Abstract

In this work, we demonstrate high-performance electrically injected GaN/InGaN core-shell nanowire-based LEDs grown using selective-area epitaxy and characterize their electro-optical properties. To assess the quality of the quantum wells, we measure the internal quantum efficiency (IQE) using conventional low temperature/room temperature integrated photoluminescence. The quantum wells show a peak IQE of 62%, which is among the highest reported values for nanostructure-based LEDs. Time-resolved photoluminescence (TRPL) is also used to study the carrier dynamics and response times of the LEDs. TRPL measurements yield carrier lifetimes in the range of 1–2 ns at high excitation powers. To examine the electrical performance of the LEDs, current density–voltage (J-V) and light-current density-voltage (L-J-V) characteristics are measured. We also estimate the peak external quantum efficiency (EQE) to be 8.3% from a single side of the chip with no packaging. The LEDs have a turn-on voltage of 2.9 V and low series resistance. Based on FDTD simulations, the LEDs exhibit a relatively directional far-field emission pattern in the range of \(\pm \)15°. This work demonstrates that it is feasible for electrically injected nanowire-based LEDs to achieve the performance levels needed for a variety of optical device applications.

Similar content being viewed by others

Introduction

III-nitride based micro-light emitting diodes (µ-LEDs) are expected to become the next generation of pixel-level emitters in display technology. These displays include indoor/outdoor video walls, smart phones, tablets, televisions, smart watches, and head-mounted displays. µ-LEDs offer potential advantages compared to conventional organic LEDs (OLEDs) and liquid crystal displays (LCDs). Some advantages include higher brightness, higher transparency, longer lifetimes, lower power consumption, and shorter response times1,2,3,4. III-nitride based µ-LEDs exhibit a luminance of 105 cd/m2, while the luminance of LCDs and OLEDs are 3000 cd/m2 and 1500 cd/m2, respectively4. Additionally, µ-LEDs exhibit nanosecond response times, in contrast to the millisecond and microsecond response times of LCDs and OLEDs, respectively4. The short response times of µ-LEDs pave the way for the next generation of indoor LED-based data communication, known as light-fidelity (Li-Fi)5. The brightness, etendue, and acceptable light efficiency of µ-LED displays are also strongly dependent on the far-field emission pattern of the individual devices6. A small far-field radiation angle of ±15–20° is critical in full-color LED displays6,7. The photonic crystal (PhC) effect has been used to engineer the far-field emission pattern of conventional planar LEDs, although processing of photonic crystal structures poses challenges8,9,10,11,12 Alternatively, µ-LEDs based on nanowire structures (nanowire-based LEDs) enable engineering of the far-field emission pattern using the periodic nature of the nanowires themselves. Indeed, a more directional far-field emission pattern has been achieved experimentally using nanowire-based LEDs7,13. In addition, nanowire-based emitters offer an approach to monolithically integrated RGB-based white LEDs and lasers14,15,16,17,18. These monolithically integrated multi-colored µ-LEDs can be achieved in a single growth by varying the pitch spacing between the nanowire pattern, potentially providing significant cost reduction due to fewer processing steps and consumed sources compared to pick-and-place approaches. In addition to display technology, RGB-based white µ-LEDs are preferred over phosphor-converted approaches for visible-light communication (VLC) systems with high data rates19 due to the slow response of the phosphors in conventional phosphor-converted white LEDs20,21. Dynamic color tuning is also achievable using a multi-color approach22, which could potentially lead to multiplexing within VLC over several wavelength channels. In addition to LEDs, III-nitride nanowires are promising candidates for the next generation of other optoelectronic and electronic devices such as high power transistors23, gas sensors24,25, DNA sensors26,27, visible-blind UV photodetectors28,29, solar cells30,31,and atomic force microscopy (AFM) probe tips32.

Figure 1 shows a schematic of a gallium nitride/indium gallium nitride (GaN/InGaN) core-shell nanowire-based LED. These LEDs offer several advantages over conventional planar structures, including lower dislocation density33 and substantially larger active region surface area (~4–8X) than their planar foot-print suggests34. Larger active region area leads to lower carrier density for a given drive current, which could mitigate the effects of LED efficiency droop. Lower efficiency droop for nanowire-based LEDs has been shown experimentally35,36. In addition, conventional c-plane GaN-based µ-LEDs suffer from internal polarization-related electric fields37,38 that hinder their radiative efficiency. Quantum wells (QWs) grown on nonpolar or semipolar planes have significantly reduced spontaneous and piezoelectric polarizations. Reduction of internal electric fields improves the radiative efficiency, reduces the carrier lifetime, and reduces the efficiency droop39,40. Despite promising results, the small area and high cost of free-standing GaN substrates are two main obstacles for the commercial adoption of nonpolar and semipolar LEDs. Alternately, nonpolar and semipolar devices based on nanostructures such as nano-micro walls41,42,43, nanowires44,45,and triangular-stripes46,47,48 grown on commercial c-plane sapphire substrates could potentially overcome these obstacles and enable RGB LEDs on a single chip.

The recombination lifetime is also a key parameter that determines the 3dB modulation speed of µ-LEDs. The 3dB modulation speed plays a critical role in the performance of µ-LEDs used for Li-Fi technology and VLC. The presence of internal electric fields reduces the spatial overlap of the electron-hole wave functions in polar c-plane QWs and increases the radiative recombination lifetime49. The recombination lifetimes of planar c-plane LEDs range from 4–20 ns at room temperature50,51,52. These recombination lifetimes correspond to 3dB modulation bandwidths of less than 50 MHz. However, a modulation speed of 1.1 GHz has been shown experimentally using GaN/InGaN core-shell nanowire-based LEDs53. Theoretical work has also predicted a range of tens of picoseconds for the carrier lifetime of plasmonic GaN/InGaN core shell nanowire-based LEDs. With proper engineering to increase light extraction, the plasmonic approach may enable LEDs that leverage the Purcell effect to operate at modulation speeds in the range of tens of GHz54,55,56,57.

