Abstract

Growing III-V semiconductor materials on Si substrates for opto-electronic applications is challenging because their high lattice mismatch and different thermal expansion coefficients cause the epitaxial layers to have low quality. Here we report the growth of a high-quality AlN template on a micro-circle-patterned Si substrate by using NH3 pulsed-flow multilayer AlN growth and epitaxial lateral overgrowth techniques. Then, we fabricated and characterized a deep-ultraviolet light-emitting diode (UV-LED) device using this AlN/patterned Si. By using standard lithography and inductively coupled plasma etching, the Si substrate was prepared with very high pattern density and was made deep enough to grow a thick AlN template with high crystal quality and very few threading dislocations, allowing for further re-growth of the deep UV-LED device. And by combining a transparent p-AlGaN contact layer, an electron blocking layer and using this high quality AlN template: a deep UV-LED device fabricated and showed a strong single sharp electroluminescence (EL) peak at 325 nm and achieved an external quantum efficiency (EQE) of about 0.03%, for a deep UV-LED grown on Si substrate.

Similar content being viewed by others

Introduction

AlGaN-based deep UV-LEDs with emission wavelengths from 200 to 360 nm have many important applications in environmental, industrial, medical, and life sciences for water and air disinfection, sensing, medical curing, printing, counterfeit detection, and other areas1,2,3,4. To date, commercial deep UV-LEDs for the living environment, which have been developed on only expensive substrates such as sapphire, display very high EQE values (depending on the emission wavelength)1,5 due to improvements in the crystal quality, electron injection current, and light extraction efficiency as well as optimization of structures1,6,7,8. However, developing deep UV-LEDs based on Si substrates is challenging: the growth of the AlN template, which is necessary to include as a layer on the Si substrate, generally suffers from cracking due to the different thermal expansion coefficients of Si and AlN. Moreover, AlN/Si contains a high threading dislocation density due to the large lattice mismatch between the AlN and Si components9,10,11. Although we have been able to grow a crack-free AlN template on a flat Si substrate layer with thickness of less than 1 µm, it has not been possible to obtain a high crystal quality and low threading dislocation density simultaneously for such a thin AlN template. Therefore, the best choice has been to use a patterned Si substrate since a thick AlN template with a high crystal quality can be grown on this type of substrate, and recently a few groups have obtained very good results in this regard, and such a process could be used to further develop deep UV-LEDs12,13,14. For these reasons, and because Si substrates are inexpensive, show good thermal conductivity and are available in very large sizes and possibility of integrating LEDs on Si devices;15,16 the development of deep UV-LEDs based on Si substrates shows considerable promise.

The greatest remaining challenge for the development of deep UV-LEDs on Si substrates, however, may be its low light extraction efficiency17, which is due to several factors. One factor is the unique optical polarization properties of the spontaneous emission from the active layer, i.e., AlGaN multi-quantum wells (MQWs) emit light with transverse-magnetic polarization along the direction normal to the surface, leading to the low efficiency. Note that the emission of TM-polarized light from the AlGaN MQWs is significantly dependent on the amount of Al in the MQWs17,18,19. The second reason is the different reflective indexes of the p-type layer to the p-metal electrode on the front side and the LEDs to the air on the back side emission. A third reason may be that the p-GaN typically used for the contact layer strongly absorbs the light emitted from the AlGaN MQWs, resulting in low light extraction from the surface18,20,21. For these reasons, there have been very few reports about the development of deep UV-LEDs on Si substrates with high quantum efficiency and wavelengths shorter than 350 nm, which requires high Al content.

In this paper, we report on the growth, fabrication, and characterization of a deep UV-LED on patterned Si substrate with an emission wavelength belongs to UVA. The metal–organic chemical vapor deposition reactor (MOCVD) grows an AlN template on a micro-circle-patterned Si substrate (mPSiS) by using a combination of NH3 pulsed-flow multilayer AlN growth and epitaxial lateral overgrowth techniques. The details of pattern fabrication and growth methods can be found somewhere14,22. The AlN template was then placed in another MOCVD reactor to regrow a deep UV-LED structure and fabricate a device with an emission wavelength of 325 nm and high EQE.

Results and Discussion

Figure 1 shows XRD FWHM rocking curves of an 8-µm-thick AlN template grown on a micro-circle-patterned Si substrate at 1380 °C. The FWHM values of the XRD peaks corresponding to the (002) and (102) reflection planes were measured to be 620 arcsec and 1141 arcsec, respectively. These values are, to our knowledge, the lowest reported (002) and (102) FWHM values for an AlN grown on a Si substrate. These low values may have been due to the high pattern density with a small edge-to-edge distance of the patterns22. Thus, the quality of this AlN crystal was greatly improved, by about 25%, compared with that in our previously report14 and much lower than the crystal quality in other current reports10,12,23,24.

