Abstract

A search for new phosphor materials that exhibit high light-emission, spectral purity, long-time stability and processability capture particular attention to modern solid-state lighting. Here, polymerizable silane pre-functionalized carbon dot (SiCD) fluids were dripped and co-polymerized or completely bulk polymerized to build color conversion and encapsulation coatings of commercially available GaN blue LEDs. Most parameters of SiCD-based white LEDs were similar to or even better than those of phosphor-based white LEDs, particularly the insensitivity to excitation wavelength and working current. Thus, SiCDs were superior to those phosphors in terms of broadband properties, high transparency (no light blocking and leaking), as well as arbitrary doping of its content as color conversion and encapsulation layers simultaneously, unique solubility, flexible chemical, optical and mechanical processability. Thus, designing new CD-based white LEDs, instead of inorganic rare earth phosphor-based LEDs, is possible for better performance solid state lighting devices.

Similar content being viewed by others

Introduction

The development of white and full-color light-emitting technology is significant for display and lighting. Among them, light-emitting diodes (LEDs) have dominated lighting study and market share because of their energy efficiency, long-lifetime, reliability, and wide application range, such as in LED-based solid-state lighting1. In general, commercial white LEDs (WLEDs) are generated by combining a blue LED (2014 Nobel Prize in Physics) with a color conversion layer (CCL) such as yellow phosphors for dichromatic (yellow & blue) WLED, and recently, red and green phosphors for trichromatic (red, green & blue) WLED, to realize a high color rendering index (CRI) Ra and color tuning. However, today’s traditional phosphors, delivering up to 150–230 lm/W luminous efficiency LEDs1, rely solely on using combinations of rare-earth ions. The use of most of these rare-earth based phosphors is restricted by some intrinsic optical defect (relatively low color quality, light blocking and light leakage for microscale phosphors, and performance degradation for nanoscale phosphors), limited and hard preparation conditions (>1200 °C), high cost, toxicity and pollution in mining and refining, as well as requirement of international export and limited resource of rare-earth materials2,3,4,5.

Accordingly, a key and challenging assignments essential to modern solid-state lighting is searching for new CCL phosphor materials that exhibit high emission quantum yields (QY), spectral purity, long-term photo-stability, and long-term thermal-stability and good processability as well as breakup of monopoly to6,7,8,9,10,11. Since the same year (1996) of founding of blue LED and WLED, many efforts have been devoted to developing new CCLs, such as photoluminescent (PL) organic and polymers2,3,4,5, quantum dots (QDs)6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24, and carbon dots (CDs)25,26,27,28,29,30,31,32,33 for WLED applications. Organopolymer CCLs have already attracted significant interest thanks to their broad absorption & emission, moderate price, and ease of fabrication, but concerns over their stability. Recently, Bae et al. reported dye-bridged nanohybrid CCLs5, in which red and green-emitting silane-functionalized dyes were covalently linked to functional oligosiloxane. So, trichromatic nanohybrids exhibit broad color tunability and high CRI for white LED. However, four silane-functionalized dyes and organic compounds are also required by this system.

Since their inception 20 years ago, electrically driven QD-LEDs in which QD is used as an electroluminescence layer (ELL), have increased in external quantum efficiency from < 0.01% to 20.5%7,8. Consequently, many efforts have been focused on the same QD materials used as CCLs3,4,5,6. For the above-mentioned two applications, one challenge is the reduction of the toxicity of QDs considering that most successful examples are cadmium-based. Hence, developing other possible candidates is needed, such as InP, ZnTe QDs or VI QD (silicon QDs21,22,23,24, CDs25,26,27,28,29,30,31,32,33,34, etc.), most of them suffer from relatively low stability and moderate QY11. Another important challenge is the compatibility of QDs with encapsulation matrix typically used in the LED industry10,11,12,13,14,15,16,17,18,19,20,21,22,23,24. To solve this problem, which could lead to surface defects and aggregation, QDs must have an appropriate surface encapsulating modification and protecting shells so QDs will be dispersed in encapsulation silicone resin without any deterioration of stability, PL and other optical properties13,14,15,16,17. These steps can risk losing the high performance and doping concentration of QDs, which are critical factors in many applications13,35. In addition, all of these abovemetioned CCL materials are less green and environmental or stablity.

As the latest form of carbon nanomaterials and novel green QDs, CDs is a promising alternative to conventional organic dyes, QDs, and rare-earth materials in terms of chemical inertness, excellent photostability, simple synthesis, low cost, eco-friendliness, and very easy surface functionalization35,36,37,38,39. CDs can be prepared in a large amount with low cost and under moderate preparation conditions by decomposing of rich-carbon organics, natural matter, or abundant raw materials. Furthermore, the size and molecular weight of CDs is small and controllable. Some of them even show size-quantization effect in recently reports40,41,42,43,44,45. They can also be easily surface functionalized by various functional groups and imparted with excellent suitability and solubility for subsequent functionalization with various units. Thus, CDs can be used in a wide-ranging technologies, but tangible applications was not achieved expect for the potential bioimaging and sensor since their discovery in 200440.

