Abstract

The magnetic and electrical properties of complex oxide thin films are closely related to the phase stability and cation ordering, which demands that we understand the process-structure-property relationships microscopically in functional materials research. Here we study multiferroic thin films of double-perovskite La2NiMnO6 epitaxially grown on SrTiO3, KTaO3, LaAlO3 and DyScO3 substrates by pulsed laser deposition. The effect of epitaxial strains imposed by the substrate on the microstructural properties of La2NiMnO6 has been systematically investigated by means of advanced electron microscopy. It is found that La2NiMnO6 films under tensile strain exhibit a monoclinic structure, while under compressive strain the crystal structure of La2NiMnO6 films is rhombohedral. In addition, by optimizing the film deposition conditions a long-range ordering of B-site cations in La2NiMnO6 films has been obtained in both monoclinic and rhombohedral phases. Our results not only provide a strategy for tailoring phase stability by strain engineering, but also shed light on tuning B-site ordering by controlling film growth temperature in double-perovskite La2NiMnO6 films.

Similar content being viewed by others

Introduction

Double-perovskite multiferroic La2NiMnO6 (LNMO) received much attention in recent decades due to its abundant magnetoresistance, magnetocapacitance1,2,3 and dielectric properties2,4,5. In particular, the near room temperature magnetic properties have opened up a wealth of promising applications in ferromagnetic semiconductor for spintronics and magnetoelectronics6,7,8. For LNMO materials, chemical ordering of B-site cations (Ni/Mn) strongly affects physical properties, particularly magnetic properties5,7,9,10,11. B-site ordered LNMO shows a single paramagnetic-to-ferromagnetic curie temperature (about 280 K) due to the Ni2+-O-Mn4+ superexchange interaction6,12. In contrast, for B-site disordered LNMO, Ni-O-Ni and Mn-O-Mn bonds are believed to have antiferromagnetic superexchange interactions6,13,14. Additionally, ordering of B-site cations affects crystal structure of LNMO. It was reported that orthorhombic LNMO (Pbnm) is B-site disordered and monoclinic LNMO (P21/n) exhibits a long-range B-site ordering15,16,17,18. For epitaxial films, it is important to note that synthetic conditions such as film-growth temperature and oxygen pressure could affect crystal structure and physical properties of the films7,19,20,21,22, e.g. BaTiO3 films grown on SrTiO3 substrates at different oxygen partial pressures21. Particularly, B-site ordering in double-perovskite films could be influenced by oxygen partial pressure, e.g. La2CoMnO623 and La2NiMnO619,24. It should be noted that the ordering of B-site cations in the double-perovskite films could be improved by controlling the growth temperature, e.g. La2CuSnO6 films25.

In addition, the epitaxial strain of thin films affects the microstructural and physical properties of the films26,27,28,29,30,31,32,33,34,35. R. J. Zeches et al.28 reported that strain-driven phase evolution occurs in multiferroic BiFeO3 films by controlling the epitaxial strain imposed by the substrate. For the double-perovskite Y2NiMnO6 films27, the magnetic properties and the related ferromagnetic transition temperature (T c ) show a strong dependence on the biaxial tensile strain in the films. It is noted that in comparison with the significant studies on the synthesis and properties of bulk materials1,6,13,18,36,37, there was a lack of information on the ordering of B-site in double-perovskite films related to the growth parameters and the epitaxial strain induced structure evolution. In our previous work, the short-range ordering of the B-site cation was obtained in the LNMO films coherently grown on the perovskite-type STO and LSAT substrates at 800 °C26. Nevertheless, phase stability of LNMO films related to the strain relaxation and the effect of film-growth temperature on the chemical ordering of B-site cations in LNMO films are less concerned.

Nowadays, based on aberration-corrected electron microscopy, advanced imaging techniques in combination with atomic-resolution energy-dispersive X-ray spectroscopy (EDS) mapping provide us with unrivaled capability to understand the structural and chemical properties of materials at the atomic scale38,39,40,41,42,43,44. In this work, by applying these microscopic analytical techniques, we have systematically investigated phase structure of LNMO films affected by the epitaxial strain and misfit strain relaxation of LNMO films grown on different perovskite-type substrates including KTaO3 (KTO), DyScO3 (DSO), SrTiO3 (STO) and LaAlO3 (LAO). We have also studied the effect of film-growth temperature on the ordering of B-site cation in LNMO films. We hope that the present studies would promote the understanding of the effect of the growth process on the structural and physical properties in double-perovskite LNMO films.