XRD rocking curve of the AlN template grown on a micro-circle-patterned Si substrate with FWHM values of 620 arcsec (002) and 1141 arcsec (102) reflection planes. As we mentioned in the introduction; Hence, the sample used to carry out the fabrication and measurement for this paper is also the sample that was used in the Ref.14.

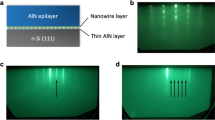

To determine the coalescence thickness as well as the threading dislocation density of the AlN template grown on the mPSiS, we first used a focused ion beam technique to cut the sample as shown in Fig. 2 A According to the cross-sectional SEM image, coalescence began at the end of the third AlN layer, and the fourth and fifth (i.e., last) layers were completely coalesced without any voids inside. These completely coalesced layers were also observed to be very thick (i.e., more than 3.0 µm). This result indicates that the XRD FWHM of this AlN template was an excellent achievement. The effect of AlN quality on the UV-LEDs performance can be found somewhere14,22.

(A) Cross-sectional SEM image of the AlN template taken after using focused ion beam processing. A thick completely coalesced on the top of the AlN template can be seen (where the fifth AlN layer started to grow). (B-D) Corresponding TEM images revealed many dislocations near the bottom of the AlN template, but almost none on the top. They are very similar to the results of Ref.14 since we took them at a nearby position.

Cross-sectional TEM images of the AlN/patterned Si substrate were taken with g = < 11–20 > and showed the dislocation densities to be different in different regions of the sample. Many dislocations were observed in the bottom of the template (Fig. 2 D), although fewer in its middle (Fig. 2 C) where some dislocations terminated and most of them could not reach the surface. Therefore, very few dislocations were seen in fifth (top) layer of the AlN template (Fig. 2 B). As estimated results, the dislocation densities were estimated to be about 5 × 107 cm−2 (screw) and 7.5 × 107 cm−2 (edge) in the top region, and on around the order of 109 cm−2 in the middle and bottom regions.

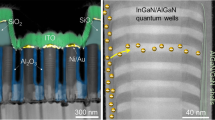

The AlN/patterned-Si substrate was then used to grow and fabricated into a deep UV-LED device, with the schematic of this device shown in Fig. 3. First, we loaded the substrate into another MOCVD reactor to grow the deep UV-LED structure with an approximate 1.3 µm n-Al0.6Ga0.4N layer by doping Si, and then a three-undoped Al0.2Ga0.8N/Al0.7Ga0.3N MQWs/barriers layer was continuously grown with about 2 nm and 6 nm for each well and barrier layer, respectively. A 25 nm p-Al0.95Ga0.05N layer doped with Mg was used as an electron-blocking layer (EBL), and finally, an approximately 100 nm transparent p-Al0.7Ga0.3N layer was grown on the top for the contact layer with the p-type doping concentration to be expected at about 1016/cm3. All these layers were grown using a low-pressure MOCVD reactor with detailed growth conditions are listed in Table 1. The p-AlGaN contact layer was grown at 1150 °C, and the other layers at 1200 °C. The growth pressure is kept in constant for all layers at 76 Torr. After the growth, the sample was heated at 850 °C in a N2 atmosphere for 50 min. Ni/Au metal and In balls were then used as p- and n-contact electrodes, respectively. The thickness of the Ni and Au components of the p-electrode were about 15 nm and 25 nm, respectively, and the final device is shown in the inset of Fig. 4. The transparent p-AlGaN layer was one of keys contributor to improving the light extraction efficiency of the deep UV-LED. The transmittance of the p-AlGaN with about 70% Al composition has been carried out6 and found that transmittance ratio exceeded 95% for the wavelength range from 250 nm to 400 nm.

The electroluminescence spectrum was measured at room temperature under CW operation and various current injections. A single sharp peak without any shoulders was observed at a wavelength of 325 nm. The inset figure is the deep UV-LED device which was grown and fabricated on Si substrate and used to measure and present the data in this work.