Among them, the performance of CDs is superior in terms of excellent luminescence such as remarkable photostability and chemical stability, high luminescent efficiency, as well as the broadly adjustable spectrum of absorption, excitation and emission. CDs can simultaneously act as donors and acceptors show a slow “thermal” carrier relaxation, and can easily form effective electron transferring, contributing to their optoelectronic conversation and photocatalysis. To date, a few studies have been performed and a proof-of-concept has demonstrated that CDs could achieve white46,47 and multicolor40,41,42,43,44,45 light emission and be used as an active material in optoelectronic devices, such as ELL of OLED25,26,27,28, and CCL of InGaN LED28,29,30,31,32,33,34. We have accomplished direct white-light emission based on CDs’ PL under laser excitation46 and WLED devices based on CDs’ EL, but very high operation voltage is required to obtain reasonable brightness25. Chen28 and Lau32,33 et al. reported CD-based LEDs showing limited absorption in deep-blue (260–300 nm) region. Thus, InGaN blue LEDs with wavelengths between 450 and 460 nm, which are the most commonly used and cost-effective base LEDs, cannot be effective. Furthermore, the performance of CD-based LEDs significantly limits because aggregation of solid-state CDs typically leads to serious PL quenching31. Therefore, a better understanding of CDs must be gained to guide the design and optimization of their use in lighting devices34.

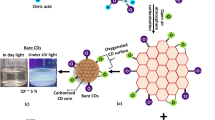

Recently, we have designed and developed a simple method, i.e., one-pot pyrolysis method, for preparing organic pre-functionalized CDs. Especially, silane functionalized CD (SiCD)35,48, the first silane pre-functionalized, completely polymerizable nanomaterial and inorganic material, could be bulk self-polymerized or hybrid copolymerized with silanes to form many environmental stable, transparent, and highly luminescent nanohybrid solid Ormosil structures (nanospheres, films, coatings, xerogel glasses, aerogels, and fibers). Stable covalent connection at the molecular level and arbitrary doping (0%–100% scale) of SiCDs in solid nanohybrids could be achieved, and these properties could be easily modulated. These SiCD-based materials prove to be useful in many technologies35,48,49,50,51,52,53,54,55,56,57,58,59,60, such as bioimaging, laser, solar cell, optical limiting, sensors, photocatalyst, etc. Given that they exhibit surprisingly high PL performance and relatively high QY (55% for SiCD, 88% for SiCD gel glass35, and 68% for SiCD-epoxy composite53), these materials should be an excellent CCLs. In this study, we fabricated white LEDs (SiCD-WLEDs) using polymerized SiCDs as CCL and encapsulation layer. Compared with the two types of material layers (conventional mixture of a phosphor and polymer matrix), SiCDs were a one-component system. This system could only be drip-coated on bare GaN blue LEDs and subsequently cured to SiCD nanohybrids by thermal polymerization at a modest temperature (<100 °C or room temperature) without adding any curing reagent and catalyst. White, blue, green, yellow, and orange LEDs could be achieved and simply modulated by changing preparation condition as well as doping ratios and amount of coated SiCDs (Figs 1 and 2). It is more important that the SiCD nanohybrids coating exhibit broad color tunability and high CRI for white emission from GaN blue LED. Luminous efficiency was 79.4 lm/W at 350 mA, which was much higher than those of previous best efficacy of organopolymers, QDs or CDs based light-conversion WLEDs, and near that of yellow phosphor based light-conversion WLEDs.

Results

Preparation of SiCD based WLED

SiCDs materials were prepared using a modified method reported in literature35. SiCDs 1–4 (see Figure S1) were utilized as a light-conversion material for WLEDs excited by commercial blue GaN-based LEDs. A few of drops of SiCDs or SiCDs and organosilane (same as the sample shown in scheme 1) were dripped onto a commercially available blue GaN LED chip (peak emission of ~450 nm) using a transfer liquid gun. SiCDs are tended to hydrolyze and condense to complete bulk polymerization catalyzed by heating and/or trace water in airs35. After self- or co-polymerization (with silane) of SiCDs were completed by elevated temperature (80 °C for 2 h, 100 °C for 1 h) or room temperature (6 h) without adding any curing reagent and catalyst, a layer of polymerized SiCDs was formed on LED surface. White light was obtained by mixing the transmitting blue light from the blue LED and yellow-green light emitting from SiCDs excited by a blue LED. Figure 2(a) and (b) show SiCDs and blue GaN based LED device, respectively. From the top view, almost the same visibility of LED chip in SiCD-WLED and blue LED shows excellent light transmittance performance of SiCDs polymerized hybrid coatings. Phosphor WLED device in Fig. 2(c), which LED chip coated with yellow phosphors, has strong light blocking and light leaking for microscale phosphors. The corresponding EL photograph of SiCD-WLED and phosphor WLED at 350 mA is shown in Fig. 2(d) and (f), respectively. True color badge shows good color rendering performance of SiCD-WLED. Figure 2(e) shows the EL photograph of a blue GaN-based LED device at 350 mA with poor color rendering performance. Thus, SiCD-WLEDs could produce warm white light, and SiCDs are superior to those phosphors for high transparency, and absence of light blocking and leakage. As a contrast, a yellow phosphor based light-conversion WLED was prepared by conventional coating and encapsulation process.

