Abstract

The focus of this study is investigating the performance of graphene oxide (GO) in the protective effect of olive oil on Bacillus thuringiensis (Bt) after being exposed to UV radiations. Biological pesticides Bt subsp. Kurstaki is one of the most important biological control agents. We compared the protective effect of two UV protectant; GO and olive oil and also the combination of both, on the stability of the formulation of Bt after exposure to UV radiations. Spore viability was measured for protective effect and bioassay test was performed on the formulations of Bt. The combination of GO and olive oil revealed the highest viabilities of 50.62% after 96 h exposure to UV radiation, while viabilities of free spore, olive oil formulation and GO formulation were 32.54%, 37.19%,and 45.20%, respectively. The mortality of irradiated combination formulation on second-instar larvae Ephestia Kuehniella was 68.89%, while the same parameter for free spore, olive oil formulation and GO formulation were 40%, 46.66%,and 56%, respectively.

Similar content being viewed by others

Introduction

Nowadays the most chemical pesticides in agriculture are under stress to be eliminated from the market due to their harmful effects on the environment because people turn to biological pesticide use1. Bacillus thuringiensis (Bt) is the most common bacterial agent that is used for insect pest control2, which is a gram-positive and spore-forming bacteria. One of the disadvantages of biological pesticides is it’s low stability against natural factors such as UltraViolet (UV) radiation because the persistence of Bt crystal against insect pests are deactivated3. One way to prevail these disadvantages is to make the formulation of biopesticides by adding diverse UV protectants4. Nanotechnology is a novel technique which improves the stability of biopesticides against UV radiation by protecting the B.thuringiensis spores and crystals with the nanoparticle. Nanomaterials caused stable biological activity of the active agent in microbial pesticides and increased efficiency and the performance of their formulations.

GO, the two-dimensional (2D) nanoparticle with hydroxyl and epoxy bridge functional groups on the basal plane and carbonyl and carboxyl groups on the edges have obtained a quickly growing research interest5,6,7. These plentiful hydrophilic O-functional groups on the surfaces were beneficial in synthesizing in composites and maximizing the profit of the unique various properties8. In recent years graphene and graphene oxide (GO) were affirmed to be the ideal substrates for anchoring particles on their nanosheets’ surfaces, because of strong intermolecular bonding, high loading capacity, low surface energy and weak intermolecular bonding9.

Olive oil is a fat procured from the oil10. It’s authentication is based on the assessment of many parameters. Some of them are acidity, main fatty composition,and UV absorbance11. The UV protective effect of olive oil was determined by Jallouli12 as it has been shown, this is not the suitable property of olive oil.

In the present study, a nano-formulation of B. thuringiensis was prepared by Graphene oxide. The performance of graphene oxide in the protective effect of olive oil on Bt after exposure UV radiations was investigated. The effect of two UV protectant; GO and olive oil and the combined effect on the stability of formulations exposed to UV radiation were compared. The potency and spores viability of nano-formulation and non-nano-formulation were evaluated by the experimental methods in our laboratory.

Results

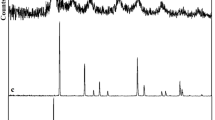

Assessment synthesis of GO

Figure 1 shows the XRD patterns of graphene oxide. Pristine graphite has a sharp diffraction peak at 26.34° which corresponds to a d-spacing of 0.334 nm13. This peak (002) has been disappeared after oxidation, while a peak at 10.79° was revealed which corresponds to a d-spacing of 0.85 nm and confirmed the successful preparation of GO14. An increased interlayer distance might be due to the formation of oxygen-containing functional groups, such as epoxy, hydroxyl, and carboxyl15, 16.

The morphology and structure of GO nanosheets were studied using FE-SEM which has been illustrated in Fig. 2. The image is clearly indicative that GO nanosheets have layered structures with wrinkles and folds on the surface of GO.

Figure 3 shows FT-IR spectra of GO. The graph illustrates the O-H group stretching vibrations at 3438 cm−1. The absorption band at 1729 and 1619cm−1 corresponding to C=O stretching carboxylic functional groups and aromatic C=C bond, respectively. The band at 1048 cm−1 is assigned to the C–O stretching vibrations17.

screening of UV protectant

Photoinactivation of Bt which is one of the main environmental factors affecting its resistance has been investigated18. Evaluation of two UV protectants effect revealed that combination of olive oil and GO (0.0125% w/v) offered a significant Bt protection. Then, among the different tested GO concentrations, 0.0125% w/v was the most effective protecting formulation of Bt (Fig. 4) and for SPSS analysis this concentration was applied.

