Abstract

Selenium and selenium nanoparticles (SeNPs) are extensively used in biomedicine, electronics and some other industrial applications. The bioproduction of SeNPs is gaining interest as a green method to manufacture these biotechnologically relevant products. Several microorganisms have been used for the production of SeNPs either under aerobic or anaerobic conditions. Vibrio natriegens is a non-pathogenic fast-growing bacterium, easily cultured in different carbon sources and that has recently been engineered for easy genetic manipulation in the laboratory. Here we report that V. natriegens was able to perfectly grow aerobically in the presence of selenite concentrations up to 15 mM with a significant survival still observed at concentrations as high as 100 mM selenite. Electron microscopy and X-ray spectroscopy analyses demonstrate that V. natriegens cells growing aerobically in selenite-containing LB medium at 30 °C produced spherical electron-dense SeNPs whose size ranged from 100–400 nm. Selenite reduction just started at the beginning of the exponential growth phase and the release of SeNPs was observed after cell lysis. Remarkably, V. natriegens produced SeNPs faster than other described microorganisms that were proposed as model bioreactors for SeNPs production. Thus, the fast-growing V. natriegens bacterium becomes a suitable biocatalyst for bioremediation of selenite and for speeding-up the eco-friendly synthesis of SeNPs.

Similar content being viewed by others

Introduction

Selenium is a metalloid widely used in several industrial applications. In biomedicine selenium is used as supplement in the diet with healing benefits1,2. Due to its semiconductor and photoelectrical properties selenium is also used in electronics, photocopiers, solar cells, photography or rectifiers3,4. Selenium nanoparticles (SeNPs) with defined size and shape have also important biotechnological applications in electronics, cosmetics, coating and packaging5,6. In biomedicine, SeNPs have shown demonstrated antioxidant properties7,8, antitumoral and therapeutic activities against breast and lung cancer cells6,9,10,11, and antimicrobial activity against bacteria and fungi12. SeNPs can be synthetized by physical or chemical methods such as laser ablation, UV radiation, hydrothermal techniques, precipitation catalytic reduction, acid decomposition13,14,15,16,17. However, some of the conditions used, e.g., acidic pH or poisonous chemicals, render NPs unsafe for medical applications16. In general, the production of NPs using alive organism such as bacteria, fungi or plants is less expensive and safer since it uses eco-friendly non-toxic materials6,18,19,20,21,22. Biogenic SeNPs synthetized employing microorganisms have many biomedical applications6. In biomedicine bioproduced SeNPs has been demonstrated their antimicrobial activity against pathogenic microorganism12,23 being able to disrupt microbial biofilm24. SeNPs also show antioxidant activity since are able to scavenge reactive oxygen species7,25. The activity of the SeNPs is size dependent, e.g., the smallest SeNPs have the highest free radical scavenging potential7, being biosynthesis controlled conditions the easiest way to produce SeNPs of the desired size. Moreover, whereas the SeNPs produced by physical-chemical methods require the addition of stabilizing agents during their synthesis26, bioproduced SeNPs are naturally coated by organic molecules that prevent their aggregation enhancing their stability and biological, e.g. anticancer, efficiency27,28.

Selenium is widely distributed in nature and is present in different species depending on the environmental prevailing redox conditions29. The predominant oxyanions of selenium, i.e., selenite [Se(IV), SeO3 2−] and selenate [Se(VI), SeO4 2−], might cause severe toxicity in the environments and promote harmful effects on the cell viability30. Bacteria are able to greatly contribute to the interchange of the selenium forms being important elements in the selenium cycle in nature31. The selenium oxyanions can be reduced to elemental selenium [Se(0)], a less toxic and insoluble form. In addition, some bacteria are able to methylate selenium generating organic methylated forms, such as dimethyl selenide or dimethyl diselenide [Se2−]32. On the other hand, selenium is also an essential trace element extremely important in the physiology of the cell as part of selenocysteine, coenzyme Q, glutathione peroxidase or thioredoxin reductase33,34. Bacteria have developed several mechanisms of resistance to avoid the toxicity of selenium oxyanions, but the molecular basis of some of these mechanisms has not been completely elucidated yet. It has been proposed that the reduction of selenate to selenite involves the participation of reductases, e.g., the nitrate or nitrite reductases, in denitrifying bacteria such as Ralstonia eutropha or Paracoccus spp.35, but some bacteria, such as Thauera selenatis or Desulfurispirillum indicum, are able to use selenate as terminal electron acceptor by specific periplasmic selenate reductases29,36. Selenite is transformed to Se(0) by several specific or unspecific reductases, e.g., thiol-containing or gluthatione reductases, nitrite reductases, and a vast variation of small molecules and enzymatic activities, in different bacterial species37,38,39,40,41. Occasionally, the bacterial reduction of selenium oxyanions is associated with the production of SeNPs with defined size and shape31.

