Abstract

We report on a strain-induced and temperature dependent uniaxial anisotropy in V2O3/Ni hybrid thin films, manifested through the interfacial strain and sample microstructure, and its consequences on the angular dependent magnetization reversal. X-ray diffraction and reciprocal space maps identify the in-plane crystalline axes of the V2O3; atomic force and scanning electron microscopy reveal oriented rips in the film microstructure. Quasi-static magnetometry and dynamic ferromagnetic resonance measurements identify a uniaxial magnetic easy axis along the rips. Comparison with films grown on sapphire without rips shows a combined contribution from strain and microstructure in the V2O3/Ni films. Magnetization reversal characteristics captured by angular-dependent first order reversal curve measurements indicate a strong domain wall pinning along the direction orthogonal to the rips, inducing an angular-dependent change in the reversal mechanism. The resultant anisotropy is tunable with temperature and is most pronounced at room temperature, which is beneficial for potential device applications.

Similar content being viewed by others

Introduction

Proximity effects in heterostructures are of keen interest in magnetism due to both emergent phenomena1,2,3,4 and potential applications, e.g., in advanced data storage and sensor technologies5,6,7,8,9. Interface coupling of magnetically ordered structures can induce behaviors such as exchange bias10,11,12 and exchange spring5,13 effects. Recent studies have demonstrated strain-induced proximity effects in vanadium oxide (V2O3, VO2)/Ni bilayer films14,15. In particular, V2O3 undergoes a simultaneous rhombohedral to monoclinic (structural), paramagnetic to antiferromagnetic (magnetic), and metal to insulator (electronic) phase transition as the temperature is decreased below 160 K16. Strain induced in the Ni film by the V2O3 structural phase transition (SPT)17 causes drastic changes in its magnetic properties, including a spike in the coercivity (H C ) midway through the V2O3 phase transition. Interestingly, the observed magnetic properties were highly dependent on the sample microstructure along the out-of-plane direction - specifically the interface roughness - although the strain was expected to be predominantly in the film plane14,15. An interface roughness of 1.5 nm suppressed the coercivity spike, while a general increase in H C due to an isotropic strain persisted. This emphasizes the sensitivity of the V2O3/Ni system to its microstructure. With the current interest in strain control of materials, including magnetic materials18 and multiferroics19,20,21, among others22,23, understanding the intricacies of strain and its potential interplay with the microstructure is of crucial importance. This interest, and the known sensitivity of the (V2O3, VO2)/Ni system, motivates an investigation on how the magnetic properties are impacted by the strain through the in-plane microstructure.

Here we present a detailed angular and temperature (T) dependent study of the magnetic characteristics of V2O3/Ni thin films. We observe long-range oriented terraces and long voids (“rips”) in the microstructure, which induce a uniaxial magnetic anisotropy in the Ni film. Ferromagnetic resonance (FMR) shows a uniaxial enhancement of the in-plane field, and damping of the magnon excitation. Comparison measurements performed on sapphire/Ni samples without rips show similar uniaxial anisotropy, but without the magnon damping, suggesting that both the strain and microstructure are important in the observed properties of V2O3/Ni films. The quasi-static magnetization reversal was investigated with first order reversal curve (FORC) measurements. FORC diagrams show a different reversal mechanism when the field is applied parallel or orthogonal to the rips. Measurements performed at 45° relative to the rips show both reversal mechanisms, tunable by the measurement temperature. The FORC studies lead to understanding of the domain nucleation, propagation, and pinning behavior resulted from the microstructure and strain. The presence of oriented, in-plane magnetic anisotropy, emergent without patterning or magneto-crystalline considerations, offers new opportunities for scalable nanomagnetic devices.

