Abstract

Replacement of precious platinum catalyst with efficient and cheap bifunctional alternatives would be significantly beneficial for electrocatalytic oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) and the application of these catalysts in fuel cells is highly crucial. Despite numerous studies on electrocatalysts, the development of bifunctional electrocatalysts with comparatively better activity and low cost remains a big challenge. In this paper, we report a nanomaterial consisting of nanocactus-shaped Co3O4 grown on carbon nanotubes (Co3O4/CNTs) and employed as a bifunctional electrocatalyst for the simultaneous catalysis on ORR, and OER. The Co3O4/CNTs exhibit superior catalytic activity toward ORR and OER with the smallest potential difference (0.72 V) between the \({{\boldsymbol{E}}}_{{{\boldsymbol{j}}}_{{\bf{10}}}}\) (1.55 V) for OER and E1/2 (0.83 V) for ORR. Thus, Co3O4/CNTs are promising high-performance and cost-effective bifunctional catalysts for ORR and OER because of their overall superior catalytic activity and stability compared with 20 wt% Pt/C and RuO2, respectively. The superior catalytic activity arises from the unique nanocactus-like structure of Co3O4 and the synergetic effects of Co3O4 and CNTs.

Similar content being viewed by others

Introduction

Fabrication of hybrid nanomaterials that preserves improved properties other than the original properties of their base materials is an important issue in nanoscience and technology. Among the different allotropes of carbon nanomaterials, carbon nanotubes (CNTs) are one of the most promising nanomaterials for catalysis and sensing1,2,3,4. The catalytic sites in renewable and green energy systems need to be supported on conducting materials. These sites can be made of metallic nanostructures (such as nanoparticles and nanoflowers) or organometallic complexes. CNTs are potential ideal support material for electrocatalysts because of its electrical conductivity, high surface area, and relatively enhanced durability5. Noncovalent chemical approach to ensure a close incorporation between the CNTs and the metallic sites is promising because of its simple fabrication method and better preservation of the electronic properties of the CNTs without damaging the π-configuration.

Persistent environmental impact and increasing demands of traditional energy resources, such as, oil, gas, and coal have stimulated extensive efforts worldwide to develop renewable and green energy technologies, such as fuel cells (FCs) and water splitting systems1,6,7,8,9,10,11,12. Among many electrochemical reactions in FCs, the oxygen reduction reaction (ORR) is considered as the heart of FCs because it is the only reaction in cathode. By contrast, electrocatalytic oxygen evolution reaction (OER) through water splitting has been recognized as one of the most promising ways to generate oxygen4. Precious metals such as platinum (Pt) and/or its alloy materials have been most frequently used active electrocatalyst for both reactions13,14,15,16. However, Pt-based materials are susceptible to the poor durability and crossover effect in FCs17,18. Moreover, the high cost and bottleneck reserve in nature of Pt have also prohibited the full commercialization of FCs19,20. Meanwhile, transition metals and their alloys21,22,23,24 have been demonstrated as promising catalysts for ORR and/or OER. So far, the catalytic activities of many nonprecious metal electrocatalysts remain too low compared with those of noble metal catalysts. Moreover, the catalytic activity of the former electocatalysts is largely hindered by their inherent corrosion and oxidation susceptibility.

A number of cobalt oxides with uniform porous structure and large surface area have been employed as nonprecious catalysts to the electrochemical energy conversion reactions25,26,27,28,29. These catalysts have currently attracted much interest in the field of electrocatalysis because of their chemical and physical properties29. In particular, Co3O4 with spinel crystal structure is beneficial for the electron transport between Co2+ and Co3+ ions. Thus, Co3O4 has been widely considered as an efficient electrocatalyst for ORR and OER30,31,32,33. However, Co3O4 itself shows lower electrocatalytic activity because of its low electrical conductivity and dissolution, short active site density and agglomeration nature during electrocatalytic processes30. Nevertheless, further studies have exhibited that the synergy between carbon nanomaterials (i.e. graphene and CNTs) and Co3O4 can give a huge promotion of the electrocatalytic activity26,28,34,35,36,37. Many researches have investigated on Co3O4-based hybrid catalysts and obtained uniformly dispersed Co3O4 nanostructures (i.e. nanoparticles, core-shell, and hollow sphere) to improve electrocatalyst activity30,38,39,40,41. The results show that the size and shape of the nanocatalysts are deeply related to their electrocatalytic performances, and using these hybrid catalysts is considered one of the best strategies for improving catalytic activity and stability42.

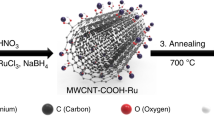

Multifunctional (i.e. bifunctional or trifunctional)28,41,43 catalyst systems have been reported. However, a bifunctional catalyst system with enhanced activity for ORR and OER is difficult to develop because of the pH-dependent activity and stability43. OER electrocatalysts exhibit poor performance in alkaline electrolyte than acid electrolyte44. So far, doped-free and noncovalent CNTs with Co3O4-hybrid bifunctional catalyst for ORR, and OER has not been reported to date, although the N-doped graphene or CNTs with Co3O4-hybrid catalysts are rarely discussed28,30. Therefore, new strategies to develop a simply prepared, highly efficient, and cost-effective Co3O4- and CNT-based hybrid bifunctional electrocatalysts for ORR and OER is desirable for the large-scale production of clean energy. In this study, we have developed a simple strategy to synthesize Co3O4 nanocactus grown on CNTs (Co3O4/CNTs; in Fig. 1). For the first time, the Co3O4/CNTs were successfully employed as bifunctional Co3O4-based electrocatalyst for ORR and OER. The porous Co3O4/CNTs exhibited superior electrocatalytic activity and stability than the benchmarks Pt/C or RuO2 for ORR and OER, respectively, because of their high density of active sites and excellent charge transport capability.

