,26, the possible effect of UV-radiation emitted by the plume has not been considered, although the plasma plume is known to emit UV-radiation4. Further UV radiation is known to induce persistent photo conductivity27,28, as well as to enhance the oxygen incorporation rate29,30,31,32,33, in STO.

One obstacle with respect to evaluate the influence of UV-radiation during PLD growth is the problem of separating its influence from that of the impinging species within the plume. In order to allow such a separation, we designed a new sample holder, allowing UV-radiation to reach the sample, but not the impinging species. STO samples are processed in this new holder at typical low pressure PLD conditions, one sample with an ignited plume and, as a reference, one without. Hall measurements show an increase in charge carrier concentration in STO samples exposed to the plume UV-radiation, compared to the reference sample. Cross sectional scanning Kelvin probe microscopy (SKPM) measurements revealed a difference in the carrier concentration profile between the two samples. Variable energy positron annihilation lifetime spectroscopy (VEPALS) measurements detect Ti vacancy – oxygen vacancy complexes (V Ti V O ) in the near-surface region of both types treated STO samples.

Results

The first step towards an understanding of the role of UV radiation during PLD processes is to characterize the spectrum. The UV-spectrum of the plasma plume resulting from the PLD ablation of an STO target is simulated using Saha-LTE. To obtain the ionization levels from the NIST atomic spectra database needed for this simulation the electron temperature and density in the plasma plume are required34. The electron temperature (kT) in the plasma plume can be derived from the power density of the used ablation laser, \((1\pm 0.5)\times {10}^{8}\tfrac{{\rm{W}}}{{{\rm{cm}}}^{2}}\), using the corresponding equation by Schriever et al.35, to be 0.885 ± 0.135 eV. The electron density in the plasma plume is estimated to be ≈1 × 1018 cm−3 as given by Gilgenbach et al.36. The simulated UV-radiation spectrum of the plasma plume resulting from ablation of an STO target is shown in Fig. 1(a). Strong emission lines at ≈215 nm due to strontium are observed, and will contribute considerable intensity to the emitted UV radiation.

(a) Simulated spectra in the UV regime for an STO plasma plume. (b) Sample holder designed to separate the influence of the UV-radiation and the impinging species from the plasma plume during PLD. The front sapphire window is transparent to UV-radiation, but prevents the ablated atomic and molecular species of the plume from reaching the STO sample.

The sample holder designed for this study is shown in Fig. 1(b), the laser plume is blocked by a sapphire window which is transparent to UV-radiation ≥150 nm37. The STO sample is separated from the window by four 1 × 1 × 0.5 mm3 STO spacers, this exposes the sample surface to a gas exchange volume. The STO sample is mounted into the holder with a Ni-foil placed between the rear of the sample and a second sapphire window. The foil acts as an absorber for the infrared diode laser heater which provides precise control of the sample temperature. The back sapphire window enables transmission of the IR-radiation and prevents the ablation of the Ni-foil. Finally a spacer is placed between the second window and the holder frame to tighten the whole stack and improve heat transfer.

Experiments were performed on TiO2-terminated STO samples38 heated to 800 °C and in chamber pressure of 10−5 mbar oxygen for one hour. The sample temperature is rapidly quenched to room temperature by switching off the laser heater (cool down time ≈65 s). These are typical conditions for low pressure growth of oxide thin films, for which we showed in our earlier studies no reoxidization appears even after one hour20. At the same time, quenching restores as best as possible the defect state obtained immediately after the growth, and, hence allows to decouple growth phenomena from thermodynamic phenomena, such as reoxidation kinetics addressed in our previous work19. The effect of the UV-radiation from the plasma plume was then investigated by ablating an STO single crystal target using a excimer laser with a wavelength of 248 nm and a 5 Hz pulse repetition rate. Laser ablation was maintained for the 1 h period and the STO target was rotated at 5 rpm. Samples were prepared with and without the presence of the laser plume.

The sheet carrier concentration, n S , of the processed STO samples, with and without exposure to UV-irradiation, were measured using a Hall measurement system. Measurements were performed immediately following processing and after 50 days of storage in air for at least four equally treated samples. The averaged results including the standard deviation are shown in Table 1. Both the UV-irradiated and the non-irradiated samples exhibit a high sheet carrier concentration immediately after preparation. It is well known that annealing of STO at 10−5 mbar can result in the reduction of the samples20,39,40,41. The sheet carrier concentration of the UV-irradiated samples, however, is approximately twice that of the non irradiated samples immediately after processing. More strikingly, after 50 days the difference between the two types of samples becomes marked. The sheet carrier concentration of the UV-irradiated samples is unchanged, while the concentration in the non-irradiated samples has fallen below the measurement limit (<1010 cm−2).