The small dimensions of nanowires also help reduce the threading dislocation (TD) density in heteroepitaxial growth by virtue of dislocation bending toward the sidewalls of the nanowires33 and TD filtering using a dielectric mask58. Due to the small dimensions of nanowires, lateral strain relaxation on the nonpolar m-plane sidewalls allows higher levels of indium (In) incorporation during InxGa1−xN/GaN (x = mole fraction of In) core-shell growth59,60. The higher growth rate of InGaN QWs grown on GaN nanowires, caused by a larger periodic spacing of the nanowires, also leads to higher levels of indium (In) incorporation during the core-shell growth18.

The three most common approaches for achieving GaN nanowires are catalyst-assisted, catalyst-free selective-area epitaxy (SAE) using in-situ deposition of a dielectric layer, and catalyst-free SAE using ex-situ deposition of a dielectric layer. The catalyst-assisted approach uses a vapor-liquid-solid (VLS) technique in either metalorganic chemical vapor deposition (MOCVD)61,62 or laser-assisted catalytic growth63. In-situ catalyst-free SAE may use either molecular beam epitaxy (MBE)64 or MOCVD65. Ex-situ catalyst-free SAE may also use either MBE66,67,68 or MOCVD69,70,71,72. The catalyst-assisted VLS growth technique using MOCVD does not enable well-controlled GaN nanowires and the metal catalyst is often incorporated as a deep level impurity73. Among catalyst-free techniques, the ex-situ approach is best suited to increase the homogeneity of the nanowires since the in-situ technique results in poor uniformity in the position and dimension of the nanowires. However, for the MBE ex-situ technique, the shadowing effect limits the growth of core-shell QWs74,75,76. Using the MOCVD ex-situ catalyst-free technique, the geometry of the nanowires is well controlled with a dielectric mask, the shadowing effect is absent, and no metal catalyst incorporates into the GaN. Therefore, the MOCVD ex-situ catalyst-free technique is a promising approach for growing controlled arrays of uniform, high-quality GaN nanowires.

Although there are numerous reports related to growth techniques for bottom-up core-shell nanowires using SAE, few of these reports demonstrate high-performance electrically-injected nanowire-based LEDs36,44,45,77. One of the most significant challenges in obtaining electrically injected devices is achieving efficient p-type doping in the core-shell nanowire LEDs. Previously, we developed a technique to improve the p-GaN growth in nanostructure-based LEDs78. This technique provides a path toward high-performance electrically-injected GaN/InGaN core-shell nanowire-based LEDs by improving the turn-on voltage and reducing the reverse-leakage current.

Here we present electrically-injected GaN/InGaN core-shell nanowire-based LEDs with among the highest performance levels reported thus far36,44,45,77. We perform a thorough investigation of the optical and electrical characteristics and compare the device performance to previously reported core-shell nanowire LEDs. In addition, we study the carrier dynamics of the LEDs to understand the response times, which are critical for predicting performance in VLC and Li-Fi systems. This work demonstrates that GaN/InGaN core-shell nanowire LEDs have the potential to reach the performance levels needed for a variety of lighting and display applications.

Experimental growth and LED fabrication

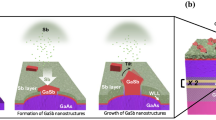

The GaN nanowires were grown on a selectively patterned c-plane GaN template on a sapphire substrate using a turbo disc VEECO p-75 MOCVD system. Initially, a 2-μm-thick GaN layer doped with silicon (n-GaN) was grown on a 2 inch single-side-polished sapphire substrate using conventional continuous-mode MOCVD and typical group III (TMGa) and group V (NH3) precursors. The wafer was then cleaned and 120 nm of SiNx was deposited using plasma enhanced chemical vapor deposition (PECVD), followed by interferometric lithography79 and Cl2-based reactive-ion etching to pattern arrays of circular apertures of 400 nm diameter in the SiNx. The periodic spacing (pitch) between the apertures was 1 µm. A secondary contact lithography was performed to define the mesa size of the devices34,46. The samples were then cleaned in piranha etchant and loaded into the reactor for the nanowire growth. The GaN nanowires were grown using pulsed-mode MOCVD in an H2-N2 atmosphere. The chamber pressure was maintained at 90 Torr during the nanowire growth and the H2 and N2 flows were 3000 and 1000 sccm, respectively. 150 pulsed-mode cycles (see Fig. 2) were employed to grow the GaN nanowires. The growth temperature was held constant at 925 °C during the nanowire growth. The TMGa injection, TMGa interruption, NH3 injection, and NH3 interruption times were 18, 27, 6, and 15 seconds, respectively. The TMGa and NH3 flow rates were 26.7 µmol min−1 and 8 mmol min−1, respectively. The V/III ratio was 100. Under conventional continuous-mode MOCVD growth conditions with the relatively high V/III ratios used to grow GaN planar templates on sapphire substrates, SAE growth of GaN nanostructures predominately results in pyramidal structures limited by \(\{10\bar{1}1\}\) semipolar planes46. As an alternative to the continuous-mode growth - where the nitrogen and gallium precursors are injected at the same time - Hersee et al.69 used a pulsed-mode technique for the controlled growth of GaN nanowires, wherein the group V (N) and group III (Ga) precursors are temporally pulsed (Fig. 2). The mechanisms of nanowire formation by the pulsed-mode growth technique were discussed later by Lin et al.80 and Jung et al.70. Recently, Choi et al.81 and Coulon et al.72 have also successfully demonstrated GaN nanowire growth using the continuous growth mode with a very low V/III ratio.

