Abstract

The electrical transport and structural properties of tin oxide nanoparticles under compression have been studied by in situ impedance measurements and synchrotron X-ray diffraction (XRD) up to 27.9 GPa. It was found that the conduction of SnO2 can be improved significantly with compression. Abnormal variations in resistivity, relaxation frequency, and relative permittivity were observed at approximately 12.3 and 25.0 GPa, which can be attributed to pressure-induced tetragonal- orthorhombic-cubic structural transitions. The dielectric properties of the SnO2 nanoparticles were found to be a function of pressure, and the dielectric response was dependent on frequency and pressure. The dielectric constant and loss tangent decreased with increasing frequency. Relaxation-type dielectric behaviour dominated at low frequencies. Whereas, modulus spectra indicated that charge carrier short-range motion dominated at high frequencies.

Similar content being viewed by others

Introduction

Transparent conductive oxides (TCOs) attract increasing attention in modern optoelectronic devices due to their large optical transparency and high electrical conductivity1. SnO2 is one of the widely used TCOs, with a bandgap Eg of ~3.6 eV. It shows high electrical conductivity and optical transparency in the visible region, making it useful in optoelectronic devices such as flat panel displays, organic light emitting diodes, and transparent electrodes for solar cells2,3,4. The crystal morphology of SnO2 can considerably improve the performance of electronic devices, as exemplified by the SnO2 nanomaterials that show larger electrical and optical variation than those of bulk SnO25.

It is well known that the electrical transport of material plays a central role in the performance of optoelectronic devices. For SnO2, studies of its conduction mechanism have provided possible routes for optimising nanocrystalline SnO2-based devices6,7. Various approaches have been proposed to enhance the electrical conductivity, including changing the grain size8 and chemical doping9. Applying pressure compression has been shown to be one of the effective approaches to tuning the crystalline structure, the electrical structures and the electrical transport properties of materials, which inspired us to further explore the pressurisation of SnO2. A previously reported observation indicated that with application of pressure, SnO2 transforms from rutile (tetragonal structure with P42/mnm symmetry) to a CaCl2-type phase (orthorhombic structure with Pnnm symmetry) under hydrostatic pressure or an α-PbO2-type phase (orthorhombic structure with Pbcn symmetry) at ~12 GPa under non-hydrostatic pressure conditions. Both α-PbO2-type and CaCl2-type phases were found to transform to a modified fluorite-type phase (cubic structure with Pa-3 symmetry) at with further compression up to 21 GPa. How compression tunes the structural properties of SnO2 has been well studied10,11,12,13,14,15,16,17,18. However, very few works have focused on the effects of pressure on the electrical resistivity of SnO219, which significantly precludes our understanding of the conduction mechanism of nanocrystalline SnO2.

Since SnO2 is a semiconducting dielectric material and widely applied in optoelectronic devices, its resistivity and dielectric properties are two important factors to characterize this material. For example, the resistance and dielectric change will affect the feature and efficiency of device, such as thermal loss, leakage current, refractive index, signal responding speed and so on. SnO2 as a transparent conductive electrode material, the resistivity affects power conversion efficiency (PCE) of devices, while the dielectric affects light transmittance. The optimization of device development based on SnO2 material requires a better understanding of the dielectric properties20.

Herein, we track the evolutions of electrical, structural, and dielectric properties of SnO2 nanoparticles in situ under compression using a combination of AC impedance spectroscopy and X-ray diffraction (XRD) experiments. The electrical and dielectric properties of nanocrystalline SnO2 under compression have been well discussed.

Methods

Our sample is nanocrystalline SnO2 powder (99.996%) purchased from Alfa Aesar Co. High pressure was obtained by a diamond anvil cell (DAC), with one pair of diamonds with a culet of 300 μm in diameter and a T-301 steel gasket. A 150 μm hole with was drilled in the centre of the indentation area. To insulate the metallic gasket and electrodes, the hole was covered with compressed alumina (Al2O3) and epoxy powders. Another hole with a diameter of 100 μm was then drilled in the centre of the compressed Al2O3 for use as a sample chamber. Thin-film Mo electrodes were magnetically sputtered onto the diamond anvil, forming a pair of capacitance block-electrodes for electrical transport measurements. More detailed information about the configuration of the parallel plate was reported in previously21. AC impedance spectroscopy measurements were conducted on a Solartron 1260 impedance analyser equipped with a Solartron 1296 dielectric interface with a frequency range from 10−1 to 107 Hz. During the measurements, the DAC was shielded with a metal box to avoid any electromagnetic background and pseudo linear responses from the inner structure of the cell.