Since, as mentioned above, SeNPs have remarkable industrial and biomedical applications42, understanding the formation of SeNPs and developing more efficient biocatalysts and bioprocesses for the synthesis of SeNPs is of great biotechnological interest. Among the ongoing trends towards bioprocess improvement, reducing the process cycle time is one of the main target issues43,44. In this work we analyze the aerobic bioproduction of SeNPs by the bacterium Vibrio natriegens. V. natriegens [formerly known as Pseudomonas natriegens 45 and Beneckea natriegens 46] is a non-pathogenic fast-growing bacterium (doubling time of less than 10 minutes)45, easily cultured in the laboratory, able to utilize a great variety of organic substrates as source of carbon and energy46, and that has recently been genetically engineered and proposed for speeding up biotechnological processes47. Here we show that V. natriegens is able to reduce selenite to Se(0) producing SeNPs faster than other microorganisms proposed to be suitable bioreactors for SeNPs production. The use of V. natriegens as bacterial chassis may offer a significant reduction of time in an eco-friendly bioprocess to produce SeNPs. As far as we know this is the first example of the utilization of V. natriegens as model biocatalyst for speeding up a biotechnological process.

Results and Discussion

V. natriegens tolerates selenite

As indicated above, V. natriegens has been recently proposed to be an excellent chassis for biotechnological applications due to its fast growth and, hence, rapid biosynthesis of desired compounds47. As a proof of concept, we analyzed whether V. natriegens was able to resist aerobically selenium oxyanions, such as selenate (Na2SeO4) and selenite (Na2SeO3), and to reduce them to elemental selenium Se(0), as an example of biotechnological relevant process. To this end, we grew V. natriegens cells in rich medium (LB) supplemented with 1 mM selenate or 1 mM selenite, respectively. After 12 hours of aerobic growth at 30 °C, the culture medium containing selenite acquired a red color (Fig. 1) that suggested the reduction of selenite to elemental selenium. No color change was observed if the selenite-containing medium was not inoculated with V. natriegens cells, suggesting the active participation of this bacterium in selenite reduction. Interestingly, V. natriegens was able to perfectly grow aerobically in the presence of selenite concentrations up to 15 mM, and a significant survival was still observed at concentrations as high as 100 mM selenite (Fig. 2). These data reveal that V. natriegens possesses a level of resistance to selenite much higher than that described for other bacteria (Table 1), even those widely used in environmental applications, e.g. P. putida KT244048, and close to that reported for highly tolerant strains such Pseudomonas moraviensis 49 or Comamonas testosteroni S4450.

Analysis of the resistance of V. natriegens to selenite. Evaluation of the viability of V. natriegens cultures, measured as the logarithm of colony forming units (CFU) ml−1, grown in the presence of different selenite concentrations. Cell counting was as detailed in Methods. Error bars represent the standard deviation of at least three independent experiments.

V. natriegens was also able to grow aerobically in the presence of selenate in the medium, however no red color was observed after 24 h of growth suggesting that selenate was not reduced to selenite and then to elemental selenium. The level of resistance to selenate was lower than that observed for selenite since concentrations of 20 mM selenate decreased the viability of the culture in more than four orders of magnitude and V. natriegens was not able to grow in a medium containing 50 mM selenate (data not shown).

Taken together all these results reveal for the first time that V. natriegens possesses an outstanding ability to tolerate, and likely reduce, selenite under aerobic conditions. To confirm and exploit this new and biotechnologically relevant property of V. natriegens further studies were accomplished.

