Abstract

Layered perovskite Sr2TiO4 photocatalyst was synthesized by using sol-gel method with citric acid. In order to increase the surface area of layered perovskite Sr2TiO4, and thus to improve its photocatalytic activity for CO2 reduction, its surface was modified via hydrogen treatment or exfoliation. The physical and chemical properties of the prepared catalysts were characterized by X-ray diffraction, high-resolution transmission electron microscopy, elemental mapping analysis, energy-dispersive X-ray spectroscopy, N2 adsorption-desorption, UV-Vis spectroscopy, X-ray photoelectron spectroscopy, photoluminescence, and electrophoretic light scattering. CO2 photoreduction was performed in a closed reactor under 6 W/cm2 UV irradiation. The gaseous products were analyzed using a gas chromatograph equipped with flame ionization and thermal conductivity detectors. The exfoliated Sr2TiO4 catalyst (E-Sr2TiO4) exhibited a narrow band gap, a large surface area, and high dispersion. Owing to these advantageous properties, E-Sr2TiO4 photocatalyst showed an excellent catalytic performance for CO2 photoreduction reaction. The rate of CH4 production from the photoreduction of CO2 with H2O using E-Sr2TiO4 was about 3431.77 μmol/gcat after 8 h.

Similar content being viewed by others

Introduction

As is well known, the temperature of Earth is increasing owing to greenhouse gas emissions, and CO2 makes up the largest portion of these greenhouse gases. The United Nations Framework Convention on Climate Change (UNFCCC) has concluded that, to maintain a stable environmental, global warming since industrialization must not exceed 2 °C. However, according to their investigation, the average ground temperature since industrialization has already increased by 0.75 °C. When we consider the heat absorbed by the sea, this temperature increases by a further 0.6 °C. Consequently, we have a temperature increase of only 0.65 °C until the temperature change set by the UNFCCC is already reached. Because of the global warming, various natural disasters have been occurred1. In order to avoid this problem, we must reduce CO2 emissions. However, it is impossible to stop CO2 emissions completely because of the current industrial systems are depending on the fossil fuels.

Carbon capture and storage (CCS) technology has been developed in order to reduce and/or control the CO2 emissions2,3. However, this CCS technology has several problems such as high cost, additional energy requirements, stability, and storage limitations. Therefore, carbon capture and utilization (CCU) technology is expected to replace it4,5,6, and is advantageous in economic and environmental view because it can prevent CO2 emissions, and convert them into useful materials. There are various strategies for CO2 utilization. One is the non-conversional use of CO2, and the others involve its conversion using chemical, biochemical, photochemical, and electrochemical methods. Of these, the photochemical method is a more promising technology in environmental terms. CO2 photoreduction using a photocatalyst can generate useful compounds such as CH4, HCOOH, HCHO, and CH3OH7. Much research has been devoted to this field since the first report by Inoue et al.8 on the photoreduction of CO2, and many different semiconductors have been developed and used as photocatalysts, such as TiO2 9, WO3 10, ZnO11, GaP12, CdS13, and SiC14. Of these, TiO2 is one of the most well-known and widely used materials. In order to improve the optical properties of TiO2, it has been combined with various metals to form hybridized composites such as Ag/TiO2 15, Pt/TiO2 16, Ru/TiO2 17, Pd/TiO2 18, Ni/TiO2 19, Cu/TiO2 20, TiO2/Cu-TiO2 21, CeO2-TiO2 22, MgO-TiO2 23, NiO-In2O3/TiO2 24, CuSx-TiO2 25, NiS-TiO2 26, In2O3/TiO2 27, TiO2/Fe-TiO2 28 and multi-walled carbon nanotube (MWCNT)@TiO2 29 in an attempt to reduce the band gap or suppress recombination of photogenerated charge carriers. Also, catalysts having a combination of an organic and metal material such as g-C3N4 30, Ni12P5/g-C3N4 31, Au cluster-NP/C3N4 32, AgX/g-C3N4 (X = Cl and Br)33, RuRu′/Ag/NS-C3N4 34,35,36,37 and Co-ZIF38,39,40,41 are being developed.

Recently, the development of TiO2 photocatalysts with the perovskite structure ABO3, has attracted due to the unique perovskite structure, their composition can be easily changed at the A, and B sites and the metal introduced can be quantitatively substituted into the skeleton. Among the perovskite semiconductors, SrTiO3 is widely used as a photocatalyst. Much like TiO2, SrTiO3 has been combined with other species to form hybrid composites such as Mn/SrTiO3 42, Cu/SrTiO3 43, N-doped TiO2-SrTiO3 44, Fe2O3/SrTiO3 45, SrTiO3:Cr/Ta/F46, SrTiO3/HZSM-547, SrTiO3/TiO2/H-titanate nanofiber48, SrTiO3:Rh/Sb49, La/Cr-doped SrTiO3 50, Pt/SrTiO3 51, Zn/SrTiO3 52, Ag3PO4/Cr-SrTiO3 53, and g-C3N4-SrTiO3:Rh54 to improve its photocatalytic performance. Studies on other perovskite catalysts, including CaxTiyO3 55, and basalt fiber@PbTiO3 56, also have been recently reported.

Another advantage of perovskite is that it forms a layered perovskite depending on the nature and contents of the A and B ions. Figure 1a shows the structure of a Ruddlesden-Popper Aj+1BjO3j+1 perovskite. Here, when the j value increases, the structure tends towards an ABO3 perovskite. In particular, A2BO4, for which j = 1, shows a layered structure with a large gap between each BO6 octahedron.