In situ high-pressure XRD experiments were conducted at BL15U1 of the Shanghai Synchrotron Radiation Facility (SSRF) and BL4W2 of the Beijing Synchrotron Radiation Facility (BSRF), using angle-dispersive XRD mode (λ = 0.6199 Å). Argon was used as the pressure transmitting medium. The instrument parameters, including the distance between the sample and detector, were calibrated using a CeO2 standard material. Ruby chips were loaded into the chamber near the sample to calibrate the pressure.

The first-principles calculations were performed based on the density functional theory and the pseudo potential method on the standard CASTEP program in the Material Studio package. The effects of electron−electron exchange correlation are depicted by CA-PZ functional in Local Density Approximation (LDA). The geometric optimization of the unit cell was conducted with the Broydene−Fletchere−Goldfarbe− Shanno (BFGS) minimization algorithm. Integration in the Brillouin zone was performed by use of special k points generated with 7 × 7× 11, 8 × 8 × 11, and 8 × 8 × 8 mesh parameter grids for the tetragonal, the orthorhombic, and the cubic phase, respectively. A plane-wave cutoff energy of 750 eV was set up for the two phases to guarantee the convergence of the enthalpy calculations.

Results and Discussion

Impedance analysis

The average grain size of SnO2 nanoparticles is about 50 nm, and it is homogeneous. The scanning electron microscopy (SEM) pattern is shown in Supplementary Fig. 1. The complex impedance spectra of the SnO2 nanoparticles at various compression pressures are shown in Fig. 1(a). A single semi-circular response corresponding to grain interiors is observed at every pressure. The components related to the grain boundaries and electrode effects were too weak compared with those of the grain contribution to be distinguished. With application of pressure, the semicircle related to the grain effect collapses considerably but the shape of the arcs remains unchanged.

The representations of the real and imaginary parts of the impedance are given as a function of angular frequency. The purpose is to evaluate the relaxation frequency of the most resistive contribution, which is related to the type and strength of the electrical relaxation in the SnO2 nanoparticles. The dependences of the experimental values of Z′ and Z″ on angular frequency ω at different pressures are shown in Fig. 2(a) and (b), respectively. In the low frequency region, the amplitude of Z′ in Fig. 2(a) is typically higher at lower pressures. It then gradually decreases with increasing frequency and pressure, indicating an increase in the AC conductivity of the SnO2 nanoparticles. In Fig. 2(a), the value of Z′ decreases with increasing frequency and attains a constant value at high frequencies at all pressures. Similar behaviour has been reported previously, which suggests a possible release of space charge, and a consequent lowering of the barrier properties in the SnO2 nanoparticles22,23.

Figure 2(b) shows that Z′′ initially reaches a maximum value (Z′′max) and then decreases with increasing frequency at all measured pressures. The maximum appears when the hopping frequency of localised electrons is approximately equal to the frequency of the applied electric field. The average position of the maximum regularly shifts to higher frequencies with increasing pressure, which demonstrates the presence of a pressure-dependent electrical relaxation phenomenon24. Furthermore, the asymmetric broadening of the maxima with increasing pressure suggests a spread of relaxation time in the SnO2 nanoparticles25. Finally, all Z″ merge in the high-frequency region under all measured pressures because the frequency-dependent relaxation process of space charge becomes fast and hence leads to the space charge polarisation decreasing with increasing frequency26.