A similar behavior was observed for samples treated at different oxygen pressure. Samples processed at 10−4 mbar oxygen showed the same behavior as samples processed at 10−5 mbar with a 50% lower sheet carrier concentration. Samples processed at 10−6 mbar showed an increased carrier concentration and no time dependence during storage in air. It can thus be assumed that their whole bulk was reduced. Samples processed at 10−3 mbar, however, showed no signs of reduction, which is in accordance with our previous results19. In the following we will exemplary discuss the samples processed at 10−5 mbar as they show the most pronounced differences between irradiated and non-irradiated samples, while having a high initial sheet carrier concentration.

In order to deliminate our results from conductivity contributions generated by photo-induced carriers only, we have carried out reference experiments at room temperature and 10−5 mbar, where photo-induced carriers may be generated by UV irradiation, while the kinetics of ionic defect formation limits the photo-induced formation of oxygen vacancies to the very-surface region. This is of high interest, as a reduction of STO is commonly also observed for room temperature depositions25,42. However no reduction of the substrates was observed without the presence of impinging species.

The higher sheet carrier concentration and its persistence after 50 days storage provide evidence that the STO sample defect structure, in particular the oxygen vacancy concentration, is altered significantly by the UV-irradiation from the plasma plume during low pressure processing.

The question arises, whether the carrier concentration is homogeneously distributed through the volume of the sample, or if a concentration profile results. To investigate the depth dependence of the carrier concentration cross-sectional SKPM measurements were performed 10 days after processing. The results are shown in Fig. 2. Figure 2(a) shows the topography image for orientation (top) and the surface potentials for the UV irradiated sample (center) and the non UV irradiated sample (bottom). With the help of the surface potentials the local carrier concentration can be determined, Fig. 2(b) 43. The carrier concentrations near the surface for the UV-irradiated and non-irradiated samples are comparable, however, while the UV-irradiated sample exhibits a very shallow depth profile, the non-irradiated sample exhibits a rapid decrease within the first 4 μm. In consequence, it can be inferred that the oxygen vacancy concentration profile resulting from low pressure annealing with UV-irradiation is markedly different from that for the samples similarly annealed but not exposed to UV-irradiation.

(a) The surface potentials below the STO surface (0 μm) measured by cross sectional SKPM including a topography image for orientation. (b) The local carrier concentration with depth below the STO surface determined via the surface potential. Samples exposed to UV-irradiation during low pressure anneal (blue), and samples low pressure annealed but without UV exposure (red).

The observation from the non-UV-irradiated samples that the sheet carrier concentration decreased below the measurement limit after 50 days (Table 1) is consistent with the restriction of the initial carrier profile to the top few microns (Fig. 2(b)). Using the oxygen-vacancy diffusivity determined for STO by De Souza et al.7, it is found that after 50 days at room temperature the diffusion length of oxygen vacancies is ≈10 μm. In consequence, the low pressure annealed sample not exposed to UV-irradiation can re-oxidize, returning to the insulating state, while the near constant depth dependent concentration of the UV-exposed sample is not detectably altered.

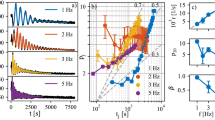

To gain further insight on the defect content of the near surface region of the samples VEPALS measurements were performed using the PLEPS instrument on the neutron induced positron source (NEPOMUC) beamline at the Heinz Maier-Leibnitz Zentrum Munich research reactor44,45. The spectra were best fitted using three positron lifetime components, a reduced bulk lifetime and two vacancy-related defect components. The defect component results for positron implantation energies between 10 keV and 18 keV, which correspond to mean implantation depths varying between approximately 300 to 800 nm, are shown in Fig. 3. The second lifetime component was found to be approximately 225 ± 6 ps, this is in good agreement with the density functional theory (DFT) calculated value for the Ti-vacancy oxygen vacancy complex, VTiVO, of 225 ps46. A significant increase in trapping to this defect was observed for the UV-irradiated low pressure annealed sample, compared to the sample annealed without UV-irradiation (samples stored in air for >50 days). The oxygen monovacancy is normally expected to be positively charged and hence not to trap positrons. If this was occurring a defect lifetime of approximately 160 ps would be expected47. The lifetime of the Ti vacancy in STO is approximately 180 ps, while that for the Sr vacancy is 280 ps47. The increase in the intensity of the VTiVO lifetime component observed here (Fig. 3) can only result from either an increase in the defect trapping coefficient, which would require a change of the charge state of the defect to a more negative value, or from an increase in the concentration of defects in the low pressure annealed sample exposed to UV-irradiation compared to the non-UV-irradiated sample. An increase in the concentration of VTiVO defects is consistent with an increase in the oxygen vacancy concentration in the UV-exposed sample.