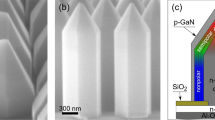

After developing the growth conditions for the GaN nanowire cores (Fig. 3a), a 25 nm underlayer of aluminum gallium nitride (AlGaN) was grown on the GaN cores, followed by a 25 nm cap layer of GaN using the pulsed-mode technique (Fig. 3b). The AlGaN underlayer was previously shown to significantly reduce the reverse-leakage current in nanostructure LEDs by suppressing the incorporation of impurities during the p-GaN growth78. Four pairs of InGaN/GaN quantum wells were grown around the cap layer, followed by a 200 nm p-GaN layer grown using continuous-mode MOCVD. The AlGaN underlayer and cap layer were grown at 930 °C and a pressure of 90 Torr. The quantum well, barrier, and p-GaN were grown at 740 °C, 780 °C, and 920 °C respectively. The pressure was held at 200 Torr during the quantum well, barrier, and p-GaN growth. Figure 4a shows the nanowires after the quantum well and p-GaN growth. The supporting information document provides more details about the processing steps and epitaxial growth. Figure 4b shows an SEM image of a fabricated nanowire-based LED. To obtain uniform lateral current spreading, a 200-nm-thick layer of indium tin oxide (ITO) was deposited on the LEDs. Ti/Al/Cr/Au and Cr/Au were used as n-contacts and p-contacts, respectively.

Optical Characterization and Study of Carrier Dynamics

Initially the PL characteristics of the nanowire LEDs were measured to evaluate the fundamental active region quality in the absence of electrical injection effects. Micro-photoluminescence (µPL) measurements were performed using 405 nm excitation from a frequency-doubled Ti:Sapphire laser. A long working distance (50x) micro-objective was used to excite a circular area with a diameter of ~10 µm. The pumping wavelength of 405 nm ensures photo-generation of carriers only within the active region and enables uniform pumping of the quantum wells. Additional details about the µPL are given in the accompanying supporting information. To understand the uniformity of the QW growth over the sample area, PL measurements were performed on 49 points (an array of 7 × 7 points) over a 1 × 1 cm area (most of the sample). The PL peak wavelength map is shown in Fig. 5. Some non-umiformity is observed on the bottom edge of the wafer, but most of the sample exhibits uniform PL near 480 nm. The non-uniformity observed along the bottom edge is due to the placement and orientation of the sample on the growth susceptor in our rotating disc reactor, which creates a non-uniform temperature profile on the sample. The sample is placed within a shallow cut-out in the susceptor that is larger than the sample, with the bottom edge being in contact with a sidewall of the cut-out, resulting in a lower temperature along the bottom edge of the sample. Since indium incorporation is very sensitive to temperature and higher for lower temperatures, longer wavelength emission results from LEDs near the bottom edge. The room-temperature (RT) µPL as a function of laser excitation power is shown in Fig. 6a. The µPL peak wavelength and full-width at half maximum (FWHM) are shown in Fig. 6b and c, respectively. The absence of defect-related yellow-band emission in the µPL spectra is indicative of high-quality, bright quantum wells. As the excitation power increases from 0.1 to 75 mW, the µPL peak wavelength shifts from 483 nm to 462 nm and the FWHM decreases from 53 nm to 43 nm. For nonpolar active regions in nanowires, the blueshift in the PL peak wavelength is attributed to the band-filling effect and non-uniform indium distribution along the nanowires82,83.

To further understand the quality of the quantum wells, the internal quantum efficiency (IQE) of the LEDs was measured. We applied the conventional method of dividing the integrated µPL at room temperature (RT) by that at low temperature (LT) −10 °K- to measure the IQE at different excitation powers84. Figure 7a shows the measured IQE versus excitation power, and the inset shows the temperature dependence of the normalized integrated µPL intensity and µPL peak energy measurement at an excitation power of 10 mW. The IQE versus excitation power plot provides important information about the efficiency droop for the nanowire-based LED. Previously, other groups only reported the peak IQE, which ranged from 8% to 58% in various studies44,45,77,83. The peak IQE here is 62%, which is among the highest reported for GaN/InGaN core-shell nanowire-based LEDs. Figures 6c and 7b show the integrated PL versus excitation power at LT and RT, respectively. At LT (10 °K) the slope of the integrated PL vs. excitation power is close to 1 for excitation powers less than 1 mW, which indicates radiative recombination is dominant85. The slope decreases to 0.61 at higher excitation powers. Even at LT, a sub-linear slope at higher excitation powers has been observed86 and can be attributed to either Auger recombination87,88, absorption saturation84,89,90, or generation of hot carriers91. The integrated PL versus excitation power at RT has a slope of 1.27 for excitation powers below 1 mW. This clearly indicates the presence of a combination of radiative and non-radiative recombination85. The slope approaches 1 for excitation powers ranging from 1–10 mW, which suggests the radiative recombination rate has become dominant over the non-radiative rate85. The slope decreases to 0.65 for excitation powers greater than 10 mW, indicating Auger recombination or carrier leakage has become dominant85,92. The change in the slope of the integrated PL (see Fig. 6c) at 10 mW directly corresponds with the peak of the IQE. The IQE is maximum at 10 mW and exhibits efficiency droop at higher excitation powers.

Optical characterization of GaN/InGaN core-shell LED (a) IQE measurement using low temperature/room temperature integrated PL technique. The inset shows the normalized integrated PL intensity and emission energy vs. temperature. (b) Integrated PL vs. excitation power in log-log scale at low temperature. (c) Integrated PL vs. excitation power in log-log scale at room temperature.