Results and Discussion

It is well known that STO and KTO have a cubic perovskite-type structure with a lattice parameter of 0.3905 and 0.3988 nm at room temperature45,46, respectively. In contrast, LAO has a rhombohedrally distorted perovskite-type structure47, and DSO has an orthorhombically distorted perovskite-type structure at room temperature48. To simplify the discussion, LAO and DSO can be treated as a pseudocubic structure with a lattice parameter (aP) of 0.3791 nm and 0.3952 (0.3957 nm) nm, respectively, where the subscript P denotes a pseudocubic perovskite-type structure.

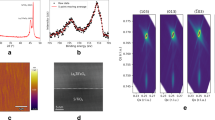

Figure 1a–c are low-magnification bight-field transmission electron microscopy (BF-TEM) images, showing an overview of LNMO films grown on (001) STO, (001) KTO and (001)p DSO substrates, respectively. The contrast variation is clearly visible in the LNMO films, which allows us to locate the film-substrate interface, as indicated by horizontal white arrows. A typical selected area electron diffraction (SAED) pattern of the LNMO/KTO heterostructure is displayed in Fig. 1d, viewed along the [010] KTO zone axis. A vertical white arrow shows the splitting of diffraction spots between LNMO and KTO, indicating that the relaxation of misfit strain occurs between LNMO film and KTO substrate. In addition, weak diffraction spots from LNMO films but different oriented domains are presented, as denoted by a blue and a red arrow. It should be noted that the weak reflections also appear in the SAED patterns of LNMO film grown on STO and DSO substrates (See Figure S1 of the Supplemental Material). The appearance of weak reflections in the diffraction patterns means that LNMO films have a monoclinic or an orthorhombic structure. It should be mentioned that monoclinic LNMO (P21/n) and orthorhombic LNMO (Pbnm) display structural similarity, which leads to impossible to discern them based on X-ray measurement17 and SAED patterns. In contrast to the coherent growth of LNMO films on (001) STO substrate, misfit dislocations are observed at the LNMO/KTO and LNMO/DSO interfaces. Figure 1e shows a typical high-resolution high-angle annular dark field (HAADF) image containing a misfit dislocation at the LNMO/KTO interface, viewed along [010] KTO zone axis. The LNMO/KTO interface is denoted by a horizontal red arrow. It is found that the misfit dislocation has a projected Burgers vector of a <100> (a is the lattice parameter of KTO), which is obtained by performing a Burgers circuit around the dislocation core, as shown in Fig. 1e.

(a–c) Low-magnification BF-TEM image of the LNMO/STO, LNMO/KTO and LNMO/DSO heterostructures, respectively, viewed along the [010] zone axis of the substrate. The horizontal white arrow denotes the film-substrate interface. (d) The SAED pattern from the LNMO/KTO heterostructure, viewed along the [010] KTO zone axis. The splitting of diffraction spots between KTO and LNMO is indicated by a vertical white arrow. The weak diffraction spot from different domains of the LNMO films is denoted by a blue and a red arrow, respectively. (e) High-resolution HAADF image showing misfit dislocations at the LNMO/KTO interface. The interface is indicated by a horizontal red arrow.