The two defect components obtained from three lifetime component free fits of the PALS spectra for positron implantation energies between 10 and 18 keV for a sample exposed to UV-irradiation during low pressure anneal (up triangle, blue), and a sample annealed but without UV exposure (down triangle, red). The inset shows a VTiVO vacancy complex.

Figure 3 also shows the results for the third lifetime component, this has negligible value for the non-UV-irradiated sample, but there is evidence of trapping to a vacancy cluster defect with an approximate lifetime of 500 ± 40 ps in the UV-exposed sample. Positron trapping vacancy cluster defects involved on the order of 10–20 vacancies have been previously observed in STO thin films48. Trapping to vacancy cluster defects in the UV-exposed sample supports the presence of an increase in oxygen vacancy defects compared to the non-UV-exposed sample.

Discussion

Considering all the results described above we propose a mechanism by which the UV radiation of the plasma plume influences STO. The VEPALS measurements observe an increase in positron trapping to oxygen vacancy containing vacancy complexes providing evidence that an increase in oxygen vacancy concentration is responsible for the increase in conductivity. The very different depth dependent carrier concentration profiles obtained from the cross sectional SKPM provide further evidence for the presence of much higher concentration of oxygen vacancies within the volume of the UV irradiated sample compared to the non UV irradiated sample. The temperature and pressure environment for both samples was equal. Further the formation of interstitials in STO can be excluded restricting the formation of oxygen vacancies to the surface6. Hence we conclude that the UV irradiation enhances the oxygen vacancy incorporation rate at the surface. The oxygen vacancy incorporation can be described by Equation 1 5,6,7,8 in the Kröger-Vink notation49.

In the same way the incorporation of oxygen can be described by Equation 2 5,6,7,8 in the Kröger-Vink notation49.

The incorporation of oxygen (Equation 2) in reality is a multi step reaction including the adsorption of molecular oxygen, electron transfer, O-O bond dissociation and incorporation of atomic oxygen into oxygen vacancies. However, in the case of sufficient oxygen vacancies being present the electron transfer is considered as the rate limiting step31,50. Considering this, the known UV-enhanced oxygen incorporation rate for STO is under consideration of Equation 2 explained by additional electrons provided by the electron hole generation of the UV radiation (Equation 3)29,30,31,32.

In a similar fashion the hole transfer can be considered the rate limiting step for the incorporation of oxygen vacancies (Equation 1) in case of sufficient lattice oxygen being present. Considering Equation 3 the enhanced oxygen vacancy incorporation can be attributed to the generation of additional holes by the UV radiation. We can consequently explain the persistent photo conductivity in STO, which has been discussed in literature controversially28, by an increased oxygen vacancy incorporation rate triggered by the generation of additional holes. Considering Equations 1, 2 and 3 we can not only explain the oxygen vacancy incorporation by the UV irradiation of the plasma plume observed in our experiments, but we can equally explain the enhanced oxygen incorporation in presence of the plasma plume reported in literature51,52. This in turn explains, why no UV induced reduction was observed at 10−3 mbar. The absence of conductivity for samples processed at room temperature may be explained by the reoxidization of the UV induced oxygen vacancies upon air exposure, as they are restricted to the surface due to the limited kinetic at such temperatures53. It further shows that the holes and electrons generated by the UV radiation of the plume are not persistent and thus do at best introduce perishable conductivity. Only if they participate in the chemical reduction of the sample persistent photo conductivity seems observable.

