Abstract

The operation of resistive and phase-change memory (RRAM and PCM) is controlled by highly localized self-heating effects, yet detailed studies of their temperature are rare due to challenges of nanoscale thermometry. Here we show that the combination of Raman thermometry and scanning thermal microscopy (SThM) can enable such measurements with high spatial resolution. We report temperature-dependent Raman spectra of HfO2, TiO2 and Ge2Sb2Te5 (GST) films, and demonstrate direct measurements of temperature profiles in lateral PCM devices. Our measurements reveal that electrical and thermal interfaces dominate the operation of such devices, uncovering a thermal boundary resistance of 28 ± 8 m2K/GW at GST-SiO2 interfaces and an effective thermopower 350 ± 50 µV/K at GST-Pt interfaces. We also discuss possible pathways to apply Raman thermometry and SThM techniques to nanoscale and vertical resistive memory devices.

Similar content being viewed by others

Introduction

Information storage and memory devices based on the change of resistance (i.e. resistive memories or memristors) hold several key advantages over contemporary charge-based memory devices. Such memory devices are two-terminal resistors that retain their resistance state as a function of the applied voltage or current. Several technologies can be included under the general term of “resistive memory”1,2, such as phase change memory (PCM)3,4, resistive random access memory (RRAM)5,6, and conductive bridge RAM (CB-RAM)7. Memristive devices are important not only for memory and storage applications; they are also being extensively studied as computing elements for neuromorphic architectures2,8.

The resistive switching in RRAM devices is based on the formation and rupture of conductive filaments in thin metal oxides, like HfO2. In PCM, a nanoscale volume of chalcogenide material (like Ge2Sb2Te5) can be SET to a crystalline (low resistive) state and RESET to an amorphous (high resistive) state using electrical pulses. Self-heating and the local temperature play a major role in the principle of operation of both PCM4 and RRAM9,10. Many of the advantages (e.g. energy efficiency improved with scaling)11,12 and shortcomings (e.g. reliability)13 of these technologies stem from their inherent dependence on self-heating. Therefore, understanding the energy and heat dissipation mechanism is vital for the evaluation, design and optimization of all such future technologies. However, experimental techniques to measure nanoscale device temperature are challenging and scarce10,14,15. In particular, spatially resolved measurements revealing energy dissipation mechanism are required for better understanding of the device physics16,17.

Here we combine Raman thermometry and scanning thermal microscopy (SThM) to measure the spatially resolved temperature rise in resistive memory devices. This powerful combination of temperature mapping techniques has been previously used on GaN nanowires18, but it is applied here to resistive memory devices for the first time. We present temperature-dependent Raman spectroscopy of thin films for two of the most commonly used RRAM oxides: HfO2 and TiO2, and for the PCM material Ge2Sb2Te5 (GST). We then show an experimental measurement of the temperature profile in a Joule-heated PCM device, providing important insights into its operation. Finally, we discuss how Raman and SThM can be used to measure the local temperature rise in vertical and other nanoscale RRAM and PCM device geometries.

Raman Spectroscopy of RRAM Oxide Films

Raman spectroscopy measures the shift in inelastically scattered light, directly corresponding to phonon energy (ℏω) and temperature (T). Stokes (anti-Stokes) lines are due to photons scattered at lower (higher) energy than the incident laser, due to phonon emission and absorption, respectively. (More Raman spectroscopy details are given in Supplementary Information Section 1.) Fundamentally, most RRAM oxides have poor Raman signal due to weak absorption (ultra-thin films with large band gap) and low degree of crystallinity. However polycrystalline oxide film regions or the programmed RRAM filament could be expected to have different Raman signals, and are yet to be studied. For example, Raman spectroscopy has been previously used to study stoichiometry, defects, and particularly oxygen vacancies in crystalline19 and nano-crystalline20 oxides. The Raman spectra of oxide powders, single crystals, and thick films have previously been reported21,22,23, but here we present the first temperature-dependent Raman spectra of nanoscale thin films which are relevant for RRAM devices.

Figure 1 shows the temperature-dependent Raman spectra of two of the most common RRAM oxides: (a) HfO2 and (b) TiO2. The 50 nm thick films were sputtered onto Pt/sapphire and SiO2/Si substrates, respectively, and did not show any measurable Raman features in their (as-deposited) amorphous state. After annealing (see Methods) the films crystallized, exhibiting Raman signals of the monoclinic (HfO2) and anatase (TiO2) phases. The insets show the temperature dependence of a selected mode. The Bg1 monoclinic HfO2 mode24 (~134 cm−1 at 25 °C) shows typical frequency downshift with temperature at rate of ~ −0.011 cm−1/C. The Eg anatase TiO2 mode (~141 cm−1 at 25 °C) however shows anomalous frequency increase with temperature. This trend was previously reported and explained via strong contribution of the quartic anaharmonicity23. For the practical purpose of device thermometry it is sufficient to have a well-defined temperature response of the Raman mode, either positive or negative.