Figure 2a is a low-magnification TEM image of 8-nm-thick LNMO films grown on (001) p LAO substrate, viewed along the [010] p LAO zone-axis. No misfit dislocations are observed at the LNMO/LAO interface, indicating the LNMO films coherently grow on the LAO substrate. In contrast, for the 100-nm-thick LNMO films grown on (001) p LAO substrates, the contrast variation is present within the LNMO films, as shown in a low-magnification BF-TEM image in Fig. 2b. The thick LNMO films exhibit a bilayer structure (referred as LNMOL and LNMOH respectively). The interface between LNMOL and LNMOH is indicated by a horizontal white arrow. The LNMOL layer coherently grows on the LAO substrate with a thickness of about 30 nm. The layer displays a uniform contrast, indicating that it is a monodomain. In comparison, a high density of dark diffuse lines can be seen in the LNMOH layer, starting from the LNMOL/LNMOH interface and penetrating in most cases the whole LNMOH layer. Figure 2c shows the SAED pattern of the LNMO/LAO heterostructure. No weak diffraction spots from LNMOL and LNMOH are observed, which indicates that both LNMO layers have a rhombohedral structure. The splitting of diffraction spots can be observed obviously for the high-index reflections. The inset shows the reflection around 402LAO as denoted by a white rectangle in Fig. 2c. It can be seen that there is no in-plane relaxation between LAO and LNMOL, which results in that the LNMOL layer has a larger out-of-plane lattice parameter (0.398 ± 0.002 nm). In contrast, in-plane relaxation occurs between LNMOH and LNMOL since the in-plane splitting of reflections can be clearly detected. The epitaxial strain between LNMOH and LNMOL is relaxed by the formation of misfit dislocation at the interface, as shown in Fig. 2d. The projected Burgers vector of the misfit dislocation is a p <100> (a p is the lattice parameter of the pseudocubic LNMO), which is obtained by drawing a Burgers circuit around the dislocation core.

Low-magnification BF-TEM image of the LNMO/LAO heterostructures with 8-nm-thick (a) and 100-nm-thick (b) LNMO films, respectively. The LNMO/LAO interface is indicated by a horizontal red arrow. The LNMOL/LNMOH and LNMOL/LAO interface is indicated by a horizontal white and a horizontal red arrow, respectively. (c) The SAED pattern recorded in the region of the LAO substrate and 100-nm-thick LNMO films, viewed along the [010] p LAO zone-axis. The insert shows the separation of the reflection spot of LNMOL, LNMOH and LAO. (d) High-resolution HAADF image of misfit dislocations at the LNMOL/LNMOH interface. The interface is denoted by a white arrow.

It is noted that both LAO and LNMO have a rhombohedral structure in the LNMO/LAO system, which might be in favor of monodomain LNMO films (LNMOL) coherently grown on the LAO substrates below a critical thickness. Accordingly, the large compressive strain is accommodated by the elastic deformation of the lattice. Furthermore, with increasing LNMO film thickness above the critical thickness (~30 nm), the film growth mechanism might change from layer-by-layer (Frank-van der Merve mode) growth to island growth to release the large in-plane compressive strain, which results in the formation of the LNMOH layer on the LNMOL layer. Meanwhile, at the LNMOH/LNMOL interface misfit dislocations appear due to the coalescence of the LNMOH nuclei during the film growth, which contributes to misfit strain relaxation in the LNMO/LAO system.

To understand the structural properties at the LNMO/LAO interface, high-resolution HAADF investigations of the interface have been performed. A typical atomic-resolution HADDF image of the LNMO/LAO interface is shown in Fig. 3a, viewed along the [010]p LAO zone axis. It is noted that the intensity of atomic columns in the HAADF image is roughly proportional to Z2 (where Z is the atomic number averaged in the atomic columns)49. The interfacial (Ni, Mn)O2 and AlO2 layer can be located, as indicated by a horizontal red and a horizontal green arrow, respectively. To obtain the chemical information of B-site cations across LNMO/LAO interface, Fig. 3b displays intensity profiles along the atomic plane marked by a red line in Fig. 3a. Obviously, the intensity of interfacial Al−O columns is higher than that of other Al−O columns, implying that the interface diffusion may occur between Al and Ni/Mn. The out-of-plane lattice parameters in the interface area have been investigated by geometrical lattice mapping directly on the high-resolution HAADF image using a 2D Gaussian fitting approach50,51. Figure 3c displays a plot of the out-of-plane lattice spacing against the distance, which provides evidence for the difference in the out-of-plane lattice parameters between LNMO and LAO across the interface.

(a) Atomic-resolution HAADF image of the LNMO/LAO interface, viewed along the [010] p LAO zone axis. The interfacial (Ni, Mn)O2 and AlO2 layer is denoted by a horizontal red and a horizontal green arrow, respectively. (b) The intensity profiles along the red line in Fig. 3a, showing the intensity variation of B-site cation columns in LNMO and LAO across the interface. (c) The value of the out-of-plane lattice parameter (c) across the LNMO/LAO interface.