Kinetics of selenite reduction

To analyze the disappearance of selenite ions when V. natriegens grows in LB medium supplemented with 1 mM selenite, we used inductively coupled plasma optical emission spectrometry (ICP-OES). Remarkably, selenite disappeared for the cell culture just from the beginning of the exponential growth phase, and about 70% selenite was consumed after 12 h of growth when the number of cells increased from 5.106 to 5.108 CFU/ml (Fig. 3A). This interesting feature contrasts with previous reports showing that in bacterial cultures that have a significant capacity to reduce selenite to Se(0) (Table 1), e.g. P. putida KT2440 cultures, selenite reduction only starts at the middle-exponential growth phase and, thus, there is a significant delay of about 12 h until selenite depletion begins48. To confirm that selenite was reduced by V. natriegens, elemental selenium produced along the growth curve was measured. At 12 h of growth, V. natriegens produced 12 μmols of Se(0) with a rate of 1 μmol h−1 (Fig. 3B), thus revealing that selenite becomes reduced by the bacterial cells.

Time course of growth and selenite reduction by V. natriegens. (A) V. natriegens was grown in LB medium containing 1 mM selenite. Kinetics of growth, measured as CFU ml−1 (triangles), and selenite depletion (circles), were determined by using ICP-OES as indicated in Methods. Error bars represent standard deviation of at least three independent experiments. (B) Time course of Se(0) produced by V. natriegens (red line) cells growing in LB medium supplemented with 1 mM selenite. The amount of Se(0) was determined as indicated in Methods. Error bars represent standard deviation of at least three independent experiments. (C) Growth and selenite reduction (monitored by red color formation) in LB microtitre plates using selenite concentrations from 0 up to 10 mM after 6, 12 and 24 hours. LB: medium without cell inoculation.

Taken advantage that V. natriegens possesses a high level of resistance to selenite (see above), we tested the reduction of selenite concentrations higher than 1 mM by monitoring the appearance of the red color in the culture medium. In all concentrations tested, V. natriegens produced the red color as fast as 12 h after inoculation (Fig. 3C), suggesting a good efficieny of selenite reduction even at high (10 mM) selenite concentrations. This result contrasts with that reported in P. putida KT2440, which required long incubations (48 h) to produce visible red precipitates in the presence of 10 mM selenite48.

Taken together all these data show that V. natriegens is a high selenite tolerant (Table 1) and represents the fastest biocatalyst for selenite reduction reported so far.

Characterization of SeNPs

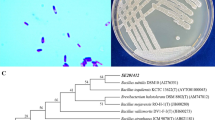

Since a good number of bacteria link the reduction of selenite to elemental selenium with the production of SeNPs, we investigated whether V. natriegens has also the ability to convert selenite to SeNPs. To this end, we collected cells of V. natriegens after 24 h of growth in the presence of 1 mM selenite, and observed them using transmission electron microscopy (TEM). Electron-dense nanoparticles were obseved (Fig. 4A and B). The elemental analysis using energy-dispersive X ray spectroscopy (EDX) showed that the electron-dense particles presented the specific selenium peak (Fig. 4C). The diffuse rings in the SAED (selected area electron diffraction) pattern suggested that selenium is present in its amorphous form (Fig. 4C, inset). SeNPs were clearly observed both inside the cells (Fig. 4A) and outside of cells associated to cellular debris (Fig. 4B), suggesting that this extracellular location is most probably consequence of cell lysis. In this sense, most of the bacteria described so far that produce SeNPs release the nanoparticles after cell lysis51.

Analysis of the SeNPs production by V. natriegens. (A and B) TEM analysis of V. natriegens cells grown in the presence of 1 mM selenite showing electron-dense nanoparticles (red arrows) located intracellularly (A) or extracellularly (B) (C) EDX analysis of one SeNP of panel B showing its selenium composition. In the inset are shown the diffuse rings in the SAED (selected area electron diffraction) pattern of one SeNP. White line on the inset represents 5 1/nm.

The produced SeNPs were purified as described in Methods52 and analyzed by TEM (Fig. 5A) and scanning electron microscopy (SEM) (Fig. 5B). Purified SeNPs appeared as spherical nanoparticles with an average size of 136 ± 31 nm (Fig. 5C). Different sizes of bioproduced SeNPs have been described53 ranging from the 11 nm in Shewanella sp. HN-4154 to the 400 nm found in Bacillus mycoides Sel TE0155 (Table 1). Since the size of the SeNPs is an important factor that determines their chemical properties and biological activities7, we checked whether the size of the SeNPs produced by V. natriegens could be tailored by adjusting the bacterial incubation time as well as the selenite concentration used. There is a general trend showing that the SeNPs size increases when increasing the incubation time and selenite concentration (Fig. 6). Remarkably, when using 10 mM selenite and incubation times of 24–48 h the SeNPs size reaches its maximum (about 400 nm). These results reveal that the V. natriegens-derived bioprocess can be tuned to produce SeNPs of different defined sizes and, therefore, it constitutes a versatile platform that may be suitable for different biotechnological applications.