Experimental Section

The Co3O4/CNTs were synthesized by a simple chemical method. In a typical preparation, CoCl2.6H2O (62 mg) was mixed with 30 mL of water. Then, 30 mg of multiwalled CNTs, which were treated with acid for 30 min45, were mixed with 30 mL of water. The solution was added into the CoCl2.6H2O solution and vigorously stirred for 1 h. The pH was controlled by slowly adding a solution of 0.21 mol L−1 NaOH and 0.066 mol L−1 Na2CO3 under vigorous stirring until pH 10 was reached at room temperature (RT). The prepared suspension was kept at 60 °C for next 24 h under gentle stirring. Finally, the Co3O4/CNTs were filtered and washed with water for and dried at 60 °C. The bare CNTs were prepared using the same protocol but without addition of CoCl2.6H2O solution. Also, the Co3O4/CNTs in various pH values (i.e. pH 7, 12, 14) were prepared by controlled addition of aforementioned alkaline solution. The electrochemical and instrumental characterizations were described in the supporting information.

Results and Discussions

Figure 1 shows that the Co3O4 precursor and clean CNTs were mixed with a simple cooperative assembly of prepared alkaline solution in water at RT. The solution was then kept at 60 °C under gentle stirring for next 24 h to form Co3O4 nanocactus onto CNTs. The growth of Co3O4 nanocactus probably goes through a modified mechanism as below46-

However, the as prepared Co3O4/CNTs were found with a highly crystalline form. The growth of Co3O4 nanocactus grown on CNTs (Figure S1) was confirmed by transmission electron microscopy (TEM) analysis in Fig. 2. TEM revealed that the numerous nano-sized Co3O4 cactus were grown onto CNTs (Fig. 2a) and the average size of a single unit of nanocactus was ~25 nm in length with ~5 nm thick sidewall (Fig. 2b). High resolution TEM (HRTEM) showed the crystalline spinel structure of the Co3O4 nanocactus (Fig. 2c) and the lattice spacing of 2.4 Å and 2.8 Å can be assigned to the (311) and (220) planes of typical Co3O447. The bulk elemental component of Co3O4/CNTs was investigated by energy dispersive X-ray spectroscopy (EDX) in Fig. 2d. The C peak at 0.2 keV was accompanied by an O peak in the EDX spectra. Three Co peaks at ~0.77, 6.9 and 7.63 keV corresponding to CoLα1, CoLβ1 and CoLγ1, respectively, were also obtained in the EDX spectra. The as-prepared Co3O4/CNTs consisted of 6.93 wt% Co, 81.93 wt% C, and 11.14 wt% O. Also, Fig. 2 shows bright-fiend TEM image (e) and C (f), Co (g) elemental mapping of Co3O4/CNTs sample which confirming once again the presence of C and Co elements.

The TEM results are consistent with the X-ray diffraction (XRD) data. XRD was performed to investigate the phase structure of Co3O4/CNTs. In Fig. 3a, several peaks of the pristine Co3O4 were consistent with the standard Co3O4 (ICDD: 98-008-8940, red line). Except for the broad peak (002) at ~25°, which may be ascribed to disordered stacked graphitic structure of CNTs, the major diffraction peaks of Co3O4/CNTs were in good agreement with those of Co3O448,49,50. The type IV N2 adsorption/desorption isotherm curve with a distinct hysteresis loop in the relative pressure range of 0.45–0.99 confirmed the presence of mesopores in Co3O4/CNTs and bare CNTs samples (Fig. 3b). The Brunaue–Emmett–Teller specific surface area (SSA) for Co3O4/CNTs was measured to be 373 m2 g−1, which was approximately 3-magnitudes higher than the corresponding typical values for Co3O4-decorated carbon nanomaterials (i.e., Co3O4/N-rGO, 103.9 m2 g−1; Co@Co3O4/NC–1, 111 m2 g−1; Co3O4/CNW-A, 166 m2 g−1)28,30,32. On the contrary, the SSA for bare CNTs was 133.2 m2 g−1. Barrett–Joyner–Halenda pore size distribution curves confirm the presence of the main mesopores with various sizes between 3 nm and 25 nm (average pore diameter, 6.9 nm) and a pore volume of 1.32 cm3 g−1. The average pore diameter and pore volume were much higher than those of bare CNTs (Fig. 3b inset). Therefore, a large SSA, high pore volume, and wide pore size distribution are the clear indication of facile electrocatalysis on Co3O4/CNTs sample.