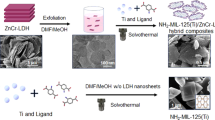

In this study, we have attempted to improve the photocatalytic performance of Sr2TiO4 layered perovskite by increasing its surface area (Fig. 1b). The surface of the synthesized catalyst was hydrogen treated or exfoliated to increase its interaction with the CO2 feed material and thus amplify its CO2 photoreduction activity. The characteristic properties of the synthesized catalysts were measured by using a variety of techniques such as using X-ray diffraction (XRD), high-resolution transmission electron microscopy (HR-TEM), N2 adsorption-desorption isotherm analysis, UV-Vis spectroscopy, photoluminescence (PL), zeta potential analysis, and X-ray photoelectron spectroscopy (XPS). Furthermore, their photocatalytic activity for the reduction of CO2 with H2O under UV light was studied.

Results

X-ray diffraction (XRD) patterns

The XRD patterns for Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 are given in Fig. 2. The peaks for Sr2TiO4 are observed at 2θ = 24.076, 28.386, 31.464, 32.656, 35.673, 42.899, 43.217, 43.852, 46.791, 55.049, 55.605, 56.319, 57.431, 65.452, and 68.390°, which are assigned to the (011), (004), (013), (110), (112), (015), (006), (114), (020), (116), (024), (017), (123), (026), and (220) planes of Sr2TiO4, respectively, identifying it as a layered perovskite-type tetragonal structure (JCPDS 00-039-1471)57. The crystallite size of Sr2TiO4 calculated using Scherer’s equation based on the (013) plane is 12.856 Å58. After hydrogen treatment, an anatase TiO2 peak is observed at 2θ = 25.429°. However, the other peaks for the Sr2TiO4 structure are maintained, and the crystallite sizes based on the Sr2TiO4 (013) plane and the TiO2 anatase (011) plane are 9.371 and 3.024 Å, respectively. Conversely, the Sr2TiO4 sample exfoliated with HNO3 and TPAOH presents a different XRD pattern. The peaks for E-Sr2TiO4 are found at 27.141, 36.070, 41.232, 54.414, 63.069, and 69.105°, which are assigned to the (110), (011), (111), (121), (130), and (031) planes of rutile TiO2, respectively59. These structural changes are due to the fact that the Sr ions located between the Sr2TiO4 layers are removed by HNO3 treatment, and only the TiO6 octahedra (corresponding to BO6) remain. The crystal structure analysis reveals that the Ti forms a rutile structure in the Sr2TiO4 and that the Sr is intercalated between the layers. The crystallite size of the catalysts was calculated using scherrer’s equation. In the case of Sr2TiO4 and H-Sr2TiO4, (013) plane was selected, and (110) plane was selected for E-Sr2TiO4. As a result, the crystallite size of Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 were found to be 11.568, 11.578, 1.165 Å, respectively.

High-resolution transmission electron microscopy (HR-TEM), element mapping and EDX analysis

The differences in the morphologies of Sr2TiO4 and E-Sr2TiO4 were investigated using HR-TEM and selected area electron diffraction (SAED) (Fig. 3). The larger particles are observed in Sr2TiO4, and whereas E-Sr2TiO4 consists of the particles form a separate sheets or randomly folded sheets. The images show that the interplanar distance for E-Sr2TiO4 is larger than that for Sr2TiO4. The d-spacings for the Sr2TiO4 (013) plane and the E-Sr2TiO4 (110) plane are 2.84 and 3.25 Å, respectively. These results are in accordance with the values derived from XRD patterns.

The compositions of Sr2TiO4 and E-Sr2TiO4 were analyzed by HR-TEM element mapping analysis and EDX, and the results are shown in Fig. 4 and Table 1. In Sr2TiO4, Sr and Ti ions are uniformly distributed throughout the particles and Sr ions are more abundant than Ti ions. The atomic percent values for Sr and Ti are 16 and 11%, respectively. However, the Sr ion content of E-Sr2TiO4 is much lower than that of Sr2TiO4. Furthermore, EDX analysis showed that the Sr ion content, which is about 1.4-times that of Ti in Sr2TiO4, is reduced to just 0.07% that of Ti in E-Sr2TiO4. Thus, these results support the assertion that the layers are separated because Sr ions are removed from the interlayers by exfoliation.

Brunaure-Emmett-Teller (BET) surface area analysis

Figure 5 shows the N2 adsorption-desorption isotherms at 77 K for P-25, which was used as a comparative sample, Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4. According to the IUPAC classification, the adsorption-desorption isotherm curves of all the catalysts belong to type III. Therefore, the synthesized catalysts are non-porous materials. However, the slight hysteresis in the curves is due to the bulk pores between the particles. The specific surface areas of Sr2TiO4 and H-Sr2TiO4 are 1.19 and 0.78 m2/g, respectively, which are very low. However, E-Sr2TiO4 has a specific surface area of 358.54 m2/g, which is much larger than those of Sr2TiO4 and H-Sr2TiO4. The increase in the specific surface are of E-Sr2TiO4 is due not only to the removal of Sr ions from between the layers, but also to the separation of the layers, as shown in the HR-TEM images. The increase in catalyst surface area leads to an increase in the number of active sites for CO2 and H2O to react, leading to an increase in reactivity. Therefore, E-Sr2TiO4 was expected to exhibit improved catalytic activity compared to those of Sr2TiO4 and H-Sr2TiO4. This specific surface area is considerably larger than that of the commercial catalyst P-25, which is 43.65 m2/g.