Size distribution of purified SeNPs. Estimation of the diameter of the SeNPs produced by V. natriegens grown at the indicated times in LB medium supplemented with 1 mM (white column), 10 mM (pale grey column), 50 mM (dark grey column) or 100 mM (black column) selenite. Error bars represent the standard deviation of at least 40 independent measurements.

The mechanisms behind the formation of SeNPs in bacteria are not fully understood yet. It has been described that SeNPs accumulate within the cell (cytoplasm and/or periplasm) or in the culture medium36, and most bacteria accumulate SeNPs during the exponential phase and release them at the stationary phase36. In the well-studied Thauera selenatis bacterium, the SefA (selenium factor A) protein was shown to be involved in the export of the SeNPs from the cytoplasm and it helps in bio-mineralization and stabilization of the nanoparticles36. Besides SefA, no other protein has been so closely related with SeNPs synthesis and exportation, and most biological functions responsible of the mineralization of selenite to Se(0) that ends in a spherical chemically pure SeNP are still unknown. Nevertheless, a good number of proteins have been isolated from the SeNPs surface, and they have been suggested to be related with the mineralization process56,57. The knowledge of how nascent (or initially precipitated) elemental selenium coalesce to develop a true spherical SeNP is a challenge that is being approached in many laboratories58,59,60. Mathematical models and mechanisms for nucleation and growth of metal NPs, including silver and gold, have been proposed58,61, but these processes have not been investigated in the case of selenium60. Thus, V. natriegens might behave as a suitable model system to study the underlying biological mechanisms of SeNPs production in bacteria.

Conclusions

The use of whole bacteria as biocatalysts is an attractive, economical and green alternative to the large scale synthesis of NPs. Several important challenges must be overcome before this green-based approach might be able to successfully compete with chemical biosynthesis62. An important factor is the selection of the best biocatalysts whose intrinsic properties allow to synthesize metallic NPs in a fast and efficient way62,63. In this sense, P. putida has been recently postulated as a suitable bioreactor for fast SeNPs production48. Here we report the use of an alternative biocatalyst, the bacterium V. natriegens, a non-pathogenic bacterium, easily cultured in a vast variety of carbon sources and genetically manipulable46,47 that shows a remarkable resistance to selenite and is able to significantly speed-up the aerobic conversion of this oxyanion for the quickest bioproduction of SeNPs so far described (Table 1). In addition, tuning the growth conditions of V. natriegens enable the production of SeNPs of different defined sizes and, therefore, it constitutes a versatile selenite bioconversion platform that may be suitable for different biotechnological applications.

Methods

Bacterial strains, culture media and growth conditions

Vibrio natriegens ATCC14048 was grown on LB64 aerobically at 30 °C with orbital shaking at 200 rpm. Solid LB medium was prepared by the addition of Bacto Agar (1.5% w/v). When appropriate, sodium selenite (Sigma-Aldrich) was added at the indicated concentration.

Estimation of selenite tolerance

To establish the selenite tolerance of V. natriegens, bacterial cells were grown in LB at 30 °C with different concentration of selenite (0–200 nM). After 24 h of incubation, 1 ml of culture was used for serial dilution (form −1 to −10) and each dilution was plated on LB media. Colony forming units (CFU) were counted after 24 h of incubation at 30 °C.

Determination of selenite concentration

Selenite concentration in the culture samples was determined by coupled plasma optical emission spectrometry (ICP-OES) (Perkin Elmer Optima 2100 DV)65.

Determination of Se(0)

The calculation of the amount of Se(0) produced by the microbial reduction of selenite was performed following a protocol previously established66. Briefly, 20 ml of cell culture grown at 30 °C on LB supplemented with 1 mM selenite was collected by centrifugation at 13000 rpm during 2 min. The pellet was washed 3 times with NaCl 1 M, gently resuspended in a solution of 400 μl Na2S 1 M, and incubated for 1 h at room temperature. Later, the mix was centrifuged for 2 min at 13000 rpm and the absorbance at 500 nm of the supernatants was determined in the spectrophotometer. The concentration of Se(0) was estimated by interpolating in a calibration curve obtained as detailed in Biswas et al.66.