Temperature dependent Raman spectra of RRAM oxide nanoscale thin films. Raman spectra of crystallized 50 nm thin films of (a) HfO2 and (b) TiO2, measured at temperatures ranging from 25 °C to 600 °C. Spectra are vertically offset for clarity. Insets show peak position shift with temperature of a selected mode, error bars represent 95% confidence bounds of Lorentzian peak fitting. The HfO2 was sputtered onto Pt (50 nm) on sapphire substrate and then annealed at 600 °C for 2 hours. All measured peaks above 110 cm−1 are assigned to monoclinic phase of HfO2 (as confirmed by XRD)24. The TiO2 was sputtered onto SiO2 (90 nm) on Si substrate and annealed at 400 °C for 1 hour. The peak at ~141 cm−1 (25 °C) is assigned to anatase TiO2 and the other peaks are from the Si substrate.

We note that temperature-dependent Raman data are presented in this section for nanoscale oxide films for the first time. However, obtaining sufficient signal in nanoscale RRAM devices is challenging, but could be addressed using signal enhancement techniques such as surface- or tip- enhanced Raman spectroscopy (SERS25 or TERS26,27). In addition, an optically transparent electrode such as graphene28, indium tin oxide (ITO), or a very thin (e.g. sub-10 nm) metal can be used to measure vertical device structures. In the next section we focus on Raman thermometry of PCM, which exhibits a sufficiently strong signal to demonstrate (spatial) device thermometry.

RAMAN Spectroscopy of PCM

Raman Spectroscopy of GST Films

Raman spectroscopy has previously been used to characterize nanoscale PCM films29,30,31. Unlike oxides, GST absorbs photons in the range of visible excitation lasers (~500–650 nm) due to its smaller band gap (~0.6 eV). In addition, much of the GST volume in a typical PCM cell is crystalline, thus Raman thermometry can be readily applied to PCM devices. Moreover, Raman spectroscopy can be used to identify phase and presence of defects in GST as outlined below.

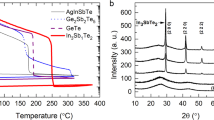

Figure 2 shows the temperature dependent Raman signal of 20 nm thin sputtered GST films (see Methods). Some previous studies have performed such measurements on 50 to 150 nm thick GST films32,33,34 but we are unaware of temperature-dependent Raman data for GST films of the thickness studied here (~20 nm), which are more relevant for modern memory devices. Figure 2(a) shows the first heating cycle on a hot stage from 25 °C to 400 °C. The as-deposited film is amorphous (a-GST) and starts to crystallize (c-GST) at ~140 °C, first to the face centered cubic (fcc) phase and then at ~240 °C to the hexagonal closest pack (hcp) phase. For assignment of the various Raman peaks to GST modes please see ref.29. Upon cooling to room temperature and heating back up to 450 °C the film remains in its stable hcp phase, as shown in Fig. 2(b). Figure 2(c) shows the measured (symbols) and fitted peak of a selected mode at stage temperatures of 25 °C (blue, ~173 cm−1) and 400 °C (red, ~168 cm−1) and Fig. 2(d) shows the peak position downshifting vs. stage temperature from 25 °C to 450 °C.

Temperature dependent Raman spectra of 20 nm thin GST film. (See Methods). (a) Raman spectra during the first heating cycle on a hot stage from 25 °C to 400 °C. As-deposited, the GST is amorphous, but after heating the film starts to crystallize first to the fcc phase and then to the hcp phase. (b) Temperature dependent Raman spectra of the stable hcp phase GST at temperatures ranging from 25 °C to 450 °C. Similar spectra were obtained for cooling (not shown). (c) Example of measured (symbols) and fitted (lines) peak for a selected mode at 25 °C and 400 °C in the hcp phase. (d) Peak position shift vs. temperature of the selected mode shown in (c). Error bars represent 95% confidence bounds of Lorentzian peak fitting.

Raman Spectroscopy of GST Devices

Thanks to its material and phase selectivity, Raman spectroscopy can be used to map GST films and PCM devices for phase analysis. However, here we uncover that patterned and processed GST devices exhibit Raman spectra that are different from blanket deposited GST films. Figure 3(a) schematically shows the Raman measurement of a lateral GST device with Pt contacts, and device fabrication details are provided in the Methods section.

