Abstract

An interesting palladium-catalyzed carbonylative procedure for the synthesis of aromatic aldehydes from aryl iodides has been developed. By using propylphosphonic anhydride as the activator for formic acid, moderate to good yields of the corresponding aldehydes were produced with formic acid as the carbonyl and hydrogen donors. Interestingly, neither additional phosphine ligand nor inert gas protection is needed here.

Similar content being viewed by others

Introduction

Aromatic aldehyde is an analogue of impotent chemicals with various usages in countless areas including pharmaceuticals, advanced materials and so on1. Furthermore, aromatic aldehydes are applied in fine chemicals synthesis as well2. Based on their importance, many synthetic procedures have been developed by organic chemists during the past years3. Among them, name reactions including Duff reaction4, Casiraghi reaction5, Gattermann-Koch reaction, Reimer-Tiemann reaction and so on6, have been established. Additionally, the oxidation of benzylic alcohols7 and methylarenes8 has been developed for aromatic aldehydes synthesis as well. Nevertheless, drawbacks such as relatively strict reaction conditions and low reaction efficiency limited the value of those procedures.

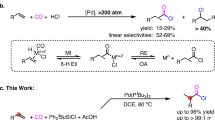

On the other hand, palladium-catalyzed carbonylation reactions represent a straightforward choice for carbonyl-containing compounds construction, including esters, amides, acids, and etc9. In the known carbonylative transformations, reductive carbonylation of aryl halides can provide aromatic and vinyl aldehydes in an efficient and straightforward manner10. In 1974, Heck and co-workers reported their pioneering studies on this topic11, since then significant improvements have been achieved during the past decades. For example, in 2006, Beller’s group reported an interesting and efficient palladium-catalyzed reductive carbonylation of (hetero)aryl bromides under the pressure of syngas (CO:H2 = 1:1)12. Even though carbon monoxide is one of the cheapest C1 source and holds non-replaceable position in large scale applications, the high toxicity, flammable and autoclave usage for its handling still limited the applications of CO gas based carbonylation in small scales. Under all those backgrounds, many new CO surrogates have been developed and applied in carbonylation reactions. The research group of Manabe prepared N-formylsaccharin and explored it as CO source for palladium-catalyzed reductive carbonylation of aryl bromides together with silane as the reductant13. The reaction efficiency is promising. Additionally, other CO sources including 9-methylfluorene-9-carbonyl chloride14, CO215, paraformaldehyde16, and acetic formic anhydride17 have been explored in this topic by different groups as well. However, the requirement of expensive reducing reagents such as silanes and metal hydrides are one of the drawbacks. More recently, we established a novel palladium-catalyzed reductive carbonylation procedure for the synthesis of aromatic aldehydes from aryl iodides18,19. By using acetic anhydride as the activator, formic acid can be used both as the CO and hydride sources. High yields of the corresponding aldehydes were produced. During our studies on carbonylation reactions, propylphosphonic anhydride comes into our view20,21,22,23,24. Propylphosphonic anhydride has been applied in carboxylic acids activation, and we believe it can activate formic acid to release CO as well. Potentially, the produced by-product, propylphosphonic acid, can acting as ligand to stabilize the active palladium center and make the addition of additional phosphine ligand not necessary. With this original idea in mind, we started the studies of applying propylphosphonic anhydride in the reductive carbonylation of aryl iodides.

Results

Initially, we chose iodobenzene as the model substrate to establish this idea (Table 1). Using the combination of Pd(OAc)2 and PPh3 as the catalytic system, with formic acid as the source of formyl group and NEt3 as the base in DMF at 100 °C for 5 hours, 10% of benzaldehyde was formed with the total conversion of iodobenzene (Table 1, entry 1). Interestingly, the reaction was totally inhibited when pyridine was used as the base (Table 1, entry 2). Then the reaction was tested without phosphine ligand, and even better yield of benzaldehyde was formed (Table 1, entry 3). Subsequently, the amounts of formic acid and propylphosphonic anhydride were tested, and 80% of benzaldehyde can be produced with higher loading of propylphosphonic anhydride (Table 1, entry 5). The conversion of iodobenzene decreased when the reaction was carried out at lower temperature (Table 1, entry 6). To our surprise, the same arrange yield of benzaldehyde can be formed with 2.5 mmol of NEt3 (Table 1, entry 7). This phenomenon implies that propylphosphonic acid as the produced by-product not necessarily to be neutralized. However, no reaction occurred in the absence of base (Table 1, entry 8). Then several other solvents were tested, but no improved yield can be obtained (Table 1, entries 9–13).