An electroluminescence spectrum was acquired at room temperature under continuous-wave (CW) operation with a Si photodetector to measure the output power. Before acquiring the spectrum, the system was calibrated by measuring the luminous flux from an LED source by using an integrating sphere system. Figure 4 shows the electroluminescence spectrum of the deep UV-LED grown on the AlN/patterned Si substrate at 1200 °C for the bare wafer condition (see the inset of Fig. 4) with a single sharp peak at 325 nm was clearly obtained under different currents. The EL emission during the measurement is shown in the supplementary information. We provided that supplementary information because the EL spectrum of a deep UV-LED device identical to our current device but using p-GaN instead of p-AlGaN for the contact layer did not show this peak. (Perhaps the p-GaN layer, because it absorbs light, yielded a light extraction efficiency too low to be observed in its EL spectrum). The output power at room temperature was also measured under CW mode and is shown in the inset of Fig. 5. The deep UV-LED wafer was placed into a calibrated system and its output power was measured by using an optical meter. A low output power was measured at an injection current of 500 mA and plotted in the inset of Fig. 5. In particular, an EQE of 0.03% was achieved, the highest value for a deep UV-LED grown on a Si substrate at the recorded wavelength of 325 nm. This EQE value is considered to be very high for deep UV-LED/Si since this value is many times higher than the latest reported value (but at different emission wavelength)25. It is, however, much lower than that of deep UV-LED/sapphire, because the Si substrate is a black body and hence completely absorbs incident light, resulting in the light extraction efficiency from the front emission being very low. The low output power was also due to the p-electrode being blocked off and the UV light being extracted from only the narrow edge of the p-electrode. Thus, removing the Si substrate to realize emission from the back side is expected to increase the light extraction efficiency and output power significantly12,26.

Conclusions

In summary, we have produced a 325-nm-wavelength AlGaN-based deep UV-LED, which was grown on a micro-circle-patterned Si substrate for the first time, with AlN template XRD FWHM rocking curves of 620 and 1141 arcsec for the (002) and (102) reflection planes, respectively. The high crystal quality of the AlN template with its very low dislocation density and absence of cracks proved that using the NH3 pulsed-flow multilayer AlN growth and epitaxial lateral overgrowth techniques with multiple growth steps could improve the quality of the AlN template significantly. The successful growth and fabrication of the deep UV-LED on the micro-circle-patterned Si substrate also demonstrated the benefit of the high crystal quality of the AlN template with a very high EQE proved. The EQE value reported here, while very lower than that of deep UV-LEDs grown on sapphire substrates, nevertheless proved that it is possible to fabricate deep UV-LEDs grown on Si substrates, and this result provides a strong motivation to improve the device performance of deep UV-LEDs on low-cost Si substrates.

Methods

The deep UV-LED device was developed using an AlGaN alloy and grown on an AlN/patterned Si substrate. MOCVD was carried out in a low-pressure reactor and trimethylaluminum, trimethylgallium, and ammonia were used as sources of Al, Ga, and N, respectively. Si and Cp3Mg were for n- and p-type doping. The thick AlN template (about 8 µm thick) included 5 sub-AlN layers grown at 1380 °C. The first thin AlN layer was grown as an interlayer between the upper layers and the patterned Si substrate. This layer was grown for 10 min at 200 Torr. The second layer was grown for 11 min at 76 Torr. The second, third, fourth, and fifth AlN layers were grown at the same pressure in order to obtain coalescence at the end of the third layer. The third, fourth, and fifth AlN layers were grown for 60, 8, and 60 min, respectively. The fourth layer was used to reduce the threading dislocation density of the fifth layer, and was also coalesced to serve as the main layer of the AlN template. The first, second, and fourth AlN layers were grown using the NH3 pulsed-flow multilayer AlN growth technique; meanwhile, the third and fifth AlN layers were grown using the epitaxial lateral overgrowth technique. To evaluate the crystal quality of the AlN template, X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) were carried out to determine the XRD full width at half-maximum (FWHM), coalescence thickness, and threading dislocation density, respectively.

References

Hirayama, H. et al. Recent progress in AlGaN-Based deep-UV LEDs. Electr. Commun. Jpn 98, 1–8 (2015).

Hirayama, H. et al. Development of 230–270 nm AlGaN-based deep-UV LEDs. Electr. Commun. Jpn 93, 24–33 (2010).

Hirayama, H. et al. Remarkable enhancement of 254-280 nm deep ultraviolet emission from AlGaN quantum wells by using high-quality AlN buffer on sapphire. Phys. Status Solidi (C) 5, 2283–2285 (2008).

Hirayama, H. et al. 222–282 nm AlGaN and InAlGaN-based deep-UV LEDs fabricated on high-quality AlN on sapphire. Phys. Status Solidi (A) 206, 1176–1182 (2009).

Khan, A. et al. Ultraviolet light-emitting diodes based on group three nitrides. Nat. Photonics 2, 77–84 (2008).

Jo, M. et al. Enhanced light extraction in 260 nm light-emitting diode with a highly transparent p-AlGaN layer. Appl. Phys. Express 9, 012102 (2016).