Temperature dependent Raman spectra of lateral GST device. (a) Device and measurement setup. The GST channel (W = 10 µm, L = 5 µm) is patterned on top of Pt electrodes and capped with PMMA (see Methods). (b) Stokes and anti-Stokes Raman spectra of patterned GST device on a hot stage at temperatures from 25 °C to 125 °C. These are dominated by Te modes35 with much higher intensity than GST modes. (c) Peak shift with temperature of a selected mode (at ~120 cm−1). (d) Anti-Stokes to Stokes intensity ratio vs. temperature of the selected mode shown in (c).

Figure 3(b) shows the Stokes and anti-Stokes Raman signal of the GST device on a hot stage from 25 °C to 125 °C. The stage temperature was kept below the highest temperature during processing (PMMA bake at 180 °C) in order to avoid changes to the GST channel and/or contacts. It is evident that the Raman signal of the GST device is dominated by two intense peaks at ~120 and ~140 cm−1, which are not present in the GST film spectra (Fig. 2). These peaks were present in the GST device immediately after lift-off, before spin-coating the PMMA capping. The intensity of these peaks is significantly larger than the GST film peaks shown in Fig. 2.

These intense peaks (~120 and ~140 cm−1) are known from previous studies as Te peaks35. We have also measured similar peaks in uncapped GST films after exposure to high laser power and formation of dark spots in the film (Supplementary Information Section 2). These peaks were also measured in other sets of lateral GST devices which were capped with different oxides36. Such oxide-capped devices switched for many cycles (~105) with good on/off ratio (~102) and low switching energy (<20 pJ). These Te peaks are likely associated with surface oxidation of the GST during processing, resulting in formation of GeOx and SbOx, and precipitation of Te. The former is also evident from X-Ray photoelectron spectroscopy (XPS) of the dark spots at the GST surface (Supplementary Information Section 2), while the latter is evidenced in our measured Raman spectra.

The position of the lower (~120 cm−1) Te peak has strong temperature dependence, as shown in Fig. 3(c) which allows us to use it efficiently as a thermometer. Raman spectroscopy can then be used to extract temperature in two different ways; one via the calibration of peak shift vs. temperature on the hot stage37,38 and the other directly from the anti-Stokes to Stokes (AS/S) intensity ratio39:

where T is the phonon temperature (in K), ω ph and ω L are the phonon shift and laser frequency, respectively, I AS/I S the anti-Stokes to Stokes intensity ratio, and k B is the Boltzmann constant. The advantage of the AS/S method is that in principle it does not require a calibration procedure and that the temperature can be obtained with a single measurement. This is attractive for spatial temperature mapping of devices since the temperature map can be obtained in a single map scan, whereas for the peak shift method a calibration measurement is needed and at least two map scans must be obtained38 (e.g. one with and the other without bias). Nonetheless, the uncertainty in the measured temperature of our GST devices using the AS/S method was large compared with the peak shift method, as described below.

The symbols in Fig. 3(d) show the measured AS/S intensity ratio of the spectra from Fig. 3(b) after baseline subtraction and Lorentzian peak fitting. The error bars are obtained from the standard deviation of ~30 measurements (carried out at ambient T = 25 °C). The blue line represents eq. (1). The main drawback of the AS/S method is the uncertainty in the temperature evaluation, because the extraction of intensity from peak fitting is less accurate than the extraction of peak position. (Similar errors are encountered when using the area under the peak instead of the peak intensity.) Moreover, the absolute temperature T (≥300 K) is obtained from the intensity ratio with relative error ~15% in our case. Since we are interested in measuring the change in temperature (ΔT ~ 100 K above room temperature) the relative error in ΔT is three times larger, or nearly ~ 50%. At the same time, the relative error in ΔT for the peak shift method is less than ~15% [e.g. see Fig. 3(c)]. Therefore, in the remainder of this study we use the peak shift method to map the temperature of the device, following the procedure outlined in ref.38 for aligning the two maps. We note that temperature sensitivity of the AS/S method should improve for phonon modes at higher frequencies (Supplementary Information Section 3).

PCM Device Thermometry

Measurement Technique

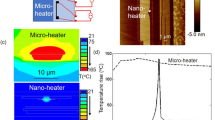

Figure 4(a) displays the schematic of the Raman thermometry measurement applied to a lateral GST device. We spatially mapped the device with 0.25 µm step size, measuring the Raman spectra at each point with and without electrical bias. The temperature is extracted by converting the peak shift (with electrical bias and self-heating) to temperature via the calibration shown in Fig. 3(c). Figure 4(b) shows the measured (symbols) and fitted (lines) Raman spectra at the center of the GST channel with (red) and without (blue) electrical bias. The Te peaks at ~120 and 140 cm−1 are clearly visible, as well as their shift with self-heating. Raman features at ~105 and 170 cm−1 may correspond to GST hcp phase, but their signal is significantly smaller.