Results

Structure analysis

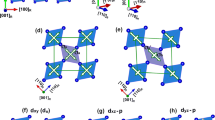

Films of V2O3 (100 nm)/Ni (10 nm)/Cu cap (7 nm) and Ni (10 nm)/Nb cap (6 nm) were grown on r-cut (102) sapphire substrates, as described in Methods. The XRD patterns, shown in Fig. 1, reveal a rhombohedral corundum structure in the as-grown V2O3 film with an (012) orientation. An out-of-plane lattice parameter of 3.658 Å is found, which agrees well with the expected corundum lattice constants of bulk V2O3. Ni is in its face centered cubic structure with a (111) texture and a lattice constant a = 3.604 ± 0.001 Å, close to reported bulk values. We assume polycrystalline growth of the Ni, but a hypothetical epitaxial relationship of V2O3(012)||Ni(111) and V2O3[1\(00\)]||Ni[10\(\bar{1}\)] would result in a lattice mismatch of only 0.7%, while for V2O3 on Al2O3 substrate a 4% mismatch can be expected. Reciprocal space mapping (RSM) of the V2O3 film confirms epitaxial growth of the film. From the RSM and pole figure measurement, Fig. 1b and c, respectively, the (2\(\bar{1}\)0) and (01\(\bar{5}\)) diffraction vectors are identified as orthogonal in-plane axes, illustrated in Fig. 1d. Henceforth, all in-plane sample angles (ϕ) are defined relative to the (\(01\mathop{5}\limits^{\bar{} }\)) diffraction vector (ϕ = 0). The V2O3 rhombohedral to monoclinic SPT was measured along the (012), (014) and (01\(\bar{4}\)) diffractions (not shown) with XRD24.

(a) High-angle θ-2θ x-ray diffraction pattern of V2O3 (100 nm)/Ni (10 nm) sample, misaligned by 0.1° to suppress the substrate peaks. The V2O3 (012), (024), and (036) peaks are identified by *, the Ni (111) identified by †, and sapphire (012) and (024) identified by ‡. (b) Reciprocal space map of V2O3 recorded along the long edge of the substrate. The (012) plane is parallel to the surface at Q || = 0, while the (104) points 48° to the surface normal. (c) Pole figure of the (104) plane showing the epitaxy of V2O3. The (\(01\mathop{4}\limits^{\bar{} }\)) lies at 82° with respect to the surface normal. (d) Schematic reconstruction of the real space orientation of the V2O3 crystal planes following from symmetry considerations of the measured planes.

The V2O3/Ni film microstructure obtained from AFM and SEM is shown in Fig. 2a and b, respectively. The micrographs identify extended rips and localized voids oriented along the V2O3 (01\(\bar{5}\)) diffraction vector (i.e. ϕ = 0°), emphasized by the ellipsoidal shape of the Fourier transformation included in Fig. 2 insets. The rips and voids are approximately 15 nm in width with length ranging from 30 nm to several hundred nanometers. The orientation of the rips is correlated with the morphology of the terraced sapphire substrate, as shown in Fig. 2c. These rips define a microstructure in the bilayer comprised of ribbon-like contiguous regions ≈100 nm in width and >500 nm in length. The Ni control sample of the same thickness grown on a bare r-cut sapphire, shown in Fig. 2d, retains the terrace morphology but does not exhibit any observable rips. This suggests that the growth of the V2O3 layer underneath the Ni is the cause of the rips. This possibly arises from the Ni film experiencing particularly strong strain at the terrace boundaries during deposition25 and the subsequent phase transition, leading to rupture of the film. This would suggest that the structure of the rips may be tuned by designing the terraces or controlling the granular structure of the film, which can be achieved by tuning of the growth parameters26.

Ferromagnetic Resonance

The oriented microstructural features are expected to introduce a uniaxial shape anisotropy in the plane of the film, which can be probed using angular-dependent FMR measurements. Indeed, the surface map of the FMR spectrum for both the V2O3/Ni, Fig. 3a, and Ni on sapphire, Fig. 3b, films show an angular dependence of the resonant field, H Res. identified by the solid lines. Variations in H Res. indicate an anisotropic in-plane effective field. In both samples the minima in H Res. occurs along ϕ = 0° and 180°, while the maxima occur along ϕ = 90° and 270°, identifying the magnetic easy and hard axes, respectively. The 180° periodicity indicates the presence of a uniaxial anisotropy. For the sapphire/Ni reference sample the anisotropy direction can be correlated to the direction of the terraces in the substrate. In addition, the FMR signal line width of the V2O3/Ni sample also exhibits an angular dependence, with strong damping parallel to the rips (ϕ = 0°). In comparison, for the Ni on sapphire sample [Fig. 3b], the FMR line width is constant at all angles, indicating that the dissipation processes are angle-independent.