Effect of UV radiations on spore count

In this study, the effect of UV-Radiation on the formulation of Bt was evaluated. As it can be seen in Table 1, the continuation of formulation’s exposure to UV radiations up to 96 h showed that spore count for free spore formulation of Bt, GO formulation, olive oil formulation and GO/olive oil formulation declined to 10.41 × 108, 14.46 × 108, 11.9 × 108,and 16.2 × 108 respectively. This is proportional to spore viability 32.54%, 45.20%, 37.19%, 50.62%. The results demonstrated that there was a significant difference between four Bt formulation at p = 0.05. Spores viability revealed that the GO/olive oil formulation has the highest protection of viability.

Effect of UV radiations on mortality against E. kuehniella larvae

The larval mortality of irradiated GO formulation, olive oil formulation, GO/olive oil formulation and free spore of Bt after 96 h exposure to UV-A radiation were 56%, 46.66%, 68.89%,and 40%, respectively. There was a significant difference between treatment with GO formulation, GO/olive oil formulation (irradiated/non-irradiated), and irradiated free spore in mortality (p = 0.0001), while there was no significant difference between olive oil with free spore of Bt. The combination formulation of GO/olive oil in 0.0125% w/v showed the highest performance in mortality of larvae (Fig. 5). Poszgay et al.19 concluded that exposure of Bt to 40 h of UV radiations resulted in the loss of activity. Jallouli12 showed that no protection was observed in the case of olive oil and spore count was not significantly different from those when compared to the negative control exposed UV radiations also its effect has been under 50% protection. Our results of mortality have demonstrated that there was not a significant difference between olive oil formulation and free spore formulation at p = 0.05 and earlier works have been confirmed. On the other hand, there was a significant difference between GO formulation and formulation of GO/olive oil with free spore formulations of Bt (p = 0.0001). It is concluded that GO nanosheets effectively protected the Bt against UV radiations.

Discussion

Since the 1990s of recent Bt strains and formulation, Bt products have advanced the development of Bt market by improvement in the insecticidal capabilities of the toxin. Bt has successfully replaced chemical pesticides for pest control in forestly20. Bt is a soil bacterium and it is the most widely used effective biological control agent in the world21. However, one of the main disadvantages is that the spores and insecticidal crystal proteins of Bt are vulnerable to degradation when exposed to ultraviolet radiation of sunlight under field condition22,23,24. Consequently, the utilization of Bt as a pesticide is more costly and finite compared to other alternatives due to the reduction of its biological activity.

It is generally believed that ultraviolet inactivation of the crystalline toxin is the significant source of the fast loss of Bt’s effectiveness12. Various materials and techniques have been checked as sunlight protectants to improve the Bt activity and prolong the efficacy of Bt pesticides in the environments such as the granular formulations, encapsulations,and addition of UV protectants25,26,27. Although this material can enhance the survival and persistence of efficacy of Bt formulations in the field they have some defects such as changeable, low shelf life, scant compatibility due to inhibition spore germination and microbial growth and wash off by the rain. So, for the choice of different adjuvants, it is needed to get necessary properties of Bt formulations28, 29.

Due to the rapid development of nanotechnology, it is crucial to understand how nanoparticles interact with living organism for biosafety reasons. The special chemical and physical properties of carbo-based nanomaterials define a broad range of options for practical applications and a range of studies have reported a positive impact of them on plant growth, exciting research on nanocarbon containing fertilizers30,31,32.

Antibacterial properties of GO were established to be dependent on the size of GO nanosheets; by enveloping bacterial cells, larger GO nanosheets can effectively isolate themselves from their environment and display stronger antibacterial activity as compared to small GO nanosheets33.

In this study, the effect of GO on the formulation of Bt with an attempt to increase its stability under UV-A radiation was examined. The GO was a UV absorbent as it was studied by Zhu34. It was shown that GO has an absorption at 335 nm and on the other hand, it has revealed a fluorescence about 440 nm. Therefore using GO in our combination formulation (GO + olive oil) resulted in UV-protectant (protection), and therefore the UV-protectant of olive oil was exclusively enhanced from 40% to 90%. This formulation has a competitive factor with other high protective agent such as molasses.