Thermometry of a lateral PCM device. (a) Measurement setup: Raman (and SThM) acquired during device operation with self-heating. (b) Measured (symbols) and fitted (lines) Raman spectra of the GST at the center of the channel with electrical bias (red: V = 10 V, I = 0.5 mA) and without bias (blue). (c) Simulated cross-section temperature profile of the device near the contact, highlighting the temperature measured by Raman (directly on GST film with Gaussian laser spot size) and SThM (top surface of PMMA capping layer).

We also carried out scanning thermal microscopy (SThM) measurements on the same devices. SThM is an atomic force microscopy (AFM) based technique that uses a thermo-resistive probe to acquire nanoscale topographic and thermal images simultaneously40,41. Unlike Raman, SThM measures only the surface temperature and requires additional calibration (see Supplementary Information Section 4), however it provides nearly AFM-like spatial resolution (<100 nm) and is therefore used here to provide complementary insight into PCM device thermometry.

Figure 4(c) shows the simulated cross-sectional temperature profile in our lateral GST device and contact. Three-dimensional (3D) finite element simulations were carried out using COMSOL Multiphysics®. To better understand the measurements, we illustrate the Raman and SThM instruments with the cross-sectional simulated temperature. The Raman method measures the temperature of the GST channel but its signal is averaged across the Gaussian laser beam spot (here ~ 400 nm). Inherently the SThM has better spatial resolution with a thermal exchange radius of <100 nm42, yet it measures the temperature at the top surface of the PMMA capping layer which spreads the heat. Simulations therefore predict slightly different temperature profiles for the Raman and SThM measurements. We note that the SThM is operated here in DC mode and is not calibrated to output temperature directly, rather it outputs a relative signal. We then use Raman thermometry (with same power input conditions) to calibrate the SThM to the temperature in the middle of the PCM device, where the GST temperature (measured by Raman) and the top PMMA temperature (measured by SThM) are similar [see cross-sectional temperature rise in Fig. 4(c)]. This calibration is made possible by the fact that the device temperature is uniform across several microns in the center of the GST channel, a region larger than the laser spot size.

The main advantage of the Raman measurement is its material selectivity which allows a differential measurement of materials in the laser path, thus enabling even atomic scale resolution in the cross-plane direction43. However, not all materials have a usable Raman signal and the spatial resolution is diffraction-limited (unless a signal enhancement technique such as TERS26 is utilized). SThM on the other hand has nearly AFM-like spatial resolution, but measures the temperature at the top surface rather than the direct temperature of the material of interest. The temperature sensitivity of the SThM can be better than that of the Raman method, but in order to convert the SThM signal (voltage) to temperature, the Raman method was used for calibration, as outlined above. Both techniques are limited in measuring vertical RRAM devices; the top electrode might block the Raman signal and laterally spread the temperature profile measured by SThM. Nonetheless, the combination of both techniques could become a very powerful tool to study the power dissipation in cases where temperature plays a major role in device operation2,3,5,10. A practical solution is to measure lateral devices or vertical devices having transparently thin top electrode.

Power Dissipation in Lateral PCM Device

Figure 5 compares the temperature profile along the device channel (including the contacts) measured by (a) SThM and (b) Raman to the simulated temperature rise with very good agreement. The full device temperature maps are shown in Supplementary Information Sections 5 and 6. Figure 5(c) shows the simulated temperature rise of the GST channel (green) as well as the profile that would be measured by SThM (red) and Raman (blue). Figure 5 highlights how the power dissipation in our devices is revealed via both Raman thermometry and SThM, with varying degrees of spatial accuracy. By inspecting the measured temperature profiles in Fig. 5 and the fitting parameters used in the simulation (summarized in Table I of Supplementary Information Section 9), several conclusion can be drawn as follows.

Measured vs. simulated temperature rise. Temperature rise along GST channel in fcc phase (black symbols) measured by (a) SThM and (b) Raman thermometry. The gray zones mark the contact regions. The simulated temperature rise fitted by finite element modeling for SThM (red dashed line) and Raman (blue dash-dot line) are also shown in (a) and (b) respectively. (c) Simulated temperature rise of the GST channel (green solid line), the SThM (top of PMMA surface averaged across thermal exchange radius42) same as in (a) and Raman (GST with Gaussian laser spot size) same as in (b). Black arrows mark hole current flow direction.