Angular-dependent ferromagnetic resonance spectrum of (a) V2O3/Ni and (b) Ni on sapphire. Contrast indicates the differential absorption. The peak in the absorption for each angle is identified by the H Res. lines. The y-axis identifies the angle ϕ between the applied magnetic field and the (\(01\mathop{5}\limits^{\bar{} }\)) diffraction vector. H Res. is indicated by the solid curve.

Magnetometry

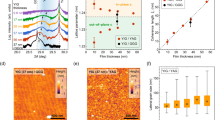

Major hysteresis loops of the V2O3/Ni sample taken at 295 K, 170 K, 160 K, and 77 K, at angles of −45° → 135° are shown in Fig. 4a–d, respectively. The temperature dependent coercivity H C and loop squareness S (ratio of remanent over saturation magnetization, M R /M S ) are shown in Fig. 4e and g, respectively. Above 170 K the sample has a small coercivity (<15 mT) which slowly increases with decreasing temperature, consistent with reduced thermal activation. Below the V2O3 phase transition at 160 K, the Ni coercivity increases to >20 mT. This has been previously attributed to strain in the Ni film induced by the V2O3 14,15,24,27. Here we find a relatively small peak in the temperature-dependent H C (Fig. 4e) presumably due to a large RMS roughness (2.5 nm measured with AFM), as discussed in ref.14. Interestingly, the H C trend shows a strong temperature dependence and very small angular dependence, while S shows a mixed trend. Above the SPT, S depends sensitively on the angle, with a maxima along ϕ = 0°, while below the SPT S exhibits a similarly large value of >0.6 for all angles. For comparison, the H C and S trends for the sapphire/Ni sample are included in Fig. 4e and f, respectively, exhibiting only a slowly increasing trend with decreasing temperature at all angles, consistent with thermal activation.

Major hysteresis loops of V2O3/Ni taken at (a) 295 K, (b) 170 K, (c) 160 K, and (d) 77 K measured at 0°, 30°, 45°, 60°, and 90° (red to blue). Trends for coercivity H C (T,ϕ) and squareness S(T,ϕ) (g,h) from (a–d) are collated (e,f) and (g,h), respectively. Results of the reference Al2O3/Ni sample are included as dashed curves in (e,f) for comparison.

Detailed polar contour plots of the angular-dependent coercivity and squareness are shown in Fig. 4f and h, respectively. At all temperatures, maxima in H C and S are observed at ϕ = 0° [along (01\(\bar{5}\))] and minima at 90° [along (2\(\bar{1}\)0)], indicating the magnetic easy and hard axes, respectively, and consistent with the FMR results. Unexpectedly, the uniaxial anisotropy is less pronounced at temperatures below the V2O3 phase transition at 160 K, as shown in the hard and easy axes coercivities [Fig. 4e] and squareness [Fig. 4g]. The percent difference in H C and S, between the hard and easy axes, can be calculated: \(\triangle {H}_{C}=\frac{{H}_{C}^{0}-{H}_{C}^{90}}{{H}_{C}^{0}}\) and \(\triangle S=\frac{{S}^{0}-{S}^{90}}{{S}^{0}}\). These differences are significantly larger at 295 K, ΔH C = −73% and ΔS = −79%, than at 77 K, ΔH C = −27% and ΔS = −14%.

First order reversal curves were measured following published procedures28,29,30,31, as discussed in Methods. The FORC results provide a mechanism to investigate the quasi-static magnetization reversal characteristics and are shown in Fig. 5 for ϕ = 0° (top), 45° (middle) and 90° (bottom) at 295 K (left), 160 K (center), and 77 K (right), respectively. A strong variation in the shape of the FORC feature is found as a function of angle and temperature, implying changes in the reversal mechanism. Along the magnetic easy axis, ϕ = 0°, the FORC distribution is oriented along the \({H}_{C}^{\ast }\) axis for all temperatures. In contrast, along ϕ = 90° the FORC distribution consists of a left-bending ‘boomerang’ feature32, with one arm oriented along the -H R axis and the other along -H, and possessing a negative feature located in the crook of the elbow. FORC distributions measured along ϕ = 45° are oriented along the \({H}_{C}^{\ast }\) axis at room temperature, and develop a boomerang structure, with symmetries along H and H R , at lower temperatures. This change in FORC structure implies a temperature and angular dependence of the magnetization reversal mechanism, as discussed below.