The AC conductivity σAC of a material is represented by two parts: σ(ω) = σ′(ω) + σ″(ω), in which σ′(ω) = 2πε 0 ε″ is the real part, and σ″(ω) = −2πε 0 ε′ is the imaginary part. The AC conductivity of the SnO2 nanoparticles as a function of frequency f at different pressures is shown in Fig. 3(a). The conductivity pattern can be divided into two parts. At low frequencies, the AC conductivity is weakly frequency dependent at each pressure which corresponds to DC conductivity. At higher frequencies, the AC conductivity shows dispersion that is characteristic of ωs. The phenomenon of the dispersion of conductivity generally obeys the power law relationship of Jonscher: σAC = σDC + AωS, where σDC is the DC conductivity, A is a complex proportionality constant and ω is the angular frequency. The exponent S is a frequency-dependent parameter of value less than unity, and its dependence on pressure determines the conduction mechanism in the material27. The variation of S with pressure in Fig. 3(b) is limited to 0.6 < S < 1 and S decreases with the increase in pressure, which indicates a hopping conduction mechanism in the SnO2 nanoparticles27,28,29. The observed dispersion of conductivity with frequency and pressure is in general agreement with the prediction of the correlated barrier hopping (CBH) model27,30.

To quantify the characteristic relaxation frequencies and electrical resistances of the SnO2 nanoparticles, Nyquist plots have been modelled using the Z-view software package. As shown in the insert in Fig. 1(b), an equivalent circuit formed by the parallel combination of the resistance R and constant phase element (CPE) was used for this purpose. Fitting data for the resistance and relaxation frequency as a function of pressure are shown in Fig. 4. With increasing compression pressure, each parameter shows three linear regions with different slopes. The slope changes occur at 13.4 and 25.0 GPa. In fact, most anomalies of the electrical parameters usually coincide with crystal structure transition. To determine the correlation between the electrical transport properties and the structure of SnO2 nanoparticles, we performed high pressure synchrotron XRD experiments.

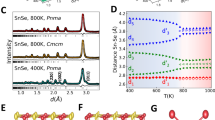

Figure 5(a) shows the collected XRD data at different pressures. From 2.9 to 12.3 GPa, the XRD pattern of nanocrystalline SnO2 is consistent with a high-crystallinity rutile structure (P42/mnm). At higher pressures, the (211) diffraction peak begins to split and broaden into the (101) and (200) reflections. This suggests that an orthorhombic phase is formed (i.e., a CaCl2-type structure with space group Pnnm). No discontinuities in the relative volume and cell constant are observed, as shown in Fig. 5(b) and (c). This indicates that the phase transition could be second order. The diffraction pattern at 22.4 GPa shows a weak peak emerging between the strong (110) and (101) peaks of the rutile structure, indicating the onset of a phase transition in the SnO2 nanoparticles. As the pressure increases, the intensities of peaks related to the rutile phase decrease, and the intensities of peaks originating from the new phase increase. The new peaks could be assigned to the high-pressure cubic fluorite (\(Pa\bar{3}\)) phase, because of the typical characteristics of the cubic fluorite phase (\(Pa\bar{3}\)) in the (111) direction. This conclusion is consistent with an earlier report31. The changes in the electrical parameters at 13.4 and 25.0 GPa are therefore attributed to the rutile-to-CaCl2 and CaCl2-to-fluorite phase transitions, respectively. The rutile, CaCl2 and fluorite structures are described in Fig. 5(d). Compared with the synchrotron XRD experiment, the transitions pressures shift approximately 1‒3 GPa towards higher pressure, which can be attributed to the pressure transmitting medium. To avoid the introduction of additional effects, our electrical experiments did not use the pressure medium, but we used argon in the high-pressure synchrotron XRD experiment. Neglecting the pressure transmitting medium can give rise to deviatoric stresses at different pressures. The absence of a pressure-transmitting medium in an electrical experiment can cause deviatoric stress.

(a) XRD patterns of the SnO2 nanoparticles at various compression pressures. (b) The relative volume of the SnO2 nanoparticles as a function of compression pressure. (c) Cell constants of the SnO2 nanoparticles as a function of compression pressure. (d) Crystal structures of the three high-pressure polymorphs of SnO2 nanoparticles.

In general, the compression always causes an energy gap narrow effect and then results the conductivity increase of the compressed sample. For SnO2, the situation is different. We have calculated the band gap of SnO2 at different phases (as shown in Fig. 6) and the pressure induced band gap broaden has been found at every phase. This result shows the intrinsic band gap change will result the conductivity decrease at every phase. The effect of band gap change on conductivity is negative. However, our experimental result shows that the conductivity of SnO2 increases with pressure increasing.