In addition to high quantum efficiency, the response time of the LEDs is critical for their implementation in displays, VLC, and Li-Fi technologies. The carrier recombination rate is a key parameter in determining the response time. Time-resolved photoluminescence (TRPL) was used to measure the carrier lifetime of the nanowire-based LEDs at RT and LT for excitation powers ranging from 0.1 mW to 75 mW. More details about this measurement are given in the supporting information. The PL transients were fit using the bi-exponential decay function, \({A}_{1}{e}^{-t/{\tau }_{1}}+{A}_{2}{e}^{-t/{\tau }_{2}}\), where A1 and A2 are amplitudes and τ1 and τ2 are the time constants of the fast decay and slow decay components, respectively. The slow decay component is considered the PL lifetime93,94,95,96. Fig. 8a shows the PL lifetimes (extracted from the slow decay component) versus excitation power at RT and LT. The inset of Fig. 8a shows a few examples of the RT PL transients for excitation powers of 1, 5, and 25 mW. The instrument response time (IRF) is also shown and verifies it is much shorter than the measured lifetimes. The PL lifetime measured for the nanowire-based LED shows a minimum of 1.3 ns, This lifetime is at least 3 times shorter than that of typical planar c-plane LEDs, which are in the range of 4–20 ns at high excitation powers51,52. The shorter lifetime in the nanowire LEDs is mostly attributed to the higher electron-hole wave function overlap for QWs grown on the m-plane side walls of the nanowires, rather than non-radiative surface recombination since the p-GaN is ~200 nm thick. Shorter carrier lifetimes provide the possibility of higher 3dB bandwidth.

Figure 8a shows the PL lifetime decreases as the excitation power increases both at RT and LT. Also, the PL lifetime at LT is longer than that at RT for all excitation powers. The difference between the PL lifetime at LT and the PL lifetime at RT is highest at low excitation powers. At low excitation powers and LT, radiative recombination is dominant (slope ≈ 1 in Fig. 6b), while at RT for the same excitation powers both radiative and non-radiative recombination exist (slope > 1 in Fig. 6c). The combination of radiative and non-radiative recombination lowers the PL lifetime at RT.

Having obtained the IQE and PL lifetime data at RT, the radiative and non-radiative lifetimes can be decoupled using equations (1) and (2),

where \({\tau }_{{PL}}\) is the PL lifetime, \({\tau }_{{R}}\) is the radiative lifetime, and \({\tau }_{{NR}}\) is the non-radiative lifetime. Fig. 8b and c show the radiative and non-radiative lifetimes versus excitation power, respectively. As the excitation power increases from 0.1–10 mW, the radiative lifetime decreases. For excitation powers beyond 10 mW, the radiative lifetime remains fairly constant. The onset of the constant radiative lifetime above 10 mW in Fig. 8b corresponds to the point at which the slope of the integrated PL versus excitation power changes to 0.65 in Fig. 7c. The non-radiative lifetime in Fig. 8c continues to decrease for excitation powers above 10 mW. At high excitation powers, both Auger recombination and carrier leakage are present based on the slope \(=0.65\) in Fig. 7c. Auger recombination is the dominant process in reducing the non-radiative lifetime in Fig. 8c. Carrier leakage opposes this reduction in non-radiative lifetime and eventually leads to the saturation of the non-radiative lifetime at higher excitation powers.

Electrical Characterization

While optical characterization techniques provide useful information for understanding the quantum well quality, these techniques do not provide information on the properties of the LED under electrical injection. These properties play a critical role in the performance of nanowire-based LEDs and include carrier transport, reverse-leakage current, series resistance, and turn-on voltage. Figure 9a shows the continuous-wave J-V plot for an LED with a 120-µm mesa size. The current density (J) is calculated based on the planar footprint. If the effective nanowire surface area is used to calculate the current density, the current density would be reduced by a factor of 2.3 in Figs 9 and 10. Figure 9b and c show the light–current density–voltage (L–J–V) characteristics and estimated EQE under room-temperature pulsed operation (2% duty cycle, 2 µs pulse width), respectively. The J-V plot does not exhibit any reverse leakage current. The LED shows a turn-on voltage of 2.9 V and a series resistance of 25 Ω. The combination of a low turn-on voltage and low series resistance places this device among the highest performing of those reported for GaN/InGaN core-shell nanowire-based LEDs in terms of current-voltage characteristics and internal quantum efficiency36,44,45,77. With advanced LED packaging techniques unavailable for this work, the light extraction efficiency (EXE) was simulated to enable an estimate of the total output power and external quantum efficiency (EQE) of the device. A commercial-grade simulator based on the finite-difference time-domain (FDTD) method (Lumerical FDTD Solutions) was used to calculate the EXE of the nanowire-based LED. The FDTD method is a fully vectorial approach that naturally gives both the time domain and frequency domain information97. An EXE of 13.2% from the top surface was calculated for the nanowire-based LED, which is higher than the simulated EXE (8.1%) from the top surface of a planar LED. The simulation methods are explained in more detail in the supporting information. Assuming an injection efficiency (IE) of 1, the total extracted power from the top surface of the LED (P) was calculated using equation (3). Here, h is Plank’s constant, υ is the LED electroluminescence (EL) emission frequency, q is electron charge, and I is current. In this calculation, we assume that the peak IQE coincides with the peak of the EQE (i.e., EXE does not depend upon injection current)

where,

Figure 10a,b and c show the electroluminescence (EL) spectra, peak wavelength, and FWHM at different current densities, respectively. As the current density increases from 80 A/cm2 to 1.9 kA/cm2, the EL peak wavelength exhibits a blueshift from 452 nm to 444 nm. The shift is attributed to non-uniformities in the indium incorporation in different regions of the nanowires36,45,82,83. Large blueshifts in the EL peak wavelength of nanowire-based LEDs, ranging from 62 nm to 180 nm, have been observed by other research groups36,98. As the current density increases from 80 to 500 A/cm2 the FWHM of the EL spectra decreases from 52 nm to 38 nm. The FWHM remains fairly constant from 500 A/cm2 to 1.25 kA/cm2 and increases to 40 nm for higher current densities. Although we were unable to perform burn-in measurements on these samples due to lack of packaging capabilities, this will be the subject of future work.