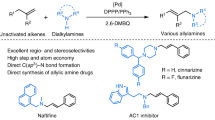

After established the optimum catalytic system, we started the scope and limitation testing. As shown in Fig. 1, moderate to good yields of the corresponding aldehydes can be produced in general. Both electron-donating and electron-withdrawing substituents on the aromatic iodides can be well tolerated. 2-Iodonaphthalene and 1-iodonaphthalene are suitable substrates as well, good yields of the desired aldehydes were produced (Fig. 1, entries 16–17). Heterocyclic substrates can be applied and smoothly transformed as well, moderate to good yields of the corresponding products can be detected (Fig. 1, entries 18–21).

Synthesis of aldehydes from aryl iodidesa. aReaction conditions: under air, aryl iodide (1 mmol), Pd(OAc)2 (1.5 mol%), formic acid (4.5 mmol), propylphosphonic anhydride (0.8 mmol), Et3N (2.5 mmol), DMF (2 mL), 100 °C for 5 h, isolated yields (see supporting information). bYield and conversion were determined by GC with hexadecane as internal standard. cIsolated yields.

Discussion

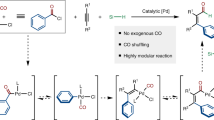

A plausible reaction mechanism is proposed and shown in Fig. 2 as well. Initially, oxidative addition of aryl iodide to Pd(0) species generates an arylpalladium complex. Then, carbon monoxide, prepared in-situ from formic acid, can be inserted into the arylpalladium complex to give an aroylpalladium species. Finally, ligand exchange of the aroylpalladium complex with another molecular of formic acid leads to an acylpalladium formic acid complex, which undergoes decarboxylation and reductive elimination to give the expected aldehyde product and regenerate the Pd(0) species.

In summary, an attractive palladium-catalyzed carbonylative procedure for transforming aryl iodides into the corresponding aldehydes has been developed. By using propylphosphonic anhydride as the activator for formic acid, moderate to good yields of the corresponding aldehydes can be formed with formic acid as the carbonyl and hydrogen donors. Interestingly, neither additional phosphine ligand nor inert gas protection is needed here.

Methods

General Procedure

Under air, Pd(OAc)2 (0.03 mmol, 1.5 mol%) was added to an oven-dried tube. Then aryl iodide (1 mmol), DMF (2 mL), HCO2H (4.5 mmol), NEt3 (2.5 mmol), and propylphosphonic anhydride (0.8 mmol; 50% in DMF) were added to the reaction tube via syringe. Subsequently, the tube was sealed and stirred at 100 °C for 5 h. Then the tube was cooling down to room temperature and 100 mg of hexadecane was added into the tube as internal standard. After properly mixed, a part of the mixture was subjected to GC analysis for determination of the yield and conversion.

References

Roempp Chemie Lexikon (Eds.: Falbe, J. & Regitz, M.), Thieme, Stuttgart (1995).

Advanced Organic Chemistry (Eds. Carey, F. A. & Sundberg, R. J.), Springer (2007).

Kantlehner, W. New Methods for the Preparation of Aromatic Aldehydes. Eur. J. Org. Chem. 2530–2546 (2003).

Ferguson, L. N. The Synthesis of Aromatic Aldehydes. Chem. Rev. 38, 227–254 (1946).

Hofsløkken, N. U. & Skattebøl, L. Convenient Method for the ortho-Formylation of Phenols. Acta Chem. Scand. 53, 258–262 (1999).

Cheung, G. K., et al. A Convenient Preparation of Pyrophosphoryl Chloride and Its Use in Vilsmeier Formylation Reactions. Synlett 77–78 (1992).

Mallat, T. & Baiker, A. Oxidation of Alcohols with Molecular Oxygen on Solid Catalysts. Chem. Rev. 104, 3037–3058 (2004).

Feng, J. B. & Wu, X. F. Transition metal-catalyzed oxidative transformations of methylarenes. Appl. Organomet. Chem. 29, 63–86 (2015).