SeNPs purification

For the purification of the SeNPs, a previously published protocol was followed52. This protocol is based on a separation by centrifugation of the SeNPs produced by the bacteria in an mixture composed by chloroform, ethyl alcohol and water (3:1:4).

Characterization of SeNPs

For Transmission Electron Microscopy (TEM) analysis, the samples were prepared by placing drops of the V. natriegens cell cultures or the purified SeNPs onto carbon-coated copper grids and allowing the solvent to evaporate. TEM observations were performed on a JEOL model JEM-2100 instrument operated at an accelerating voltage of 200 kV. The chemical composition of the SeNPs observed was determined by energy-dispersive X-ray spectroscopy (EDX) as previously described67.

For field emission Scanning Electron Microscopy (SEM), the SeNPs samples were filtered through 0.2 μm pore-size filters and successively dehydrated with acetone/water mixtures of 30, 50 and 70% acetone. After critical point drying, samples were coated with graphite and gold and examined with a JEOL JSM-6330 F microscope.

The size of the SeNPs was determined by using the ImageJ software68.

References

Rayman, M. P. The importance of selenium in human health. Lancet 356, 233–241 (2000).

Rayman, M. P. Food-chain selenium and human health emphasis on intake. Br. J. Nutr. 100, 254–268 (2008).

Johnson, J. A., Saboungi, M. J., Thiyagarajan, P., Csencsits, P. & Meisel, D. Selenium nanoparticles: a small-angle neutron scattering study. J. Phys. Chem. B 103, 59–63 (1999).

Borghese, R., Borsetti, F., Foladori, P., Ziglio, G. & Zannoni, D. Effect of the metalloid oxyanion tellurite (TeO3 2−) on growth characteristics of the phototrophic bacterium Rhodobacter capsulatus. Appl. Environ. Microbiol. 70, 6595–65602 (2004).

Thakkar, K. N., Mhatre, S. S. & Parikh, R. Y. Biological synthesis of metallic nanoparticles. Nanomed. Nanotech. Boil. Med. 6, 257–262 (2010).

Wadhwani, S. A., Shedbalkar, U. U., Singh, P. & Chopade, B. A. Biogenic selenium nanoparticles current status and future prospects. Appl. Microbiol. Biotechnol. 100, 2555–2566 (2016).

Torres, S. K. et al. Biosynthesis of selenium nanoparticles by Pantoea agglomerans and their antioxidant activity. J. Nanoparticle Res. 14, 1236 (2012).

Tapiero, H., Townsend, D. & Tew, K. The antioxidant role of selenium and seleno-compounds. Biomed. Pharmacother. 57, 134–144 (2003).

Hatfield, D. L., Tsuji, P. A. & Gladyshev, V. N. Selenium and selenocystein roles in cancer, health and development. Trend. Biochem. Sci. 39, 112–120 (2014).

Ali, E. N., El-Sonbaty, S. M. & Salem, F. M. Evaluation of selenium nanoparticles as a potential chemoprotective agent against lung carcinoma. Int. J. Pharm. Biol. Sci. 2, 38–46 (2016).

Ramamurthy, C. et al. Green synthesis and characterization of selenium nanoparticles and it augmented cyto-toxicity with doxorubicin on cancer cells. Bioprocess Biosyst. Eng. 36, 1131–1139 (2013).

Hariharan, H., Al-Harbi, N., Karuppiah, P. & Rajaram, S. Microbial synthesis of selenium nanocomposite using Saccharomyces cerevisiae and its antimicrobial activity against pathogens causing nosocomial infection. Chalcogenide Lett. 9, 509–515 (2012).

Quintana, M., Haro-Poniatowski, E., Morales, J. & Batina, N. Synthesis of selenium nanoparticles by pulsed laser ablation. Appl. Surf. Sci. 195, 175–186 (2002).

Hong Lin, Z., Chu Lin, F. & Wang, C. Observation in the growth of selenium nanoparticles. J. Chin. Chem. Soc. 51, 239–242 (2004).

Zhang, Y., Wang, J. & Zhang, L. Creation of highly stable selenium nanoparticles capped with hyperbranched polysaccharide in water. Langmuir 26, 17617–17623 (2010).

Iranifam, M. et al. A novel selenium nanoparticles-enhanced chemiluminescence system for determination of dinitrobutylphenol. Talanta 107, 263–269 (2013).

Overschelde, O., Guisbiers., G. & Snyders, R. Green synthesis of selenium nanoparticles by excimer pulsed laser ablation in water. Appl. Mater. 1, 042114 (2013).