The performance of SiCD-WLEDs

The corresponding EL spectra of SiCD-WLED are shown in Fig. 3, with emission peaks of blue LED chip and SiCD hybrid coatings were located at 460 and ~550 nm, respectively. The current-voltage (I-V) curves of SiCDs white and blue LED overlapped are shown in Figure S3. SiCDs had no negative effect on the electrical property of LEDs. After coating SiCDs, the intensity of the blue light weakened, accompanied by the presence of a broad band emitting light peaking at ~550 nm (Full width at half maximum = 94–111 nm, FWHM), which mixed with 460 nm LED blue light to obtain white light. The applied voltage and current for LEDs were 3.1 V and 350 mA (working parameters of commercially available GaN LEDs), respectively. By tuning growth parameters of the SiCDs, highly sought white LEDs with Commission International d’Eclairage (CIE) chromaticity coordinates ((0.24, 0.28)-(0.31, 0.43)) for solid-state lighting were obtained. Clearly, with a SiCD layer, CIE of blue LED demonstrated that SiCDs can convert blue light into white light. The best luminous efficiency of SiCD-LED gave 79.4 lm/W at 350 mA, which was much higher than that of the previous best efficacy of organopolymers (23.7 lm/W at 10 mA)5, QDs (47 lm/W at 60 mA)14 or CDs (42 lm/W at 20 mA)33 based light-conversion WLED, and close to that of yellow phosphor based light-conversion WLED (130–230 lm/W at 350 mA)1. This finding could be due to silane in situ pre-functionalization, covalent connection and dispersion at the chemical molecular level, completely preventable agglomeration and movement of high PL SiCDs35,61.

EL spectra of WLEDs. (a) Absolute EL spectra of WLEDs based on phosphor and SiCD 1–4 prepared by different silanes; (b) Absolute EL spectra of WLEDs based on SiCD 1a–1i with different preparation conditions (carbon source ratio and pyrolysis reaction time as shown in Table 1).

The control parameters SiCD-WLED

As shown in Fig. 3 and Table 1, absolute EL spectra of encapsulated SiCDs-WLEDs were measured with an integrating sphere and precise rapid spectral radiometer according to the industrial standard. Emission peaks of SiCD 1–4 are located at 541–549 nm. SiCD-WLED and phosphor WLED had color coordinates of (0.3025, 0.4028), (0.3028, 0.4157), (0.3454, 0.4657), and (0.3306, 0.3620) in CIE 1931 color space, respectively. The color temperature (Tc) is measured as 6228, 4455, 6432, 5223, and 5579 K, and the CRI is 71.4, 68.3, 72.6, 61.5, and 70.8. Luminous efficiency is 70.93, 73.39, 79.39, 50.88 and 108.86 lm/W. Thus, broad FWHM (111 nm), luminous efficiency, and light-emitting intensity of SiCD-LEDs were all in the same order of magnitude as phosphor-based WLEDs. All parameters demonstrated that SiCD 3-based WLED had the best performance. This could be due the ability of SiCD 3 to more faster condense into a gel with greater crosslinking because SiCD 3 contained more methoxysilyl groups than 1, as well as the quicker reaction rate of methoxysilyl groups of SiCD 3 than ethoxylsilyl groups of SiCD 2 and 4 (see Scheme S1).

SiCD-LEDs could be achieved and simply modulated by changing the preparation conditions. As the pyrolysis time of SiCD was increased from 1 to 60 min, the color of SiCD and corresponding CD-LED coatings changed, the absorption and emission (PL excited by 360 nm UV light and 459 nm LED as shown in Table 1 and Fig. 3b) shifted to longer wavelengths, QYs and luminous efficiency decreased. From the EL spectra (Fig. 3b and Table 1), the intensity of 1d white LED was found to be the highest in this series. Luminous efficiency of SiCD 1d WLED is 70.93 lm/W. Emission peaks of SiCD 1a–1i were located at 541–549 nm. The emitting light of SiCD 1d had a large light-emitting region from 485 nm to 700 nm and broad FWHM (101 nm). Color coordinates of SiCD-WLED were shown in CIE 1931 color space (Figure S5). SiCD 1d WLED has a CIE coordinate of (0.2819, 0.3523). Color temperature was measured as 6228 K, corresponding with cool white light, and CRI (Ra) was 69.1. True color badge showed the good CRI of SiCD 1d WLED.