Optical properties of photocatalysts

Figures 6 and 7 show the UV-Vis spectra and Tauc’s plots of P-25, Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4. The UV absorptions of Sr2TiO4 and H-Sr2TiO4 are blue-shifted compared to that of P-25 because of the influence of SrO, with its band gap of 5.71 eV60. Conversely, the absorbance of E-Sr2TiO4 is shifted to a longer wavelength due to the removal of Sr ions. Most interestingly, it moved to longer wavelength than that of P-25. This is because E-Sr2TiO4 has a rutile TiO2 structure (band gap: 3.0 eV), as confirmed by the XRD analysis above. Therefore, the absorbance of E-Sr2TiO4 is shifted to longer wavelength than that of P-25, which composed mainly of anatase TiO2 (band gap: 3.2 eV). The band gap was calculated using the Tauc equation61:

where α, h, ν, A, and E bg represent the absorption coefficient, Plank’s constant, light frequency, a constant, and band gap energy, respectively. In a plot of (αhν)2 versus photon energy (hν), the intercept on the x axis gives the band gap. Using this method, the band gap of P-25, Sr2TiO4, H-Sr2TiO4 and E-Sr2TiO4 were calculated to be 3.16, 3.33, 3.34, and 3.03 eV, respectively. Therefore, E-Sr2TiO4 has the narrowest band gap, making it most suitable as a photocatalyst.

Photocatalysts with narrower band gaps have advantages in terms of photosensitization. However, in order to exhibit good performance in the current system, the band gap of a photocatalyst should also include the CO2/CH4 and H2O/O2 reduction potentials. Figure 8 shows the XPS valance band spectra of the catalysts. Based on the data obtained, the valance band value of the catalysts was confirmed, and the values for P-25, Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 are 2.46, 2.34, 1.60, and 2.06 eV, respectively. When the vacuum level of 4.5 eV is corrected to 0 V for a standard hydrogen electrode (SHE) and the work function of the XPS instrument is taken as 4.62 eV62, the valance band maximum values for P-25, Sr2TiO4, H-Sr2TiO4 and E-Sr2TiO4 are 2.58, 2.46, 1.72 and 2.18 eV (vs. SHE), respectively. According to these valance band and band gap values, the conduction band minimum values for P-25, Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 are -0.58, 0.87, -1.61, and -0.84 eV (vs. SHE), respectively. Figure 9 shows the energy diagrams obtained for the catalysts using the valance and conduction band values and the band gap. All catalysts contain the CO2/CH4 and H2O/O2 reduction potential. Therefore, the synthesized catalysts are suitable for the photoreduction of CO2 with H2O to CH4.

In order to understand the recombination of excited electrons and holes, PL analysis was conducted, and the results are shown in Fig. 10. The PL spectra of the catalysts show a strong emission signal at 468.1 nm. The PL intensity of Sr2TiO4 is smaller than that of P-25. This is due to a decrease in the number of excited electrons because of the wide band gap of Sr2TiO4. The intensity for H-Sr2TiO4 is lower than that of Sr2TiO4. This is because the oxidation state of the exposed Ti on the surface is reduced to (4-δ)+, which is not +4, and the reduced Ti suppresses the recombination of electrons and holes by trapping the excited electrons in the conduction band. The E-Sr2TiO4 also exhibits a PL intensity lower than that of Sr2TiO4 and much lower than that of P-25. Generally, excited electrons and holes move from the bulk of a particle to its surface where they react with reactants. The recombination of excited electrons and holes takes place in the bulk or on the surface of a particle during transport. When the particles are exfoliated, the internal area of the particles decreases and the distance to the surface for the electrons and holes decreases. Therefore, recombination inside the particles is also reduced. This is the reason that E-Sr2TiO4 has a lower PL intensity than that of P-25. Thus, the above analysis indicates that H-Sr2TiO4 and E-Sr2TiO4 will be better photocatalysts than Sr2TiO4.

X-ray photoelectron spectroscopy (XPS) analysis

The XPS spectra of the photocatalysts were obtained to confirm the oxidation state of the elements according to their chemical bonding, and the results are shown in Fig. 11. For Sr2TiO4, the peaks located at 133.38 and 134.88 eV are assigned to Sr-3d5/2 and Sr-3d3/2 core levels respectively. In H-Sr2TiO4, the Sr 3d peaks are shifted toward a slightly lower binding energy. In E-Sr2TiO4, the intensity of the 3d peaks is greatly reduced. This is due to the removal of Sr ions from the interlayer spaces, as described above. The Ti 2p3/2 and 2p1/2 peaks of Sr2TiO4 are observed at 457.88 and 463.78 eV, respectively. The Ti 2p peaks for H-Sr2TiO4 are shifted to a lower binding energy, similarly to the Sr 3d peaks. This is because some of the Sr2+ and Ti4+ ions are reduced by hydrogen to Sr(2−δ)+ and Ti(4−δ)+, respectively. The Ti 2p peaks for E-Sr2TiO4 have significantly different peak intensities to Sr2TiO4 or H-Sr2TiO4, and its Ti 2p3/2 and Ti 2p1/2 peaks are observed at 458.18 and 464.08 eV, respectively. This binding energy is shifted slightly lower compared to that of P-25. Therefore, the Ti ions of E-Sr2TiO4 are slightly more reduced ions than in P-25. It is believed that this can induce vacancies in the crystal framework and facilitate the movement of electrons and holes, which can be advantageous for photocatalytic activity.

There are two O 1 s peaks in Sr2TiO4 and H-Sr2TiO4. The peak at ~529 eV is from oxygen bound to Ti, and the peak at ~531 eV corresponds to oxygen bound to Sr. For E-Sr2TiO4, only the peak corresponding to oxygen bonded to Ti is observed (at 529.48 eV), because the Sr is removed by exfoliation.