X-ray photoelectron spectroscopy (XPS) was performed to elucidate the chemical changes and confirmed the cobalt state during Co3O4 growth on CNTs. The peaks obtained in the XPS spectra at 284.2, 531.0 and 780.7 eV (Fig. 3c) could be ascribed to C1s, O1s and Co2p, respectively, due to the existence of carbon, oxygen and cobalt in Co3O4/CNTs. Significant difference was observed in the presence of Co3O4 in Co3O4/CNTs compared with bare CNTs. The high-resolution C1s XPS spectra of bare CNTs (Fig. 3d) and Co3O4/CNTs (Fig. 3e) represent the defective sp3-carbon and basal-plane sp2-carbon of CNTs51. Both figures showed four absorbance peaks for oxygenated sp3-carbon at 285.8, 287.3, and 289.7 eV, which were attributed to C–O, C=O, and O–C=O, respectively, including distinct oxygen-free sp2-carbon (C=C) at 285.0 eV52. Moreover, a tiny shakeup peak was obtained at 292.2 eV for π–π*, signifying higher degree of graphitization53,54. The tiny peak at low binding energy of 284.1 eV could probably be attributed to the C–Co bond in Co3O4/CNTs55. The overall elemental composition of Co3O4/CNTs is listed in Table S1. Furthermore, XPS confirmed the oxidized state of the Co-species with the detection of binding energies of 781.7 eV and 797.6 eV which were attributed to Co2p3/2 and Co2p1/2 peaks, respectively (Fig. 3f)56,57. However, the Co0, Co3+ and Co2+ species were detected at 781.4, 781.6, and 783.8 eV in Co2p3/2 with corresponding satellite peak (786.7 eV) due to the presence of Co3O4 in the Co3O4/CNTs sample. At Co2p1/2, the Co3+ and Co2+ species also appeared at 797.45 eV and 799.6 eV with its shakeup satellite at 803.3 eV. Moreover, the numerical analysis of XPS data was also recorded, and Co was detected as 6.94 wt% with a good ratio of Co3+/Co2+ (1.1) at pH 10 which was the lowest value among all pHs (Figure S2 and Table S2).

Electrochemical ORR on Co3O4/CNTs

The linear sweep voltammogram (LSV) curves on rotating disk electrode (RDE) exhibited ORR for Co3O4/CNTs, bare CNTs (catalyst mass loading, 153 μg cm−2) and 20 wt% Pt/C electrodes in O2-saturated 0.1 M KOH solution at a scan rate of 5 mV s−1 and at 1600 rpm (Fig. 4a) and signify the electrocatalytic ORR performance on all electrodes. The superior electrocatalytic ORR was observed on Co3O4/CNTs in terms of the improved onset potential (Eonset) of 0.93 V and a half-wave potential (E1/2) of 0.83 V than the CNTs (Eonset, 0.83 V and E1/2, 0.76 V (Figure S3). These values were also superior to those of commercially available Pt/C (Eonset of 0.91 V and E1/2 of 0.83 V) and several other reported Co3O4-based catalysts for ORR26,58. Moreover, the current density (j, normalized by electrode area, 0.196 cm2) at the Co3O4/CNTs electrode was higher than that of the CNTs modified electrode and closer to that of Pt/C. Thus, the Co3O4/CNTs showed better electrocatalytic activity for ORR in terms of Eonset, E1/2, and j. This result highlights the importance of the incorporation of nanocactus-shaped Co3O4 with CNTs that have mesoporous structure and higher SSA. The ORR dynamics at the Co3O4/CNTs electrode were then investigated by RDE, and the results are shown in Fig. 4b. Figure 4b displays a series of RDE curves for ORR using the Co3O4/CNTs catalyst at various rotation speeds in same electrolyte at 5 mV s−1 scan rate. The obtained data were analyzed using Koutecky–Levich (K−L) equation as follows58,59,60:

where j, jk, and jL are the measured, kinetic, and diffusion limiting current densities (mA cm−2), respectively; n is the electron transfer number per O2, and A is the surface area of the working electrode, Moreover, F and T are Faraday constant (96485.3 C mol−1) and temperature, respectively; \({D}_{{O}_{2}}\) and \({C}_{{O}_{2}}\) are the oxygen diffusion coefficient (1.9 × 10−5 cm2 s−1) and the bulk concentration (1.2 mM L−1), respectively, in 0.1 M KOH60; v is the kinetic viscosity of the electrolyte (1 × 10−2 cm2 s−1); ω is the angular velocity of electrode (2π*rpm), and k is the electron-transfer rate constant. Based on the K–L equation, a plot of jk−1 vs. ω−1/2 was yield a straight line and the slopes of those plots reflect the B factor in equation (7).

LSV curves for ORR on CNTs, Co3O4/CNTs and Pt/C catalyst in O2-saturated 0.1 M KOH solution at a scan rate of 5 mV s−1 and at a rotating speed of 1600 rpm (a), LSV curves on Co3O4/CNTs in same electrolyte at various rotating speeds and K–L plots in inset (b), RRDE curves for ORR at 1600 rpm with a constant applied potential of 0.8 V vs. RHE on the ring electrode (c), the transferred electron number and the corresponding H2O2 synthesis during ORR (d), Tafel plots (e) on CNTs, Co3O4/CNTs and Pt/C electrodes, and LSV curves on Co3O4/CNTs and Pt/C before (solid lines) and after (dotted lines) 3000 cycles (f).

However, Fig. 4b inset shows the K–L plots for Co3O4/CNTs electrode and the slopes of all K–L plots remain approximately constant over the studied potential range. This result indicates the number of electrons transferred in the ORR remained constant. Based on equations (6) and (7), the average n value in ORR was estimated to be 4, suggesting a four-electron (4e−) pathway for electrocatalytic ORR61,62,63. The ORR dynamics on the CNTs electrode were also investigated by RDE and the average n value in ORR was estimated to be 3.6 from corresponding K–L plots (Figure S4). The jk obtained from the intercept of the K–L plots for the Co3O4/CNTs (16.5 mA cm−2 at 0.8 V) was 3.1-magnitudes larger than that of bare CNTs (5.2 mA cm−2) catalyst and similar to that of Pt/C (17.3 mA cm−2). The ORR activities on as-synthesized Co3O4/CNTs at various pH values were also investigated (Figure S5a). Although the Co3O4/CNTs @ pH 12 has the highest Co3O4 (Table S2), the relatively low Co3+/Co2+ might lead to a high charge-transfer (Figure S5b). Hence, a relatively better electrocatalytic activity was observed at Co3O4/CNTs @ pH 10 in based on the higher jk among all pH-dependent Co3O4/CNTs (Figure S5a inset).