FORC distributions measured at (top) 0° [along the (\(01\mathop{5}\limits^{\bar{} }\)) diffraction vector], (middle) 45°, and (bottom) 90° [along the (\(2\mathop{1}\limits^{\bar{} }0\)) diffraction vector], at (left) 295 K, (center) 160 K, and (right) 77 K. The color range in each contour extends between the maximal and minimal value, with the background, away from the feature, identifying zero. Arrows plotted in each panel indicate the H and H R coordinate axes.

Discussion

Standard major-loop magnetometry measurements of V2O3/Ni films show an angular-dependent suppression of H C and S with minima along the direction orthogonal to the rips (ϕ = 90°), as shown in Fig. 4f and h. A similar angular-dependence was observed in the FMR H Res. for both V2O3/Ni and sapphire/Ni films, with the maxima of H Res. observed along ϕ = 90°. However, only the V2O3/Ni film showed an angular dependent FMR line width. The key difference in these films is their microstructure, with the V2O3/Ni film possessing rips, and the sapphire/Ni film possessing only terracing. This suggests that the uniaxial anisotropy seen in the FMR and magnetometry can be attributed to the microstructure, including rips, terracing, and any crystalline texture, while the rips additionally affect the FMR line width. The uniaxial anisotropy can be understood by considering the shape anisotropy: the ribbon-like contiguous regions, bounded by the rips or terrace boundaries, experience less magnetostatic interaction when the magnetization is oriented along the ribbon, compared to an orthogonal orientation33,34,35. The variation in the FMR H Res. identifies the strength of the uniaxial anisotropy as 9.8 mT. Since the room temperature coercivity along the easy axis is only 10 mT, the uniaxial anisotropy is expected to play an important role in the energy landscape. At low temperatures the film’s anisotropy increases due to strain from the V2O3 substrate, increasing the major-loop coercivity while the anisotropy from the microstructure is not expected to change significantly. Thus, the microstructure contributes less to the magnetic behavior below the V2O3 phase transition, resulting in a suppression of the relative angular dependence.

Using the FORC distributions in Fig. 5, a model of the angle- and temperature-dependent reversal behavior is developed. The film presented in this work is expected to switch by a multi-domain reversal, with each domain geometrically bounded by the rips into approximately 100 nm × 500 nm × 10 nm regions. First, we discuss the FORC distributions measured along ϕ = 0°, which show features oriented along the \({H}_{C}^{\ast }\) axis, Fig. 5a,d and g. As discussed in ref.30, a FORC feature located on the \({H}_{C}^{\ast }\) axis identifies symmetric down- and up-switching events (H = −H R ). This is common in systems of non-interacting magnetic elements, in which the switching fields are determined only by the local intrinsic anisotropy36,37. A horizontal FORC ridge along the \({H}_{C}^{\ast }\) axis similarly represents a distribution of local anisotropies. Here we expect domain nucleation to occur at local low anisotropy defect sites within the bounded regions, such as inclusions, grain boundaries, etc. Once the reversal field H R overcomes the anisotropy of the defect sites, reversal domains are nucleated and then propagate, similar to a non-defective thin film. Following the FORC measurement procedure, the field sweep direction is reversed and H is increased back towards positive saturation. The initial part of the subsequent FORC branch - just after reversing the field sweep direction - is probing H < −H R (i.e. H B < 0). The fact that the FORC diagrams in Fig. 5a,d and g show essentially no feature in this region implies that the domain which was nucleated at H R does not grow or shrink in response to the magnetic field in this field range. The primary FORC features in Fig. 5a,d and g manifest at H = −H R (i.e. H B = 0). At this field the same defect site which nucleated the negatively-oriented domain from positive saturation now nucleates a new positively-oriented domain, by symmetry arguments. Further increasing H, following the FORC branch, probes the region H > −H R (i.e. H B > 0). The FORC distributions in Fig. 5a,d and g show no features in this region, indicating that the switching event at H = −H R saturates the sample. Thus the same defect sites nucleate domains for both field sweep directions, causing a symmetry in the nucleation and annihilation events and giving rise to a feature in the FORC diagram which manifests only on the \({H}_{C}^{\ast }\) axis (H B = 0). This also directly implies that (1) the nucleated domain propagates until it encounters a pinning site which (2) has a de-pinning field larger than the initial nucleation field. The width of the \({H}_{C}^{\ast }\) distribution is reflective of the film being comprised of many such regions, each with a unique nucleating defect site. The width of the \({H}_{C}^{\ast }\) distribution increases with decreasing temperature, particularly cooling through the SPT, indicating an increase of the pinning potential distribution, likely arising from an inhomogeneous strain landscape. At the coldest temperatures (77 K) the horizontal FORC feature begins to bend, especially at the high and low \({H}_{C}^{\ast }\) ends. This indicates the onset of a domain growth mechanism, discussed below.

