Abstract

Coating of VO2-based thin film has been extensively studied for fabricating energy-saving smart windows. One of the most efficient ways for fabricating high performance films is to create multi-nanolayered structure. However, it has been highly challenge to make such layers in the VO2-based films using conventional methods. In this work, a facile two-step approach is established to fabricate multilayered VO2-TiO2 thin films. We first deposited the amorphous thin films upon sputtering, and then anneal them to transform the amorphous phase into alternating Ti- and V-rich multilayered nanostructure via a spinodal decomposition mechanism. In particular, we take advantage of different sapphire substrate planes (A-plane (11–20), R-plane (1–102), C-plane (0001), and M-plane (10-10)) to achieve different decomposition modes. The new approach has made it possible to tailoring the microstructure of the thin films for optimized performances by controlling the disorder-order transition in terms of both kinetic and thermodynamic aspects. The derived thin films exhibit superior optical modulation upon phase transition, significantly reduced transition temperature and hysteresis loop width, and high degradation resistance, these improvements indicate a high potential to be used for fabricating the next generation of energy saving smart windows.

Similar content being viewed by others

Introduction

There has been a long-standing demand for nanoscale phase separation owing to its connection to material functionalities. In recent years, intensive efforts have been devoted to understanding the connection1,2,3,4, and varied approaches for creating functional thin films have been reported, e.g., DNA-mediated self-assembly5, feedback-driven self-assembly6, and electrochemical techniques7. Conventional methods for fabricating thin films usually involve procedures such as template intermediates and/or post treatments, which make the fabrication process complicated and hence unstable. Self-assembly via spinodal decomposition is a promising solution since spinodal decomposition has proven to be efficient in controlling structural features at nanoscale8,9,10. The spinodal decomposition is a mechanism for the rapid decomposition of one thermodynamically stable mixture of liquids or solids into two coexisting phases11. In contrast to a nucleation-growth process that results in a random mixture of the two, spinodal decomposition is characterized by long-range spatial correlation, quasi-periodicity, and self-organization with a nearly sinusoidal composition modulation12. The structure with compositional fluctuations formed by spinodal decomposition tend to form at nanometer scale13. Thus, spinodal decomposition provides a practical route to produce a finely dispersed microstructure that can significantly enhance the material properties.

Most two-phase spinodal systems are consist of two phases with similar crystal structures and physical properties, e.g., metallic alloys11, SnO2-TiO2 system14,15,16, Al2O3-Cr2O3 system17 and AlN-SiC system18. This similarity limits the functionality of many decomposed systems. Spinodal decomposition of the TiO2/VO2 (TVO) system, which was discovered by Zanma and Ueda in 1998 and recently investigated in bulk materials by Z. Hiroi et al.19,20, is of great interest because of its unique properties of the two components (TiO2 and VO2). VO2 is a crucial component for achieving multi-functionalities of thin film since reversible first-order semiconductor-metal phase transition is accompanied by a drastic change in the optical, electrical, and magnetic properties between its two phases21,22,23,24. TiO2 is a commonly used wide band gap insulator and acts as an antireflection compound for VO2 to increase the transmittance of a thin film in both visible and infrared regions25,26,27. Therefore, transparent TVO thin films provide an attracting application in smart windows, that is, windows that capable of regulating solar/heat transmission for energy efficiency and comfort28. With the advantages of simple structure, automatic control without the use of switching devices, a new approach to enable large-scale producing TVO smart windows at a lower cost is highly desired.

Our previous work29 has shown the feasibility of spinodal decomposition on TVO thin films. However, the mechanism of spinodal decomposition in TVO system has not been fully uncovered, the decomposition-microstructure-property relation has not been explored. In the present work, TVO thin films with spinodal structures by performing room temperature sputtering-annealing are prepared using various sapphire substrates (A-plane, R-plane, C-plane and M-plane). We explore the decomposition-microstructure-property relation, reveal the mechanism of spinodal decomposition in TVO system, and we estimate the practical value of all the spinodal structures in smart window area. Our work provides an accurate self-assembled route to fabricate and control VO2-based multilayered thin films.