The rotating ring–disk electrode (RRDE) measurement was performed to further evaluate the ORR pathway on Co3O4/CNTs, bare CNTs, and Pt/C electrodes. The Co3O4/CNTs electrode exhibited high disk current density (jd) for ORR and much lower ring current density (jr) than CNTs. The jr profiles accompanied with further reduction of peroxide species synthesized during ORR process are shown in the upper curves. Both jd and jr from Pt/C are very similar to that of Co3O4/CNTs.

The RRDE data were used to further verify the transferred electron number and monitor the corresponding H2O2 formation on aforementioned three electrodes during ORR process from equations (9) and (10)28,64 in Fig. 4d. The average n value for ORR at the Co3O4/CNTs electrode (3.96) was consistently higher than that at the CNTs (3.6) over the tested potential range of 0.7–0.2 V (vs. RHE). The corresponding H2O2 yields were 3.5% and 9.6% for Co3O4/CNTs and CNTs, respectively, over the same potential range. The calculated n value (3.98) and H2O2 (2.9%) yield on Pt/C were slightly higher than the Co3O4/CNTs. The calculated n values are similar to the result obtained from the K–L plots, signifying that the ORR on Co3O4/CNTs hybrid was mainly by 4e− involved pathway and the main byproduct was H2O.

where N is the collection efficiency of the RRDE (0.37), and id and ir are the disk and ring electrode currents, respectively.

The estimated jk values were plotted against the electrode potential to investigate the Tafel behavior of Co3O4/CNTs, CNTs and Pt/C (Fig. 4e). The better ORR activity on Co3O4/CNTs was further confirmed by the lower Tafel slope of 63 mV dec−1 at low overpotential (η) than the CNTs (73 mV dec−1) and similar to that of Pt/C (61 mV dec−1). Furthermore, the LSV curves before and after the accelerated degradation test (ADT) on Co3O4/CNTs and Pt/C in Fig. 4f. It was found that the E1/2 shifted largely at the negative direction (21 mV), and jL lost 17.9% on Pt/C after 3000 consecutive cycles. By contrast, the 3.5- and 9-magnitudes lower E1/2 shift (6 mV) and jL loss (2%) were observed on the Co3O4/CNTs under the same conditions. Moreover, Figure S6a shows the current density as the function of time by chronoamperometry technique for Co3O4/CNTs and Pt/C at an applied potential of 0.8 V. The j was maintained up to 93% after 20 h run in real condition, indicating that the catalytic activity on Co3O4/CNTs could be sustained for a long time. For Pt/C, the catalytic activity was then maintained up to 76% with the same period of time. In addition, the Co3O4/CNTs electrode demonstrated good methanol tolerance than the Pt/C (Figure S6b). The TEM image of used Co3O4/CNTs displays the decay morphology with the crystalline nature of Co3O4 after 20 h of real-time continuous monitoring. These results indicate that the Co3O4/CNTs are a competent ORR electrocatalyst because of its better electrocatalytic activity, fuel selectivity, and operational stability than the Pt/C.

Electrochemical OER on Co3O4/CNTs

To evaluate the potential use of our hybrid catalyst, we employed Co3O4/CNTs electrode to evaluate the electrocatalytic OER. The OER catalytic activities of all catalysts were studied by LSV at 5 mV s−1. The Co3O4/CNTs were used with same mass loading and afforded higher OER activity than either bare bulk Co3O4, CNTs or RuO2 in Fig. 5. Figure 5a shows that the Eonset for bulk Co3O4 was 1.55 V and the maximum j was 13.6 mA cm−2 at 1.7 V. The Eonset for RuO2 was 1.36 V with maximum of j = 31 mA cm−2 at the same electrode potential. However, considerable negative shifted in the Eonset was observed at Co3O4/CNTs (1.43 V) with highest j = 70.8 mA cm−2 at 1.7 V and the CNTs showed the lowest performance than all electrodes. However, the Co3O4/CNTs electrode showed a potential of 1.55 V at the current density of 10 mA cm−2 \(({E}_{{j}_{10}})\), which was lower than that of bulk Co3O4 (1.68 V) and RuO2 (1.61 V). Moreover, as shown in Fig. 5a inset, the η required to drive a j10 for the Co3O4/CNTs was 280 mV, which was also significantly lower than that for the bulk Co3O4 and RuO2 (440 mV and 380 mV, respectively). Thus, the Co3O4/CNTs exhibited higher OER activity than the bulk Co3O4, CNTs and RuO2 electrodes in respect to the η and j. This result indicating that the Co3O4/CNTs have higher density of active sites than bulk Co3O4 and CNTs, and the porous Co3O4 served as the better active catalytic site for the superior OER even better than benchmark RuO2 which resulted in the synergic effect of Co3O4 and CNTs, the porous nanocactus-like structure, and better Co3+/Co2+ ratio. These characteristics allowed improved ability for electron transfer. The poor current densities of bare CNTs and Co3O4 were probably due to the degradation nature of carbon32 and aggregation with less conducive nature, respectively26.

Comparison of the OER activity of CNTs, bulk Co3O4, Co3O4/CNTs and RuO2 electrodes by LSV (a), corresponding Tafel plots of those electrodes (b), LSV curves for the 1st and 1000th potential cycles (c), bifunctional catalytic activities of CNTs, Co3O4/CNTs and benchmarks Pt/C or RuO2 catalysts toward both ORR and OER (d); the overall LSV curves in the potential range of 0.2 to 1.7 V was investigated in argon-saturated 0.1 M KOH solution at 5 mV s−1 scan rate and at the rotating speed of 1600 rpm. Insets: the comparison of overpotential at j10 (a) and OER activity of Co3O4/CNTs in argon-saturated 0.1 and 1 M KOH solution (c).