UV-A are measured to be the main part liable for inactivation of microbial pesticides. The sensitivity of Bt to UV radiations reduces its persistence in the environment. Diverse methods were used to increase the stability of biopesticides in field conditions.

The result showed that nanosheets GO could protect the formulation of Bt from UV-A and also it has an additive effect on the performance of olive oil as a protectant against UV radiation in Bt.

Methods

Materials

Natural graphite powders were purchased from Chem. Co. Fluka, sodium nitrate (NaNO3) potassium permanganate (KMnO4), concentrated sulfuric acid (H2SO495%, d = 1.98 g/mL), Triton X-100, hydrochloric acid (HCl 37%, d = 1.18 g/mL), methanol and nutrient agar were purchased from Merck Chem. Co. (Germany). Hydrogen peroxide (H2O2, 30 wt. % aqueous solution) was purchased from Mojallali, Iran. Deionized (DI) Water used throughout all experiments and was purified with the Millipore system. Extra virgin olive oil was obtained from Guillen (Spain).

Preparations of B. thuringiensis

B. thuringiensis subsp. Kurstaki KD-2 was obtained from the Iranian Research Institue of Plant Protection (Tehran, Iran). The suspension was centrifuged at 10000 rpm for 20 min and Spore Crystal Aggregate (SCA) was washed twice with distilled water and salt, that had been dried by lyophilisation and refrigerated at 4 °C35, 36.

Synthesis of GO

GO was synthesized from the natural graphite powders by modified Hummer’s method5, 37. In brief, 2.5 g of graphite powder, 57.5 mL of H2SO4 and 1.25 g of NaNO3 were mixed under a vigorous stirring condition in an ice bath for 30 min. Then, 7.5 g of KMnO4 was added gradually in the portion under stirring for 1 h and the temperature was kept at 35 °C. The reaction mixture was cooled in an ice bath and 115 mL of water was added slowly to the solution, then 350 mL water and 15 mL H2O2 were added to the suspension. The suspension turned bright yellow and was washed three times with HCl (3%, 76 mL) and seven times with DI water until neutrality. The suspension in water laminated into GO nanosheets by a titanium-alloy solid probe ultrasonicator (20 kHz, 400 W, Topsonic, Iran). Finally, the GO was obtained as a gray powder after freeze- drying38.

Preparation of nano-formulation by GO

A solution based on nano formulation by GO was prepared by dispersing 0.0125% of GO in water with ultrasonic vibration for 3 h. After, 0.20 g Bt and 0.05 g Triton X-100 was added and then shaked for 24 h in a dark place.

Preparation of olive oil formulation

A mixture of 0.2 g Bt and Triton X-100 was mixed in 10 mL olive oil and then placed on a shaker set for 24 h in a dark place.

Preparation of combination formulation by GO and olive oil

The different concentrations of GO solution (0, 0.00225, 0.00425, 0.00625, 0.0125, 0.025, 0.05, 0.075 and 0.1% w/v) were prepared by dispersed GO in water with ultrasonic vibration for 3 h, then 0.20 g of Bt and 0.05 g of Triton X-100 was added to the suspension. 10 mL of olive oil was added to the solution mentioned. The mixture was placed into a shaker set for 24 h in a dark place.

Characterization

Powder X-ray diffraction (XRD) patterns were measured on a Phillips X’Pert PRO using filtered Cu Kα radiation (λ = 1.54178 Å) in the range of 2θ = 10–80°. The surface morphology of graphene oxide was characterized by field emission-scanning electron microscopy(FE-SEM, Sigma, Zeiss) with an acceleration voltage of 15 kV. Fourier transform infrared (FT-IR) spectra (4000–400 cm−1) were taken using a Tensor 27 spectrometer (Bruker, Saarbrucken, Germany).

Assessment of nano-formulation

Assessment of spores viability after exposure to UV radiation

The diluted mixture from each of the formulations and the free spore formulation (30 mL) were exposed to UV-A radiation (385 nm) (Entela lamp model UVGL-25, 4 W). This was implemented in an open Petri dish at 15 cm distance from the lamp. Before designation of spore count, the amount of water evaporated in each sample was added to the formulation. The samples were then exposed to UV-A irradiation for 24, 48, 72, 96, and 120 h12. Spore counts were performed via serial dilution formulation spread in Petri dishes comprising nutrient agar and incubated at 28 °C for 24 h. Finally, the ratio of the number of the irradiated spores (nano or free formulation) to the number of the initial non-irradiated spores (nano or free spores), determined as spores viability, were calculated.