First, it is evident that significant heat is generated at the contacts44. Temperature artifacts due to the presence of step heights at the edge of the GST-Pt contacts are negligible here compared with the observed interfacial heating as discussed in Supplementary Information Section 6. It appears that the large contact resistivity of the GST film on the Pt contact (GST is deposited on top of the Pt electrodes) leads to highly localized power density, mainly at the edge of the electrode (also evident in the SThM maps shown in Supplementary Information Section 5). We also carried out transfer length method (TLM) measurements to directly extract the contact and sheet resistance (Supplementary Information Section 7) which served as inputs to the simulations. However, the temperature peak at the Pt-GST edge suggests that much of the contact voltage may be dropped at the imperfect GST step coverage of the Pt electrodes. To account for this, we set the GST resistivity at the Pt sidewall to be 20х larger than the bulk GST resistivity, leading to correct fitting in our simulations. The temperature rise of the 5 µm long GST channel suggests that much of the power dissipates there, yet the temperature peaks at the contacts due to the high power density there.

Second, given the power input and the measured temperature rise we can extract the thermal boundary resistance (TBR) of the GST-SiO2 and GST-Pt interfaces to be 28 ± 8 and 25 ± 9 m2K/GW respectively. Since the Si and SiO2 thermal properties are well known, and given the insensitivity to the bulk GST thermal conductivity (see Supplementary Section 9) the GST-SiO2 TBR acts as a single fitting parameter to the temperature rise at the center of the PCM device. The obtained value is in agreement with the TBR of the GST-SiO2 interface previously measured45 by the time domain thermo-reflectance (TDTR) technique, but it is extracted here within a functioning PCM device for the first time. The measured TBR of the GST-SiO2 interface is equivalent to a Kapitza length of ~50 nm of SiO2, which accounts for more than 25% of the total thermal resistance in our device. Importantly, the relative contribution of the TBR is expected to increase and dominate as devices are scaled down in size46.

Third, we also observe a clear asymmetry in heating at the two contacts, with the higher temperature at the edge of the grounded electrode. This contact heating asymmetry is due to a combination of thermoelectric and thermionic effects17,47 as confirmed by reversing the current flow direction. We extract an effective thermopower S = 350 ± 50 µV/K, which includes both thermoelectric and thermionic effects at the GST-Pt contact. Similar values were reported for GST in the mixed amorphous and fcc phase with Pt48 and with TiW49 contacts slightly above room temperature, after annealing up to ~ 150 °C. Following anneal at higher temperature (>200 °C) and higher degree of crystallization, the thermopower is expected to drop significantly (below 50 µV/K)48,49. The higher temperature at the grounded contact is also consistent with the location of damage after device breakdown, shown in Supplementary Information Section 8. The asymmetric heating highlights the importance of designing the voltage polarity of PCM programming pulses, to take advantage of thermionic and thermoelectric effects50. We note that our test devices are lateral and larger than state-of-the-art PCM devices51,52,53,54; however the physical insights are valid and highly valuable: the power generation is dominated by electrical contacts and the heat dissipation is limited by thermal interfaces in nanoscale devices44.

Conclusion

In summary, in this study we have laid the fundamental basis for thermometry of RRAM and PCM data storage devices. We presented the first measurements of thermal Raman signatures in nanoscale films of HfO2 and TiO2, and we used spatial mapping of temperature (with both Raman and SThM) to provide physical insight into the operation of PCM devices. Our approach takes advantage of the benefits of each technique, e.g. selectivity (Raman) and high spatial resolution (SThM), and can be extended to a wide variety of devices. We uncover significant heating at the contacts, suggesting that power dissipation is often dominated by electrical contact resistance. Contact heating is asymmetric, depending on current flow direction, showing that thermoelectric effects must be taken into account when designing PCM programming pulses. We also extract the TBR of the GST-SiO2 interface and find that it is equivalent to ~ 50 nm thick SiO2, contributing much of the device thermal resistance. The role of both electrical contacts and thermal interfaces will only become more dominant as devices are scaled to sub-50 nm dimensions. Uncovering the spatial distribution of temperature rise in such self-heated memristive devices is essential for their understanding, and their future design and integration.

Methods

Raman measurements were carried out on a Horiba Labram Evolution HR using a 633 nm laser with an 1800 l/mm grating. The red laser is chosen here since it provides Raman signal comparable to other laser lines in our system (e.g. 532 nm) and allows the measurement of anti-Stokes signal by using a volume Bragg grating optical filter at 633 nm. All measurements were done in air.