The far-field emission pattern of µ-LEDs has an important role in their performance. A relatively directional output power, ranging from ±15–20°, is preferred for full-color displays6,7. Such far-field emission patterns have been achieved by utilizing the photonic crystal effect for conventional planar structures10,11,12. FDTD-Lumerical was used to simulate the far-field emission pattern of the nanowire-based LED structure shown in Fig. 4a. The angular distributions of extracted light along the x and y-axes are shown in Fig. 11a and b. These angular distributions exhibit multiple lobes and a relatively directional emission pattern compared to the Lambertian-type far-field pattern of conventional planar LEDs99,100. The higher directionality is attributed to the periodic nanowire structure, which enhances the diffracted power normal to the LED surface. A directional far-field emission pattern ranging between ±15° is predicted for our nanowire-based LED. Directional far-field emission patterns in the range of \({\rm{\pm }}\)30° and below have been achieved by other research groups using nanowire-based LEDs7,13. This unique property makes nanowire-based LEDs a good candidate for the next generation of high brightness displays. We note that no extra PhC patterning or micro lenses are needed to obtain this relatively directional emission pattern from nanowire-based LEDs.

Conclusion

In this work, we demonstrated high-efficiency electrically injected GaN/InGaN core-shell nanowire-based LEDs using bottom-up selective-area epitaxy. The electrical and optical properties of the LEDs were studied in detail. The LEDs showed high IQE (62%), low turn-on voltage (2.9 V), low series resistance (25 Ω), and short carrier lifetimes (1–2 ns). These results are among the highest performance levels for nanowire-based LEDs thus far. In addition, FDTD modeling revealed that the nanowire-based LEDs have a strongly directional far-field emission pattern. Properties such as high IQE, short carrier lifetime, and emission directionality are attractive for solid-state lighting, visible-light communication, and μ-LED displays, respectively. While the performance level of nanowire-based LEDs is still below that of planar LEDs, nanowire-based LEDs offer unique properties (e.g., monolithic RGB emission and directionality) that are expected to be beneficial for some specific applications (e.g., μ-LED displays).

References

Radauscher, E. J. et al. Miniaturized LEDs for Flat-Panel Displays. Proc. of SPIE. 10124, 1012418–1 (2017).

Kang, C. M. et al. Fabrication of a vertically-stacked passive-matrix micro-LED array structure for a dual color display. Optics Express 25(3), 2489–2495 (2017).

Bonar, J.R., Valentine, G.J., Gong, Z., Small, J., Gorton, S. March. High-brightness low-power consumption microLED arrays. SPIE OPTO International Society for Optics and Photonics, 97680Y–97680Y (2016).

Day, J. et al. III-Nitride full-scale high-resolution microdisplays. Applied Physics Letters. 99(3), 031116 (2011).

Haas, H., Yin, L., Wang, Y. & Chen, C. What is LiFi? Journal of Lightwave Technology 34(6), 1533–1544 (2016).

Yu, X. J., Ho, Y. L., Tan, L., Huang, H. C. & Kwok, H. S. LED-based projection systems. Journal of display technology 3(3), 295–303 (2007).

Yanagihara, A., Ishizawa, S. & Kishino, K. Directional radiation beam from yellow-emitting InGaN-based nanocolumn LEDs with ordered bottom-up nanocolumn array. Applied Physics Express. 7(11), 112102 (2014).

Wiesmann, C., Bergenek, K., Linder, N. & Schwarz, U. T. Photonic crystal LEDs–designing light extraction. Laser & Photonics Reviews. 3(3), 262–286 (2009).

Rangel, E. et al. Directionality control through selective excitation of low-order guided modes in thin-film InGaN photonic crystal light-emitting diodes. Applied physics letters 98(8), 081104 (2011).

Wierer, J. J. et al. InGaN/GaN quantum-well heterostructure light-emitting diodes employing photonic crystal structures. Applied. Physics. Letters. 84(19), 3885–3887 (2004).

Rangel, E. et al. Interplay of cavity thickness and metal absorption in thin-film InGaN photonic crystal light-emitting diodes. Applied. Physics. Letters. 97(6), 061118 (2010).

Lai, C. F. et al. Highly-directional emission patterns based on near single guided mode extraction from GaN-based ultrathin microcavity light-emitting diodes with photonic crystals. Applied Physics Letters 97(1), 013108 (2010).

Kishino, K. & Yamano, K. Green-light nanocolumn light emitting diodes with triangular-lattice uniform arrays of InGaN-based nanocolumns. IEEE Journal of Quantum Electronics 50(7), 538–547 (2014).

Kishino, K., Nagashima, K. & Yamano, K. Monolithic integration of InGaN-based nanocolumn light-emitting diodes with different emission colors. Applied Physics Express 6(1), 012101 (2012).

Monemar, B., Ohlsson, B. J., Gardner, N. F. & Samuelson, L. Chapter Seven-Nanowire-Based Visible Light Emitters, Present Status and Outlook. Semiconductors and Semimetals 94, 227–271 (2016).

Lim, W. et al. SiO2 Nanohole Arrays With High Aspect Ratio for InGaN/GaN Nanorod-Based Phosphor-Free White Light-Emitting-Diodes. J. Vac. Sci. Technol. B. 34, 042204 (2016).

Wright, J. B. et al. Multi-colour nanowire photonic crystal laser pixels. Scientific reports 3, 2982 (2013).

Nami, M. et al. Tailoring the Morphology and Luminescence of GaN/InGaN Core–Shell Nanowires Using Bottom-up Selective-Area Epitaxy. Nanotechnology 28(2), 025202 (2016).

Cossu, G., Khalid, A. M., Choudhury, P., Crosini, R. & Ciaramella, E. 3.4 Gbit/s Visible Optical Wireless Transmission Based on RGB LED. Opt. Express. 20, B501–B506 (2012).

O'Brien, D.C. et al. Visible light communications: Challenges and possibilities. PIMRC. IEEE 19th International Symposium. 1–5 (2008).

Le Minh, H. et al. 100-Mb/s NRZ Visible Light Communications Using a Postequalized white LED. IEEE Photonics Technology Letters 21(15), 1063–1065 (2009).

Damilano, B. et al. Blue-green and white color tuning of monolithic light emitting diodes. Journal of Applied Physics 108(7), 073115 (2010).