Zeta potential analysis of photocatalysts

Since the catalytic reaction takes place in H2O, it is important to study the dispersion of the catalyst particles in H2O. The zeta potentials were measured after dispersing the catalysts in distilled water or in bubbling-CO2 solution (i.e., the reaction conditions), and the results are shown in Table 2. Generally, a larger absolute value for the measured zeta potential means that the particles are well dispersed in a solution. The zeta potentials for Sr2TiO4, H-Sr2TiO4, E-Sr2TiO4, and P-25 are -11.99, -11.15, -42.39, and -15.61 mV, respectively. Therefore, the degree of colloidal dispersion in H2O follows the order E-Sr2TiO4 > P-25 > Sr2TiO4 > H-Sr2TiO4. Thus, all catalysts can be adequately dispersed in H2O. However, the zeta potential shows a different pattern after CO2 bubbling: all the negative potential values are changed to positive values. The zeta potentials for Sr2TiO4, H-Sr2TiO4, E-Sr2TiO4, and P-25 are 1.16, 16.29, 26.22, and 22.00 mV, respectively. Therefore, the degree of colloidal dispersion in the solution after CO2 bubbling follows the order E-Sr2TiO4 > P-25 > H-Sr2TiO4 > Sr2TiO4. Thus, E-Sr2TiO4, P-25, and H-Sr2TiO4 show good dispersion under the reaction conditions, which is considered advantageous for CO2 photoreduction performance. However, in the case of Sr2TiO4, the zeta potential is low, so it is likely to exhibit poor catalytic performance owing to it being more agglomerated than the other catalysts.

Photocatalytic reduction of CO2 with H2O, property after reaction, and mechanism

The products obtained though CO2 reduction using the catalysts synthesized in this study are CH4, H2, C2H6, C2H4, and CO. Figure 12 shows the accumulation of the products according to irradiation time. The main product is CH4 and the product amounts follow the order CH4 > C2H6 > H2 > C2H4 > CO. Overall, the reactivity of the surface-treated H-Sr2TiO4 and E-Sr2TiO4 is better than that of Sr2TiO4. After 8 h reaction, the rates of CH4 production over Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 are 844.94, 1353.46, and 3431.77 μmol/gcat, respectively. In particular, E-Sr2TiO4 shows excellent reactivity and produces more CH4 than P-25 catalyst, and. Figure 12b shows the amounts of H2 produced. H2 is a necessary substance for reducing CO2. Therefore, the greater the amount of H2 generated, the easier the CO2 reduction. The amounts of H2 generated over Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 are 267.73, 373.65, and 640.71 μmol/gcat, respectively. Therefore, the CO2 reduction reaction is promoted over E-Sr2TiO4 is higher than the other catalysts. Furthermore, the C2H6 production over E-Sr2TiO4 is higher than that over the other catalysts. When E-Sr2TiO4 is used, the amount of C2H6 produced after 8 h is 150.8 μmol/gcat. If the C2H6 reacts with H2 on the catalysts surface it can be further converted to CH4. The amounts of C2H4 and CO produced over the catalysts are similar. After 8 h, the production of C2H4 and CO is 457.63–573.33 and 69.35–81.30 μmol/gcat, respectively. Figure 13 shows the product distribution on the catalysts. P-25 showed the highest CH4 selectivity, which was 80 to 90%. Next, when E-Sr2TiO4 was used, the CH4 selectivity was high and its value was about 70%. Table 3 shows the quantum yield of the catalysts and the overall quantum yield was in the order of E-Sr2TiO4, P-25, H-Sr2TiO4, and Sr2TiO4, which were 2.83, 1.96, 2.93, and 6.20%, respectively. The quantum yield for CO2 photoreduction to produce CH4 of P-25, Sr2TiO4, H-Sr2TiO4 and E-Sr2TiO4 were 2.69, 1.28, 2.56, 5.21%, respectively. The quantum yield for other products was less than 1% for all catalysts.

The XRD analysis of the catalysts after the reaction was carried out to confirm the structural stability and displayed in Fig. 14. From the XRD analysis results, it was observed that the catalysts structure was remained stable before and after the reaction. Therefore, the catalysts structure was stable during the reaction conditions.

The photoreaction of E-Sr2TiO4 showing the best activity was repeated three times. The results for CH4 production, the main product, are shown in Fig. 15. A slight amount of difference was observed in the results but similar performance was maintained without deactivation in all three times. Therefore, it was confirmed that the E-Sr2TiO4 was excellent in not only structural stability but also reusability during the reaction

Based on these results, a plausible reaction pathway over E-Sr2TiO4, which has the best performance is proposed in Fig. 16. The excited electrons on the exfoliated improved catalyst surface react with CO2 to produce ∙CO2 − radicals, and the holes react with H2O to produce OH− and H+. Hydrogen radicals (∙H) are formed by the reaction of H+ with excited electrons, and then CO is produced by the reaction of ∙H and ∙CO2 − radicals. CH4, C2H6, and C2H4 are produced finally as the CO and ∙H radicals continuously react.