Ghosh, S. et al. Synthesis of silver nanoparticles using Dioscorea bulbifera tuber extract and evaluation of its synergistic potential in combination with antimicrobial agents. Int. J. Nanomedicine 7, 483–496 (2012).

Ghosh, S. et al. Gnidia glauca flower extract mediated synthesis of gold nanoparticles and evaluation of its chemocatalytic potential. J. Nanobiotechnol. 10, 17 (2012).

Shedbalkar, U., Singh, R., Wadhwani, S., Gaidhani, S. & Chopade, B. A. Microbial synthesis of gold nanoparticles: current status and future prospects. Adv. Colloid. Interf. Sci. 209, 40–48 (2014).

Salunke, G. R. et al. Rapid efficient synthesis and characterization of silver, gold, and bimetallic nanoparticles from the medicinal plant Plumbago zeylanica and their application in biofilm control. Int. J. Nanomedicine 9, 2635–2653 (2014).

Singh, R., Shedbalkar, U., Wadhwani, S. & Chopade, B. A. Bacteriogenic silver nanoparticles: synthesis, mechanism, and applications. Appl. Microbiol. Biotechnol. 11, 4579–4593 (2015).

Shahverdi, A. et al. Antifungal activity of biogenic selenium nanoparticles. World Appl. Sci. J. 10, 918–922 (2010).

Zonaro, E., Lampis, S., Turner, R. J., Qazi, S. & Vallini, G. Biogenic selenium and tellurium nanoparticles synthesized by environmental microbial isolates efficaciously inhibit bacterial planktonic cultures and biofilms. Front. Microbiol. 6, 584 (2015).

Forootanfara, H. et al. Biosynthesis and characterization of selenium nanoparticles produced by terrestrial actinomycete Streptomyces microflavus strain FSHJ31. Res. Rev. J. Microbiol. Biotechnol. 3, 47–53 (2014).

Nancharaiah, Y. V. & Lens, P. N. L. Selenium biomineralization for biotechnological applications. Trends Biotechnol. 6, 323–330 (2015).

Ahmad, M. S., Yasser, M. M., Sholkamy, E. N., Ali, A. M. & Mehanni, M. M. Anticancer activity of biostabilized selenium nanorods synthesized by Streptomyces bikiniensis strain Ess_amA-1. Int. J. Nanomedicine 10, 3389–3401 (2015).

Li, Y. et al. The reversal of cisplatin-induced nephrotoxicity by selenium nanoparticles functionalized with 11-mercapto-1-undecanol by inhibition of ROS-mediated apoptosis. Biomaterials 2, 9068–9076 (2011).

Nancharaiah, Y. V. & Lens, P. N. L. Ecology and biotechnology of selenium-respiring bacteria. Microbiol. Mol. Biol. Rev. 79, 61–80 (2015).

Oremland, R. S. et al. Simultaneous reduction of nitrate and selenate by cell suspensions of selenium respiring bacteria. Appl. Environ. Microbiol. 65, 4385–4392 (1999).

Stolz, J. F., Basu, P. & Oremland, R. S. Microbial transformation of elements: the case of arsenic and selenium. Int. Microbiol. 5, 201–207 (2002).

Prigent-Combaret, C. et al. The bacterial thiopurine methyltransferase tellurite resistance process is highly dependent upon aggregation properties and oxidative stress response. Environ. Microbiol. 14, 2645–2660 (2012).

Schwarz, K. & Foltz, C. M. Selenium as integral part of factor 3 against dietary necrotic liver degeneration. J. Am. Chem. Soc. 79, 3292–3293 (1957).

Navarro-Alarcon, M. & Cabrera-Vique, C. Selenium in food and the human body: a review. Sci. Total Environ. 400, 115–141 (2008).

Schröder, I., Rech, S., Krafft, T. & Macys, J. M. Purification and characterization of the selenate reductase from Thauera selenatis. J. Biol. Chem. 272, 23765–23768 (1997).

Butler, C. S., Debieux, C. M., Dridge, E. J., Splatt, P. & Wright, M. Biomineralization of selenium by the selenate respiring bacterium Thauera selenatis. Biochem. Soc. Trans. 40, 1239–1243 (2012).

Kessi, J. & Hanselmann, K. W. Similarities between the abiotic reduction of selenite with glutathione and the dissimilatory reaction mediated by Rhodospirillum rubrum and Escherichia coli. J. Biol. Chem. 279, 50662–50669 (2004).