Results and Discussion

Samples are abbreviated as A-A, A-R, A-C, A-M for amorphous TVO on A-plane (11–20) sapphire, R-plane (1–102) sapphire, C-plane (0001) sapphire, M-plane (10-10) sapphire substrates respectively. Representative spinodal decomposition samples on different sapphire substrates were abbreviated as SD-A, SD-R, SD-C, SD-M, and crystalline solid solution TVO on the previously mentioned sapphire substrates were abbreviated as C-A, C-R, C-C, C-M. Single component VO2 thin film samples were abbreviated as V-A, V-R, V-C, V-M and TiO2 thin film samples were T-A, T-R, T-C, T-M.

Spinodal decomposition is illustrated on a phase diagram (Fig. 1). Usually, phase separation occurs whenever a material transforms into the thermodynamically unstable regions. The borderline of the unstable region to the stable region, often called the binodal curve, was first reported in TVO by Zamma and Ueda in 199819 from calculations based on the common tangent construction of the free-energy diagram. Below the bimodal curve, there is a spinodal region, which was re-plotted from the literature data obtain from annealing experiments on the crystalline solid solution of Ti0.4V0.6O2 at four temperatures (200, 300, 400 and 500 °C)19,30. For compositions within the spinodal, a homogeneous solution is unstable against infinitesimal fluctuations in density or composition31.

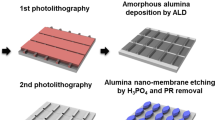

It can be stated from Fig. 1 that, to reach the spinodal region, the material must cross the binodal region. Often phase separation occurs via nucleation and growth during the transition, and hence, spinodal decomposition cannot be observed. To avoid this scenario, a very fast transition by fast quenching is required to move the solid solution from the stable region to the spinodal region. This means spinodal decomposition needs rapidly quenching from high temperature (usually above 1000 °C) and post-annealing at the decomposition temperature. So far, this approach has been used in various spinodal systems15,16,19,20, and the combination of quenching (above 700 °C) with annealing (500 °C) method (Q-A) has been proven to be efficient in our TVO system (see Supplementary Fig. S1). With respect to our magnetron sputtering technique, the fast quenching from high temperature is not suitable since both the substrates and the thin films could easily fracture upon quenching. Therefore, to ensure the composition stability and uniformity of amorphous films, we first propose a two-step approach, namely, the room temperature sputtering-annealing (RTS-A) approach in our TVO system29, the schematic diagram of which is presented in Fig. S1. In our RTS-A route, spinodal decomposition is realized by directly annealing the amorphous TVO films, instead of high temperature and fast quenching.

Thin film composition was determined by XPS analysis (Fig. S2), the molar ratio of Ti to V is 0.33 for all the samples, and hence the composition can all be written as Ti0.25V0.75O2. The composition (Ti0.25V0.75O2) and the annealing temperature (500 °C) of the thin film are illustrated by the vertical and horizontal red dashed lines in Fig. 1, respectively. At the crosspoint, the final decomposed phases should be Ti0.18V0.82O2 (V-rich) phase and the Ti0.49V0.51O2 (Ti-rich) phase.

Researches32,33,34 have found that the epitaxial growth of VO2 and TiO2 on sapphire substrates has different out-of-plane orientations in terms of the sapphire type, as follows:

A-sapphire: (101) VO2(R)//(11–20) Al2O3, (101) TiO2(R)//(11–20) Al2O3;

R-sapphire: (101) VO2(R)//(1–102) Al2O3, (101) TiO2(R)//(1–102) Al2O3;

C-sapphire: (100) VO2(R)//(0001) Al2O3, (100) TiO2(R)//(0001) Al2O3;

M-sapphire: (001) VO2(R)//(10-10) Al2O3, (001) TiO2(R)//(10-10) Al2O3.

Confirmed by XRD results (Fig. S3), spinodal decomposition samples share the same orientations with the single component ones, thus we achieve different decomposition modes. Note that both the Ti-rich and V-rich peaks are located between the peak of pure VO2 and that of TiO2, the composition of the separated phases are V-doped TiO2 (Ti-rich phase) and Ti-doped VO2 (V-rich phase), respectively.