It is known that B-site ordered LNMO displays ferromagnetic properties due to the Ni-O-Mn interaction. In contrast, apart from Ni-O-Mn superexchange interaction the Mn-O-Mn and Ni-O-Ni antiferromagnetic couplings occur in the short-range B-site ordered LNMO15. The ordering of B-site cations (Ni and Mn) in our LNMO films has been investigated by atomic-resolution energy-dispersive X-ray spectroscopy (EDS) mapping. The B-site ordering can be distinguished from the <110> P direction of pseudocubic LNMO, as a schematic model illustrated in Fig. 4a. Figure 4b shows a typical high-resolution HAADF image of LNMO films, viewed along the [110] p LNMO zone axis. Atomic-resolution EDS mapping for Mn and Ni is displayed in Fig. 4c and d, respectively, which shows a long-range ordering of Ni and Mn in LNMO. It was reported that in contrast to the orthorhombic phase, the monoclinic phase of LNMO is B-site cations ordered17. Thus, under our LNMO film-growth conditions, the monoclinic LNMO phase has been obtained. In addition, in contrast to the short-range B-site ordered LNMO films grown at 800 °C (See Figure S2 of the supplemental material), both rhombohedral and monoclinic LNMO films display a long-range B-site ordering at 900 °C (See Figure S3 of the Supplemental Material). It should be mentioned that bond length and bond angle of Ni2+-O-Mn4+ in the B-site ordered monoclinic and rhombohedral LNMO should be essentially different, which affects the superexchange interactions and the related physical properties (e.g. ferromagnetic) of the films.

(a) Schematic structure model of B-site ordered LNMO, viewed along <110> p LNMO zone axis. (b–d) Atomic-resolution HAADF image of LNMO films and EDS maps of Mn and Ni. (e–h) HAADF image of the LNMO/LAO interface and EDS maps of Al, Mn and Ni. (i–l) HAADF image of the LNMO/STO interface and EDS maps of Ti, Mn and Ni.

In addition, applying atomic-resolution EDS mapping the chemical composition of the LNMO/LAO and LNMO/STO heterointerface has been investigated. Figure 4e shows a high-resolution HAADF image of the LNMO/LAO interface. The corresponding EDS map for Al, Mn and Ni is displayed in Fig. 4f–h, respectively. A monolayer interdiffusion between Mn/Ni and Al was observed at the interface, as indicated by a horizontal white arrow. It can be seen that the rhombohedral LNMO films also exhibit a long-range B-site ordering at the interface area. A high-resolution HAADF image of the LNMO/STO interface is shown in Fig. 4i. The EDS map of B-site cations at the interface is shown in Fig. 4j–l, respectively. The interfacial Ti-O layer is indicated by a horizontal white arrow. Slight interdiffusion between Mn/Ni and Ti occurs at the interface. Also, B-site cations in LNMO display a long-range ordering at the LNMO/STO interface area.

To understand the phase stability of LNMO films, we calculated misfit strain between LNMO films and a variety of substrates, as shown in Table 1. In fact, the unit cell parameters of double-perovskite LNMO structure52 can be related to an ideal ABO3 perovskite-type unit cell. The monoclinic LNMO has lattice parameters a = 5.467 Å, b = 5.510 Å (aP1 ≈ aP2 ≈ \(\sqrt{{a}^{2}+{b}^{2}}/2\) ≈ 3.881 Å), c = 7.751 Å (aP3 = c/2 ≈ 3.875 Å), and β = 90.12°, where aP1, aP2 and aP3 are pseudocubic unit-cell lengths. The rhombohedral LNMO has lattice parameters a = 5.475 Å (aP1 = aP2 = aP3 ≈ \(a/\sqrt{2}\)≈ 3.871 Å), and β = 60.67°. In the case of the monoclinic LNMO on the substrates, several types of film-substrate orientation relationship may exist depending on the crystallographic structure of the substrate, e.g. O1, O2 and O3 in the LNMO/DSO system, which leads to different in-plane strains in the two orthogonal directions. Also, anisotropic in-plane strain may occur in the rhombohedral LNMO because of the substrate with different in-plane lattice parameters, e.g. in the LNMO/DSO system. As list in the Table 1, both monoclinic and rhombohedral LNMO films undergo tensile strain if the films coherently grow on STO, DSO and KTO. Nevertheless, in-plane mismatch strain of monoclinic LNMO is smaller than that of rhombohedral LNMO. In contrast, although compressive epitaxial strain would be induced in both monoclinic and rhombohedral LNMO films if the films coherently grow on LAO, (001) (La, Sr)(Al,Ta)O3 (LSAT) (Pn \(\overline{3}\) m)53 and (001) LaSrAlO4 (LSAO) (I4/mmm)54, in-plane mismatch strain of monoclinic LNMO is larger than that of rhombohedral LNMO. The different in-plane mismatch strain possibly results in the formation of monoclinic LNMO films under the tensile strain and rhombohedral LNMO films under the compressive strain. The relationship of strain-induced phase transition in LNMO films is shown in Fig. 5.