Huang, Y., Duan, X., Cui, Y. & Lieber, C. Gallium Nitride Nanowire Nanodevices. Nano Lett. 2, 101–104 (2002).

Teubert, J., Becker, P., Furtmayr, F. & Eickhoff, M. GaN Nanodiscs Embedded in Nanowires as Optochemical Transducers. Nanotechnology. 22, 275505 (2011).

Paul, S. et al. Opto-chemical sensor system for the detection of H2 and hydrocarbons based on InGaN/GaN nanowires. Sensors and Actuators B: Chemical 173, 120–126 (2012).

Ganguly, A. et al. Functionalized GaN nanowire-based electrode for direct label-free voltammetric detection of DNA hybridization. Journal of Materials Chemistry 19(7), 928–933 (2009).

Chen, C. P. et al. Label-Free Dual Sensing of DNA Molecules Using GaN Nanowires. Analytical chemistry 81(1), 36–42 (2008).

Bugallo, A. L. et al. Visible-Blind Photodetector Based on p–i–n Junction GaN Nanowire Ensembles. Nanotechnology. 21, 315201 (2010).

Babichev, A. V. et al. GaN Nanowire Ultraviolet Photodetector With a Graphene Transparent Contact. Appl. Phys. Lett. 103, 201103 (2013).

Park, C. Y., Lim, J. M., Yu, J. S. & Lee, Y. T. Structural and Antireflective Characteristics of Catalyst-Free GaN Nanostructures on GaN/Sapphire Template for Solar Cell Applications. Appl. Phys. Lett. 96, 151909 (2010).

Howell, S. L. et al. Spatial Mapping of Efficiency of GaN/InGaN Nanowire Array Solar Cells Using Scanning Photocurrent Microscopy. Nano. Lett. 13, 5123–5128 (2013).

Behzadirad, M., Nami, M., Rishinaramangalam, A., Feezell, D. & Busani, T. GaN Nanowire Tips for Nanoscale Atomic Force Microscopy. Nanotechnology. 28(20), 20LT01 (2017).

Hersee, S. D., Rishinaramangalam, A. K., Fairchild, M. N., Zhang, L. & Varangis, P. Threading Defect Elimination in GaN Nanowires. J. Mater. Res. 26, 2293–2298 (2011).

Rishinaramangalam, A. K. et al. Controlled Growth of Ordered III-Nitride Core–Shell Nanostructure Arrays for Visible Optoelectronic Devices. J. Elec. Mat. 44, 1255–1262 (2013).

Nguyen, H. P. T. et al. Controlling electron overflow in phosphor-free InGaN/GaN nanowire white light-emitting diodes. Nano letters 12(3), 1317–1323 (2012).

Tzou, A. J. et al. High-Efficiency InGaN/GaN Core–Shell Nanorod Light-Emitting Diodes With Low-Peak Blueshift and Efficiency Droop. IEEE Transactions on Nanotechnology 16(2), 355–358 (2017).

Chichibu, S., Azuhata, T., Sota, T. & Nakamura, S. Spontaneous emission of localized excitons in InGaN single and multiquantum well structures. Applied Physics Letters 69(27), 4188–4190 (1996).

Bernardini, F. & Fiorentini, V. Spontaneous vs. piezoelectric polarization in III-V nitrides: conceptual aspects and practical consequences. Phys. Status Solidi (b) 216, 391–398 (1999).

Ling, S. C. et al. Low efficiency droop in blue-green m-plane InGaN/GaN light emitting diodes. Appl.Phys. Lett. 96, 231101 (2010).

Zhao, Y. et al. High-power blue-violet semipolar (2021) InGaN/GaN light-emitting diodes with low efficiency droop at 200 A/cm2. Applied. Physics. Eexpress 4(8), 082104 (2011).

Rishinaramangalam, A.K. et al. Ordered arrays of bottom-up III-nitride core-shell nanostructures. SPIE Nanoscience+ Engineering, International Society for Optics and Photonics, 955308–955308 (2015).

Nami, M., Rishinaramangalam, A. & Feezell, D. Analysis of light extraction efficiency for gallium nitride-based coaxial microwall light-emitting diodes. Physica. Status. Solidi. (c) 3(11), 766–770 (2014).

Hartmann, J. et al. High Aspect Ratio GaN Fin Microstructures with Nonpolar Sidewalls by Continuous Mode Metalorganic Vapor Phase Epitaxy. Crystal Growth & Design 16(3), 1458–1462 (2016).

Tu, C. G. et al. Regularly patterned non-polar InGaN/GaN quantum-well nanorod light-emitting diode array. Optics express 22(107), A1799–A1809 (2014).

Schimpke, T. et al. Position-controlled MOVPE growth and electro-optical characterization of core-shell InGaN/GaN microrod LEDs. International Society for Optics and Photonics. Spie Opto. 97680T–97680T (2016).

Rishinaramangalam, A. K. et al. Semipolar InGaN/GaN nanostructure light-emitting diodes on c-plane sapphire. Applied Physics Express 9(3), 032101 (2016).

Nakajima, Y. & Dapkus, P. D. The role of surface diffusion and wing tilt in the formation of localized stacking faults in high In-content InGaN MQW nanostructures. Applied. Physics. Letters. 109(8), 083101 (2016).

Wunderer, T. et al. Three‐dimensional GaN for semipolar light emitters. Physica. Status. Solidi. (b) 248(3), 549–560 (2011).

Takeuchi, T. et al. Quantum-confined Stark effect due to piezoelectric fields in GaInN strained quantum wells. Japanese Journal of Applied Physics 36(4A), L382 (1997).

Waltereit, P. et al. Nitride semiconductors free of electrostatic fields for efficient white light-emitting diodes. Nature. 406, 865–868 (2000).

Ji, Y. et al. Comparative study of field-dependent carrier dynamics and emission kinetics of InGaN/GaN light-emitting diodes grown on (11–22) semipolar versus (0001) polar planes. Applied. Physics. Letters 104(14), 143506 (2014).