Standard lattice parameters of rutile TiO2 are a = 4.582, c = 2.953 (PDF: 78-1510), and of tetragonal VO2 are a = 4.554, c = 2.8557 (PDF: 79-1655). The lattice mismatch in TVO system is 0.61% along the a axis and 3.3% along the c axis. In this case, spinodal decomposition modulation in the TVO system should occur along the c axis to minimize the elastic strain energy at the interface. The expected multilayers should be parallel to the (001) plane of TVO. This hypothesis is confirmed in TVO bulk crystals where spinodal decomposition occurs only for hkl reflections with l ≠ 020. Similarly, spinodal decomposition occurs only along the c axis, i.e., [001] direction in the TiO2/SnO2 system15,35. Combined with the XRD results, we can infer the direction of decomposed multilayers will be slanted with respect to the substrate for SD-A and SD-R, perpendicular to the substrate for SD-C, and parallel to the substrate for SD-M. Schematic diagrams of the microstructure of the spinodally decomposed TVO thin films are shown in Fig. 2. Figure 2 also shows the cross-sectional EDS elemental mapping of Ti and V (originate from the STEM in Fig. S4), in high consistence with the schematic structures. The overall thickness of the TVO film was measured to be about 120 nm (Fig. S5), the thickness of Ti-rich layer is estimated to be ~20 nm(Fig. S4). Detailed high-resolution TEM analyses are shown in Fig. S5.

Schematic diagrams of the microstructure of spinodally decomposed TVO for (a) SD-A, (b) SD-R, (c) SD-C and (d) SD-M, and the related EDS elemental mapping (Ti and V) analyses of the selected area in Fig. S4.

Evolution of the separated phases during spinodal decomposition was monitored on SD-M samples annealed for different annealing time, as shown in Fig. 3. Since there is no thermodynamic barrier to the reaction inside the spinodal region (Fig. 1), spinodal decomposition proceeds solely via diffusion mechanism, and the schematic diagram of the element (Ti or V) content fluctuation evolution is shown in Fig. 3(a). It is a sinusoidal wave curve, the amplitude increases along with annealing time and the amplitude is limited by the composition of original solid solution. The film thickness of amorphous sample (A-M) is about 120 nm, investigated by TEM (Fig. 3(b)) and the film surface is flat. TEM proves that A-M was predominantly amorphous since only few crystalline domains are present. Moreover, in HRTEM of Fig. 3(c), there is a pronounced epitaxial crystalline layer of ~10 nm forms in the interface between the substrate and TVO film. The interplanar crystal spacing is measured to be 2.9 Å, matching well with the 2d value calculated from XRD (002) peaks of sample C-M (64.45°, d = 1.46 Å) in Fig. S3(d). It is reasonable to state that the sapphire substrate is effective in promoting epitaxial growth and the epitaxial thin layer can act as seeds of the two separated phases in the following annealing process.

(a) Schematic diagram of element (Ti or V) content fluctuation in phase separation evolution progress. (b) TEM image of A-M sample. (c) High resolution TEM image of the select red square area in image (b). (d–f) EDS elemental mapping of the selected area (white square in Fig. S6) and line scanning of selected line (yellow line in Fig. S6) analyses for (e) sample annealing for 1 h, (f) sample annealing for 5 h, (g) sample annealing for 10 h. All the EDS line scanning images begin from the interface between TVO film and substrate and end at the surface of TVO film.

EDS elemental mapping, and EDS line scanning are shown in Fig. 3(d),(e) and (f) for annealing times of 1 h, 5 h, 10 h, respectively (originate from the STEM images in Fig. S6). The images of each EDS line scan, which starts from the interface between the substrate and TVO and ends at the surface of TVO film, agree well with the schematic diagrams in Fig. 3(a), supporting the diffusional scenario. At the beginning of annealing (1 h, Fig. 3(d)), the as-grown film is a homogeneous solid solution and only little fluctuation can be observed. With the annealing, fluctuations grow until individual phases can be identified (5 h, Fig. 3(e)), but the phase separation is incomplete and appears to be wavy lamellar structures at this stage. After sufficient annealing (over 10 h, Fig. 3(f)), the final equilibrium of phase separation with relatively sharp interface structure has been established. The final phase is stable with extending the annealing time at the fixed annealing temperature, because compared with the 10 h annealed sample, the longer time annealed (20 h) one displays similar XRD intensity (Fig. S7), similar transmittance spectra (Fig. S8(a and b)), and similar hysteresis loops (Fig. S8(c)).