According to the Arrhenius relationship, the relaxation frequency of the grain can be expressed by the following equation:

where H represents the activation energy of the grain, and corresponds to the energy barrier that carriers pass over in the grain interior. k B is the Boltzmann constant, and T is the temperature. Assuming that f and H are the only functions of pressure, and if f 0 remains constant, then:

Linear fitting of the curve of lnf versus P yields the pressure dependence of the activation energy dH/dP, as shown in Table 1. It is seen that the activation energy decreases with increasing pressure in the tetragonal and orthorhombic phases but slightly decreases in the cubic phase. The decrease in activation energy under pressure indicates that pressure plays an important role in decreasing the energy barriers, which consequently enhances the conductivity. The electrical conduction of semiconducting metal oxides such as SnO2 and ZnO strongly depends upon lattice vacancies at oxygen sites6,19. The conductivity may also result from the migration of charged particles of SnO2, such as O−, O2−, and \({O}_{2}^{-}\), or the migration of oxygen defects across the grain interior. A pressure increase leads to an energy barrier decrease in the grain of the SnO2 nanoparticles, which results in the resistance decrease shown in Fig. 4(a). Another reason for conductivity growing in SnO2 with pressure increasing is due to the connectivity between neighbor grains in compressed SnO2 nanoparticles is improved.

Dielectric properties

With the parallel-plate electrode model, the relative permittivity (ɛr) of the grain as a function of pressure is given by Eq. 3:

where d is the sample thickness, ɛ 0 is the vacuum permittivity, S is the area of the electrode, and f is the relaxation frequency of the grain. The change in ɛ r with increasing pressure is shown in Fig. 4(c). Two abnormal slope changes occur at 13.4 and 24.2 GPa. The high-pressure XRD experiments indicate that the SnO2 nanoparticles are subjected to tetragonal-to-orthorhombic and orthorhombic-to-cubic phase transitions under high pressure. Therefore, the abnormal slope changes in Fig. 4(c) are attributed to these phase transitions. The relative permittivity is measured at a single relaxation frequency and is a static permittivity. The variation of relative permittivity under compression indicates that the dielectric performance of SnO2 nanoparticles is modulated by pressure. The pressure makes the polarization rate of SnO2 nanoparticles decrease, which is beneficial to its application in the micro-circuit integration.

The complex permittivity is measured in the alternating electric field which known as the dynamic permittivity. The complex dielectric constant ε′ and dielectric loss ε″ are determined from the following relationships:

where C0 is the vacuum capacitance of the cell.

Figure 7 shows the frequency dependences of ε′ and ε″ as functions of pressure. As seen, the dielectric constant ε′ of SnO2 nanoparticles increases with pressure in all frequency regions. The dielectric behaviour is strongly related to their conduction mechanism32,33. At higher pressure, the charge carrier mobility and the rate of hopping increase, hence, the dielectric polarisation increases, causing an increase in the dielectric constant. With increasing frequency, the charge carrier hopping cannot follow the alternating current which leads to a decrease polarisation. This type of polarization mechanism has been discussed by Aziz et al.34.

ε″ is a measure of the dissipated energy in the dielectric material, due to the presence of an applied electric field. The evolution of ε″ as a function of frequency at different pressures is shown in Fig. 7(b). At low frequencies, ε″ decreases rapidly with increasing frequency and then becomes constant at higher frequencies. The fast decrease in ε″ at lower frequencies is attributed to space charge polarisation in the pellet sample. ε″ is almost constant at higher frequencies, because of an inability to follow the applied external electric field. This type of polarisation can be explained using the Maxwell-Wagner-Sillars theory of dielectric dispersions35,36. The ε″ peak position shifts towards higher frequency with increasing pressure, showing that the relaxation process increases with the pressure. This could be because, as the pressure increases, the polar charge carriers are freer to orient, allowing them to adjust to the changing electric field.

Additional information that can be deduced from the loss tangent tanδ (=ε″/ε′), which is proportional to the amount of energy dissipated in a dielectric material. The variation of tanδ with frequency at different pressure is shown in Fig. 7(c). It can be seen that tanδ decreases rapidly at low frequencies, and becomes almost constant at high frequencies. This confirms that the Maxwell-Wagner relationship is responsible for the enhanced dielectric permittivity at low frequency. The decrease in tanδ at low frequencies suggests that the present SnO2 nanoparticles could be used in high frequency devices.