According to our experimental results, the small lattice mismatch could be fully accommodated by the elastic deformation of the lattice and oriented domains, which leads to the coherent growth of films on substrates, e.g. in the LNMO/STO and LNMO/LSAT systems26. In most cases, with the increase of the film-substrate lattice mismatch, apart from the formation of oriented domains in the LNMO films misfit dislocations appear at the film-substrate interface, contributing to misfit strain relaxation. As a result, the films and the substrates form the semi-coherent interface, e.g. in the LNMO/DSO and LNMO/KTO systems. It is important to note that both coherently and semi-coherently strained LNMO films under the tensile strain exhibit a monoclinic structure and under the compressive strain a rhombohedral structure.

Additionally, in comparison with the partially disordered LNMO films grown at 800 °C26, the LNMO films prepared at 900 °C exhibit a long-range B-site ordering. In fact, with the exception of the growth temperature, the deposition conditions were held the same for preparing LNMO films in these two works. In other words, our works indicate that B-site ordering in LNMO films could be improved efficiently by increasing growth temperature. It is noted that the growth temperature can significantly influence the film growth kinetics, e.g. the thermal diffusion of the cations in the lattice55,56,57. Increasing film-growth temperature increases the kinetic energy of the diffusing cations in the LNMO, which could lead the B-site cations (Ni and Mn) to arrange themselves in the cation sublattice in an ordered manner. In fact, the ordering of B-site in bulk LNMO could be improved by changing the thermal annealing parameters24. In this viewpoint, post-growth annealing of the LNMO films may provide an alternative way of manipulating the B-site ordering in order to enhance their performance in device applications.

Conclusions

In summary, by means of advanced electron microscopy we have demonstrated that the misfit strain of LNMO films grown on different substrates could be partially released by the formation of oriented domains within the films and misfit dislocations at the interfaces. Importantly, phase stability of LNMO films could be tuned effectively by elastic strains imposed by the substrate. Under tensile stain, LNMO films exhibit a monoclinic structure, while under compressive strain LNMO films are rhombohedral. In addition, a long-range B-site ordered LNMO films have been successfully prepared at 900 °C. Our work indicates that the ordering of B-site cations in LNMO films could be affected by controlling film-growth temperature. Importantly, the atomic-scale characterization of chemical and structural properties of double-perovskite multiferroic LNMO films would extend our understanding of the process-structure-property relationship in the materials and explore their potential applications.

Methods

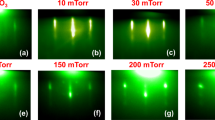

LNMO thin films were deposited on STO, KTO, DSO and LAO substrates by the pulsed laser deposition (PLD) technique. A KrF excimer laser (wavelength: 248 nm) was applied for ablation of a sintered LNMO target. The film deposition conditions were held the same for all different substrates, including the substrate temperature (900 °C), oxygen pressure (250 mTorr), target-substrate distance (10 cm), laser fluence (2 J/cm2), and repetition frequency (5 Hz).

Cross-sectional TEM specimens were prepared by conventional TEM sample preparation technique and focused ion beam (FIB) lift-out technique using an FEI Helios600i FIB/SEM system58. BF-TEM images and SAED patterns were acquired on a JEM 2100 microscope. Atomic-resolution HAADF imaging and EDS mapping were performed on a JEOL ARM200F microscope equipped with an aberration corrector for a probe-forming system and an Oxford X-MaxN 100TLE spectrometer, operated at 200 kV. The HAADF detector covered an angular range of 90–176 mrad and the convergence semi-angle was set to 22 mrad for HAADF imaging.