The SiCD emission performance excited by GaN blue LED can be tuned by adjusting the amount of SiCDs as shown in Figure S2. With the increasing of self-polymerized SiCDs coating amount, emission peak intensity relatively increased and emission peak position red-shifted from 535 nm to 539 nm. This red-shift may originate from the self-absorption of SiCDs. Aparts from self-polymerization, SiCDs could polycondense with silanes and silicone. The loading fraction of SiCDs can be easily controlled from 0% to 100% by changing the ratio of SiCDs to silane, and properties of as-obtained SiCD-WLED could be accordingly modulated. As the loading fraction of SiCDs decreased, the following changes were observed. The color of SiCD-based LED under nature light changed from reddish brown to colorless. Luminous efficiency and intensity decreased, and spectra shifted toward longer wavelengths (Fig. 4 and Table 1). SiCD coatings with a high loading fraction (>55 wt %) showed higher luminous efficiency and greater WLED performance.

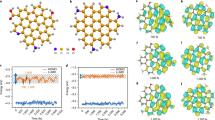

Arbitrarily doped SiCDs. (a) Optical photographs of a series of arbitrarily doped (0–100 wt% scale) SiCDs upon visible light (top), 365 nm (middle) UV and 254 nm (bottom) UV light illuminations. (b) EL spectra of SiCD white LEDs under various doping volume fractions with methyltriethoxysilane (40–100 wt%). TEM images showing the distribution of SiCDs in coatings. (c) close to the edge of the film cross-section on TEM grid, and (d) an exemplary location at an inner point across the thickness of cross-section, as is repeated at other locations (scale bar = 5 and 2 nm).

Figure 4a shows that all SiCDs were amorphous liquid CD fluids and intermiscible with water, common solvents, and silanes. Thus, molecular level and arbitrarily doping (0–100% scale) of SiCDs in most solvent, copolymerized sol-gel Ormosil solid hybrid structures, and blended epoxy resin composites53 could be achieved. These properties of prepared solutions and composites could also be accordingly modulated. These solid structures were optically, thermally, and mechanically stable, as well as highly transparent (>80%) in the visible to near-IR region35. To study homogeneity and optical quality of produced layers, TEM studies of slides prepared by microtome cross-sectional cutting of SiCD polymerized hybrid coatings were conducted. TEM images taken at different positions of sample demonstrated the uniformity of SiCDs dispersed within host gel (see Fig. 4c,d)62. SiCDs were observed be spherical and uniformly distributed in gel without aggregation. As a result, agglomeration and phase separation of SiCDs, which commonly appeared in other most composites, are completely prevented. Resultant hybrids also offered sustained and even surpassed PL performance. SiCDs can be homogeneously dispersed in gel layer to avoid unnecessary optical absorption losses. Therefore, SiCDs had well compatibility (arbitrarily doping) with silicone and epoxy matrix typically used to fabricate CCLs in the LED industry.

EL spectra of SiCD-WLEDs under various forward currents are shown in Fig. 5a. Emission peaks of blue LED chip and SiCDs were located at 450 nm and 538 nm at 350 mA, respectively. Both blue and green-yellow emission intensities steadily increased with increased current, revealing that LEDs had stable light-conversion and color quality. The luminous efficiency of SiCD-WLEDs at different forward currents is shown in Fig. 5b. The luminous efficiency of SiCD WLED was 100.04 lm/W under 50 mA, whereas that of the blue LED was 20.05 lm/W. Although a slight decrease in luminous efficiency from 100.04 to 79.39 lm/W was observed when forward current increases from 50 mA to 350 mA, luminous efficiency of SiCD-WLED was higher than those of reported organopolymer5, QD14, and CD33-based LEDs. The light conversion (blue-to-SiCD emission) efficiency of SiCD white LED slowly decreased from 44.7% to 39.5% with increased current. The light conversion (blue-to-phosphor emission) efficiency of phosphor white LED were maintained from 72.6% to 72.5% with increased current. Results revealed that SiCD exhibited good light conversion stability compared with the recently reported QD-based WLED.

The CIE coordinates of LED (Figure S5) was changed from (0.2960, 0.4086) to (0.2949, 0.3879), and no obvious change of CIE coordinates was observed at different applied currents, indicating greater color stability of output light. Blue LEDs with the same parameters except wavelength were also used as exciting light sources. A 459.1 nm LED and a 445.1 nm LED were coated with the same amount of SiCDs. As shown in Figure S5, Tables S1 and S2, the peak wavelength of emission light was maintained at 539 nm. In short, within excited wavelength and various forward current ranges, energy conversion efficiency and peak wavelength of emission light were maintained.