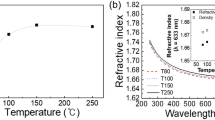

For application purposes, spinodally decomposed TVO thin films (SD-A, SD-R, SD-C, SD-M) are regarded as VO2 and TiO2 multilayer thin films. Based on the semiconductor-metal transition of VO2, those thin films are expected to be utilized as smart windows27. The vis-near-infrared transmittance spectra of the composite films were characterized at 20 °C (before phase transition) and 90 °C (after phase transition) to determine their optical modulation capability, as shown in Fig. 4(a–d). Transmittance spectra of single VO2 samples (V-A, V-R, V-C, V-M) are also shown for comparison. The application of VO2 for smart windows relies on the enhancement in both luminous transmittance (T lum ) and solar modulating ability (ΔT sol ), which are determined using the following equation36:

where T(λ) is the transmittance at wavelength λ, ρ denotes lum or sol for calculations, ψ lum is the standard efficiency function for photopic vision, and ψ sol is the solar irradiance spectrum for an air mass of 1.5 (corresponding to the sun standing 37° above the horizon). The optical features of samples are summarized in Table 1.

(a–d) Vis-near-infrared transmittance spectra at 20 °C and 90 °C of samples (a) V-A, SD-A, (b) V-R, SD-R, (c) V-C, SD-C, (d) V-M, SD-M. (e–h) emperature-varied transmittance hysteresis loops of samples (e) V-A, SD-A, (f) V-R, SD-R, (g) V-C, SD-C, (h) V-M, SD-M. Insets are the first-order differential curves of transmittance to temperature (dT/dt).

In Fig. 4(a–d) and Table 1, each spinodally decomposed TVO film (SD-A, SD-R, SD-C, SD-M) displays thermochromic properties, compare with the optical properties of the recently reported VO2-based thermochromic films prepared by magnetron sputtering (listed in Table S2), one can see that all the film can potentially be applied as smart coating material. However, compared to the single VO2, the relative tendency is not uniform across the four types. Comparing SD-A to V-A, the T lum remains constant, while the ΔT sol increases significantly from 6.1% for V-A to 9.6% for SD-A. The transmittance difference of typical wavelength of 2000 nm (ΔT2000 nm) is measured as 46.4% for V-A and 51.7% for SD-A. For SD-R relative to V-R, and both T lum and ΔT sol decrease while ΔT 2000 nm increases. This indicates that the Ti-rich coatings slightly increase the total transmittance, but lead to a red shift of the absorption edge in Fig. 4(b), consistent with the function of TiO2 coatings in VO2 based thin films37. SD-C exhibits an increase in T lum , but more obvious decrease in ΔT sol compared to V-C (Fig. 4(c)). The change is reasonable because the perpendicular orientation of the microscopic structure causes incomplete coverage of the V-rich layers on the substrate thus increases the total transmittance for the higher transparent property of Ti-rich layer29, and lowers the thermochromic functional area. SD-M displays relatively high thermochromic performance with T lum of 32.3% at 20 °C, 35.9% at 90 °C, ΔT sol of 6.6%, and ΔT 2000 nm of 51.9%. These data are slightly lower than those of V-M. For the relatively high-level Ti-doping in V-rich layers, the total transmittance improvement and red shift phenomena are similar to SD-R and SD-A. More detailed band gap calculation data are discussed and shown in Fig. S9.

As shown in Fig. 4(e–h), the hysteresis loops were measured at 2000 nm. Phase-transition temperatures of heating lines (T c-heating ) and cooling lines (T c-cooling ) are obtained from the peak value of the first-order differential curves (dT/dt), respectively38. Usually, T c-heating is often used to represent the phase-transition temperature (T c ). The hysteresis loop width (ΔT c ) is estimated through ΔT c = T c-heating -T c-cooling (see the insets of Fig. 4(e–h) and Table 1).