References

Rogado, N. S., Li, J., Sleight, A. W. & Subramanian, M. A. Magnetocapacitance and magnetoresistance near room temperature in a ferromagnetic semiconductor: La2NiMnO6. Adv. Mater. 17, 2225–2227 (2005).

Tirmali, P. M., Mane, S. M., Patil, S. K. & Kulkarni, S. B. Effects of partial site substitution on magnetic and dielectric behavior of La2NiMnO6 double perovskite. J. Mater. Sci. - Mater. Electron. 27, 4314–4320 (2016).

Takahashi, R. et al. A site driven ferroelectricity in strained ferromagnetic La2NiMnO6 thin films. Phys. Rev. B. 91, 134107 (2015).

Cao, Z. Z. et al. Extrinsic and intrinsic contributions for dielectric behavior of La2NiMnO6 ceramic. Physica B. 477, 8–13 (2015).

Lin, Y. Q., Wu, S. Y. & Chen, X. M. Effects of ordering domain structure on dielectric properties of double perovskite La2NiMnO6. J Adv Dielectr. 01, 319–324 (2011).

Dass, R. I., Yan, J. Q. & Goodenough, J. B. Oxygen stoichiometry, ferromagnetism, and transport properties of La2−xNiMnO6+δ. Phys. Rev. B. 68, 064415 (2003).

Kitamura, M. et al. Ferromagnetic properties of epitaxial La2NiMnO6 thin films grown by pulsed laser deposition. Appl. Phys. Lett. 94, 132506 (2009).

Ullah, M. et al. Electronic, thermoelectric and magnetic properties of La2NiMnO6 and La2CoMnO6. J. Magn. Magn. Mater. 377, 197–203 (2015).

Truong, K. D., Singh, M. P., Jandl, S. & Fournier, P. Influence of Ni/Mn cation order on the spin-phonon coupling in multifunctional La2NiMnO6 epitaxial films by polarized Raman spectroscopy. Phys. Rev. B. 80, 134424 (2009).

Singh, M. P. et al. Absence of long-range Ni/Mn ordering in ferromagnetic La2NiMnO6 thin films. Appl. Phys. Lett. 91, 012503 (2007).

Vasala, S. & Karppinen, M. A2B′B″O6 perovskites: A review. Prog. Solid State Chem. 43, 1–36 (2015).

Blasse, G. Ferromagnetic interactions in non-metallic perovskites. J. Phys. Chem. Solids. 26, 1969–1971 (1965).

Wold, A., Arnott, R. J. & Goodenough, J. B. Some magnetic and crystallographic properties of the system LaMn1−xNixO3+λ. J. Appl. Phys. 29, 387–389 (1958).

Joly, V. L. J., Joy, P. A., Date, S. K. & Gopinath, C. S. Two ferromagnetic phases with different spin states of Mn and Ni in LaMn0.5Ni0.5O3. Phys. Rev. B. 65, 184416 (2002).

Choudhury, D. et al. Near room temperature colossal magnetodielectricity and multiglass properties in partially disordered La2NiMnO6. Phys. Rev. Lett. 108, 127201 (2012).

Blasco, J. et al. Magnetic properties of LaNi1−xMnxO3+δ perovskites. Eur. Phys. J. B. 30, 469–479 (2002).

Blasco, J., Sanchez, M. C., Perez-Cacho, J. & Campo, J. Synthesis and structural study of LaNi1−xMnxO3+δ perovskites. J. Phys. Chem. Solids. 63, 781–792 (2002).

Devi Chandrasekhar, K., Das, A. K., Mitra, C. & Venimadhav, A. The extrinsic origin of the magnetodielectric effect in the double perovskite La2NiMnO6. J Phys Condens Matter. 24, 495901 (2012).

Hashisaka, M. et al. Epitaxial growth of ferromagnetic La2NiMnO6 with ordered double-perovskite structure. Appl. Phys. Lett. 89, 032504 (2006).

Sakurai, Y., Ohkubo, I., Matsumoto, Y., Koinuma, H. & Oshima, M. Influence of substrates on epitaxial growth of B-site-ordered perovskite La2NiMnO6 thin films. J. Appl. Phys. 110, 063913 (2011).