Most importantly, after CD incorporation, most blue emission was absorbed by SiCDs and down-converted to green and yellow lights, thereby creating white-light emission from specific GaN based LEDs. If we assume that CD incorporation did not affect extraction efficiency from GaN structure, by integrating the spectra of a GaN LED and a SiCD-WLED in excitation (blue) and emission (green, red) areas, down-conversion quantum efficiency in SiCD-WLED would be 42.8%. This value very well agreed with our CDs’ QY. Figure S4 compares photographic images of blue and white emission from two different locations (region A and B after CDs incorporation) along the device. By analyzing emission spectrum, the CIE chromaticity coordinates for SiCD-WLED emission yielded values of x = 0.33 and y = 0.21. Color temperature was 5030 K, and CRI (Ra) was 74. Notably, the proximity of CDs to LED active blue-emitting region led to rather efficient optical pumping because of high “on-site” pumping intensity and increased optical path length of pumping photons in a diffusive nanoporous structure, as well as the superposition of all of RGB-emitting sources. This phenomenon should be contrasted to conventional solid-state lighting luminaire structures, wherein phosphors were typically placed in a separate space to the LED wafer, and were far away from the pump source, such as the inner surface of encapsulation cap.

Discussion

In summary, green and low-cost polymerizable SiCDs prepared by one-pot pre-functionalized method were used as the color conversion and encapsulation layer of commercially available GaN blue LED. In contrast to the conventional mixture of a phosphor and polymer matrix, SiCDs were individually polymerized one-component system, which was drip-coated and bulk polymerized on GaN LEDs. The SiCDs exhibit excellent light converting properties as compared to organopolymers, semiconductor-based QDs or other CDs, and are close to that of yellow phosphor based light-conversion WLED. The organic–inorganic hybrid siloxane component and covalently bridged structure of SiCDs hybrid coatings induced environmental stability, broad band PL, high transparency (no light blocking and light leakage), and arbitrary doping. Importantly, the performance of SiCD-LED could be controlled by coating amount, arbitrary doping concentration of SiCDs hybrid coatings, preparation conditions, surface functional groups, and types of SiCDs. Energy conversion efficiency and emission wavelength of SiCD-based LED were not insensitive to excitation wavelength and working current of blue GaN-based LEDs. These results demonstrate that a CD CCL with an appropriate structure will hope to replace phosphors color conversion and encapsulation layers simultaneously for LED applications. The unique and excellent solubility, flexible chemical and mechanical processability, nontoxic nature, arbitrary polymerization doping, easy surface- functionalization and hybridization63,64,65,66,67, as well as white-light emission from SiCDs will make this material promising for a wide range of optoelectronic devices.

Materials and Methods

Materials

The silanes were purchased from Aldrich and Beijing Shenda Fine Chemical Co. Ltd. Commercial YAG Phosphor (0911008) was purchased from Xiamen kemingda science and Technology Co., Ltd. The other reagents were obtained from the Chinese Reagent Corporation and were of analysis grade. All the reagents were used as received without further purification. The Blue LEDs with a size of 45 mil*45 mil and patterned sapphire substrate emitted blue light of about 459 nm were used as the exciting light sources. The LED chips were manufactured and supported by Shandong Inspur HuaGuang Optoelectronics CO., LTD.

Preparation of the SiCDs

10 mL organosilane (Figure S1) was placed into a 100 mL three-necked flask, and degassed with nitrogen for 15 minutes. Upon reaching the appropriate temperature, appropriate weight (Table 1) citric acid was quickly added to the solution under vigorous stirring, and then kept for 1–60 min under the temperature. The final products SiCD 1–4 were purified by precipitating with petroleum ether three times or using silica gel column chromatography.

Preparation of the SiCD-LEDs

About 5 µL SiCDs was dropped onto a blue LED chip fixed on a LED basal plate with a 20 µL pipette filler or transfer liquid gun. LEDs coated with SiCDs or/and methyltriethoxysilane were heated at 80 °C for 2 h in an oven or at room temperature for 6 h to solidify SiCDs. The LEDs were covered with semicircle PMMA caps. The gap between the LED and cap was filled with silicone resin. Then, LEDs were heated at 100 °C for 1 h to solidify the silicone resin. Phosphor based white LED was manufactured based on the same process.

Characterization

Fluorescence spectra were recorded using F-4500 fluorescence spectrophotometer. UV-Vis spectra were measured on UV-1601PC UV-visible spectrophotometer. Samples for scanning electron microscopy (SEM) were coated with gold and the energy dispersive X-ray spectroscopy were measured using Hitachi S-4300 field emission scanning electron microscope. Transmission electron microscopy (TEM) images were obtained from JEM 2100 F (Japan, JEOL) operating at 200 kV accelerating voltage. The absolute EL spectra of encapsulated SiCD-WLEDs were measured by a precise rapid spectral radiometer (EVERFINE HAAS-2000) with an integrating sphere according to the industrial standard. The LEDs were driven at rated current of 350 mA. All optical and electrical parameters were automatically calculated by the radiometer based on the absolute EL spectra.