Conclusion

In this study, nanosized layered perovskite Sr2TiO4 photocatalyst was successfully synthesized by using sol-gel technique with the assistance of citric acid. The surface of layered perovskite Sr2TiO4 photocatalyst was treated to improve the CO2 photoreduction activity. The particles were treated with HNO3 to remove the Sr ions present between the layers, and the layers were exfoliated by treatment with TPAOH. The catalyst, E-Sr2TiO4 showed the rutile TiO2 structure after exfoliation because the Sr2TiO4 structure was collapsed. The shape of the exfoliated thin film was confirmed by TEM. In comparison to Sr2TiO4 and H-Sr2TiO4 photocatalysts, the exfoliated catalyst E-Sr2TiO4 showed an excellent performance in CO2 photoreduction to CH4, and after 8 h, 3431.77 μmol/gcat of CH4 was generated. The reason for the excellent performance of E-Sr2TiO4 can be explained by the following factors.

First, it has a narrow band gap compared to the other two catalysts, and exhibits reduced electron-hole recombination. Therefore, a relatively larger number of electrons and holes transferred to CO2 and H2O. Next, a large amount of CO2 and H2O can interact with the active sites on the surface because it has a large surface area and is well dispersed in the solution. Based on the excellent physical and photochemical properties of the exfoliated layered perovskite catalyst, it may be employed for different photocatalytic applications as well as the CO2 photoreduction reactions.

Methods

Synthesis of photocatlysts

The synthesis of layered perovskite Sr2TiO4 was performed as follows: Strontium nitrate (Sr(NO3)2, 97.0%, Junsei Chemical, Japan) and titanium isopropoxide (Ti(OCH(CH3)2)4, TTIP, 98.0%, Junsei Chemical, Japan) were used as precursors. First, 0.1 mol of Sr(NO3)2 was dissolved in double distilled water (100 mL) with continuous stirring. Then, 10 mL of HNO3 (60%, OCI company Ltd., Republic of Korea) was added with stirring to prevent hydrolysis. This solution was labeled A. In a separate vessel, 0.05 mol of TTIP was dissolved in EtOH (99.9%, OCI company Ltd., Republic of Korea), and then glacial acetic acid (CH3COOH, 99.0%, Ducsan, Republic of Korea) was added with stirring to prevent hydrolysis. This solution was labeled as B. The solutions A and B were then mixed with stirring, and citric acid monohydrate (C6H8O7·H2O, 99.5%, Daejung Chemicals and Metals Co Ltd., Republic of Korea), which is a complexing agent for the gel, was added, and the mixture was stirred until it became homogeneous. Then, the solvent was removed without the temperature exceeding 323.15 K to obtain a sol gel, which was subsequently pretreated at 493.15 K. Finally, a white powder was obtained by thermal treatment at 1323.15 K for 6 h. In some cases, hydrogen treatment was then performed at 1123.15 K for 3 h in H2 atmosphere. In other cases, exfoliation was achieved by a three-step process, as shown in Fig. 17. Ion exchange of Sr for H cations was carried out in 1 M HNO3 for 5 days using ultrasonication. The powder obtained was treated in tetrapropylammonium hydroxide (TPAOH, 25.0%, in water, ACROS, Belgium) for 3 weeks using ultrasonication. The final white precipitate was washed several times with distilled water and ethanol and dried at 343 K for 24 h. The hydrogen-treated and exfoliated Sr2TiO4 samples were labeled H-Sr2TiO4 and E-Sr2TiO4, respectively.

Characterization of photocatalysts

The structures and crystallinities of the as-prepared Sr2TiO4, H-Sr2TiO4, and E-Sr2TiO4 samples were confirmed with XRD (model MPD from PANalytical) using nickel-filtered CuKα radiation (40.0 kV, 30.0 mA). The morphologies were investigated using HR-TEM (Tecnal G2 F20 S-TWIN, FEI, Netherlands) operated at 200 kV. The presence of different elements was confirmed using the elemental mapping and energy dispersive X-ray spectroscopy (EDS) attached to the TEM setup. The specific surface areas (SBET) were calculated according to the Brunauer-Emmett-Teller theory using a Belsorp II mini (BEL, Japan Inc.). The UV-Vis absorption spectra were obtained using a SCINCO Neosys-2000 spectrometer fitted with a reflectance sphere. PL profiles were obtained using a SCINCO FluoroMate FS-2 at room temperature using a He-Cd laser source at a wavelength of 325 nm. XPS measurements were performed on a K-alpha (Thermo Scientific, UK) using Al Kα X-rays as the excitation source. The zeta potential of the material was determined by electrophoretic mobility using an electrophoresis measurement apparatus (ELS 8000, Otsuka Electronics, Japan) with a plate sample cell. Electrophoretic light scattering (ELS) determination was performed in reference beam mode with a 670 nm laser light source at a modular frequency of 250 Hz and a scattering angle of 15°. The standard error of the zeta potential, converted from the experimentally determined electrophoretic mobility, was typically <1.5% with 5% error. To measure the zeta potentials, the samples were dispersed in deionized water or bubbling-CO2 water at 0.1 wt%. The final zeta potentials were obtained by averaging 2 or 3 measurements.

Photocatalytic activity measurements

The photocatalytic tests for the reduction of CO2 with H2O were performed in a photoreactor comprising a quartz chamber with a total volume of 150.0 cm3 (Fig. 18). To photoreduce CO2, 0.01 g of the catalyst was placed in the reactor chamber with 50 mL of double distilled water, and the reactor was closed. A UV lamp (6 W/cm2, 20 cm length × 2.0 cm diameter, Shinan, Republic of Korea) emitting light at 365 nm was used to irradiate the reaction mixture. Supercritical-fluid-grade CO2 with a certified maximum hydrocarbon content of <1 ppm was used as the reactant. Before the reaction was initiated by illumination, the reactor was purged with CO2 gas for 5 min. The lamp was then switched on to start the experiment. The reaction temperature and pressure were maintained at 303 K and 1 atm, respectively. The gas products were analyzed using a gas chromatograph (iGC7200, DS Science, Republic of Korea) equipped with a thermal conductivity detector (TCD) and a flame ionization detector (FID). The product yield33 and quantum yield63 during reaction was calculated using following equation (2–3).