HfO2 films were deposited by reactive sputtering from an Hf target in an Ar:O2 (7:3) plasma at 4 mTorr, with a forward RF power of 150 W, at room temperature onto thin Pt films (50 nm) on a sapphire substrate. The Pt/sapphire substrate was used to enhance the Raman signal of the HfO2 film. TiO2 films were sputtered from a Ti target in an Ar:O2 (14:1) plasma at 5 mTorr onto SiO2 (90 nm) on Si substrates. To obtain Raman signal the films were crystallized by annealing: the TiO2 for 1 hour at 400 °C and the HfO2 for 2 hours at 600 °C, both in air.

Blanket GST films (20 nm) discussed in the section “Raman Spectroscopy of GST Films” were sputtered onto SiO2 (90 nm) on Si substrates, immediately followed (without breaking chamber vacuum) by sputtering 20 nm SiO2 to prevent oxidation when later exposed to air. GST devices (section “Raman Spectroscopy of GST Devices”) were prepared as follows. First, contacts and pads were defined by photolithography. Contact separation defined channel lengths L = 2 to 20 µm. The 40 nm Pt contacts (with 2 nm Ti adhesion layer) were then deposited by e-beam evaporation followed by patterning of channels (of widths W = 1 to 10 µm) with e-beam lithography, sputtering of 20 nm GST and lift-off. Devices were capped by spin coating ~150 nm poly(methyl methacrylate) (PMMA) to prevent oxidation, then baked on a hot plate at 180 °C for 10 minutes (in air) to crystallize the GST film.

The SThM measurements were carried out in passive mode and under DC bias. Measured PCM devices were Joule heated electrically by applying constant voltage to the contact pads for ~10 minutes during the SThM scan. The SThM thermal probe model used in this work is a DM-GLA-5 from Anasys®, which is made of a thin Pd layer on SiN.

References

Strukov, D. B., Snider, G. S., Stewart, D. R. & Williams, R. S. The missing memristor found. Nature 453, 80–83 (2008).

Yang, J. J., Strukov, D. B. & Stewart, D. R. Memristive devices for computing. Nature Nanotechnology 8, 13–24 (2012).

Wong, H.-S. P. et al. Phase change memory. Proceedings of the IEEE 98, 2201–2227 (2010).

Raoux, S., Xiong, F., Wuttig, M. & Pop, E. Phase change materials and phase change memory. MRS bulletin 39, 703–710 (2014).

Wong, H.-S. P. et al. Metal–oxide RRAM. Proceedings of the IEEE 100, 1951–1970 (2012).

Waser, R., Dittmann, R., Staikov, G. & Szot, K. Redox-Based Resistive Switching Memories–Nanoionic Mechanisms, Prospects, and Challenges. Advanced Materials 21, 2632–2663 (2009).

Valov, I., Waser, R., Jameson, J. R. & Kozicki, M. N. Electrochemical metallization memories—fundamentals, applications, prospects. Nanotechnology 22, 254003 (2011).

Prezioso, M. et al. Training and operation of an integrated neuromorphic network based on metal-oxide memristors. Nature 521, 61–64 (2015).

Larentis, S., Nardi, F., Balatti, S., Gilmer, D. C. & Ielmini, D. Resistive switching by voltage-driven ion migration in bipolar RRAM—Part II: Modeling. IEEE Transactions on Electron Devices 59, 2468–2475 (2012).

Yalon, E. et al. Thermometry of Filamentary RRAM Devices. IEEE Transactions on Electron Devices 62, 2972–2977 (2015).

Xiong, F., Liao, A. D., Estrada, D. & Pop, E. Low-power switching of phase-change materials with carbon nanotube electrodes. Science 332, 568–570 (2011).

Xiong, F. et al. Self-aligned nanotube–nanowire phase change memory. Nano Letters 13, 464–469 (2013).

Ielmini, D., Sharma, D., Lavizzari, S. & Lacaita, A. L. Reliability impact of chalcogenide-structure relaxation in phase-change memory (PCM) cells—Part I: Experimental study. IEEE Transactions on Electron Devices 56, 1070–1077 (2009).

Yalon, E., Cohen, S., Gavrilov, A. & Ritter, D. Evaluation of the local temperature of conductive filaments in resistive switching materials. Nanotechnology 23, 465201 (2012).

Sharma, A. A., Noman, M., Skowronski, M. & Bain, J. A. High-speed in-situ pulsed thermometry in oxide RRAMs. In 2014 International Symposium on VLSI Technology, Systems and Application (VLSI-TSA). (IEEE, https://doi.org/10.1109/VLSI-TSA.2014.6839687).

Grosse, K. L., Bae, M.-H., Lian, F., Pop, E. & King, W. P. Nanoscale Joule heating, Peltier cooling and current crowding at graphene-metal contacts. Nature Nanotechnology 6, 287–290 (2011).