The Tafel slope of each catalyst beyond the Eonset was calculated to understand in detail the OER mechanism and the result are shown Fig. 5b. Tafel plots display a lower Tafel slope of 64 mV dec−1 for Co3O4/CNTs than those of RuO2 (71 mV dec−1), bulk Co3O4 (73 mV dec−1) and CNTs (98 mV dec−1), indicating more favorable kinetics toward OER on the Co3O4/CNTs electrode32,65. The Tafel slope of Co3O4/CNTs was also comparable to other reported Co3O4-based OER catalysts26,66. The OER mechanism can be assumed as follows according to the Tafel slope of Co3O4/CNTs. The OER on active Co−O-system65 in Co3O4/CNTs catalyst was initiated by water adsorption and the formation of adsorbed (ads) reactive intermediate, \({{\rm{OH}}}_{{\rm{abs}}}^{\ast }\), by releasing a proton and electron in equation (12). Afterwards, this \({{\rm{OH}}}_{{\rm{abs}}}^{\ast }\) was converted to another type OH, \({{\rm{OH}}}_{{\rm{abs}}}^{\ast }\), in equation (13) (both OH are chemically same but energetically different). In equation (14), a second proton and electron transfer yielded an oxide intermediate, and this step is a rate-determining step (RDS). Recombination of two oxide intermediates completed one reaction turnover in equation (15)67.

Furthermore, the electrochemical stability of Co3O4/CNTs electrode was also compared with RuO2 under a fixed η and electrolyte conditions. Good stability of Co3O4/CNTs electrode was confirmed by the similar LSV curves measured at the 1st and 1000th potential cycles (Fig. 5c). The used catalyst was characterized by XPS, and the results suggest that amperometric operation did not change significantly in the chemical states except the increase in C–O bond in CNTs and satellite band in cobalt (Figure S7). These results also suggest that Co3O4/CNTs have longer stability in electrochemical process than the RuO2. The OER processes at Co3O4/CNTs electrode in 0.1 and 1 M KOH exhibit the same Eonset of 1.43 V (Fig. 5c inset). At higher potentials, the more rapid increase in current density was observed for 1 M KOH owing to higher conductivity of the electrolyte. At 270 mV overpotential, j = 22 mA cm−2 was obtained in 1 M KOH solution, while it was 10 mA cm−2 in 0.1 M KOH.

The overall oxygen activity of the Co3O4/CNTs as a bifunctional catalyst could be evaluated (Fig. 5d) by the potential difference (ΔE) between the \({E}_{{j}_{10}}\) for OER and E1/2 for ORR68. However, the Co3O4/CNTs catalyst showed the smallest ΔE of 0.72 V and this value was markedly lower than the ΔE obtained using commercial Pt/C (0.85 V) and many other Co- and Co3O4-based materials i.e., Co-N/G-600, 0.96 V; Co@Co3O4/NC-1, 0.85 V; Co3O4/N-Gas, 0.79 V21,30,67. This result signifies better reversible oxygen electrode. The detailed comparison with various Co- and Co3O4-based materials is shown in Table 1. These results clearly indicate that the Co3O4/CNTs catalyst is a promising low-cost and efficient catalyst for both ORR and OER.

Conclusion

We demonstrated an easy and generic method to synthesize a unique nanocactus-like structure of Co3O4 material embedded onto CNTs for bifunctional electrocatalysis. The newly developed Co3O4/CNTs were an effective bifunctional ORR and OER electrocatalyst with comparatively better activities and stability than the Pt/C or RuO2 because of their unique architecture with large surface area, rich active sites, and good electron transfer properties. The excellent catalysis and stability of Co3O4/CNTs with abundant active sites could be attributed to the strong interaction between the nanocactus-shaped Co3O4 and CNTs. Thus, Co3O4/CNTs are promising alternatives to noble metal-based catalysts for FCs and water splitting applications because of their low-cost, facile synthesis, and excellent catalysis and stability.

References

Dai, L., Xue, Y., Qu, L., Choi, H.-J. & Baek, J.-B. Metal-free catalysts for oxygen reduction reaction. Chem. Rev. 115, 4823–4892 (2015).

Ahmed, M. S., Jeong, H., You, J.-M. & Jeon, S. Electrocatalytic reduction of dioxygen at a modified glassy carbon electrode based on Nafion-dispersed single-walled carbon nanotubes and cobalt–porphyrin with palladium nanoparticles in acidic media. Electrochim. Acta 56, 4924–4929 (2011).

Boyd, A., Dube, I., Fedorov, G., Paranjape, M. & Barbara, P. Gas sensing mechanism of carbon nanotubes: From single tubes to high-density networks. Carbon 69, 417–423 (2014).

Begum, H., Ahmed, M. S. & Jeon, S. A novel δ-MnO2 with carbon nanotubes nanocomposite as an enzyme-free sensor for hydrogen peroxide electrosensing. RSC Adv. 6, 50572–50580 (2016).

Li, L. et al. Chemical strategies for enhancing activity and charge transfer in ultrathin Pt nanowires immobilized onto nanotube supports for the oxygen reduction reaction. ACS Appl. Mater. Interfaces 8, 34280–34294 (2016).

Hu, C. et al. Newly-designed complex ternary Pt/PdCu nanoboxes anchored on three-dimensional graphene framework for highly efficient ethanol oxidation. Adv. Mater. 24, 5493–5498 (2012).