Electric modulus analysis

Investigating the form of the complex electric modulus M is another approach to exploring the electrical properties of the SnO2 nanoparticles. This approach can also magnify other effects present in the sample because of different relaxation time constants. The real (M′) and imaginary (M″) parts of the complex electric modulus were obtained from the impedance data in a conventional way according to the following equations37:

M′ and M″ for our SnO2 nanoparticles at various compression pressures are shown in Fig. 8(a) and (b), respectively. In Fig. 8(a), M′ tends to zero at low frequencies, suggesting that the interface effect tends to be eliminated in the modulus representation. At high frequencies, M′ displays a maximum value corresponding to M′max, which can be attributed to the phenomenon of conduction due to the mobility of charge carriers at a small distance. The plots in Fig. 8(b) are characterized by the presence of a relaxation peak. At lower frequencies, charge carriers can move freely over longer distances, up to a certain frequency (peak maximum). A further increase in frequency confines carriers to potential wells. Therefore, the region where the peak occurs indicates the transition from long-range to short-range mobility with increasing frequency38.

(a) Dependence of the (a) real M′ and (b) imaginary M″ parts of the complex modulus on frequency for the SnO2 nanoparticles at different compression pressures. (c) Normalised imaginary part of the electric modulus M″/M″max versus normalised frequency f/fmax for the SnO2 nanoparticles under different compression pressures. (d) M″/M″max and Z″ versus angular frequency ω, for the SnO2 nanoparticles at a compression pressure of 12.6 GPa.

Figure 8(c) shows the dielectric spectra of the normalised imaginary part of the electric modulus M″/M″max as a function of the normalised frequency f/fmax, at different pressure. The data under different pressures overlap almost perfectly, except for their high-frequency tails. This indicates that all dynamic processes occurring on different time scales exhibit a distribution of relaxation times that is independent of compression pressure.

The combined plot of M″/M″max and Z″ versus angular frequency can distinguish whether the short- or long- range movement of charge carriers dominates the relaxation process. Figure 8(d) shows plots of M″/M″max and Z″ versus angular frequency, at a compression pressure of 12.6 GPa. The peak maxima of the two curves do not occur at the same frequency. This indicates that the relaxation process is dominated by the short range movement of charge carriers, and thus departs from ideal Debye-type behaviour39.

Conclusions

The electric and dielectric properties of SnO2 nanoparticles were investigated as a function of frequency and pressure. The pressure-induced structural phase transitions in the SnO2 nanoparticles correspondingly change their electrical transport and dielectric properties. Complex impedance plots reveal only one semi-circular curve, which is attributed to the grain effect. The AC conductivity and electric modulus studies suggest hopping-type conduction in this system. Frequency-dependent AC conductivity data obey the universal power law at each compression pressure. The dielectric constant and dielectric loss factor decrease with increasing frequency and pressure, which can be interpreted by the Maxwell-Wagner-Sillars model. Furthermore, detailed studies of modulus spectra suggest that the SnO2 nanoparticles exhibit a non-Debye type of relaxation mechanism. These findings hint at the potential of SnO2 nanoparticles in dielectric applications.

References

Jiang, J. et al. Transport mechanisms in SnO2:N, H thin film grown by chemical vapor deposition. Phys. Status Solidi B. 254 https://doi.org/10.1002/pssb.201700003 (2017).

Parveen, A., Ahmad, S. A., Agrawal, S. & Azam, A. Room temperature variation in dielectric and electrical properties of Mn doped SnO2 nanoparticles. Mater. Today Proc. 4, 9429–9433 (2017).

Khan, R. Zulfiqar, Fashu, S. & Zaman, Y. Magnetic and dielectric properties of (Co, Zn) co-doped SnO2 diluted magnetic semiconducting nanoparticles. J Mater Sci: Mater Electron. 27, 5960–5966 (2016).

Le, Tran, Dang, Huu Phuc & Le, VanHieu Determination of the optimum annealing temperature and time for Indium-doped SnO2 films to achieve the best p-type conductive property. J Alloy Compd. 696, 1314–1322 (2017).

Biswas, S. & Bhattacharya, S. Influence of SnO2 nanoparticles on the relaxation dynamics of the conductive processes in polyaniline. Phys Lett A. 381, 3424–3430 (2017).