Mi, S. B. et al. Heterostructures of BaTiO3 bilayer films grown on SrTiO3 (001) under different oxygen pressures. J. Cryst. Growth. 283, 425–430 (2005).

Jing, H. M. et al. Microstructure and electrical conductivity of (Y, Sr)CoO3−δ thin films tuned by the film growth temperature. J. Alloys Compd. 714, 181–185 (2017).

Singh, M. P., Charpentier, S., Truong, K. D. & Fournier, P. Evidence of bidomain structure in double-perovskite La2CoMnO6 thin films. Appl. Phys. Lett. 90, 211915 (2007).

Singh, M. P., Truong, K. D., Jandl, S. & Fournier, P. Long-range Ni/Mn structural order in epitaxial double perovskite La2NiMnO6 thin films. Phys. Rev. B. 79, 224421 (2009).

Masuno, A. et al. Epitaxial growth and B-site cation ordering in layered double perovskite La2CuSnO6 thin films. Appl. Phys. Lett. 89, 211913 (2006).

Jin, X. W., Lu, L., Mi, S. B., Liu, M. & Jia, C. L. Phase stability and B-site ordering in La2NiMnO6 thin films. Appl. Phys. Lett. 109, 031904 (2016).

Xie, C. Z. & Shi, L. Tuning of magnetic properties for epitaxial Y2NiMnO6 thin film: Substrate is crucial. Appl. Surf. Sci. 384, 459–465 (2016).

Zeches, R. J. et al. A strain-driven morphotropic phase boundary in BiFeO3. Science. 326, 977–980 (2009).

Dixit, H. et al. Understanding strain induced phase transformations in BiFeO3 thin films. Adv Sci (Weinh). 2, 1500041 (2015).

Du, C. et al. Control of magnetocrystalline anisotropy by epitaxial strain in double perovskite Sr2FeMoO6 films. Phys. Rev. Lett. 110, 147204 (2013).

Infante, I. C. et al. Bridging multiferroic phase transitions by epitaxial strain in BiFeO3. Phys. Rev. Lett. 105, 057601 (2010).

Zhou, X. L., Stern, I., Silwal, P., Miao, L. D. & Ho Kim, D. Coherent in-plane tensile strain in perovskite Ba0.8Sr0.2TiO3 films on spinel MgAl2O4 substrates. Appl. Phys. Lett. 100, 032902 (2012).

Dupé, B. et al. Competing phases in BiFeO3 thin films under compressive epitaxial strain. Phys. Rev. B. 81, 144128 (2010).

Hatt, A. J., Spaldin, N. A. & Ederer, C. Strain-induced isosymmetric phase transition in BiFeO3. Phys. Rev. B. 81, 054109 (2010).

Mix, C. & Jakob, G. Multiferroic and structural properties of BiFeO3 close to the strain induced phase transition on different substrates. J. Appl. Phys. 113, 17D907 (2013).

Goodenough, J. B., Wold, A., Arnott, R. J. & Menyuk, N. Relationship between crystal symmetry and magnetic properties of ionic compounds containing Mn3+. Phys. Rev. 124, 373–384 (1961).

Sayed, F. N. et al. Role of annealing conditions on the ferromagnetic and dielectric properties of La2NiMnO6. J. Mater. Res. 26, 567–577 (2011).

Jia, C. L., Lentzen, M. & Urban, K. Atomic-resolution imaging of oxygen in perovskite ceramics. Science. 299, 870–873 (2003).

Jia, C. L. & Urban, K. Atomic-resolution measurement of oxygen concentration in oxide materials. Science. 303, 2001–2004 (2004).

Jia, C. L., Urban, K. W., Alexe, M., Hesse, D. & Vrejoiu, I. Direct observation of continuous electric dipole rotation in flux-closure domains in ferroelectric Pb(Zr,Ti)O3. Science. 331, 1420–1423 (2011).

Pennycook, T. J. et al. 3D elemental mapping with nanometer scale depth resolution via electron optical sectioning. Ultramicroscopy. 174, 27–34 (2017).

Gázquez, J. et al. Applications of STEM-EELS to complex oxides. Mater. Sci. Semicond. Process. 65, 49–63 (2017).