The T c of the VO2 single crystal should be ~68 °C39, but our single VO2 samples are decreased to: 57.6 °C for V-A, 52.7 °C for V-R, 55.8 °C for V-C, and 55.6 °C for V-M. The decrease in Tc is ascribed mainly to the stress arising from ion bombardment during the deposition process and the mismatch in coefficient of thermal expansion between VO2 film and sapphire. For spinodally decomposed TVO films, only SD-C displays an increase in T c , others show decrease in T c . Jin et al. have indicated that the T c reduction of VO2 film results mainly from doping and/or lattice stress37. Researches have found that the Tc value of VO2 would slightly increase by Ti doping40,41, which seems not to be the main influence factor of the variation. Generally, for lattice stress in VO2-based thermochromic multilayer film, the anisotropic compression pressure along the c axis of VO2 layer is the most effective strain, compressive stress along c axis causes the incerease in T c , while the tensile stress decreases T c . As we discussed above, spinodal decomposition in our TVO system occurs along the c axis to minimize the elastic strain energy. Since the a axis of TiO2 (a = 4.582, PDF: 78-1510) is larger than VO2, (a = 4.554, PDF: 79-1655), the a axis of V-rich layer should be under tensile stress while the c axis is under compressive stress in the V-rich phase, causing the reduction in Tc in SD-A, SD-R, and SD-M samples. For the V-rich layer in SD-C, the same influence from Ti-rich also exist. Nevertheless, since the orientation relationship between V-rich layer and the substrate is (100) VO2(R)//(0001) Al2O3, and the spinodally decomposed layers are perpendicular to the substrate, b axis and c axis of VO2(R) (tetragonal, a = 4.55, c = 2.86) are extended for the larger lattice paremeter of Al2O3(hexagonal, a = 4.75), schematic illustration of heteroepitaxial relationship and tensile stress in VO2 of VO2/Al2O3 interface could be found in our previous work34. Put these two competitive factors together, the c axis of V-rich layer is suffered tensile stress in SD-C sample at length.

Ladd has reported that anisotropic compression along c axis could theoretically reduce T c by −12 °C/GPa42. From Table 1, the reduction of SD-A is 7.0 °C, SD-R is 1.1 °C, and SD-M is 5.5 °C, thus the anisotropic pressure is estimated as ≥0.58 GPa in SD-A, ≥0.1 GPa in SD-R, and ≥0.46 GPa in SD-M. Thus, we can state that spinodal decomposition is a new route to achieve huge anisotropic stress. Internal stress is of importance for high-frequency response VO2 applications, and this is confirmed by the reduction in hysteresis loop width (ΔT c ) of SD-A, SD-R, and SD-M (Table 1).

Moreover, to evaluate the stability of spinodally decomposed films, durability experiments have been performed on V-M and SD-M, with the condition of a constant-temperature 60 °C and relative humidity of 90%, shown in Fig. S10. Results shown the thermochromism nearly vanishes after about 15 days’ treatment for V-M and 36 days for SD-M, pronounced the improvement in durability with spinodal decomposition. For a comparison, protective Al2O3 coating can be thermochromic only for 7 days43, while WO3 coatings are durable even after 20 days44.

Conclusions

Fabrication of self-assembled lamella multilayer VO2-TiO2 thin films was realized by a two-steps approach of room temperature magnetron sputtering - post annealing via spinodal decomposition mechanism. The spinodally decomposed TVO film has been achieved on different sapphire substrates (A-plane (11–20) sapphire, R-plane (1–102) sapphire, C-plane (0001) sapphire, M-plane (10-10) sapphire substrates). All decomposed films display nano-scaled multilayer structures with well-ordered alternating Ti-rich and V-rich parallel layers, while the multilayered TVO structure and substrate have different orientations. The decomposed films tend to be slanted on A- and R-sapphire, perpendicular on C-sapphire, and parallel on M-sapphire. The spinodal decomposition is governed by a diffusional mechanism.