Conclusion

Summarizing, we have been able to separate the influence of the UV-irradiation accompanying the PLD laser plume on the oxide sample from the possible effects caused by the impinging growth species. STO samples were exposed to typically low pressure oxide film growth PLD conditions with and without an ignited plume. Our specially designed holder enabled samples to be prepared without being exposed to impinging species, but at the same time being exposed to the UV radiation. Marked differences in the carrier concentration profile and variation with time were observed. The UV-exposed samples demonstrated a high carrier concentration that was nearly constant with both depth and time. By contrast the non-UV-exposed STO samples showed a carrier concentration that decreased strongly with depth and time. The results suggest that the oxygen vacancy concentration is higher and that the profile with depth is markedly shallower in the UV-exposed samples compared to the non-UV-irradiated samples. The depth dependent positron lifetime measurements detect an increase in trapping to VTiVO divacancies in the UV-exposed sample consistent with an increased oxygen vacancy concentration. We have clearly shown that the UV radiation emitted by the plasma plume during pulsed laser deposition of oxide thin films plays a key role for their properties. The mechanism behind this was identified as a UV enhanced oxygen vacancy incorporation rate, thus also providing an explanation for persistent photo conductivity in STO reported in literature. Our studies identified the UV radiation of the plasma plume as a key influence factor on the redox-processes relevant for the oxidization state of oxide thin films and the underlying substrate during PLD.

Methods

The base pressure in the used PLD system was 10−8 mbar and the excimer laser is a Compex 205F - COHERENT. An IR-Diode laser heater with a wavelength of 925 nm was used as heater. The Hall measurement system is a Lakeshore 8400 Series. The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Rao, C. Transition metal oxides. Annual Review of Physical Chemistry 40, 291–326 (1989).

Christen, H. M. & Eres, G. Recent advances in pulsed-laser deposition of complex oxides. Journal of Physics: Condensed Matter 20, 264005 (2008).

Lowndes, D. H., Geohegan, D. B., Puretzky, A. A. & Norton, D. P. Synthesis Thin-Film Materials by Pulsed Deposition Laser. Science 273, 898–903 (2012).

Willmott, P. R. & Huber, J. R. Pulsed laser vaporization and deposition. Reviews of Modern Physics 72, 315–328 (2000).

Moos, R., Menesklou, W. & Hardtl, K. H. Hall-Mobility of Undoped N-Type Conducting Strontium-Titanate Single-Crystals Between 19-K and 1373-K. Applied Physics a-Materials Science & Processing 61, 389–395 (1995).

Moos, R. & Hardtl, K. H. Defect chemistry of donor-doped and undoped strontium titanate ceramics between 1000 degrees and 1400 degrees C. Journal of the American Ceramic Society 80, 2549–2562 (1997).

De Souza, R. A., Metlenko, V., Park, D. & Weirich, T. E. Behavior of oxygen vacancies in single-crystal SrTiO 3: Equilibrium distribution and diffusion kinetics. Physical Review B - Condensed Matter and Materials Physics 85, 1–11 (2012).

Gunkel, F. et al. High temperature conductance characteristics of LaAlO3/SrTiO3-heterostructures under equilibrium oxygen atmospheres. Applied Physics Letters 97, 012103 (2010).

Kozuka, Y., Hikita, Y., Bell, C. & Hwang, H. Y. Dramatic mobility enhancements in doped SrTiO3 thin films by defect management. Applied Physics Letters 97, 11–14 (2010).

Ohnishi, T., Shibuya, K., Yamamoto, T. & Lippmaa, M. Defects and transport in complex oxide thin films. Journal of Applied Physics 103, 0–6 (2008).

Son, J. et al. Epitaxial SrTiO3 films with electron mobilities exceeding 30,000 cm2 V(-1) s(-1). Nature materials 9, 482–484 (2010).

Keeble, D. J. et al. Suppression of vacancy defects in epitaxial La-doped SrTiO3 films. Applied Physics Letters 99, 97–100 (2011).

Andrä, M. et al. Oxygen partial pressure dependence of surface space charge formation in donor-doped SrTiO3. APL Materials 5, 056106 (2017).

Gunkel, F. et al. Influence of charge compensation mechanisms on the sheet electron density at conducting LaAlO3/SrTiO3-interfaces. Applied Physics Letters 100, 3–6 (2012).

Gunkel, F. et al. Space charges and defect concentration profiles at complex oxide interfaces. Physical Review B 93, 1–10 (2016).

Meyer, R., Zurhelle, A. F., De Souza, R. A., Waser, R. & Gunkel, F. Dynamics of the metal-insulator transition of donor-doped SrTi O3. Physical Review B 94 (2016).