References

Dollen, P. V., Pimputkar, S. & Speck, J. S. Let there be light-with gallium nitride: the 2014 Nobel Prize in Physics. Angew. Chem. Int. Ed. 53, 13978–13980 (2014).

Hide, F., Kozodoy, P., DenBaars, S. P. & Heeger, A. J. White light from InGaN/conjugated polymer hybrid light-emitting diodes. Appl. Phys. Lett. 70, 2664–2666 (1997).

Zhang, C. & Heeger, A. J. Gallium nitride/conjugated polymer hybrid light emitting diodes: Performance and lifetime. J. Appl. Phys. 84, 1579–1582 (1998).

Huyal, O., Koldemir, U., Ozel, T., Demir, H. V. & Tuncel, D. On the origin of high quality white light emission from a hybrid organic/inorganic light emitting diode using azide functionalized polyfluorene. J. Mater. Chem. 18, 3568–3574 (2008).

Kwak, S. Y., Yang, S. C., Kim, N. R., Kim, J. H. & Bae, B. S. Thermally Stable, Dye-bridged nanohybrid-based white light-emitting diodes. Adv. Mater. 23, 5767–5772 (2011).

Bourzac, K. Quantum dots go on display: adoption by TV makers could expand the market for light-emitting nanocrystals. Nature 493, 283 (2013).

Dai, X. et al. Solution-processed, high-performance light-emitting diodes based on quantum dots. Nature 515, 96–100 (2014).

Shirasaki, Y., Supran, G. J., Bawendi, M. G. & Bulović, V. Emergence of colloidal quantum-dot light-emitting technologies. Nature Photon. 7, 13–23 (2013).

Erdem, T. & Demir, H. V. Semiconductor nanocrystals as rare-earth alternatives. Nature Photon. 5, 126 (2011).

Demir, H. V. et al. Quantum dot integrated LEDs using photonic and excitonic color conversion. NanoToday 6, 632–647 (2011).

Tan, S. T., Sun, X. W., Demir, H. V. & DenBaars, S. P. Advances in the LED materials and architectures for energy-saving solid-state lighting toward lighting revolution. IEEE Photonics J. 4, 613–619 (2012).

Kim, S., Im, S. H. & Kim, S. W. Performance of light-emitting-diode based on quantum dots. Nanoscale 5, 5205–5214 (2013).

Jeong, S. et al. One-step preparation of strongly luminescent and highly loaded CdSe quantum dot-silica films. J. Phys. Chem. C 114, 14362–14368 (2010).

Jun, S., Lee, J. & Jang, E. Highly luminescent and photostable quantum dot-silica monolith and its application to light-emitting diodes. ACS Nano 6, 1472–1477 (2013).

Ziegler, J. et al. Silica-coated InP/ZnS nanocrystals as converter material in white LEDs. Adv. Mater. 20, 4068–4073 (2008).

Koole, R. et al. On the incorporation mechanism of hydrophobic quantum dots in silica spheres by a reverse microemulsion method. Chem. Mater. 20, 2503–2512 (2008).

Otto, T. et al. Colloidal nanocrystals embedded in macrocrystals: robustness, photostability, and color purity. Nano Lett. 12, 5348–5354 (2012).

Lee, J., Sundar, V. C., Heine, J. R., Bawendi, M. G. & Jensen, K. F. Full color emission from IIVI semiconductor quantum dot-polymer composites. Adv. Mater. 12, 1102–1105 (2000).

Wood, V. et al. Inkjet-printed quantum dot-polymer composites for full-color ac-driven displays. Adv. Mater. 21, 2151–2155 (2009).

Zou, W., Du, Z., Li, H. & Zhang, C. A transparent and luminescent epoxy nanocomposite containing CdSe QDs with amido group-functionalized ligands. J. Mater. Chem. 21, 13276–13282 (2011).

Maier-Flaig, F. et al. Multicolor silicon light emitting diodes (SiLEDs). Nano Lett. 13, 475–480 (2013).

Mastronardi, M. L. et al. Silicon nanocrystal oleds: effect of organic capping group on performance. Small 8, 3647–3654 (2012).

Cheng, K. Y., Anthony, R., Kortshagen, U. R. & Holmes, R. J. High-effciency silicon nanocrystal light-emitting devices. Nano Lett. 11, 1952–1956 (2011).

Cheng, K. Y., Anthony, R., Kortshagen, U. R. & Holmes, R. J. Hybrid silicon nanocrystal-organic light-emitting devices for infrared electroluminescence. Nano Lett. 10, 1154–1157 (2010).

Wang, F., Chen, Y. H., Liu, C. Y. & Ma, D. G. White light-emitting devices based on carbon dots’electroluminescence. Chem. Commun. 47, 3502 (2011).