The annealing at 500 °C for 10 h can lead to a complete phase separation via our RTS-A method. All spinodally decomposed TVO films display thermochromic properties, and hence, our new technique has a high potential to be applied on smart coatings. The decomposed films on A-, R-, and M-sapphire also show both the reduced transition temperature and the narrowed hysteresis loop of the thermochromic V-rich layer. The spinodally decomposed TVO thin film bears anisotropic stress, and thus, it is promising to be utilized in optical switching. Moreover, the spinodally decomposed films display significantly better durability than VO2 thin film. These self-assembled multilayer-structures and outstanding regulating optical properties indicate that spinodal decomposition is an ideal approach for fabricating VO2-based smart windows.

Methods

Amorphous TVO thin films (A-A, A-R, A-C, A-M) were first deposited by magnetron sputtering (ULVAC, ACS-4000-C4) on A-sapphire, R-sapphire, C-sapphire, M-sapphire substrates respectively, and then annealed for spinodal decomposition. The deposition of these amorphous TVO samples was carried out by co-sputtering from a VO2 ceramic target at 70 W dc power and a TiO2 ceramic target at 100 W rf power at room temperature with Ar and O2 flow of 39 and 1 sccm, respectively. Representative spinodal decomposition (SD) samples (SD-A, SD-R, SD-C, SD-M) were then obtained by annealing the amorphous samples at 500 °C for 10 h at 1 mTorr. For comparison, crystalline solid solution TVO (C-A, C-R, C-C, C-M) were prepared under nearly identical conditions as the amorphous samples, except that the substrate temperature was kept at 450 °C while sputtering. Single component VO2 thin film samples (V-A, V-R, V-C, V-M) and TiO2 thin film samples (T-A, T-R, T-C, T-M) were prepared at 450 °C by alternatively DC sputtering a VO2 ceramic target at 70 W and RF sputtering a TiO2 ceramic target at 100 W. A schematic diagram of the preparation processes can be found in Fig. S1(a).

X-ray photoemission spectroscopy (XPS) analysis was conducted on ThermoFisher ESCAlab250 to detect the elementary composition and content of TVO. Thin film X-ray diffraction (XRD) analysis was carried out on a Rigaku Ultima IV diffractometer with Cu Kα radiation (λ = 1.5418 Å) using the θ-2θ scanning model. Transmission electron microscopy (TEM) observations were carried out with the electron microscope (FEI, TECNAI G2 F20) equipped with an EDS analyzer (OXFORD, X-MaxN). The optical transmittance of the films in the wavelength range from 350 nm to 2600 nm at 20 °C and 90 °C was measured using a UV-Vis spectrophotometer (HITACHI, UV-4100). The temperature was measured precisely with a temperature sensor in contact with the surface of films and controlled by a temperature controlling unit.

In addition, summary of the acronyms in this manuscript has been listed at the last of the supporting information in Table S3.

Data availability statement

All data generated or analysed during this study are included in this published article and its Supplementary Information files.

References

MaCmanus-Driscoll, J. L. et al. Strain control and spontaneous phase ordering in vertical nanocomposite heteroepitaxial thin films. Nat. Mater. 7, 314–320 (2008).

Yabu, H., Koike, K., Motoyoshi, K., Higuchi, T. & Shimomura, M. A Novel Route for Fabricating Metal-Polymer Composite Nanoparticles with Phase-Separated Structures. Macromol. Rapid Commun. 31, 1267–1271 (2010).

Zheng, H. et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 303, 661–663 (2004).

Harrington, S. A. et al. Thick lead-free ferroelectric films with high Curie temperatures through nanocomposite-induced strain. Nat. Nanotechnol. 6, 491–495 (2011).

Young, K. L. et al. Using DNA to Design Plasmonic Metamaterials with Tunable Optical Properties. Adv. Mater. 26, 653–659 (2014).

Yang, S. et al. Feedback-driven self-assembly of symmetry-breaking optical metamaterials in solution. Nat. Nanotechnol. 9, 1002–1006 (2014).

Yao, J. et al. Optical negative refraction in bulk metamaterials of nanowires. Science 321, 930–930 (2008).

Nan, C. W. & Jia, Q. X. Obtaining ultimate functionalities in nanocomposites: Design, control, and fabrication. Mrs Bull. 40, 719–723 (2015).