Heylen, K. et al. The incidence of nirS and nirK and their genetic heterogeneity in cultivated denitrifiers. Environ. Microbiol. 8, 2012–2021 (2006).

Basaglia, M. et al. Selenite-reducing capacity of the copper containing nitrite reductase of Rhizobium sullae. FEMS Microbiol. Lett. 269, 124–130 (2007).

Debieux, C. M. et al. A bacterial process for selenium nanosphere assembly. Proc. Natl. Acad. Sci. USA 108, 13480–13485 (2011).

Chen, J. & Strous, M. Denitrification and aerobic respiration hybrid electron transport chains and co-evolution. Biochem. Biophys. Acta 1827, 136–144 (2013).

Cai, S. J. et al. Effect on nano-selenium on performance, meat quality, immune function, oxidation resistance, and tissue selenium content in broilers. Poult. Sci. 91, 2532–2539 (2012).

Wohlgemuth, R. Biocatalyst-key to sustainable industrial chemistry. Curr. Op. Biotech. 21, 713–724 (2010).

Jiménez-González, C. & Woodley, J. M. Bioprocesses: modeling needs for process evaluation and sustainability assessment. Computers Chem. Eng. 34, 1009–1017 (2010).

Payne, W. J., Eagon, R. G. & Williams, A. K. Some observations on the physiology of Pseudomonas natriegens nov. spec. Antonie Van Leeuwenhoek 27, 121–128 (1961).

Baumann, P., Baumann, L. & Mandel, M. Taxonomy of marine bacteria: the genus. Beneckea. J. Bacteriol. 107, 268–294 (1971).

Weinstock, M. T., Hesek, E. D., Wilson, C. M. & Gibson, D. G. Vibrio natriegens as a fast-growing host for molecular biology. Nat. Methods 13, 849–851 (2016).

Avendaño, R. et al. Production of selenium nanoparticles in Pseudomonas putida KT2440. Sci. Rep. 6, 37155 (2016).

Staicu, L. C. et al. Pseudomonas moraviensis subsp. stanleyae, a bacterial endophyte of hyperaccumulator Stanleya pinnata, is capable of efficient selenite reduction to elemental selenium under aerobic conditions. J. Appl. Biotech. 119, 400–410 (2015).

Zheng, S. et al. Selenite reduction by the obligate aerobic bacteria Comamonas testosteroni S44 isolated from a metal-contaminated soil. BMC Microbiol. 14, 204 (2014).

Gonzalez-Gil, G., Lens, P. N. L. & Saikaly, P. Selenite reduction by anaerobic microbial aggregates: microbial community structure, and proteins associated to the produced selenium spheres. Front. Microbiol. 7, 571 (2016).

Baharami, K., Nazari, P., Sepehrizadeh, Z., Zarea, B. & Shahverdi, A. R. Microbial synthesis of antimony sulfide nanoparticles and their characterization. Ann. Microbiol. 62, 1419–1425 (2012).

Fernández-Llamosas, H., Castro, L., Blázquez, M. L., Díaz, E. & Carmona, M. Biosynthesis of selenium nanoparticles by Azoarcus sp. CIB. Microb. Cell Fact. 15, 109 (2016).

Tam, K. et al. Growth mechanism of amorphous selenium nanoparticles synthesized by Shewanella HN-41. Biosci. Biotecnol. Biochem. 74, 696–700 (2010).

Lampis, S. et al. Delayed formation of zero-valent selenium nanoparticles by Bacillus mycoides SelTE01 as a consequence of selenite reduction under aerobic conditions. Microb. Cell Fact. 13, 35 (2014).

Li, S. et al. Rapid, room-temperature synthesis of amorphous selenium/protein composites using Capsicum annuum L extract. Nanotechnology 18, 405101 (2007).

Dobias, J. & Suvorova, E. I. Role of proteins in controlling selenium nanoparticle size. Nanotechnology 22, 195605 (2011).

Privman, V. Mechanisms of diffusional nucleation of nanocrystals and their self-assembly into uniform colloids. Ann. N. Y. Acad. Sci. 1161, 508–525 (2009).

Thill, A. et al. Spheres growing on a sphere: a model to predict the morphology yields of colloidal molecules obtained through a heterogeneous nucleation route. Langmuir 28, 11575–11583 (2012).