Barnard, C. F. J. Palladium-Catalyzed Carbonylation-A Reaction Come of Age. Organometallics 2008 27, 5402–5422 (2008).

Neumann, K. T., Laursen, S. R., Lindhardt, A. T., Bang-Andersen, B. & Skrydstrup, T. Palladium-Catalyzed Carbonylative Sonogashira Coupling of Aryl Bromides Using Near Stoichiometric Carbon Monoxide. Org. Lett. 16, 2216–2219 (2014).

Schoenberg, A. & Heck, R. F. Palladium-catalyzed formylation of aryl, heterocyclic, and vinylic halides. J. Am. Chem. Soc. 96, 7761–7764 (1974).

Klaus, S. et al. A General and Efficient Method for the Formylation of Aryl and Heteroaryl Bromides. Angew. Chem. Int. Ed. 45, 154–158 (2006).

Ueda, T., Konishi, H. & Manabe, K. Palladium-Catalyzed Reductive Carbonylation of Aryl Halides with N-Formylsaccharin as a CO Source. Angew. Chem. Int. Ed. 52, 8611–8615 (2013).

Korsager, S., Taaning, R. H., Lindhardt, A. T. & Skrydstrup, T. Reductive Carbonylation of Aryl Halides Employing a Two-Chamber Reactor: A Protocol for the Synthesis of Aryl Aldehydes Including 13C- and D-Isotope Labeling. J. Org. Chem. 78, 6112–6120 (2013).

Yu, B. et al. Pd/C-catalyzed direct formylation of aromatic iodides to aryl aldehydes using carbon dioxide as a C1 resource. Chem. Commun. 50, 2330–2333 (2014).

Natte, K., Dumrath, A., Neumann, H. & Beller, M. Palladium-Catalyzed Carbonylations of Aryl Bromides using Paraformaldehyde: Synthesis of Aldehydes and Esters. Angew. Chem. Int. Ed. 53, 10090–10094 (2014).

Cacchi, S., Fabrizi, G. & Goggiamani, A. Palladium-Catalyzed Synthesis of Aldehydes from Aryl Iodides and Acetic Formic Anhydride. J. Comb. Chem. 6, 692–694 (2004).

Qi, X., Li, C.-L. & Wu, X.-F. A Convenient Palladium-Catalyzed Reductive Carbonylation of Aryl Iodides with Dual Role of Formic Acid. Chem. Eur. J. 22, 5835–5838 (2016).

Wu, F.-P., Peng, J.-B., Meng, L.-S., Qi, X. & Wu, X.-F. Palladium-Catalyzed Ligand-Controlled Selective Synthesis of Aldehydes and Acids from Aryl Halides and Formic Acid. ChemCatChem 9, 3121–3124 (2017).

García, A. L. T3P: A Convenient and Useful Reagent in Organic Synthesis. Synlett 1328–1329 (2007).

Coulthard, G., Unsworth, W. P. & Taylor, R. J. K. Propylphosphonic anhydride (T3P) mediated synthesis of β-lactams from imines and aryl-substituted acetic acids. Tetrahedron Lett. 56, 3113–3116 (2015).

Basavaprabhu Narendra, N., Lamani, R. S. & Sureshbabu, V. V. T3P® (propylphosphonic anhydride) mediated conversion of carboxylic acids into acid azides and one-pot synthesis of ureidopeptides. Tetrahedron Lett. 51, 3002–3005 (2010).

Ech-Chahad, A., Minassi, A., Berton, L. & Appendino, G. An expeditious hydroxyamidation of carboxylic acids. Tetrahedron Lett. 46, 5113–5115 (2005).

Raghavendra, G. M., Kumar, C. S. P., Suresha, G. P., Rangappa, K. S. & Mantelingu, K. T3P catalyzed one pot three-component synthesis of 2,3-disubstituted 3H-quinazolin-4-ones. Chin. Chem. Lett. 26, 963–968 (2015).

Acknowledgements

The publication of this article was funded by the Open Access Fund of the Leibniz Association.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The author declares no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, XF. Palladium-Catalyzed Synthesis of Aldehydes from Aryl Iodides and Formic acid with Propylphosphonic Anhydride as the Activator. Sci Rep 8, 8389 (2018). https://doi.org/10.1038/s41598-018-26850-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-26850-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.