Gong, K., Du, F., Xia, Z., Durstock, M. & Dai, L. Nitrogen-doped carbon nanotube arrays with high electrocatalytic activity for oxygen reduction. Science 323, 760–764 (2009).

Jiao, L., Zhou, Y.-X. & Jiang, H.-L. Metal–organic framework-based CoP/reduced graphene oxide: high-performance bifunctional electrocatalyst for overall water splitting. Chem. Sci. 7, 1690–1695 (2016).

Begum, H., Ahmed, M. S. & Jeon, S. Highly efficient dual active palladium nanonetwork electrocatalyst for ethanol oxidation and hydrogen evolution. ACS Appl. Mater. Interfaces 9, (39303–39311 (2017).

Shui, J., Wang, M., Du, F. & Dai, L. N-doped carbon nanomaterials are durable catalysts for oxygen reduction reaction in acidic fuel cells. Sci. Adv. 1, e1400129 (2015).

Wang, H. et al. Bifunctional non-noble metal oxide nanoparticle electrocatalysts through lithium-induced conversion for overall water splitting. Nat. Commun. 6, 7261 (2015).

Wang, J. et al. Recent progress in cobalt-based heterogeneous catalysts for electrochemical water splitting. Adv. Mater. 28, 215–230 (2016).

Ahmed, M. S., Park, D. & Jeon, S. Ultrasmall PdmMn1–mOx binary alloyed nanoparticles on graphene catalysts for ethanol oxidation in alkaline media. J. Power Sources 308, 180–188 (2016).

Lim, B. et al. Pd-Pt bimetallic nanodendrites with high activity for oxygen reduction. Science 324, 1302–1305 (2009).

Choe, J. E., Ahmed, M. S. & Jeon, S. 3,4-ethylenedioxythiophene functionalized graphene with palladium nanoparticles for enhanced electrocatalytic oxygen reduction reaction. J. Power Sources 281, 211–218 (2015).

Begum, H., Ahmed, M. S. & Jeon, S. Simultaneous reduction and nitrogen functionalization of graphene oxide using lemon for metal-free oxygen reduction reaction. J. Power Sources 372, 116–124 (2017).

Shao, Y., Liu, J., Wang, Y. & Lin, Y. Novel catalyst support materials for PEM fuel cells: current status and future prospects. J. Mater. Chem. 19, 46–59 (2009).

Ahmed, M. S. & Jeon, S. Highly active graphene-supported NixPd100−x binary alloyed catalysts for electro-oxidation of ethanol in an alkaline media. ACS Catal. 4, 1830–1837 (2014).

Joo, Y., Ahmed, M. S., Han, H. S. & Jeon, S. Preparation of electrochemically reduced graphene oxide-based silver-cobalt alloy nanocatalysts for efficient oxygen reduction reaction. Int. J. Hydrogen Energy 42, 21751–21761 (2017).

Tian, J., Liu, Q., Cheng, N., Asiri, A. M. & Sun, X. Self-supported Cu3P nanowire arrays as an integrated high-performance three-dimensional cathode for generating hydrogen from water. Angew. Chem. Int. Ed. 53, 9577–9581 (2014).

Wang, Q., Hu, W. & Huang, Y. Nitrogen doped graphene anchored cobalt oxides efficiently bi-functionally catalyze both oxygen reduction reaction and oxygen revolution reaction. Int. J. Hydrogen Energy 42, 5899–5907 (2017).

Laursen, A. B. et al. Nanocrystalline Ni5P4: a hydrogen evolution electrocatalyst of exceptional efficiency in both alkaline and acidic media. Energy Environ. Sci. 8, 1027–1034 (2015).

Tüysüz, H., Hwang, Y. J., Khan, S. B., Asiri, A. M. & Yang, P. Mesoporous Co3O4 as an electrocatalyst for water oxidation. Nano Res. 6, 47–54 (2013).

Li, G. et al. Design of ultralong single-crystal nanowire-based bifunctional electrodes for efficient oxygen and hydrogen evolution in a mild alkaline electrolyte. J. Mater. Chem. A 5, 10895–10901 (2017).

Abidat, I. et al. Electrochemically Induced Surface Modifications of Mesoporous Spinels (Co3O4-δ, Mnco2o4-δ, Nico2o4-δ) as the origin of the OER activity and stability in alkaline medium. J. Mater. Chem. A 3, 17433–17444 (2015).

Liang, Y. et al. Co3O4 nanocrystals on graphene as a synergistic catalyst for oxygen reduction reaction. Nat. Mater. 10, 780–786 (2011).

Liu, Y., Jiang, H., Zhu, Y., Yang, X. & Li, C. Transition metals (Fe, Co, And Ni) encapsulated in nitrogen-doped carbon nanotubes as bi-functional catalysts for oxygen electrode reactions. J. Mater. Chem. A 4, 1694–1701 (2016).

Huang, Y., Zhang, M., Liu, P., Cheng, F. & Wang, L. Co3O4 supported on N, P-doped carbon as a bifunctional electrocatalyst for oxygen reduction and evolution reactions. Chinese J. Catal. 37, 1249–1256 (2016).

Grewe, T., Deng, X., Weidenthaler, C., Schuth, F. & Tuysuz, H. Design of ordered mesoporous composite materials and their electrocatalytic activities for water oxidation. Chem. Mater. 25, 4926–4935 (2013).

Aijaz, A. et al. Co@Co3O4 encapsulated in carbon nanotube-grafted nitrogen-doped carbon polyhedra as an advanced bifunctional oxygen electrode. Angew. Chem. Int. Ed. 55, 4087–4091 (2016).