FORC distributions measured at ϕ = 90°, Fig. 5c,f and i, have extended arms oriented along the -H R and -H directions, forming a ‘boomerang’ feature. This feature is observed often in systems which reverse by domain nucleation and growth mechanisms28,32,38,39. The ‘left-bending’ orientation of the boomerang is suggestive of strong exchange interactions (compared to dipolar interactions) within the system32, as expected for an in-plane film. Similar to the above discussion for the ϕ = 0° data, once the reversal field H R overcomes the anisotropy of the defect sites, reversal domains are nucleated which then propagate. Following the FORC measurement procedure, the field sweep direction is reversed, and H is increased back towards positive saturation, initially probing H < −H R (i.e. H B < 0). The -H arm of the FORC feature resides in this region, indicating that the domains contract in response to the magnetic field before reaching the H = −H R , distinctly different than the ϕ = 0° measurements. This domain contraction implies that the barrier to domain wall motion is much less for the measurements at ϕ = 90° compared to the measurements along ϕ = 0°, resulting in an entirely different field evolution. This lack of pinning could indicate that the nucleated domain does not fill the ribbon-like regions after the initial nucleation event, and thus is only weakly pinned. The arm parallel to the H R axis identifies the progressive negative saturation of the sample and domain re-nucleation from negative saturation28.

FORCs measured at ϕ = 45°, Fig. 5b,e and h, show features along \({H}_{C}^{\ast }\) at room temperature and bending towards a boomerang structure at low temperatures. This explicitly identifies a temperature-dependent transition in the reversal mechanism from localized domain reversal at room temperature to domain growth at low temperatures. This change is possibly due to an increase in strain-induced pinning sites at low temperature due to the coupling of Ni to V2O3 14,15, which prevent the long-range expansion of the domain wall. In this scenario, at high temperatures the magnetic domains propagate over large regions, appearing as switching at single field steps, while at lower temperatures magnetic domains are nucleated and incrementally grow following a Barkhausen-type jumps over multiple field steps40. Alternatively, at lower temperatures, the Ni anisotropy increases14,15 and correspondingly the domain nucleation field also increases. Thus, at high temperatures, along a FORC branch, domains which are pinned on defect sites at H R may nucleate a new domains before the domain wall becomes de-pinned, manifesting as reversal in what appears as single-field jumps. At low-temperatures the increased anisotropy may push the nucleation field beyond the de-pinning field, causing an apparent change in the reversal mechanism to an incremental growth mode in which the domain wall jumps between pinning sites.

Conclusions

In summary, the magnetization reversal characteristics of V2O3/Ni bilayer films with a strain-induced uniaxial anisotropy, manifested in the sample microstructures, was investigated. X-ray diffraction and microscopy show rips and voids in the Ni oriented along the (\(01\overline{5}\)) diffraction vector of the V2O3. FMR results show these rips attenuate magnon excitation, while strain induced by microstructural terracing causes an effective uniaxial anisotropy field of 9.8 mT, emphasizing the combined contributions from sample microstructure and strain. Standard magnetometry confirmed a uniaxial easy axis, as revealed by the measured coercivity and major loop squareness. The effective anisotropy was demonstrated to be tunable by temperature, with the effect being much weaker below the V2O3 SPT. First order reversal curve measurements revealed that the anisotropy causes two different reversal mechanisms to exist within the sample, depending on the angle. Along the magnetic easy axis the domains reverse by a defect-induced localized magnetization reversal mechanism, while the hard axis shows reversal by domain nucleation/growth mechanism. FORC measurements performed between the hard and easy axes show a temperature-dependent transition between these reversal mechanisms. This temperature evolution of the magnetic reversal provides insight into Ni microstructure change due to the strain exerted by V2O3 transition. The results demonstrate an approach to achieve in-plane uniaxial shape anisotropy emergent in the films without patterning or magneto-crystalline considerations, controllable with temperature. Such tunable oriented structures may be relevant to other research fields, including the design of bidirectional phonon conductors for directed thermal transport, or angular dependent plasmon conductors.