MacManus-Driscoll, J. L., Suwardi, A. & Wang, H. Composite epitaxial thin films: A new platform for tuning, probing, and exploiting mesoscale oxides. Mrs Bull. 40, 933–942 (2015).

Chen, Z. et al. Self-Assembled, Nanostructured, Tunable Metamaterials via Spinodal Decomposition. ACS nano 10, 10237–10244 (2016).

Cahn, J. W. On Spinodal Decomposition. Acta Metall. Mater. 9, 795–801 (1961).

Cahn, J. W. & Hilliard, J. E. Free Energy of a Nonuniform System .1. Interfacial Free Energy. J. Chem. Phys. 28, 258–267 (1958).

Guiton, B. S. & Davies, P. K. Nano-chessboard superlattices formed by spontaneous phase separation in oxides. Nat. Mater. 6, 586–591 (2007).

Padurow, N. N. Mischbarkeit Im System Rutil-Zinnstein. Naturwissenschaften 43, 395–396 (1956).

Shuichi, A., Kenji, M., Ko-ichi, K. & Toshinobu, Y. Hirano, S.-i., Gas-Sensing Properties of Spinodally Decomposed (Ti, Sn)O2 Thin Films. J. Am. Ceram. Soc. 82, 225–228 (1999).

Chaisan, W., Yimnirun, R., Ananta, S. & Cann, D. P. The effects of the spinodal microstructure on the electrical properties of TiO2–SnO2 ceramics. J. Solid State Chem. 178, 613–620 (2005).

Schultz, A. H. & Stubican, V. S. Separation of Phases by Spinodal Decomposition in Systems Al2O3-Cr2O3 and Al2O3-Cr2O3-Fe2O3. J. Am. Ceram. Soc. 53, 613–616 (1970).

Chen, J., Tian, Q. & Virkar, A. V. Phase-Separation in the Sic-Aln Pseudobinary System - the Role of Coherency Strain-Energy. J. Am. Ceram. Soc. 75, 809–821 (1992).

Hiroi, Z., Hayamizu, H., Yoshida, T., Muraoka, Y. & Okamoto, Y. Yamaura, J.-i.; Ueda, Y., Spinodal Decomposition in the TiO2–VO2 System. Chem. Mater. 25, 2202–2210 (2013).

Hiroi, Z., Yoshida, T., Yamaura, J. & Okamoto, Y. Spinodally decomposed nanostructures in a TiO2–VO2 crystal. APL Mater. 3, 062508 (2015).

Yang, S. et al. Bottom-up approach toward single-crystalline VO2-graphene ribbons as cathodes for ultrafast lithium storage. Nano Lett. 13, 1596–601 (2013).

Dey, K. K. et al. VO2 nanorods for efficient performance in thermal fluids and sensors. Nanoscale 7, 6159 (2015).

O’Callahan, B. T. et al. Inhomogeneity of the ultrafast insulator-to-metal transition dynamics of VO2. Nat. Commun. 6, 6849 (2015).

Zhang, H. T. et al. Wafer-scale growth of VO2 thin films using a combinatorial approach. Nat. Commun. 6, 8475 (2015).

Sun, G. et al. Low-temperature deposition of VO2 films with high crystalline degree by embedding multilayered structure. Solar Energy Materials and Solar Cells 161, 70–76 (2017).

Tazawa, M., Yoshimura, K., Jin, P. & Xu, G. Design, formation and characterization of a novel multifunctional window with VO2 and TiO2coatings. Appl. Phys. A: Mater. Sci. Process. 77, 455–459 (2003).

Zheng, J., Bao, S. & Jin, P. TiO2(R)/VO2(M)/TiO2(A) multilayer film as smart window: Combination of energy-saving, antifogging and self-cleaning functions. Nano Energy 11, 136–145 (2015).

Zhou, Y., Cai, Y., Hu, X. & Long, Y. Temperature-responsive hydrogel with ultra-large solar modulation and high luminous transmission for “smart window” applications. J. Mater. Chem. A 2, 13550 (2014).