References

Dewi, M. S., Hartono, D. M., Moersidik, S. S. & Kustiwan, I. Green housing evaluation through carbon footprint dynamic model: questioned the urban policy sustainability. Procedia Soc. Behav Sci. 227, 317–324 (2016).

Najafi-Marghmaleki, A., Barati-Harooni, A. & Mohammadi, A. Impact of gas impurities on CO2 mole fraction: Application in carboncapture and storage (CCS) processes. Int. J. Greenhouse Gas Control. 57, 173–184 (2017).

Mechleri, E., Brown, S., Fennell, P. S. & Dowell, N. M. CO2 capture and storage (CCS) cost reduction viainfrastructure right-sizing. Chem. Eng. Res. Des. 119, 130–139 (2017).

Oh, S. T. & Martin, A. Thermodynamic efficiency of carbon capture and utilisation in anaerobic batch digestion process. J. CO2 Util. 16, 182–193 (2016).

Kang., D. et al. Carbon capture and utilization using industrial wastewater under ambient conditions. Chem. Eng. J. 308, 1073–1080 (2017).

Pan, S. –Y., Lafuente, A. M. L. & Chiang, P. –C. Engineering, environmental and economic performance evaluation of high-gravity carbonation process for carbon capture and utilization. Appl. Energy 170, 269–277 (2016).

Li, X. et al. Engineering heterogeneous semiconductors for solar water splitting. J. Mater. Chem. A 3, 2485–2534 (2015).

Enoue, T., Fujishima, A., Konishi, S. & Honda, K. Photoelectrocatalytic reduction of carbon dioxide in aqueous suspensions of semiconductor powders. Nature 277, 637–638 (1979).

Chen, L. et al. Photoreduction of CO2 by TiO2 nanocomposites synthesized through reactive direct current magnetron sputter deposition. Thin Solid Films 517, 5641–5645 (2009).

Wang, P. –Q., Bai, Y., Luo, P. –Y. & Liu, J. –Y. Graphene–WO3 nanobelt composite: Elevated conduction band toward photocatalytic reduction of CO2 into hydrocarbon fuels. Catal. Commun. 38, 82–85 (2013).

Li, X. et al. Green synthesis and photo-catalytic performances for ZnO-reduced graphene oxide nanocomposites. J. Colloid Interface Sci. 411, 69–75 (2013).

Marcì, G., Garía-López, E. I. & Palmisano, L. Photocatalytic CO2 reduction in gas–solid regime in the presence of H2O by using GaP/TiO2 composite as photocatalyst under simulated solar light. Catal. Commun. 53, 38–41 (2014).

Beigi, A. A., Fatemi, S. & Salehi, Z. Synthesis of nanocomposite CdS/TiO2 and investigation of its photocatalytic activity for CO2 reduction to CO and CH4 under visible light irradiation. J. CO2 Util. 7, 23–29 (2014).

Li, H. et al. Photocatalytic reduction of carbon dioxide to methanol by Cu2O/SiC nanocrystallite under visible light irradiation. J. Nat. Gas Chem. 20, 145–150 (2011).

Zhao, C., Krall, A., Zhao, H., Zhang, Q. & Li, Y. Ultrasonic spray pyrolysis synthesis of Ag/TiO2 nanocomposite photocatalysts for simultaneous H2 production and CO2 reduction. Int. J. Hydrogen Energy 37, 9967–9976 (2012).

Wang, W. –N. et al. Size and Structure Matter: Enhanced CO2 Photoreduction Efficiency by Size-Resolved Ultrafine Pt Nanoparticles on TiO2 Single Crystals. J. Am. Chem. Soc. 134, 11276–11281 (2012).

Lee, C. –W. et al. Photocatalytic conversion of CO2 to hydrocarbons by light-harvesting complex assisted Rh-doped TiO2 photocatalyst. J. CO2 Util. 5, 33–40 (2014).

Zbudniewek, K., Góralski, J. & Rynkowski, J. Studies on TiO2/SiO2 and Pd/TiO2/SiO2 Catalysts in Photoreduction of CO2 with H2O to Methanol1. Russ. J. Phys. Chem. A 86, 2057–2062 (2012).

Kwak, B. S. et al. Methane formation from photoreduction of CO2 with water using TiO2 cluding Ni ingredient. Fuel 143, 570–576 (2015).

Tseng, I. –H., Wu, J. C. S. & Chou, H. –Y. Effects of sol–gel procedures on the photocatalysis of Cu/TiO2in CO2 photoreduction. J. Catal. 221, 432–440 (2004).

Park, M., Kwak, B. S., Jo, S. W. & Kang, M. Effective CH4 production from CO2 photoreduction using TiO2/x mol% Cu–TiO2 double-layered films. Energy Convers. Manage. 103, 431–438 (2015).

Abdullah, H., Khan, M. R., Pudukudy, M., Yaakob, Z. & Ismail, N. A. CeO2-TiO2 as a visible light active catalyst for the photoreduction of CO2 to methanol. J. Rare Earths 33, 1155–1161 (2015).

Wang, F., Zhou, Y., Li, P., Kuai, L. & Zou, Z. Synthesis of bionic‐macro/microporous MgO‐modified TiO2 for enhanced CO2 photoreduction into hydrocarbon fuels. Chin. J. Catal. 37, 863–868 (2016).