Breckenfeld, E. et al. Effect of growth induced (non)stoichiometry on interfacial conductance in LaAlO3/SrTiO3. Physical Review Letters 110, 1–6 (2013).

Herranz, G. et al. Full oxide heterostructure combining a high- TC diluted ferromagnet with a high-mobility conductor. Physical Review B - Condensed Matter and Materials Physics 73, 216803 (2006).

Xu, C. et al. Disentanglement of growth dynamic and thermodynamic effects in LaAlO3/SrTiO3 heterostructures. Scientific reports 6, 22410 (2016).

Hensling, F. V. E., Xu, C., Gunkel, F. & Dittmann, R. Unraveling the enhanced Oxygen Vacancy Formation in Complex Oxides during Annealing and Growth. Scientific reports 7, 39953 (2017).

Lee, H. N., Seo, S. S. A., Choi, W. S. & Rouleau, C. M. Growth control of oxygen stoichiometry in homoepitaxial SrTiO3 films by pulsed laser epitaxy in high vacuum. Scientific reports 6, 19941 (2016).

Sambri, A. et al. Plasma plume effects on the conductivity of amorphous-LaAlO3/SrTiO3 interfaces grown by pulsed laser deposition in O2 and Ar. Applied Physics Letters 100, 231605 (2012).

Scullin, M. L. et al. Pulsed laser deposition-induced reduction of SrTiO3 crystals. Acta Materialia 58, 457–463 (2010).

Chen, F. et al. Optical real-time monitoring of the laser molecular-beam epitaxial growth of perovskite oxide thin films by an oblique-incidence reflectance-difference technique: erratum. Journal of the Optical Society of America B 19, 1218 (2002).

Chen, Y. et al. Metallic and insulating interfaces of amorphous SrTiO3-based oxide heterostructures. Nano Letters 11, 3774–3778 (2011).

Schneider, C. W. et al. The origin of oxygen in oxide thin films: Role of the substrate. Applied Physics Letters 97, 95–98 (2010).

Mochizuki, S., Fujishiro, F. & Minami, S. Photoluminescence and reversible photo-induced spectral change of SrTiO3. Journal of Physics-Condensed Matter 17, 923–948 (2005).

Tarun, M. C., Selim, F. A. & McCluskey, M. D. Persistent photoconductivity in strontium titanate. Physical Review Letters 111, 1–5 (2013).

Merkle, R., Souza, R. A. D. & Maier, J. Optically Tuning the Rate of Stoichiometry Changes: Surface-Controlled Oxygen Incorporation into Oxides under UV Irradiation. Angewandte Chemie (International ed. in English) 4, 2126–2129 (2001).

Merkle, R. & Maier, J. Oxygen incorporation into Fe-doped SrTiO3: Mechanistic interpretation of the surface reaction. Physical Chemistry Chemical Physics 4, 4140–4148 (2002).

Merkle, R. & Maier, J. How is oxygen incorporated into oxides? A comprehensive kinetic study of a simple solid-state reaction with SrTiO3 as a model material. Angewandte Chemie - International Edition 47, 3874–3894 (2008).

Leonhardt, M., De Souza, R. A., Claus, J. & Maier, J. Surface kinetics of oxygen incorporation into SrTiO3. Journal of the Electrochemical Society 149, J19–J26 (2002).

Walch, G. et al. A solid oxide photoelectrochemical cell with UV light-driven oxygen storage in mixed conducting electrodes. Journal of Materials Chemistry A 5, 1637–1649 (2017).

Kramida, A., Ralchenko, Y., Reader, J. & Team, N. A. NIST Atomic Spectra Database, https://physics.nist.gov/asd (2018).

Schriever, G. et al. Laser-produced lithium plasma as a narrow-band extended ultraviolet radiation source for photoelectron spectroscopy. Applied optics 37, 1243–8 (1998).

Gilgenbach, R. M., Ching, C. H., Lash, J. S. & Lindley, R. A. Laser diagnostic experiments. Physics of Plasmas 1, 1619–1625 (1994).

Dobrovinskaya, E. R., Lytvynov, L. A. & Pishchik, V. Properties of Sapphire. In Sapphire: Material, Manufacturing, Applications, chap. 2, 55–176 (Springer Science + Business Media, New York, 2009).

Kawasaki, M., Maeda, T., Tsuchiya, R. & Koinuma, H. Atomic Control of the SrTiO3 Crystal Surface. Science 266, 1–3 (1993).