Sun, G. et al. Self-Assembled Multilayer Structure and Enhanced Thermochromic Performance of Spinodally Decomposed TiO2–VO2Thin Film. ACS Appl. Mater. Interfaces 8, 7054–7059 (2016).

Hiroi, Z. Structural instability of the rutile compounds and its relevance to the metal–insulator transition of VO2. Prog. Solid State Chem. 43, 47–69 (2015).

Jones, R. A. L. Soft Condensed Matter. Oxford University Press: 2004.

Li, J. & Dho, J. Controlling metal–insulator transition in the hetero-epitaxial VO2/TiO2 bilayer grown on Al2O3. J. Cryst. Growth 312, 3287–3291 (2010).

Zhao, Y. et al. Structural, electrical, and terahertz transmission properties of VO2 thin films grown on c-, r-, and m-plane sapphire substrates. J. Appl. Phys. 111, 053533 (2012).

Sun, G. et al. Structure and enhanced thermochromic performance of low-temperature fabricated VO2/V2O3 thin film. Appl. Phys. Lett. 109, 143903 (2016).

Stubican, V. S. & Schultz, A. H. Spinodal Decomposition in System TiO2-SnO2. J. Am. Ceram. Soc. 51, 290–291 (1968).

Gao, Y. et al. Enhanced chemical stability of VO2 nanoparticles by the formation of SiO2/VO2 core/shell structures and the application to transparent and flexible VO2-based composite foils with excellent thermochromic properties for solar heat control. Energy Environ. Sci. 5, 6104 (2012).

Jin, P., Xu, G., Tazawa, M. & Yoshimura, K. Design, formation and characterization of a novel multifunctional window with VO2 and TiO2coatings. Appl. Phys. A: Mater. Sci. Process. 77, 455–459 (2003).

Chen, C. et al. VO2 multidomain heteroepitaxial growth and terahertz transmission modulation. Appl. Phys. Lett. 97, 211905 (2010).

Morin, F. J. Oxides Which Show a Metal-to-Insulator Transition at the Neel Temperature. Phys. Rev. Lett. 3, 34–36 (1959).

Nishikawa, M., Nakajima, T., Kumagai, T., Okutani, T. & Tsuchiya, T. Ti-Doped VO2 Films Grown on Glass Substrates by Excimer-Laser-Assisted Metal Organic Deposition Process. Jpn. J. Appl. Phys. 50, 01BE04 (2011).

Chen, S., Liu, J., Wang, L., Luo, H. & Gao, Y. Unraveling Mechanism on Reducing Thermal Hysteresis Width of VO2 by Ti Doping: A Joint Experimental and Theoretical Study. J. Phys. Chem. C 118, 18938–18944 (2014).

Ladd, L. A. & Paul, W. Optical and Transport Properties of High Quality Crystals of V2O4 near Metallic Transition Temperature. Solid State Commun. 7, 425–428 (1969).

Ji, Y. X., Li, S. Y., Niklasson, G. A. & Granqvist, C. G. Durability of thermochromic VO2 thin films under heating and humidity: Effect of Al oxide top coatings. Thin Solid Films 562, 568–573 (2014).

Long, S. et al. Thermochromic multilayer films of WO3/VO2/WO3 sandwich structure with enhanced luminous transmittance and durability. RSC Adv. 6, 106435–106442 (2016).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (NSFC, 51572284), and the Shanghai Sailing Program (17YF1429800). And the authors are grateful for The Youth Innovation Promotion Association, Chinese Academy of Sciences (No. 2018288).

Author information

Authors and Affiliations

Contributions

G.S. wrote the main manuscript text under guidance of X.C. and P.J. Y.Y. and X.G. contributed to the result discussion. S.L., N.L. and R.L. assisted for sample synthesis and basic characterization. G.S. conceived the experiments under supervision of H.L. and P.J. X.C. and P.J. planned and supervised this study. All authors participated in discussions and manuscript writing.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, G., Cao, X., Yue, Y. et al. Multi-nanolayered VO2/Sapphire Thin Film via Spinodal Decomposition. Sci Rep 8, 5342 (2018). https://doi.org/10.1038/s41598-018-23412-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-23412-4

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.