Tahir, M. & Amin, N. S. Performance analysis of nanostructured NiO–In2O3/TiO2 catalyst for CO2 photoreduction with H2 in a monolith photoreactor. Chem. Eng. J. 285, 635–649 (2016).

Lee, H. et al. Assembly of a check-patterned CuSx–TiO2 film with an electron-rich pool and its application for the photoreduction of carbon dioxide to methane. Appl. Surf. Sci. 393, 385–396 (2017).

Lee, J. H., Kim, S.-I., Park, S.-M. & Kang, M. A p-n heterojunction NiS-sensitized TiO2 photocatalytic system for efficient photoreduction of carbon dioxide to methane. Ceram. Int. 43, 1768–1774 (2017).

Tahir, M., Tahir, B., Amin, N. A. S. & Alias, H. Selective photocatalytic reduction of CO2 by H2O/H2 to CH4 and CH3OH over Cu-promoted In2O3/TiO2 nanocatalyst. Appl. Surf. Sci. 389, 46–55 (2016).

Do, J. Y., Im, Y., Kwak, B. S., Kim, J. –Y. & Kang, M. Dramatic CO2 photoreduction with H2O vapors for CH4 production using the TiO2 (bottom)/Fe–TiO2 (top) double-layered films. Chem. Eng. J. 275, 288–297 (2015).

Gui, M. M., Chai, S. –P. & Mohamed, A. R. Modification of MWCNT@TiO2 core–shell nanocomposites with transition metal oxide dopants for photoreduction of carbon dioxide into methane. Appl. Surf. Sci. 319, 37–43 (2014).

Zhou, M., Hou, Z. & Chen, X. The Effects of Hydrogenation on Graphitic C3N4 Nanosheets for Enhanced Photocatalytic Activity. Part. Part. Syst. Charact. 2017, 1700038–1700046 (2017).

Zeng, D. et al. Ni12P5 nanoparticles embedded into porous g-C3N4 nanosheets as a noble-metal-free hetero-structure photocatalyst for efficient H2 production under visible light. J. Mater. Chem. A, https://doi.org/10.1039/C7TA04816E (2017).

Chen, W. et al. Synergetic enhancement of plasmonic hot-electron injection in Au cluster-nanoparticle/C3N4 for photocatalytic hydrogen evolution. J. Mater, Chem. A, https://doi.org/10.1039/C7TA03808A (2017).

Ong, W.-J., Putri, L. K., Tan, L.-L., Chai, S.-P. & Yong, S.-T. Hetrostructured AgX/g-C3N4 (X = Cl and Br) nanocomposites via a sonication-assisted deposition-precipitation approach: Emerging role of halide ions in the synergistic photocatalytic reduction of carbon dioxide. Appl. Catal., B 180, 530–543 (2016).

Kuriki, R. et al. Robust Binding between Carbon Nitride Nanosheets and a binuclear Ruthenium (II) Complex Enabling Durable, Selective CO2 Reduction under Visible Light in Aqueous Solution. Angew. Chem. Int. Ed. 56, 4867–4871 (2017).

Kuriki, R. et al. Nature-Inspired, Highly Durable CO2 Reduction System Consisting of a Binuclear Ruthenium(II) Complex and an Organic Semiconductor Using Visible Light. J. Am. Chem. Soc. 138, 5159–5170 (2016).

Ong, W.-J. et al. Unraveling charge carrier dynamics in protonated g-C3N4 interfaced with carbon nano dots as co-catalysts toward enhanced photocatalytic CO2 reduction: A combined experimental and first-principles DFT study. Nano Res. 10, 1673–1676 (2017).

Ong, W.-J., Tan, L.-L., Ng, Y. H., Yong, S.-T. & Chai, S.-P. Graphitic Carbon Nitride (g-C3N4)-Based Photocatalysts for Artificial Photosynthesis and Environmental Remediation: Are We a Step Closer To Achieving Sustainability? Chem. Rev. 116, 7159–7329 (2016).

Wang, S., Yao, W., Lin, J., Ding, Z. & Wang, X. Cobalt Imidazolate Metal-Organic Frameworks Photosplit CO2 under Mild Reaction Conditions. Angew. Chem. Int. Ed. 53, 1034–1038 (2014).

Wang, S. & Wang, X. Imidazolium Ionic Liquids, Imidazolylidene Heterocyclic Carbenes, and Zeolitic Imidazolate Frameworks for CO2 Capture and Photochemical Reduction. Angew. Chem. Int. Ed. 55, 2308–2320 (2016).

Wang, S. & Wang, X. Multifunctional Metal-Organic Frameworks for Photocatalysis. Small 11, 3097–3112 (2015).

Wang, S. & Wang, X. Photocatalytic CO2 reduction by CdS promoted with a zeolitic imidazolate framework. Appl. Catal., B 162, 494–500 (2015).

Wu, G. et al. Hydrothermal synthesis and visible-light-driven photocatalytic degradation for tetracycline of Mn-doped SrTiO3 nanocubes. Appl. Surf. Sci. 333, 39–47 (2015).

Bui, D.-N., Mu, J., Wang, L., Kang, S.-Z. & Li, X. Preparation of Cu-loaded SrTiO3 nanoparticles and their photocatalytic activity for hydrogen evolution from methanol aqueous solution. Appl. Surf. Sci. 274, 328–333 (2013).

Ruzimuradov, O. et al. A facile preparation of dual-phase nitrogen-doped TiO2–SrTiO3 macroporous monolithic photocatalyst for organic dye photodegradation under visible light. J. Eur. Ceram. Soc. 35, 1815–1821 (2015).