Akiba, M. et al. Growth of flat p-GaN contact layer by pulse flow method for high light-extraction AlGaN deep-UV LEDs with Al-based electrode. Phys. Status Solidi (C) 9, 806–809 (2012).

Lee, K. H. et al. Light-extraction efficiency control in AlGaN-based deep-ultraviolet flip-chip light-emitting diodes: a comparison to InGaN-based visible flip-chip light-emitting diodes. Opt. Express 23, 20340–20349 (2015).

Tran, B. T. et al. Growth of lattice-matched InAlN/GaN on Si (111) substrate for ultraviolet photodiode application. Electron. Mater. Lett. 9, 705–708 (2013).

Lin, K.-L. et al. Growth of GaN films on circle array patterned Si (111) substrates. J. Cryst. Growth 401, 648–651 (2014).

Tran, B. T. et al. Fabrication and characterization of n-In0.4Ga0.6N/p-Si solar cell. Sol. Energy Mater. Sol. Cells 102, 208–211 (2012).

Mino, T. et al. Realization of 256–278 nm AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes on Si Substrates Using Epitaxial Lateral Overgrowth AlN Templates. Appl. Phys. Express 4, 092104 (2011).

Fujikawa, S. et al. In Proceeding of the 22nd IEEE International Semiconductor Laser Conference; 26–30 September 2010; Palma de Mallorca Spain. Abstract 21–22. http://ieeexplore.ieee.org/document/5642771/.

Tran, B. T. et al. Performance improvement of AlN crystal quality grown on patterned Si (111) substrate for deep UV-LED applications. Sci. Rep. 6, 35681 (2016).

Takeuchi, T. et al. Growth of single crystalline GaN film on Si substrate using 3C-SiC as an intermediate layer. J. Cryst. Growth 115, 634–638 (1991).

Huang, J. J. Kuo, H.-C & Shen, S.-C. Nitride Semiconductor Light-Emitting Diodes (LEDs): Materials, Technologies and Applications (Woodhead Publishing Limited, Oxford, 2014).

Kneissl, M. & Jens, R. III-Nitride Ultraviolet Emitters: Technology and Applications (Springer, 2016).

Shakya, J. et al. Polarization of III-nitride blue and ultraviolet light-emitting diodes. Appl. Phys. Lett. 86, 091107 (2005).

Cao, N. et al. Surface-plasmon-enhanced deep-UV light emitting diodes based on AlGaN multi-quantum wells. Sci. Rep. 2, 816 (2012).

Kolbe, T. et al. Optical polarization characteristics of ultraviolet (In)(Al)GaN multiple quantum well light emitting diodes. Appl. Phys. Lett. 97, 171105 (2010).

Takafumi, Y. & Hong, S.-K. Oxide and Nitride Semiconductors: Processing, Properties, and Applications (Springer, 2009).

Tran, B. T. et al. Direct growth and controlled coalescence of thick AlN template on micro-circle patterned Si substrate. Sci. Rep. 5, 14734 (2015).

Zhang, J. X. et al. Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf. Coat. Technol. 198, 68–73 (2005).

Tamura, Y. et al. AlN Nanowall structures grown on Si (111) substrate by molecular beam epitaxy. Nanoscale Res. Lett. 10, 1–5 (2015).

Kent, T. F. et al. Deep ultraviolet emitting polarization induced nanowire light emitting diodes with AlxGa1-xN active regions. Nanotechnology 25, 455201 (2014).

Zhang, Y. et al. Near milliwatt power AlGaN-based ultraviolet light emitting diodes based on lateral epitaxial overgrowth of AlN on Si (111). Appl. Phys. Lett. 102, 011106 (2013).

Acknowledgements

The authors acknowledge funding support from RIKEN Institute for this work under the Foreign Postdoctoral Researcher Program.

Author information

Authors and Affiliations

Contributions

B.T.T. designed the experiments and contributed to growing samples, measurements, and data analysis. B.T.T. wrote the manuscript and H.H. supervised the project. All authors discussed the results and reviewed the manuscript before submission.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tran, B.T., Hirayama, H. Growth and Fabrication of High External Quantum Efficiency AlGaN-Based Deep Ultraviolet Light-Emitting Diode Grown on Pattern Si Substrate. Sci Rep 7, 12176 (2017). https://doi.org/10.1038/s41598-017-11757-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-11757-1

This article is cited by

-

Vertical semiconductor deep ultraviolet light emitting diodes on a nanowire-assisted aluminum nitride buffer layer

Scientific Reports (2022)

-

Nanophotonic crystals on unpolished sapphire substrates for deep-UV light-emitting diodes

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.