Xu, L. et al. Plasma-engraved Co3O4 nanosheets with oxygen vacancies and high surface area for the oxygen evolution reaction. Angew. Chem. Int. Ed. 55, 5277–5281 (2016).

Liu, S., Li, L., Ahn, H. S. & Manthiram, A. Delineating the roles of Co3O4 and N-doped carbon nanoweb (CNW) in bifunctional Co3O4/CNW catalysts for oxygen reduction and oxygen evolution reactions. J. Mater. Chem. A 3, 11615–11623 (2015).

Yeo, B. S. & Bell, A. T. Enhanced activity of gold-supported cobalt oxide for the electrochemical evolution of oxygen. J. Am. Chem. Soc. 133, 5587–5593 (2011).

Nguyen, T. T. et al. Facile synthesis of cobalt oxide/reduced graphene oxide composites for electrochemical capacitor and sensor applications. Solid State Sci. 53, 71–77 (2016).

Zhang, Y. et al. Crystal plane-dependent electrocatalytic activity of Co3O4 toward oxygen evolution reaction. Catal. Commun. 67, 78–82 (2015).

Begum, H., Ahmed, M. S. & Jeon, S. Ultra-fast and highly sensitive enzyme-free glucose biosensing on a nickel–nickel oxide core–shell electrode. RSC Adv. 7, 3554–3562 (2017).

Fan, T., Yin, F., Wang, H., He, X. & Li, G. A metaleorganic-framework/carbon composite with enhanced bifunctional electrocatalytic activities towards oxygen reduction/evolution reactions. Int. J. Hydrogen Energy 42, 17376–17385 (2017).

Lu, H., Huang, Y., Yan, J., Fan, W. & Liu, T. Nitrogen-doped graphene/carbon nanotube/Co3O4 hybrids: one-step synthesis and superior electrocatalytic activity for the oxygen reduction reaction. RSC Adv. 5, 94615–94622 (2015).

Xu, N. et al. Self-assembly formation of bi-functional Co3O4/MnO2-CNTs hybrid catalysts for achieving both high energy/power density and cyclic ability of rechargeable zinc-air battery. Sci. Rep. 6, 33590 (2016).

Li, X. et al. 3D hollow sphere Co3O4/MnO2 -CNTs: its high-performance bi-functional cathode catalysis and application in rechargeable zinc-air battery. Green Energy & Environ. 2, 316–328 (2017).

Hong, W., Shang, C., Wang, J. & Wang, E. Bimetallic PdPt nanowire networks with enhanced electrocatalytic activity for ethylene glycol and glycerol oxidation. Energy Environ. Sci. 8, 2910–2915 (2015).

Begum, H., Ahmed, M. S. & Jeon, S. Electrodeposited palladium nanotubes on nanoclusters mosaic basement for electrooxidation of hydrazine. J. Nanosci. Nanotechnol. 17, 4961–4969 (2017).

Hu, C. & Dai, L. Multifunctional carbon-based metal-free electrocatalysts for simultaneous oxygen reduction, oxygen evolution, and hydrogen evolution. Adv. Mater. 29, 1604942 (2017).

Kim, H. et al. Coordination tuning of cobalt phosphates towards efficient water oxidation catalyst. Nat. Commun. 6, 8253 (2015).

Ahmed, M. S. & Jeon, S. Electrochemical activity evaluation of chemically damaged carbon nanotube with palladium nanoparticles for ethanol oxidation. J. Power Sources 282, 479–488 (2015).

Hussain, M. M., Rahman, M. M., Asiriab, A. M. & Awual, M. R. Non-enzymatic simultaneous detection of Lglutamic acid and uric acid using mesoporous Co3O4 nanosheets. RSC Adv. 6, 80511–80521 (2016).

Liu, Q., Xu, J., Changab, Z. & Zhang, X. Direct electrodeposition of cobalt oxide nanosheets on carbon paper as free-standing cathode for Li–O2 battery. J. Mater. Chem. A 2, 6081–6085 (2014).

Ahmed, M. S., Kim, D. & Jeon, S. Covalently grafted platinum nanoparticles to multi walled carbon nanotubes for enhanced electrocatalytic oxygen reduction. Electrochim. Acta 92, 168–175 (2013).

Liu, Q. et al. Carbon nanotubes decorated with CoP nanocrystals: a highly active non-noble-metal nanohybrid electrocatalyst for hydrogen evolution. Angew. Chem. 126, 6828–6832 (2014).

Zhou, X. et al. Facile synthesis of a Co3O4@carbon nanotubes/polyindole composite and its application in all-solid-state flexible supercapacitors. J. Mater. Chem. A 3, 13011–13015 (2015).

Ahmed, M. S., Han, H. S. & Jeon, S. One-step chemical reduction of graphene oxide with oligothiophene for improved electrocatalytic oxygen reduction reactions. Carbon 61, 164–172 (2013).

Ahmed, M. S. & Jeon, S. New functionalized graphene sheets for enhanced oxygen reduction as metal-free cathode electrocatalysts. J. Power Sources 218, 168–173 (2012).

Tao, L. et al. Edge-rich and dopant-free graphene as a highly efficient metal-free electrocatalyst for the oxygen reduction reaction. Chem. Commun. 52, 2764–2767 (2016).

Begum, H., Ahmed, M. S. & Jeon, S. New approach for porous chitosan−graphene matrix preparation through enhanced amidation for synergic detection of dopamine and uric acid. ACS Omega 2, 3043–3054 (2017).

Deniau, G., Azoulay, L., Jegou, P., Chevallier, G. L. & Palacin, S. Carbon-to-metal bonds: electrochemical reduction of 2-butenenitrile. Surf. Sci. 600, 675–684 (2006).