Kalabukhov, A. et al. Effect of oxygen vacancies in the SrTiO3 substrate on the electrical properties of the LaAlO3 SrTiO3 interface. Physical Review B - Condensed Matter and Materials Physics 75, 2–5 (2007).

Frederikse, H. P. R., Thurber, W. R. & Hosler, W. R. Electronic transport in strontium titanate. Physical Review 134, 2–5 (1964).

Peng, H. Y. et al. Effects of electrode material and configuration on the characteristics of planar resistive switching devices. APL Materials 1, 052106–7 (2013).

Chen, Y. Z. et al. Scavenging of oxygen vacancies at modulation-doped oxide interfaces: Evidence from oxygen isotope tracing. Physical Review Materials 1, 052002 (2017).

Maragliano, C. et al. Quantifying charge carrier concentration in ZnO thin films by Scanning Kelvin Probe Microscopy. Scientific Reports 4, 4203 (2014).

Hugenschmidt, C., Piochacz, C., Reiner, M. & Schreckenbach, K. The NEPOMUC upgrade and advanced positron beam experiments. New Journal of Physics 14, 055027 (2012).

Egger, W. Pulsed low-energy positron beams in materials sciences. In Dupasquier, A., Mills, A. P. & Brusa, R. S. (eds) Physics with Many Positrons, 419–449 (IOS Press, Amsterdam, 2010).

Keeble, D. J. et al. Identification of vacancy defects in a thin film perovskite oxide. Physical Review B - Condensed Matter and Materials Physics 81, 1–5 (2010).

Keeble, D. J. et al. Identification of A- and B-site cation vacancy defects in perovskite oxide thin films. Physical Review Letters 105, 3–6 (2010).

Keeble, D. J. et al. Nonstoichiometry accommodation in SrTiO3 thin films studied by positron annihilation and electron microscopy. Physical Review B 87, 195409 (2013).

Kröger, F. A. & Vink, H. J. Relations between the Concentrations of Imperfactions in Crystalline Solids. Solid State Physics 3, 310–435 (1956).

Dittmann, R. Stoichiometry in epitaxial oxide thin films. In Epitaxial growth of complex oxides, chap. 9, 231–260 (Elsevier, Cambridge, 2015).

Gomez-San Roman, R., Pérez Casero, R., Maréchal, C., Enard, J. & Perrière, J. 18O isotopic tracer studies of the laser ablation of Bi2Sr2Ca1Cu2O8. Journal of Applied Physics 80 (1996).

Perez-Casero, R. et al. Thin films of oxygen-deficient perovskite phases by pulsed-laser ablation of strontium titanate. Physical Review B - Condensed Matter and Materials Physics 75, 1–7 (2007).

Meevasana, W. et al. Creation and control of a two-dimensional electron liquid at the bare SrTiO3 surface. Nature Materials 10, 114–118 (2011).

Acknowledgements

We acknowledge funding from the W2/W3 program of the Helmholtz association. The research has furthermore been supported by the Deutsche Forschungsgemeinschaft (SFB 917 ‘Nanoswitches’). D.J.K. acknowledges European Commission Programme (RII3-CT-2003-505925). J.Z. and S.S.N. acknowledge the support of the National Science Foundation (NSF CBET-1706113). We thank R.A. De Souza for helpful discussions and critical reading. We thank J. Börgers for providing part of the inset of Figure 3.

Author information

Authors and Affiliations

Contributions

F.H. has written the manuscript. F.H., C.X., F.G. and R.D. have planned the experiments. F.H. and C.X. have designed the holder. F.H. has performed the PLD experiments and Hall measurements. D.J.K. and W.E. have performed the VEPALS measurements. J.Z. and S.S.N. have performed the SKPM measurements. S.B. and S.D. have simulated the spectra. R.D. supervised the research. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hensling, F.V.E., Keeble, D.J., Zhu, J. et al. UV radiation enhanced oxygen vacancy formation caused by the PLD plasma plume. Sci Rep 8, 8846 (2018). https://doi.org/10.1038/s41598-018-27207-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-27207-5

This article is cited by

-

Insight into structural, optical, electrical, dielectric, and photovoltaic behaviour of cerium-doped strontium titanate by a modified combustion method

Journal of Materials Science: Materials in Electronics (2023)

-

On the emergence of conductivity at SrTiO3-based oxide interfaces – an in-situ study

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.