Lee, Y. J. et al. Study of the excitation power dependent internal quantum efficiency in InGaN/GaN LEDs grown on patterned sapphire substrate. IEEE Journal of selected Topics in Quantum Electronics 15(4), 1137–1143 (2009).

Koester, R. et al. High-speed GaN/GaInN nanowire array light-emitting diode on silicon (111). Nano. Lett. 15, 2318–2323 (2015).

Nami, M. & Feezell, D. Optical properties of Ag-coated GaN/InGaN axial and core–shell nanowire light-emitting diodes. J. Opt. 17, 025004 (2015).

Nami, M. & Feezell, D. F. Optical properties of plasmonic light-emitting diodes based on flip-chip III-nitride core-shell nanowires. Opt. Express. 22, 29445–29455 (2014).

Khurgin, J. B. & Sun, G. Comparative analysis of spasers, vertical-cavity surface-emitting lasers and surface-plasmon-emitting diodes. Nat. Photonics. 8, 468–473 (2014).

Nami, M., Wright, J., Feezell, D.F. Investigation of purcell factor and light extraction efficiency in Ag-Coated GaN/InGaN core-shell nanowires. Lasers and Electro-Optics (CLEO), Conference on IEEE, 1–2 (2014).

Colby, R. et al. Dislocation filtering in GaN nanostructures. Nano. Lett. 10, 1568–1573 (2010).

Li, Q. & Wang, G. T. Strain influenced indium composition distribution in GaN/InGaN core-shell nanowires. Applied Physics Letters 97(18), 181107 (2010).

Huang, C. F. et al. Prestrained effect on the emission properties of InGaN∕GaN quantum-well structures. Appl. Phys. Lett. 89, 051913 (2006).

Qian, F. et al. Gallium nitride-based nanowire radial heterostructures for nanophotonics. Nano Lett. 4, 1975–1979 (2004).

Kuykendall, T. et al. Crystallographic alignment of high-density gallium nitride nanowire arrays. Nature materials. 3, 524–528 (2004).

Duan, X. & Lieber, C. M. Laser-assisted catalytic growth of single crystal GaN nanowires. J. Am. Chem. Soc. 122, 188–189 (2000).

Yoshizawa, M., Kikuchi, A., Mori, M., Fujita, N. & Kishino, K. Growth of self-organized GaN nanostructures on Al2O3 (0001) by RF-radical source molecular beam epitaxy. Jpn. J. Appl. Phys. 36, L459–L462 (1997).

Köster, R., Hwang, J. S., Durand, C., Dang, D. L. & Eymery, J. Self-assembled growth of catalyst-free GaN wires by metal–organic vapour phaseepitaxy. Nanotechnology. 21, 015602 (2009).

Sekiguchi, H., Kishino, K. & Kikuchi, A. Ti-mask selective-area growth of GaN by RF-plasma-assisted molecular-beam epitaxy for fabricating regularly arranged InGaN/GaN nanocolumns. Appl. Phys. Express. 1(12), 124002 (2008).

Kishino, K., Hoshino, T., Ishizawa, S. & Kikuchi, A. Selective-area growth of GaN nanocolumns on titanium-mask-patterned silicon (111) substrates by RF-plasma-assisted molecular-beam epitaxy. Electronics. Letters. 44, 819–821 (2008).

Brubaker, M. D. et al. Polarity-Controlled GaN/AlN Nucleation Layers for Selective-Area Growth of GaN Nanowire Arrays on Si(111) Substrates by Molecular Beam Epitaxy. Cryst. Growth Des. 16(2), 596–604 (2016).

Hersee, S., Sun, X. & Wang, X. The controlled growth of GaN nanowires. Nano. Lett. 6, 1808–1811 (2006).

Jung, B. O. et al. Morphology development of GaN nanowires using a pulsed-mode MOCVD growth technique. Cryst.Eng.Comm. 16(11), 2273–2282 (2014).

Lin, Y. T., Yeh, T. W., Nakajima, Y. & Dapkus, D. Catalyst‐Free GaN Nanorods Synthesized by Selective Area Growth. Adv. Funct. Mater. 24(21), 3162–3171 (2014).

Coulon, P. M. et al. Selective area growth of Ga‐polar GaN nanowire arrays by continuous‐flow MOVPE: A systematic study on the effect of growth conditions on the array properties. Physica. Status. Solidi. 252(5), 1096–1103 (2015).

Chez, C. et al. Direct Comparison of Catalyst-Free and Catalyst-Induced GaN Nanowires. Nano. Research. 3, 528–536 (2010).

Sekiguchi, H., Kishino, K. & Kikuchi, A. Emission color control from blue to red with nanocolumn diameter of InGaN/GaN nanocolumn arrays grown on same substrate. Applied physics letters 96(23), 231104 (2010).

Armitage, R. & Tsubaki, K. Multicolour luminescence from InGaN quantum wells grown over GaN nanowire arrays by molecular-beam epitaxy. Nanotechnology. 21(19), 195202 (2010).

Albert, S. et al. Monolithic integration of InGaN segments emitting in the blue, green, and red spectral range in single ordered nanocolumns. Applied. Physics. Letters 102(18), 181103 (2013).

Tu, C. G. et al. Multi-section core-shell InGaN/GaN quantum-well nanorod light-emitting diode array. Optics express 23(17), 21919–21930 (2015).

Rishinaramangalam, A.K. et al. Reduction of reverse‐leakage current in selective‐area‐grown GaN‐based core–shell nanostructure LEDs using AlGaN layers. Physica. Status. Solidi. (a). 1–5 (2016).

Brueck, S. R. J. Optical and interferometric lithography-nanotechnology enablers. Proceedings of the IEEE 93(10), 1704–1721 (2005).