Methods

Thin films of V2O3 (100 nm)/Ni (10 nm)/Cu cap (7 nm) and Ni (10 nm)/Nb cap (6 nm) were grown by sputtering in a high vacuum chamber (P Base ≈ 10−5 Pa) on r-cut (102) sapphire substrates in a 0.53 Pa Ar atmosphere. The V2O3 was grown at 1000 K substrate temperature from a stoichiometric target and the Ni, Cu, and Nb layers were sputtered at room temperature from elemental targets. The metal-insulator transition in V2O3 was largest when grown on an r-cut sapphire substrate41. X-ray diffraction (XRD) was performed in an inert atmosphere over 90 K–300 K using Cu-Kα radiation. All in-plane directions are identified by the corresponding (hkl) diffraction vectors of the V2O3 lattice planes in the high temperature rhombohedral phase using the short hexagonal lattice notation. Surface morphology was investigated by scanning electron microscopy (SEM) and atomic force microscopy (AFM). Magnetic measurements were performed between 77 K and 295 K, using a zero-field cooling sequence, on a vibrating sample magnetometer (VSM) with a liquid nitrogen flow cryostat and the magnetic field was applied in the film plane.

Ferromagnetic resonance (FMR) was measured using an electron paramagnetic resonance spectrometer with a cylindrical cavity resonator at 9.4 GHz. The sample was placed in the center of the cavity, and mounted on a quartz rod allowing for in-plane orientation of the dc magnetic field. An automatic goniometer allowed for precise rotation with an accuracy of Δθ = 0.025°. Alignment of the sample with respect to the ac and dc fields was performed from the highest resonant field while rotating the sample about the out-of-plane direction (θ = 0°) within 0.2°. The dc magnetic field was swept from 0 to 0.9 T at 6 mT/s. The microwave power was kept constant at 1 mW in order to increase the signal-to-noise ratio. The line width (ΔH) and resonance field (H Res.) were obtained by fitting the FMR signal to the derivative of a Lorentzian function.

The FORC measurements42,43 were performed following procedures discussed previously28,29,30,31. Starting from positive saturation, the applied magnetic field was decreased to a reversal field, H R , at which point the field sweep direction was reversed and the magnetization, M, is recorded as the applied field, H, was increased back to positive saturation. This sequence measures a single FORC branch and is performed for a series of H R between positive and negative saturation, collecting a family of FORCs. A mixed second order derivative was applied to extract the FORC distribution: \(\rho (H,{H}_{R})=-\frac{1}{2}\frac{{\partial }^{2}M(H,{H}_{R})}{\partial H\partial {H}_{R}}\). Recognizing that progressing to more-negative H R probes new down-switching events, and along each FORC branch, increasing H probes up-switching events, a new coordinate system can be defined by the local coercivity, \({H}_{C}^{\ast }=\frac{H-{H}_{R}}{2}\), and bias field, \({H}_{B}=\frac{H+{H}_{R}}{2}\).

The FORC distribution is a mapping of the switching events within a system. In its most basic application, the reversal mechanism (domain growth, coherent rotation, vortex, etc.) can be uniquely fingerprinted29,44. Furthermore, intricate details of the nanoscale system, including magnetic interactions30,32 and intrinsic distributions36, can be qualitatively, and sometimes quantitatively, identified. One approach which can be used to extract these details from the FORC distribution is to use the (\(H\), \({H}_{R}\)) coordinates of features in the FORC distribution and correlate it back to the family of FORCs.

References

Jin, B. Y. & Ketterson, J. B. Artificial metallic superlattices. Adv. Phys. 38, 189–366 (1989).

Vobornik, I. et al. Magnetic Proximity Effect as a Pathway to Spintronic Applications of Topological Insulators. Nano Lett. 11, 4079–4082 (2011).