Gao, Y. et al. Double metal ions synergistic effect in hierarchical multiple sulfide microflowers for enhanced supercapacitor performance. ACS Appl. Mater. Interfaces 7, 4311–4319 (2015).

An, T. et al. Co3O4 nanoparticles grown on N-doped vulcan carbon as a scalable bifunctional electrocatalyst for rechargeable zinc–air batteries. RSC Adv. 5, 75773–75780 (2015).

Xu, J., Gao, P. & Zhao, T. S. Non-precious Co3O4 nano-rod electrocatalyst for oxygen reduction reaction in anion-exchange membrane fuel cells. Energy Environ. Sci. 5, 5333–5339 (2012).

Ahmed, M. S. & Kim, Y.-B. 3D graphene preparation via covalent amide functionalization for efficient metal-free electrocatalysis in oxygen reduction. Sci. Rep. 7, 43279 (2017).

Wang, S., Yu, D., Dai, L., Chang, D. W. & Baek, J.-B. Polyelectrolyte-functionalized graphene as metal-free electrocatalysts for oxygen reduction. ACS Nano 8, 6202–6209 (2011).

Ahmed, M. S. & Kim, Y.-B. Amide-functionalized graphene with 1,4-diaminobutane as efficient metal-free and porous electrocatalyst for oxygen reduction. Carbon 111, 577–586 (2017).

Zheng, Y., Jiao, Y., Ge, L., Jaroniec, M. & Qiao, S. Z. Two-step boron and nitrogen doping in graphene for enhanced synergistic catalysis. Angew. Chem. Int. Ed. 52, 3110–3116 (2013).

Park, D., Ahmed, M. S. & Jeon, S. Covalent functionalization of graphene with 1,5- diaminonaphthalene and ultrasmall palladium nanoparticles for electrocatalytic oxygen reduction. Int. J. Hydrogen Energy 42, 2061–2070 (2017).

Lee, K., Ahmed, M. S. & Jeon, S. Electrochemical deposition of silver on manganese dioxide coated reduced graphene oxide for enhanced oxygen reduction reaction. J. Power Sources 288, 261–269 (2015).

Zhu, J., Ren, X., Liu, J., Zhang, W. & Wen, Z. Unraveling the catalytic mechanism of Co3O4 for the oxygen evolution reaction in a Li−O2 battery. ACS Catal. 5, 73–81 (2015).

Yu, D., Xu, C., Su, Y., Liu, D. & He, X. Nitrogen-doped graphene aerogels-supported cobaltosic oxide nanocrystals as high-performance bi-functional electrocatalysts for oxygen reduction and evolution reactions. J. Electroanal. Chem. 787, 46–54 (2017).

Antolini, E. Iridium as catalyst and cocatalyst for oxygen evolution/reduction in acidic polymer electrolyte membrane electrolyzers and fuel cells. ACS Catal. 4, 1426–1440 (2014).

Chen, S. et al. Ionic liquid-assisted synthesis of N/S-double doped graphene microwires for oxygen evolution and Zn–air batteries. Energy Storage Mater. 1, 17 (2015).

Prabu, M., Ramakrishnan, P. & Shanmugam, S. CoMn2O4 nanoparticles anchored on nitrogen-doped graphene nanosheets as bifunctional electrocatalyst for rechargeable zinc–air battery. Electrochem. Commun. 41, 59–63 (2014).

Ganesan, P., Prabu, M., Sanetuntikul, J. & Shanmugam, S. Cobalt sulfide nanoparticles grown on nitrogen and sulfur codoped graphene oxide: an efficient electrocatalyst for oxygen reduction and evolution reactions. ACS Catal. 5, 3625–3637 (2015).

Masa, J. et al. Mn x O y /NC and Co x O y /NC nanoparticles embedded in a nitrogen-doped carbon matrix for high-performance bifunctional oxygen electrodes. Angew. Chem. Int. Ed. 53, 8508–8512 (2014).

Acknowledgements

This work was supported in part by the National Research Foundation of Korea (15H1C1A1035825 and 15R1A4A1041746) and in part by Korea Electric Power Cooperation (KEPCO).

Author information

Authors and Affiliations

Contributions

M.S. Ahmed performed all electrochemical experiments, wrote the manuscript and analyzed all the results with due discussion with B. Choi and Y.B. Kim.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ahmed, M.S., Choi, B. & Kim, YB. Development of Highly Active Bifunctional Electrocatalyst Using Co3O4 on Carbon Nanotubes for Oxygen Reduction and Oxygen Evolution. Sci Rep 8, 2543 (2018). https://doi.org/10.1038/s41598-018-20974-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-20974-1

This article is cited by

-

Achievement of an efficient oxygen reduction electrocatalyst based on carbon boosted with MnOx/MnCo2O4 with excellent electrocatalytic activity in neutral media

Carbon Letters (2024)

-

Composite Nanoarchitectonics of Co3O4 Nanopolyhedrons with N-Doped Carbon and Carbon Nanotubes for Alkaline Oxygen Evolution Reaction

Catalysis Letters (2024)

-

A critical review of research progress for metal alloy materials in hydrogen evolution and oxygen evolution reaction

Environmental Science and Pollution Research (2022)

-

Functionalization of UiO-66-NH2 by In-Situ Incorporation of Nanomaterials to Enhance Photocatalytic Efficiency Towards Oxygen Evolution Reaction

Catalysis Letters (2022)

-

A new MnxOy/carbon nanorods derived from bimetallic Zn/Mn metal–organic framework as an efficient oxygen reduction reaction electrocatalyst for alkaline Zn-Air batteries

Journal of Solid State Electrochemistry (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.