Son, D. I. et al. Emissive ZnO-graphene quantum dots for white-light-emitting diodes. Nat. Nanotech. 7, 465–471 (2012).

Zhang, X. Y. et al. Color-switchable electroluminescence of carbon dot light-emitting diodes. ACS Nano 7, 11234–41 (2013).

Choi, H. et al. surface plasmon resonance of carbon dot-supported silver nanoparticles Versatility in polymer optoelectronic devices. Nat. Photon. 7, 732–738 (2013).

Guo, X., Wang, C. F., Yu, Z. Y., Chen, L. & Chen, S. Facile access to versatile fluorescent carbon dots toward light-emitting diodes. Chem. Commun. 48, 2692–2694 (2012).

Kwon, W. et al. Freestanding luminescent films of nitrogen-rich carbon nanodots toward large-scale phosphor-based white-light-emitting devices. Chem. Mater. 25, 1893–1899 (2013).

Kwon, W., Lee, G., Do, S., Joo, T. & Rhee, S. W. Size-controlled soft-template synthesis of carbon nanodots toward versatile photoactive materials. Small 10, 506–513 (2014).

Tang, L. B. et al. Deep ultraviolet photoluminescence of water-soluble self- passivated graphene quantum dots. ACS Nano 6, 5102–5110 (2012).

Luk, C. M. et al. An efficient and stable fluorescent graphene quantum dot-agar composite as a converting material in white light emitting diodes. J. Mater. Chem. 22, 22378–22381 (2012).

Li, X. M. et al. Intercrossed carbon nanorings with pure surface states as low-cost and environment-friendly phosphors for white-light-emitting diodes. Angew. Chem. Int. Ed. 54, 1759–1764 (2015).

Xie, Z., Wang, F. & Liu, C. Organic-inorganic hybrid functional carbon dot gel glass. Adv. Mater. 24, 1716–1721 (2012).

Baker, S. N. & Baker, G. A. Luminescent carbon nanodots: emergent nanolights. Angew. Chem. Int. Ed. 49, 6726–6744 (2010).

Li, H., Kang, Z., Liu, Y. & Lee, S. T. Carbon nanodots: synthesis, properties and applications. J. Mater. Chem. 22, 24230–24253 (2012).

Ding, C., Zhu, A. & Tian, Y. Functional surface engineering of C-dots for fluorescent biosensing and in vivo bioimaging. Acc. Chem. Res. 42, 20–30 (2013).

Li, X., Rui, M., Song, J., Shen, Z. & Zeng, H. Carbon and graphene quantum dots for optoelectronic and energy devices: a review. Adv. Funct. Mater. 25, 4929–4947 (2015).

Xu, X. Y. et al. Electrophoretic analysis and purification of fluorescent single-walled carbon nanotube fragments. J. Am. Chem. Soc. 126, 12736–12737 (2004).

Wang, X., Qu, K., Xu, B., Ren, J. & Qu, X. Multicolor luminescent carbon nanoparticles: synthesis, supramolecular assembly with porphyrin, intrinsic peroxidase-like catalytic activity and applications. Nano Res. 4, 908–920 (2011).

Liu, H. P., Ye, T. & Mao, C. D. Fluorescent carbon nanoparticles derived from candle soot. Angew. Chem. Int. Ed. 46, 6473–6475 (2007).

Tetsuka, H. et al. Optically tunable amino-functionalized graphene quantum dots. Adv. Mater. 24, 5333–5338 (2012).

Bao, L., Liu, C., Zhang, Z. L. & Pang, D. W. Photoluminescence-tunable carbon nanodots: surface-state energy-gap tuning. Adv. Mater. 27, 1663–1667 (2015).

Hu, S., Trinchi, A., Atkin, P. & Cole, I. Tunable photoluminescence across the entire visible spectrum from carbon dots excited by white light. Angew. Chem. Int. Ed. 54, 2970–2974 (2015).

Wang, F., Kreiter, M., He, B., Pang, S. P. & Liu, C. Y. Synthesis of carbogenic quantum dots with direct white-light emitting. Chem. Commun. 46, 3309–3311 (2010).

Zhang, W. F., Tang, L. B., Yu, S. F. & Lau, S. P. Observation of white-light amplified spontaneous emission from carbon nanodots under laser excitation. Opt. Mater. Express 2, 490–495 (2012).

Wang, F., Xie, Z., Zhang, H., Liu, C. & Zhang, Y. Highly luminescent organosilane-functionalized carbon dots. Adv. Funct. Mater. 23, 1027–1031 (2011).

Mao, Y., Bao, Y., Han, D., Li, F. & Niu, L. Efficient one-pot synthesis of molecularly imprinted silica nanospheres embedded carbon dots for fluorescent dopamine optosensing. Biosens. Bioelectr 38, 55–60 (2012).