Soltan, W. B., Nasri, S., Lassoued, M. S. & Ammar, S. Structural, optical properties, impedance spectroscopy studies and electrical conductivity of SnO2 nanoparticles prepared by polyol method. J Mater Sci: Mater Electron. 28, 6649–6656 (2017).

Singh, A. K., Janotti, A., Scheffler, M. & Van de Walle, C. G. Sources of electrical conductivity in SnO2. Phys. Rev. Lett. 101, 055502 (2008).

Bose, A. C., Balaya, P., Thangadurai, P. & Ramasamy, S. Grain size effect on the universality of AC conductivity in SnO2. J. Phys. Chem. Solids 64, 659–663 (2003).

Liu, Y. et al. Highly conductive In-SnO2/RGO nano-heterostructures with improved lithium-ion battery performance. Sci. Rep. 6, 25860 (2016).

Helainne, T. G. et al. Pressure-Induced Disordering in SnO2 Nanoparticles. J. Phys. Chem. C. 121, 15463–15471 (2017).

Garg, A. B. Pressure-induced volume anomaly and structural phase transition in nanocrystalline SnO2. Phys. Status Solidi B 251, 1380–1385 (2014).

Shieh, S. R., Kubo, A., Duffy, T. S., Prakapenka, V. B. & Shen, G. High-pressure phases in SnO2 to 117 GPa. Phys. Rev. B 73, 014105 (2006).

Ono, S. et al. Thermoelastic properties of the high-pressure phase of SnO2 determined by in situ X-ray observations up to 30 GPa and 1400 K. Physics and Chemistry of Minerals 27, 618–622 (2000).

Jiang, J. Z., Gerward, L. & Olsen, J. S. Pressure induced phase transformation in nanocrystal SnO2. Scr. Mater. 44, 1983–1986 (2001).

Hellwig, H., Goncharov, A. F., Gregoryanz, E., Mao, H. K. & Hemley, R. J. Brillouin and Raman spectroscopy of the ferroelastic rutile-to-CaCl2 transition in SnO2 at high pressure. Phys. Rev. B 67, 174110 (2003).

Moreno, M. S., Egerton, R. F. & Midgley, P. A. Differentiation of tin oxides using electron energy-loss spectroscopy. Phys. Rev. B 69, 233304 (2004).

Ono, S., Funakoshi, K., Nozawa, A. & Kikegawa, T. High-pressure phase transitions in SnO2. Journal of Applied Physics 97, 073523 (2005).

da Silva, A. F. et al. Optical properties of oxide compounds PbO, SnO2 and TiO2. Phys. Scr. T 109, 180 (2004).

Thangadurai, P. C., Bose, A. C., Ramasamy, S., Kesavamoorthy, R. & Ravindran, T. R. High pressure effects on electrical resistivity and dielectric properties of nanocrystalline SnO2. J. Phys. Chem. Solids 66, 1621–1627 (2005).

Zulfiqar, Y. Y. et al. Structural, dielectric and ferromagnetic behavior of (Zn, Co) co-doped SnO2 nanoparticles. Ceram. Int. 42, 17128–17136 (2016).

Wang, Y. et al. In situ impedance measurements in diamond anvil cell under high pressure. Rev. Sci. Instrum. 81, 013904 (2010).

Kumar, A., Singh, B. P., Choudhary, R. N. P. & Thakur, A. K. Characterization of electrical properties of Pb-modified BaSnO3 using impedance spectroscopy. Materials Chemistry and Physics 99, 150–159 (2006).

Sati, P. C., Arora, M., Chauhan, S., Kumar, M. & Chhoker, S. Structural, magnetic, vibrational and impedance properties of Prand Ti co doped BiFeO3 multiferroic ceramics. Ceram. Int. 40, 7805–7816 (2014).

Rhimi, T., Toumi, M., Khirouni, K. & Guermazi, S. AC conductivity, electric modulus analysis of KLi(H2PO4)2 compound. J. Alloy Compd 714, 546–552 (2017).

Ram, M. Synthesis and electrical properties of (LiCo3/5Fe1/5Mn1/5)VO4 ceramics. Solid State Sci. 12, 350–354 (2010).