Bioassay procedures

Second instars larvae of E. kuehniella Zeller was used for carrying out bioassay. Fifteen larvae were transferred to a sterile Petri dish which contained five peanut pieces that had been soaked in 30 mL of the formulation (irradiated and non-irradiated) under sterile conditions for 3 min and dried. Then incubated at 28 °C and 50–60% humidity39. A similar process was performed for non-nano-formulation and compared to nano-formulation and the control (peanut pieces soaked in sterile distilled water instead of bacterial suspension). Mortality was checked out every 24 h during 10 days and each treatment was repeated in triplicate.

Data analysis

Analysis of Variance (ANOVA) was applied in Statistical Package for the Social Sciences (SPSS 1998). In order to determine the significant differences between treatments means, Duncan Test was applied.

References

Vilas-Boas, G. T., Peruca, A. P. S. & Arantes, O. M. N. Biology and taxonomy of Bacillus cereus, Bacillus anthracis, and Bacillus thuringiensis. Can. J. Microbiol. 53, 673–687 (2007).

Hernández-Rodríguez, C. S., de Escudero, I. R., Asensio, A. C., Ferré, J. & Caballero, P. Encapsulation of the Bacillus thuringiensis secretable toxins Vip3Aa and Cry1Ia in Pseudomonas fluorescens. Biol. Control 66, 159–165 (2013).

Sansinenea, E., Salazar, F., Ramirez, M. & Ortiz, A. An Ultra-Violet Tolerant Wild-Type Strain of Melanin-Producing Bacillus thuringiensis. Jundishapur J. Microbiol. 8 (2015).

Moxtarnejad, E., Safaralizade, M. H. & Aramideh, S. The protective material effect in combination with Bacillus thuringiensis var. kurstaki (Btk) against UV for control Pieris brassicae L.(Lep.: Pieridae). Arch. Phytopathol. Plant Prot. 47, 2414–2420 (2014).

Hong, B. J., Compton, O. C., An, Z., Eryazici, I. & Nguyen, S. T. Successful stabilization of graphene oxide in electrolyte solutions: enhancement of biofunctionalization and cellular uptake. ACS Nano 6, 63–73 (2011).

Kong, J.-Y. et al. Preparation and properties of polyimide/graphene oxide nanocomposite films with Mg ion crosslinker. Eur. Polym. J. 48, 1394–1405 (2012).

Posudievsky, O. Y., Kozarenko, O. A., Khazieieva, O. A., Koshechko, V. G. & Pokhodenko, V. D. Ultrasound-free preparation of graphene oxide from mechanochemically oxidized graphite. J. Mater. Chem. A 1, 6658–6663 (2013).

Pham, T. A., Kim, J. S., Kim, D. & Jeong, Y. T. Facile preparation of water‐dispersible graphene nanosheets by covalent functionalization with poly (3‐aminobenzene sulfonic acid). Polym. Eng. Sci. 52, 1854–1861 (2012).

Meng, Y., Su, F. & Chen, Y. Synthesis of nano-Cu/graphene oxide composites by supercritical CO 2-assisted deposition as a novel material for reducing friction and wear. Chem. Eng. J. 281, 11–19 (2015).

Benito, M., Oria, R. & Sánchez-Gimeno, A. C. Characterization of the olive oil from three potentially interesting varieties from Aragon (Spain). Food Sci. Technol. Int. 16, 523–530 (2010).

Guimet, F., Ferré, J. & Boqué, R. Rapid detection of olive–pomace oil adulteration in extra virgin olive oils from the protected denomination of origin ‘Siurana’ using excitation–emission fluorescence spectroscopy and three-way methods of analysis. Anal. Chim. Acta 544, 143–152 (2005).

Jallouli, W., Sellami, S., Sellami, M. & Tounsi, S. Efficacy of olive mill wastewater for protecting Bacillus thuringiensis formulation from UV radiations. Acta Trop. 140, 19–25 (2014).

Zhao, X., Zhang, Q., Chen, D. & Lu, P. Enhanced mechanical properties of graphene-based poly (vinyl alcohol) composites. Macromolecules 43, 2357–2363 (2010).

Yang, S.-T. et al. Removal of methylene blue from aqueous solution by graphene oxide. J. Colloid Interface Sci. 359, 24–29 (2011).