Mi, S. B., Jia, C. L., Vrejoiu, I., Alexe, M. & Hesse, D. Atomic-scale structure and properties of epitaxial PbZr0.2Ti0.8O3/SrRuO3 heterointerfaces. Adv. Mater. Interfaces. 2, 1500087 (2015).

Findlay, S. D. et al. Robust atomic resolution imaging of light elements using scanning transmission electron microscopy. Appl. Phys. Lett. 95, 191913 (2009).

Howard, S. A., Yau, J. K. & Anderson, H. U. Structural characteristics of Sr1−xLaxTi3±δ as a function of oxygen partial pressure at 1400 °C. J. Appl. Phys. 65, 1492–1498 (1989).

Zhurova, E. A., Ivanov, Y., Zavodnik, V. & Tsirelson, V. Electron density and atomic displacements in KTaO3. Acta Cryst. B56, 594–600 (2000).

Hayward, S. A. et al. Transformation processes in LaAlO3: Neutron diffraction, dielectric, thermal, optical, and Raman studies. Phys. Rev. B. 72, (2005).

Liferovich, R. P. & Mitchell, R. H. A structural study of ternary lanthanide orthoscandate perovskites. J. Solid State Chem. 177, 2188–2197 (2004).

Nellist, P. D. et al. Aberration-corrected STEM: current performance and future directions. J. Phys. 26, 7–12 (2006).

Jin, L., Jia, C. L. & Vrejoiu, I. Engineering 180° ferroelectric domains in epitaxial PbTiO3 thin films by varying the thickness of the underlying (La,Sr)MnO3 layer. Appl. Phys. Lett. 105, 132903 (2014).

Du, H. C. et al. Atomic structure of antiphase nanodomains in Fe-doped SrTiO3 films. Adv. Funct. Mater. 25, 6369–6373 (2015).

Bull, C. L., Gleeson, D. & Knight, K. S. Determination of B-site ordering and structural transformations in the mixed transition metal perovskites La2CoMnO6 and La2NiMnO6. J. Phys.: Condens. Matter. 15, 4927–4936 (2003).

Pawlak, D. A. et al. Structure and spectroscopic properties of (AA′)(BB′)O3 mixed-perovskite crystals. J. Mater. Res. 20, 3329–3337 (2011).

Magrez, A. et al. Using CBED and crystallographic image processing to evidence a structural distortion in a new family of ionic conductor Sr1−xLa1+xAl1−xMgxO4. J. Solid State Chem. 172, 243–251 (2003).

Borg, R. J. & Dienes, G. J. An introduction to solid state diffusion. Academic press. (1988).

Yang, X. et al. Two-step sintering: An approach to prepare Ba(Zn1/3Nb2/3)O3 ceramics with high degree of cation ordering. J. Alloys Compd. 723, 930–935 (2017).

Kaczmarek, S. E. & Thornton, B. P. The effect of temperature on stoichiometry, cation ordering, and reaction rate in high-temperature dolomitization experiments. Chem. Geol. 468, 32–41 (2017).

Jin, X. W. et al. Atomic scale investigation of planar defects in 0.95Na0.5Bi0.5TiO3–0.05BaTiO3 thin films on SrTiO3 (001) substrates. J. Alloys Compd. 676, 173–180 (2016).

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Nos 51471169 and 51390472) and the National Basic Research Program of China (No. 2015CB654903).

Author information

Authors and Affiliations

Contributions

S.B.M. supervised this work. S.C. and M.L. prepared thin films. L.L. prepared (S)TEM specimens. S.Q.W., S.D.C., X.W.J. and S.B.M. conducted (S)TEM investigations. S.B.M. and S.Q.W. analyzed the results and wrote the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, SQ., Cheng, S., Lu, L. et al. B-site ordering and strain-induced phase transition in double-perovskite La2NiMnO6 films. Sci Rep 8, 2516 (2018). https://doi.org/10.1038/s41598-018-20812-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-20812-4

This article is cited by

-

Self-assembling behavior and interface structure in vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)1-x:(CeO2)x films on (001) (La,Sr)(Al,Ta)O3 substrates

Scientific Reports (2020)

-

An overview of La2NiMnO6 double perovskites: synthesis, structure, properties, and applications

Journal of Sol-Gel Science and Technology (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.