Zhang, Z., Liu, G. & Mao, Y. Improved separation efficiency of photogenerated carriers for Fe2O3/SrTiO3 heterojunction Semiconductor. Int. J. Hydrogen Energy 38, 9349–9354 (2013).

Kang, H. W., Park, S. B., Kim, J. G. & Kim, I. T. Effects of F for enhancement of H2 evolution on visible-light-driven photocatalyst of SrTiO3:Cr/Ta/F prepared by spray pyrolysis. Int. J. Hydrogen Energy 39, 5537–5545 (2014).

Zhang, W., Du, L., Bi, F. & He, H. A novel SrTiO3/HZSM-5 photocatalyst prepared by sol–gel method. Mater. Lett. 157, 103–105 (2015).

Liu, Y. et al. Sandwich SrTiO3/TiO2/H-Titanate nanofiber composite photocatalysts for efficient photocatalytic hydrogen evolution. Appl. Surf. Sci. 315, 314–322 (2014).

Niishiro, R., Tanaka, S. & Kudo, A. Hydrothermal-synthesized SrTiO3 photocatalyst codoped with rhodium and antimony with visible-light response for sacrificial H2 and O2 evolution and application to overall water splitting. Appl. Catal. B 150–151, 187–196 (2014).

Shen, S., Jia, Y., Fan, F., Feng, Z. & Li, C. Time‐resolved infrared spectroscopic investigation of roles of valence states of Cr in (La,Cr)‐doped SrTiO3 photocatalysts. Chin. J. Catal. 34, 2036–2040 (2013).

Hirayama, J., Abe, R. & Kamiya, Y. Combinational effect of Pt/SrTiO3:Rh photocatalyst and SnPd/Al2O3 non-photocatalyst for photocatalytic reduction of nitrate to nitrogen in water under visible light irradiation. Appl. Catal. B 144, 721–729 (2014).

Zou, J.-P. et al. Preparation and photocatalytic activities of two new Zn-doped SrTiO3 and BaTiO3 photocatalysts for hydrogen production from water without cocatalysts loading. Int. J. Hydrogen Energy 37, 17068–17077 (2012).

Guo, J. et al. A new heterojunction Ag3PO4/Cr-SrTiO3 photocatalyst towards efficient elimination of gaseous organic pollutants under visible light irradiation. Appl. Catal. B 134–135, 286–292 (2013).

Kang, H. W., Lim, S. N., Song, D. & Park, S. B. Organic-inorganic composite of g-C3N4-SrTiO3:Rh photocatalyst for improved H2 evolution under visible light Irradiation. Int. J. Hydrogen Energy 37, 11602–11610 (2012).

Kwak, B. S. & Kang, M. Photocatalytic reduction of CO2 with H2O using perovskite CaxTiyO3. Appl. Surf. Sci. 337, 138–144 (2015).

Do, J. Y., Im, Y., Kwak, B. S., Park, S. –M. & Kang, M. Preparation of basalt fiber@perovskite PbTiO3 core–shell composites and theireffectsonCH4 production fromCO2 photoreduction. Ceram. Int. 42, 5942–5951 (2016).

Sun, X. & Xu, X. Efficient photocatalytic hydrogen production over La/Rh co-doped Ruddlesden-Popper compound Sr2TiO4. Appl. Catal. B 210, 149–159 (2017).

Zak, A. K., Majid, W. H. A., Abrishami, M. E., Yousefi, R. & Parvizi, R. Synthesis, magnetic properties and X-ray analysis of Zn0.97X0.03O nanoparticles (X = Mn, Ni, and Co) using Scherrer and size-strain plot methods. Solide State Sci. 14, 488–494 (2012).

Yu, Q. et al. Different toxicity of anatase and rutile TiO2 nanoparticles on macrophages: Involvement of difference in affinity to proteins and phospholipids. J. Hazard. Mater. 335, 125–134 (2017).

Khan, I., Ahmad, I., Amin, B., Murtaza, G. & Ali, Z. Bandgap engineering of Cd1−xSrxO. Physica B 406, 2509–2514 (2011).

Tumuluri, A., Naidu, K. L. & Raju, K. C. J. Band gap determination using Tauc’s plot for LiNbO3 thin films. Int J Chemtech Res 6, 3353–3356 (2014).

Huang, Y. et al. Preparation of 2D hydroxyl-rich carbon nitride nanosheets for photocatalytic reduction of CO2. RSC adv. 5, 33254–33261 (2015).

Park, H.-A., Choi, J. H., Choi, K. M., Lee, D. K. & Kang, J. K. Highly porous gallium oxide with a high CO2 affinity for the photocatalytic conversion of carbon dioxide into methane. J. Mater. Chem. 22, 5304–5307 (2012).

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of the Science ICT & Future Planning (NRF-2015R1A1A3A04001268).

Author information

Authors and Affiliations

Contributions

B.S.K. and M.K. designed the study, performed experiments, analyzed data and wrote the manuscript. J.Y.D. carried out catalytic stability test, N.-K. Park performed XRD analysis of the catalyst after reaction. All authors discussed the results and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kwak, B.S., Do, J.Y., Park, NK. et al. Surface modification of layered perovskite Sr2TiO4 for improved CO2 photoreduction with H2O to CH4 . Sci Rep 7, 16370 (2017). https://doi.org/10.1038/s41598-017-16605-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-16605-w

This article is cited by

-

Recent advances in 2D semiconductor nanomaterials for photocatalytic CO2 reduction

Nano Research (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.