Huang, S. Y. et al. Transport Magnetic Proximity Effects in Platinum. Phys. Rev. Lett. 109, 107204 (2012).

Montero, M. I. et al. Nanostructures and the proximity effect. J. Phys. D-Appl. Phys. 35, 2398–2402 (2002).

Fullerton, E. E., Jiang, J. S., Grimsditch, M., Sowers, C. H. & Bader, S. D. Exchange-spring behavior in epitaxial hard/soft magnetic bilayers. Phys. Rev. B 58, 12193 (1998).

Thiele, J. U., Maat, S. & Fullerton, E. E. FeRh/FePt exchange spring films for thermally assisted magnetic recording media. Appl. Phys. Lett. 82, 2859–2861 (2003).

Victora, R. H. & Shen, X. Exchange coupled composite media for perpendicular magnetic recording. IEEE Trans. Magn. 41, 2828–2833 (2005).

Suess, D. Multilayer exchange spring media for magnetic recording. Appl. Phys. Lett. 89, 113105 (2006).

Kirby, B. J. et al. Vertically graded anisotropy in Co/Pd multilayers. Phys. Rev. B 81, 100405 (2010).

Nogues, J. & Schuller, I. K. Exchange Bias. J. Magn. Magn. Mater. 192, 203 (1999).

Kiwi, M. Exchange bias theory. J. Magn. Magn. Mater. 234, 584–595 (2001).

Stamps, R. L. Mechanisms for exchange bias. J. Phys. D: Appl. Phys. 33, R247–R268 (2000).

Kneller, E. F. & Hawig, R. The exchange-spring magnet: a new material principle for permanent magnets. IEEE Trans. Magn. 27, 3588 (1991).

de la Venta, J., Wang, S., Ramirez, J. G. & Schuller, I. K. Control of magnetism across metal to insulator transitions. Appl. Phys. Lett. 102, 122404 (2013).

de la Venta, J. et al. Coercivity enhancement in V2O3/Ni bilayers driven by nanoscale phase coexistence. Appl. Phys. Lett. 104, 062410 (2014).

Kosuge, K. The phase diagram and phase transition of the V2O3-V2O5, system. J. Phys. Chem. Solids 28, 1613–1621 (1967).

Imada, M., Fujimori, A. & Tokura, Y. Metal-insulator transitions. Rev. Mod. Phys. 70, 1039–1263 (1998).

Grutter, A., Wong, F., Arenholz, E., Liberati, M. & Suzuki, Y. Enhanced magnetization in epitaxial SrRuO3 thin films via substrate-induced strain. J. Appl. Phys. 107, 09E138 (2010).

Schlom, D. G. et al. Strain tuning of ferroelectric thin films. Annu. Rev. Mater. Res. 37, 589–626 (2007).

Ramesh, R. & Spaldin, N. A. Multiferroics: progress and prospects in thin films. Nat. Mater. 6, 21–29 (2007).

Zeches, R. et al. A strain-driven morphotropic phase boundary in BiFeO3. Science 326, 977–980 (2009).

Guinea, F., Katsnelson, M. & Geim, A. Energy gaps and a zero-field quantum Hall effect in graphene by strain engineering. Nat. Phys. 6, 30–33 (2010).

Fei, R. & Yang, L. Strain-Engineering the Anisotropic Electrical Conductance of Few-Layer Black Phosphorus. Nano Lett. 14, 2884–2889 (2014).

Saerbeck, T. et al. Coupling of magnetism and structural phase transitions by interfacial strain. J. Mater. Res. 29, 2353 (2014).

McLeod, A. S. et al. Nanotextured phase coexistence in the correlated insulator V2O3. Nat. Phys. 13, 80–86 (2017).

Thornton, J. A. High rate thick film growth. Annu. Rev. Mater. Sci. 7, 239–260 (1977).

Ramirez, J. G. et al. Effect of disorder on the metal-insulator transition of vanadium oxides: Local versus global effects. Phys. Rev. B 91, 205123 (2015).

Davies, J. E. et al. Magnetization reversal of Co/Pt multilayers: Microscopic origin of high-field magnetic irreversibility. Phys. Rev. B 70, 224434 (2004).