Grosse, K. L., Xiong, F., Hong, S., King, W. P. & Pop, E. Direct observation of nanometer-scale Joule and Peltier effects in phase change memory devices. Applied Physics Letters 102, 193503 (2013).

Soudi, A., Dawson, R. D. & Gu, Y. Quantitative heat dissipation characteristics in current-carrying GaN nanowires probed by combining scanning thermal microscopy and spatially resolved Raman spectroscopy. ACS Nano 5, 255–262 (2011).

Tenne, D. et al. Raman study of oxygen reduced and re-oxidized strontium titanate. Physical Review B 76, 024303 (2007).

Kosacki, I., Suzuki, T., Anderson, H. U. & Colomban, P. Raman scattering and lattice defects in nanocrystalline CeO2 thin films. Solid State Ionics 149, 99–105 (2002).

Li, C. W., McKerns, M. M. & Fultz, B. Raman spectrometry study of phonon anharmonicity of hafnia at elevated temperatures. Physical Review B 80, 054304 (2009).

Quintard, P. E., Barbéris, P., Mirgorodsky, A. P. & Merle‐Méjean, T. Comparative Lattice‐Dynamical Study of the Raman Spectra of Monoclinic and Tetragonal Phases of Zirconia and Hafnia. Journal of the American Ceramic Society 85, 1745–1749 (2002).

Ohsaka, T. Temperature dependence of the Raman spectrum in anatase TiO2. Journal of the Physical Society of Japan 48, 1661–1668 (1980).

Gao, L. et al. Effect of oxygen vacancies and strain on the phonon spectrum of HfO2 thin films. Journal of Applied Physics 121, 224101 (2017).

Stiles, P. L., Dieringer, J. A., Shah, N. C. & Van Duyne, R. P. Surface-enhanced Raman spectroscopy. Annu. Rev. Anal. Chem. 1, 601–626 (2008).

Deckert, V. Tip‐Enhanced Raman Spectroscopy. Journal of Raman Spectroscopy 40, 1336–1337 (2009).

Stöckle, R. M., Suh, Y. D., Deckert, V. & Zenobi, R. Nanoscale chemical analysis by tip-enhanced Raman spectroscopy. Chemical Physics Letters 318, 131–136 (2000).

Baeumer, C. et al. Spectromicroscopic insights for rational design of redox-based memristive devices. Nature Communications 6, 8610 (2015).

Němec, P. et al. Amorphous and crystallized Ge–Sb–Te thin films deposited by pulsed laser: Local structure using Raman scattering spectroscopy. Materials Chemistry and Physics 136, 935–941 (2012).

Kolobov, A. V. et al. Understanding the phase-change mechanism of rewritable optical media. Nature Materials 3, 703–708 (2004).

Andrikopoulos, K., Yannopoulos, S., Kolobov, A., Fons, P. & Tominaga, J. Raman scattering study of GeTe and Ge2Sb2Te5 phase-change materials. Journal of Physics and Chemistry of Solids 68, 1074–1078 (2007).

Tominaga, J. & Atoda, N. Study of the crystallization of GeSbTe films by Raman spectroscopy. Japanese Journal of Applied Physics 38, L322 (1999).

Wu, Y., Liu, K., Li, D., Guo, Y. & Pan, S. In situ AFM and Raman spectroscopy study of the crystallization behavior of Ge2Sb2Te5 films at different temperature. Applied Surface Science 258, 1619–1623 (2011).

Guo, S. et al. Temperature and concentration dependent crystallization behavior of Ge2Sb2Te5 phase change films: tungsten doping effects. RSC Advances 4, 57218–57222 (2014).

Pine, A. & Dresselhaus, G. Raman spectra and lattice dynamics of tellurium. Physical Review B 4, 356 (1971).

Fong, S. J. et al. Dual-layer Dielectric Stack for Thermally-isolated Low-energy Phase-change Memory. IEEE Transactions on Electron Devices 64, 4496–4502 (2017).

Freitag, M. et al. Energy dissipation in graphene field-effect transistors. Nano Letters 9, 1883–1888 (2009).

Yalon, E. et al. Energy Dissipation in Monolayer MoS2 Electronics. Nano Letters 17, 3429–3433 (2017).

Kip, B. J. & Meier, R. J. Determination of the local temperature at a sample during Raman experiments using Stokes and anti-Stokes Raman bands. Applied Spectroscopy 44, 707–711 (1990).

Majumdar, A. Scanning thermal microscopy. Annual Review of Materials Science 29, 505–585 (1999).

Borca-Tasciuc, T. Scanning probe methods for thermal and thermoelectric property measurements. Annu. Rev. Heat Transfer 16, 211–258 (2013).