González-Gil, G., Lens, P. N. L. & Saikaly, P. E. Selenite reduction by anaerobic microbial aggregates: microbial community structure, and proteins associated to the produced selenium spheres. Front. Microbiol. 7, 571 (2016).

Thanh, N. T. K., Maclean, N. & Mahiddine, S. Mechanisms of nucleation and growth of nanoparticles in solution. Chem. Rev. 114, 7610–7630 (2014).

Iravani, S. Green synthesis of metal nanoparticles using plants. Green Chem. 13, 2638–2650 (2011).

Korbekandi, H., Iravani, S. & Abbasi, S. Production of nanoparticles using organisms. Crit. Rev. Biotech. 4, 279–306 (2009).

Sambrook, J. & Russell, D. W. Molecular cloning: a laboratory manual (eds Sambrook, J. & Russell, D. W.) A2.2 (Cold Spring Harbor, 2001).

Nawaz, F., Ahmad, R., Ashraf, M. Y., Waraich, E. A. & Khan, S. Z. Effect of selenium foliar spray on physiological and biochemical processes and chemical constituents of wheat under drought stress. Ecotoxicol. Environ. Saf. 113, 191–200 (2015).

Biswas, K. C. et al. A novel method for the measurement of elemental selenium produced by bacterial reduction of selenite. J. Microbiol. Meth. 86, 140–144 (2011).

Li, D. B. et al. Selenite reduction by Shewanella oneidensis MR-1 is mediated by fumarate reductase in periplasm. Sci. Rep. 4, 3735 (2014).

Collins, T. J. ImageJ for microscopy. Biotechniques 43(1-Suppl), 25–30 (2007).

Lampis, S. et al. Selenite biotransformation and detoxification by Stenotrophomonas maltophilia SeITE02: Novel clues on the route to bacterial biogenesis of selenium nanoparticles. J. Hazard Mater. S0304–3894, 30162–30165 (2016).

Li, B. et al. Reduction of selenite to red elemental selenium by Rhodopseudomonas palustris strain N. PLoS ONE 9, e95955 (2014).

Hnain, A., Brooks, J. & Lefebvre, D. D. The synthesis of elemental selenium particles by Synechococcus leopoliensis. Appl. Microbiol. Biotechnol. 97, 10511–10519 (2013).

Kessi, J., Ramuz, M., Wehrli, E., Spycher, M. & Bachofen, R. Reduction of selenite and detoxification of elemental selenium by the phototrophic bacterium Rhodospirillum rubrum. Appl. Environ. Microbiol. 65, 4734–4740 (1999).

Acknowledgements

The technical work of A. Valencia is greatly appreciated. This work was supported by Ministry of Economy, Industry and Competitiveness of Spain Grants BIO2016-79736-R, PCIN-2014-113 and MAT2014-50222R, Fundación Ramón-Areces XVII CN. H. Fernández-Llamosas was the recipient of a Research Personnel Formation (FPI) fellowship from the Ministry of Economy and Competitiveness of Spain.

Author information

Authors and Affiliations

Contributions

H.F.L.L., L.C. and M.C. performed most experiments. H.F.L.L., E.D. and M.C. designed and analyzed data. H.F.L.L., L.C., M.L.B., E.D. and M.C. initiated and coordinated the study and contributed to the experimental design and data interpretation. M.C. and E.D. mainly wrote the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fernández-Llamosas, H., Castro, L., Blázquez, M.L. et al. Speeding up bioproduction of selenium nanoparticles by using Vibrio natriegens as microbial factory. Sci Rep 7, 16046 (2017). https://doi.org/10.1038/s41598-017-16252-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-16252-1

This article is cited by

-

Vibrio species as next-generation chassis for accelerated synthetic biology

Biotechnology and Bioprocess Engineering (2024)

-

Characterization of green synthesized selenium nanoparticles (SeNPs) in two different indigenous halophilic bacteria

BMC Chemistry (2023)

-

Preparation, characteristics and cytotoxicity of green synthesized selenium nanoparticles using Paenibacillus motobuensis LY5201 isolated from the local specialty food of longevity area

Scientific Reports (2023)

-

High-cell-density cultivation of Vibrio natriegens in a low-chloride chemically defined medium

Applied Microbiology and Biotechnology (2023)

-

Selenite bioreduction with concomitant green synthesis of selenium nanoparticles by a selenite resistant EPS and siderophore producing terrestrial bacterium

BioMetals (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.