Lin, Y. T., Yeh, T. W. & Dapkus, P. D. Mechanism of selective area growth of GaN nanorods by pulsed mode metalorganic chemical vapor deposition. Nanotechnology. 23(46), 465601 (2012).

Choi, K., Arita, M. & Arakawa, Y. Selective-area growth of thin GaN nanowires by MOCVD. J. Cryst. Growth. 357, 58–61 (2012).

Riley, J. R. et al. Three-Dimensional Mapping of Quantum Wells in a GaN/InGaN Core− Shell Nanowire Light-Emitting Diode Array. Nano letters 13(9), 4317–4325 (2013).

Mohajerani, M. S. et al. Direct correlations of structural and optical properties of three-dimensional GaN/InGaN core/shell micro-light emitting diodes. Japanese Journal of Applied Physics 55(5S), 05FJ09 (2016).

Watanabe, S. et al. Internal quantum efficiency of highly-efficient InxGa1−xN-based near-ultraviolet light-emitting diodes. Applied physics letters 83(24), 4906–4908 (2003).

Kim, K. S., Han, D. P., Kim, H. S. & Shim, J. I. Analysis of dominant carrier recombination mechanisms depending on injection current in InGaN green light emitting diodes. Applied Physics Letters 104(9), 091110 (2014).

Iwata, Y., Banal, R. G., Ichikawa, S., Funato, M. & Kawakami, Y. Emission mechanisms in Al-rich AlGaN/AlN quantum wells assessed by excitation power dependent photoluminescence spectroscopy. Journal of Applied Physics 117(7), 075701 (2015).

Laubsch, A. et al. On the origin of IQE‐‘droop’in InGaN LEDs. physica status solidi (c) 6(S2), S913–S916 (2009).

Laubsch, A., Sabathil, M., Baur, J., Peter, M. & Hahn, B. High-power and high-efficiency InGaN-based light emitters. IEEE transactions on electron devices 57(1), 79–87 (2010).

Shatalov, M. et al. Efficiency of light emission in high aluminum content AlGaN quantum wells. Journal of Applied Physics 105(7), 073103 (2009).

Kohno, T. et al. Internal quantum efficiency and nonradiative recombination rate in InGaN-based near-ultraviolet light-emitting diodes. Japanese Journal of Applied Physics 51(7R), 072102 (2012).

Binet, F., Duboz, J. Y., Off, J. & Scholz, F. High-excitation photoluminescence in GaN: Hot-carrier effects and the Mott transition. Physical Review B 60(7), 4715 (1999).

Schubert, M. F. et al. On resonant optical excitation and carrier escape in GaInN/GaN quantum wells. Applied Physics Letters 94(8), 081114 (2009).

Kawakami, Y. et al. Origin of high oscillator strength in green-emitting In Ga N∕ Ga N nanocolumns. Applied. Physics. Letters. 89(16), 163124 (2006).

Chan, C. C. et al. Optical studies of the surface effects from the luminescence of single GaN/InGaN nanorod light emitting diodes fabricated on a wafer scale. Applied. Physics. Letters. 102(11), 111906 (2013).

Monemar, B. et al. Recombination of free and bound excitons in GaN. Physica. Status. Solidi. (b) 245(9), 1723–1740 (2008).

Ščajev, P., Jarašiūnas, K., Okur, S., Özgür, Ü. & Morkoç, H. Carrier dynamics under two‐and single‐photon excitation in bulk GaN. Physica. Status. Solidi. (b) 249(3), 503–506 (2012).

Taflove, A., Hagness, S.C. Computational electrodynamics. Artech house (2005).

Hong, Y. J. et al. Visible‐color‐tunable light‐emitting diodes. Advanced Materials 23(29), 3284–3288 (2011).

Shen, Y. C. et al. Optical cavity effects in InGaN/GaN quantum-well-heterostructure flip-chip light-emitting diodes. Applied. Physics. Letters. 82(14), 2221–2223 (2003).

Moreno, I. & Sun, C. C. Modeling the radiation pattern of LEDs. Optics express 16(3), 1808–1819 (2008).

Acknowledgements

This work was supported by Defense Advanced Research Projects Agency (DARPA) under award number D13AP00055. This work was performed, in part, at the Center for Integrated Nanotechnologies, an office of science user facility operated for the U.S. department t of energy (DOE) office of science. Sandia National Laboratories is a multi mission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC., a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525.

Author information

Authors and Affiliations

Contributions

D.F. Feezell oversaw the research and manuscript preparation. M. Nami developed the selective-area growth of the GaN/InGaN core-shell nanowire LEDs, performed the electroluminescence characterization, FDTD-Lumerical simulation, and prepared the manuscript. I.E. Stricklin performed photoluminescence measurements, including internal quantum efficiency and time-resolved photoluminescence. K. DaVico assisted in external quantum efficiency analysis. S. Mishkat-Ul-Masabih assisted in processing. A.K. Rishinaramangalam assisted in growth. S.R.J. Brueck and I. Brener assisted with the photolithography and photoluminescence measurements, respectively.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nami, M., Stricklin, I.E., DaVico, K.M. et al. Carrier Dynamics and Electro-Optical Characterization of High-Performance GaN/InGaN Core-Shell Nanowire Light-Emitting Diodes. Sci Rep 8, 501 (2018). https://doi.org/10.1038/s41598-017-18833-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-18833-6

This article is cited by

-

Correlative analysis on InGaN/GaN nanowires: structural and optical properties of self-assembled short-period superlattices

Discover Nano (2023)

-

Ultra-thin broadband solar absorber based on stadium-shaped silicon nanowire arrays

Frontiers of Optoelectronics (2022)

-

Wafer-scale transfer route for top–down III-nitride nanowire LED arrays based on the femtosecond laser lift-off technique

Microsystems & Nanoengineering (2021)

-

Role of Molecular Orbital Energy Levels in OLED Performance

Scientific Reports (2020)

-

Direct imaging of Indium-rich triangular nanoprisms self-organized formed at the edges of InGaN/GaN core-shell nanorods

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.