Puyoo, E., Grauby, S., Rampnoux, J.-M., Rouvière, E. & Dilhaire, S. Thermal exchange radius measurement: Application to nanowire thermal imaging. Review of Scientific Instruments 81, 073701 (2010).

Chen, C.-C., Li, Z., Shi, L. & Cronin, S. B. Thermal interface conductance across a graphene/hexagonal boron nitride heterojunction. Applied Physics Letters 104, 081908 (2014).

Xiong, F., Yalon, E., Behnam, A., Neumann, C., Grosse, K., Deshmukh, S. & Pop, E. Towards ultimate scaling limits of phase-change memory. In 2016 IEEE International Electron Devices Meeting (IEDM). 4.1.1–4.1.4 (IEEE, https://doi.org/10.1109/IEDM.2016.7838342).

Battaglia, J.-L. et al. Thermal characterization of the SiO2-Ge2Sb2Te5 interface from room temperature up to 400 °C. Journal of Applied Physics 107, 044314 (2010).

Reifenberg, J. P., Kencke, D. L. & Goodson, K. E. The impact of thermal boundary resistance in phase-change memory devices. IEEE Electron Device Letters 29, 1112–1114 (2008).

Pop, E. Energy dissipation and transport in nanoscale devices. Nano Research 3, 147–169 (2010).

Lee, J., Kodama, T., Won, Y., Asheghi, M. & Goodson, K. E. Phase purity and the thermoelectric properties of Ge2Sb2Te5 films down to 25 nm thickness. Journal of Applied Physics 112, 014902 (2012).

Grosse, K. L., Pop, E. & King, W. P. Heterogeneous nanometer-scale Joule and Peltier effects in sub-25 nm thin phase change memory devices. Journal of Applied Physics 116, 124508 (2014).

Lee, J., Asheghi, M. & Goodson, K. E. Impact of thermoelectric phenomena on phase-change memory performance metrics and scaling. Nanotechnology 23, 205201 (2012).

Kim, I. et al. High performance PRAM cell scalable to sub-20nm technology with below 4F2 cell size, extendable to DRAM applications. In 2010 Symposium on VLSI Technology (VLSIT). 203–204 (IEEE, https://doi.org/10.1109/VLSIT.2010.5556228).

Kau, D. et al. A stackable cross point Phase Change Memory. In 2009 IEEE International Electron Devices Meeting (IEDM). 617–620 (IEEE, https://doi.org/10.1109/IEDM.2009.5424263).

Kinoshita, M. et al. Scalable 3-D vertical chain-cell-type phase-change memory with 4F2 poly-Si diodes. In 2012 Symposium on VLSI Technology (VLSIT). 35–36 (IEEE, https://doi.org/10.1109/VLSIT.2012.6242448).

Ahn, S. et al. Highly manufacturable high density phase change memory of 64Mb and beyond. In 2004 IEEE International Electron Devices Meeting (IEDM). 907–910 (IEEE, https://doi.org/10.1109/IEDM.2004.1419329).

Acknowledgements

We thank Ajay Sood, Scott Fong and Ilya Karpov for helpful discussions. We acknowledge the Stanford Nanofabrication Facility (SNF) and Stanford Nano Shared Facilities (SNSF) for enabling device fabrication and measurements. This work was supported in part by the NSF Center for Power Optimization of Electro-Thermal Systems (POETS), by the NSF grant DMREF 1534279, by DARPA Matrix program (HRL Laboratories subcontract), and by the Stanford Non-Volatile Memory Technology Research Initiative (NMTRI). E.Y. acknowledges partial support from Ilan Ramon Fulbright Fellowship and from Andrew and Erna Finci Viterbi Foundation.

Author information

Authors and Affiliations

Contributions

E.Y. and E.P. conceived the idea and designed the experiments. S.D. deposited the films and fabricated the devices. E.Y. performed the Raman measurements and analysis. M.M.R. carried out the AFM measurements. M.M.R. and E.Y. carried out the SThM measurements. E.Y. performed the electro-thermal modeling. F.L. assisted with Raman measurements. C.M.N. and F.X. assisted with Raman analysis. E.Y. and E.P. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yalon, E., Deshmukh, S., Muñoz Rojo, M. et al. Spatially Resolved Thermometry of Resistive Memory Devices. Sci Rep 7, 15360 (2017). https://doi.org/10.1038/s41598-017-14498-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-14498-3

This article is cited by

-

Impact of Temperature on GST/ITO/Soda-Lime Glass Substrate Thin Film Devices

Journal of Electronic Materials (2022)

-

Theoretical potential for low energy consumption phase change memory utilizing electrostatically-induced structural phase transitions in 2D materials

npj Computational Materials (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.