Chen, P. C., Chen, Y. N., Hsu, P. C., Shih, C. C. & Chang, H. T. Photoluminescent organosilane- functionalized carbon dots as temperature probes. Chem. Commun. 49, 1639–1641 (2012).

Quaranta, A. Highly fluorescent xerogels with entrapped carbon dots for organic scintillators. Thin Solid Films 553, 188–192 (2014).

Yan, F. et al. Highly photoluminescent carbon dots-based fluorescent chemosensors for sensitive and selective detection of mercury ions and application of imaging in living cells. Sens. Actu. B 192, 488–495 (2014).

Zhang, W. F. et al. Wide-bandwidth lasing from C-dots/epoxy nano-composite Fabry Perot cavities with ultralow threshold. J. Mater. Chem. C 2, 1525–1531 (2014).

Huang, J. J. et al. An easy approach of preparing strongly luminescent carbon dots and their polymer based composites for enhancing solar cell efficiency. Carbon 70, 190–198 (2014).

Wang, F., Xie, Z. & Liu, C. Mechanically strong and highly luminescent monolith by polymerization of carbon nanodots. New J. Chem. 38, 1601–1608 (2014).

Liu, X., Zhang, N., Bing, T. & Shangguan, D. Carbon dots based dual-emission silica nanoparticles as a ratiometric nanosensor for Cu2+. Anal. Chem. 86, 2289–2296 (2014).

Wang, Y. et al. Thickness-dependent full-color emission tunability in a flexible carbon dot ionogel. J. Phys. Chem. Lett. 5, 1412–1420 (2014).

Huang, Y. F. et al. One-pot synthesis of highly luminescent carbon quantum dots and their nontoxic ingestion by zebrafish for in vivo imaging. Chem. Eur. J. 20, 5640–5648 (2014).

Tang, J. et al. Solar-driven photoelectrochemical probing of nanodot/nanowire/cell interface. Nano Lett. 14, 2702 (2014).

Shih, C. C., Chen, P. C., Lin, G. L., Wang, C. W. & Chang, H. T. Optical and electrochemical applications of silicon-carbon dots/silicon dioxide nanocomposites. ACS Nano 9, 312–319 (2015).

Xie, Z., Wang, F. & Liu, C. Handbook of Functional Nanomaterials. Volume 4 Properties and Commercialization (Nova Sci Publishers, Inc., 2014).

Mutlugun, E. et al. Large-area (over 50 cm × 50 cm) freestanding films of colloidal InP/Zns quantum dots. Nano Lett. 12, 3986–3993 (2012).

Zhang, H. S. et al. Surface-Plasmon-Enhanced Gan-LED Based on A Multilayered M-Shaped Nano-Grating. Opt. Express 21, 13492–13501 (2013).

Zhu, J., Zhang, H. S., Zhu, Z. D., Li, Q. Q. & Jin, G. F. Surface-Plasmon-Enhanced Gan-LED Based on the Multilayered Rectangular Nano-Grating. Opt. Commun. 322, 66–72 (2014).

Song, J. et al. Quantum Dot Light-Emitting Diodes Based on Inorganic Perovskite Cesium Lead Halides (CsPbX3). Adv. Mater. 27, 7162–7167 (2015).

Li, X. et al. CsPbX3 Quantum Dots for Lighting and Displays: Room-Temperature Synthesis, Photoluminescence Superiorities, Underlying Origins and White Light-Emitting Diodes. Adv. Funct. Mater. 26, 2435–2445 (2016).

Li, J. et al. 50-Fold EQE Improvement up to 6.27% of Solution-Processed All-Inorganic Perovskite CsPbBr3 QLEDs via Surface Ligand Density Control. Adv. Mater. 29, 1603885 (2017).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC No. 21214002, 20904063, 51602168), 973 program (2009CB930500) and Natural Science Foundation of Qingdao (15-9-1-22-jch).

Author information

Authors and Affiliations

Contributions

X.Z. and H.X.P. conceived and designed the experiments and analyzed the data. X.Z. prepared and test SiCD and their polymerized coating. D.Q.Q. assisted with SiCD experiments. Y. Z.M. prepared and test the SiCD-WLED device. X.Z. and Y.Z.M. wrote the paper. H.X.P., W.Y.Z. and L.C.Y. directed the project and revised the manuscript. X. X.G. provided the chip and the test system of LED and WLED. All authors contributed to refining the paper.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xie, Z., Yin, Z., Wu, Y. et al. White Light-Emitting Diodes Based on Individual Polymerized Carbon Nanodots. Sci Rep 7, 12146 (2017). https://doi.org/10.1038/s41598-017-12083-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-12083-2

This article is cited by

-

Optimization of the Pechini-derived synthesis of rare-earth free aluminum borate phosphors presenting tunable white emission

Journal of Materials Science (2022)

-

White and yellow light emission from ZrO2:Dy3+ nanocrystals synthesized by a facile chemical technique

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.