Nasri, S., Megdiche, M. & Gargouri, M. The investigation of dielectric properties and ac conductivity of new ceramic diphosphate Ag0.6Na0.4FeP2O7 using impedance spectroscopy method. Physica E: Low-dimensional Systems and Nanostructures 84, 182–190 (2016).

Chizhov, A. S., Rumyantseva, M. N. & Gaskov, A. M. Frequency-dependent electrical conductivity of nanocrystalline SnO2. Neorg. Mater. 49, 1000–1004 (2013).

Sahay, P. P., Mishra, R. K., Pandey, S. N., Jha, S. & Shamsuddin, M. AC transport properties of nanocrystalline SnO2 semiconductor. Ceram. Int. 38, 1281–1286 (2012).

Sahay, P. P., Mishra, R. K., Pandey, S. N., Jha, S. & Shamsuddin, M. Structural, dielectric and photoluminescence properties of co-precipitated Zn-doped SnO2 nanoparticles. Curr. Appl. Phys. 13, 479–486 (2013).

Elliott, S. R. Temperature dependence of a.c. conductivity of chalcogenide glasses. Philos. Mag. 37, 553–560 (1978).

He, Y. et al. High-pressure behavior of SnO2 nanocrystals. Phys. Rev. B 72, 212102 (2005).

Zhang, J. et al. Electrical Transport Properties of SnO2 under High Pressure. J. Phys. Chem. C. 115, 20710–20715 (2011).

Thakur, S., Katyal, S. C. & Singh, M. Improvement in electric and dielectric properties of nanoferrite synthesized via reverse micelle technique. Appl. Phys. Lett. 91, 262501 (2007).

Aziz, A. et al. Effect of Gd and Cu on the structural, electrical, and dielectric properties of MnFeO3 nanomaterials synthesized by the sol–gel method. J. Electron. Mater. 44, 4300–4307 (2015).

Maxwell, J. C. Electricity and magnetism. (Oxford University Press, New York, 1973).

Chaari, M. & Matoussi, A. Effect of Sn2O3 doping on structural, optical and dielectric properties of ZnO ceramics. Mater. Sci. Eng. B 178, 1130–1139 (2013).

Ben Rhaiem, A. B., Guidara, K., Gargouri, M. & Daoud, A. Electrical properties and equivalent circuit of trimethylammonium monobromodichloromercurate. J. Alloy. Compd 392, 68–71 (2005).

Das, P. S., Chakraborty, P. K., Behera, B. & Choudhary, R. N. P. Electrical properties of Li2BiV5O15 ceramics. Physica B: Condensed Matter 395, 98–103 (2007).

Pant, M., Kanchan, D. K. & Gondaliya, N. Transport properties and relaxation studies in BaO substituted Ag2O–V2O5–TeO2 glass system. Mater. Chem. Phys. 115, 98–104 (2009).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11674404, 11374121, 11404133, 11304034, 11774126 and 11604133), the Open Project of the State Key Laboratory of SuperhardMaterials (Jilin University, Grant No. 201612), and Project 2017113 supported by the Graduate Innovation Fund of Jilin University.

Author information

Authors and Affiliations

Contributions

C.G. conceived and designed the research; W.S., T.O., J.W., T.Q., G.Z., and X.Z. performed high-pressure in situ AC impedance measurements; W.S. performed high-pressure X-ray diffraction measurements; Y.H. and Y.M. refined the data; W.S. wrote the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shen, W., Ou, T., Wang, J. et al. Effects of high pressure on the electrical resistivity and dielectric properties of nanocrystalline SnO 2 . Sci Rep 8, 5086 (2018). https://doi.org/10.1038/s41598-018-22965-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-22965-8

This article is cited by

-

Impedance analysis and modulus behavior of Ca0.85Er0.1Ti(1−x)Co4x/3O3 (x = 0.15 and 0.20) ceramic prepared by sol–gel reaction

Applied Physics A (2022)

-

Green Synthesis of SnO2 Nanoparticles for Catalytic Degradation of Rhodamine B

Iranian Journal of Science and Technology, Transactions A: Science (2020)

-

Microstructural, structural and dielectric analysis of Ni-doped CaCu3Ti4O12 ceramic with low dielectric loss

Journal of Materials Science: Materials in Electronics (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.