Dumas, R. K., Liu, K., Li, C. P., Roshchin, I. V. & Schuller, I. K. Temperature induced single domain-vortex state transition in sub-100 nm Fe nanodots. Appl. Phys. Lett. 91, 202501 (2007).

Gilbert, D. A. et al. Quantitative Decoding of Interactions in Tunable Nanomagnet Arrays Using First Order Reversal Curves. Sci. Rep. 4, 4204 (2014).

Gilbert, D. A. et al. Realization of Ground State Artificial Skyrmion Lattices at Room Temperature. Nat. Commun. 6, 8462 (2015).

Gilbert, D. A. et al. Magnetic yoking and tunable interactions in FePt-based hard/soft bilayers. Sci. Rep. 6, 32842 (2016).

Kou, X. et al. Memory Effect in Magnetic Nanowire Arrays. Adv. Mater. 23, 1393–1397 (2011).

Krawczyk, M. & Grundler, D. Review and prospects of magnonic crystals and devices with reprogrammable band structure. J. Phys. Condens. Matter 26, 123202 (2014).

Gross, K., Westerholt, K. & Zabel, H. Domain wall dynamics of periodic magnetic domain patterns in Co2MnGe-Heusler microstripes. New J. Phys. 18, 033007 (2016).

Gilbert, D. A. et al. Probing the A1 to L10 transformation in FeCuPt using the first order reversal curve method. APL Mater. 2, 086106 (2014).

Pike, C. R. First-order reversal-curve diagrams and reversible magnetization. Phys. Rev. B 68, 104424 (2003).

Dumas, R. K. et al. Accessing different spin-disordered states using first-order reversal curves. Phys. Rev. B 90, 104410 (2014).

Ma, L. et al. Magnetization reversal in perpendicualrly magnetized L10 FePd/FePt heterostructures. J. Appl. Phys. 116, 033922 (2014).

Zapperi, S., Cizeau, P., Durin, G. & Stanley, H. E. Dynamics of a ferromagnetic domain wall: Avalanches, depinning transition, and the Barkhausen effect. Phys. Rev. B 58, 6353–6366 (1998).

Valmianski, I., Ramirez, J. G., Urban, C., Batlle, X. & Schuller, I. K. Deviation from bulk in the pressure-temperature phase diagram of V2O3 thin films. Phys. Rev. B 95, 155132 (2017).

Mayergoyz, I. D. Mathematical Models of Hysteresis (Springer-Verlag, 1991).

Pike, C. R., Roberts, A. P. & Verosub, K. L. Characterizing interactions in fine magnetic particle systems using first order reversal curves. J. Appl. Phys. 85, 6660–6667 (1999).

Brandt, R. et al. Size-dependent magnetization switching characteristics and spin wave modes of FePt nanostructures. J. Appl. Phys. 113, 203910 (2013).

Acknowledgements

Work at UCD was supported by the National Science Foundation DMR-1008791 (D.A.G.) and ECCS-1611424 (K.L.). The magnetism aspect of this research at UCSD was supported by DOE Grant No. DE-FG02-87ER-45332 and the oxide related research by AFOSR Grant No. FA9550-12-1-0381. J.T. and I.K.S. thank B. Dodrill for his extensive measurements and interactions. J.T. acknowledges the support from the Fundación Ramón Areces (Spain). D.A.G. acknowledges support from the National Research Council Research Associateship Program. J.G.R. acknowledges the support from FAPA program through Facultad de Ciencias and Vicerrectoria de Investigaciones of Universidad de los Andes, Bogotá Colombia and Colciencias under contracts 120471250659 and 120424054303.

Author information

Authors and Affiliations

Contributions

The samples were fabricated by J.G.R., J.V. and I.K.S. X-ray measurements and analysis were performed by T.S., J.V. and I.K.S. FMR measurements and microscopy were performed by J.G.R., J.V. and I.K.S. Magnetic characterization and FORC measurements were performed by D.A.G. and K.L. D.A.G., J.V. and K.L. wrote the first draft of the manuscript. All authors contributed to discussions and manuscript revision. J.V. coordinated the project.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gilbert, D.A., Ramírez, J.G., Saerbeck, T. et al. Growth-Induced In-Plane Uniaxial Anisotropy in V2O3/Ni Films. Sci Rep 7, 13471 (2017). https://doi.org/10.1038/s41598-017-12690-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-12690-z

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.