El Achaby, M., Arrakhiz, F. Z., Vaudreuil, S., Essassi, E. M. & Qaiss, A. Piezoelectric β-polymorph formation and properties enhancement in graphene oxide–PVDF nanocomposite films. Appl. Surf. Sci. 258, 7668–7677 (2012).

Wojtoniszak, M. et al. Synthesis, dispersion, and cytocompatibility of graphene oxide and reduced graphene oxide. Colloids Surfaces B Biointerfaces 89, 79–85 (2012).

He, J. & Fang, L. Controllable synthesis of reduced graphene oxide. Curr. Appl. Phys. 16, 1152–1158 (2016).

Zhang, J., Yan, J., Zheng, D., Sun, Y. & Yuan, Z. Expression of mel gene improves the UV resistance of Bacillus thuringiensis. J. Appl. Microbiol. 105, 151–157 (2008).

Saxena, D. et al. A UV tolerant mutant of Bacillus thuringiensis subsp. kurstaki producing melanin. Curr. Microbiol. 44, 25–30 (2002).

van Frankenhuyzen, K. In Entomopathogenic bacteria: from laboratory to field application 371–382 (Springer, 2000).

Heylen, K. et al. Cultivation of denitrifying bacteria: optimization of isolation conditions and diversity study. Appl. Environ. Microbiol. 72, 2637–2643 (2006).

McGuire, M. R., Behle, R. W., Goebel, H. N. & Fry, T. C. Calibration of a sunlight simulator for determining solar stability of Bacillus thuringiensis and Anagrapha falcifera nuclear polyhedrovirus. Environ. Entomol. 29, 1070–1074 (2000).

Ifoulis, A. A. & Savopoulou-Soultani, M. Biological control of Lobesia botrana (Lepidoptera: Tortricidae) larvae by using different formulations of Bacillus thuringiensis in 11 vine cultivars under field conditions. J. Econ. Entomol. 97, 340–343 (2004).

Brar, S. K., Verma, M., Tyagi, R. D. & Valéro, J. R. Recent advances in downstream processing and formulations of Bacillus thuringiensis based biopesticides. Process Biochem. 41, 323–342 (2006).

Amalraj, D. D. et al. Efficacy of aqueous suspension and granular formulations of Bacillus thuringiensis (Vectobac) against mosquito vectors. Acta Trop. 75, 243–246 (2000).

Koch, S., Schwinger, C., Kressler, J., Heinzen, C. H. & Rainov, N. G. Alginate encapsulation of genetically engineered mammalian cells: comparison of production devices, methods and microcapsule characteristics. J. Microencapsul. 20, 303–316 (2003).

Schisler, D. A., Slininger, P. J., Behle, R. W. & Jackson, M. A. Formulation of Bacillus spp. for biological control of plant diseases. Phytopathology 94, 1267–1271 (2004).

Burges, H. D. Formulation of microbial biopesticides: beneficial microorganisms, nematodes and seed treatments (Springer Science & Business Media, 2012).

Brar, S. K., Verma, M., Tyagi, R. D. & Valéro, J. R. Screening of Different Adjuvants for Wastewater/Wastewater Sludge-Based Bacillus thuringiensis Formulations Screening of Different Adjuvants for Wastewater/Wastewater Sludge-Based Bacillus thuringiensis Formulations. 99, 1065–1079 (2006).

Sarlak, N., Taherifar, A. & Salehi, F. Synthesis of nanopesticides by encapsulating pesticide nanoparticles using functionalized carbon nanotubes and application of new nanocomposite for plant disease treatment. J. Agric. Food Chem. 62, 4833–4838 (2014).

Pereira, A. E. S., Grillo, R., Mello, N. F. S., Rosa, A. H. & Fraceto, L. F. Application of poly (epsilon-caprolactone) nanoparticles containing atrazine herbicide as an alternative technique to control weeds and reduce damage to the environment. J. Hazard. Mater. 268, 207–215 (2014).

Kumar, R. S. S. et al. Distinctive effects of nano-sized permethrin in the environment. Environ. Sci. Pollut. Res. 20, 2593–2602 (2013).

Akhavan, O. & Ghaderi, E. Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 4, 5731–5736 (2010).

Zhu, H. et al. Highly photostable and biocompatible graphene oxides with amino acid functionalities. J. Mater. Chem. C 2, 7126–7132 (2014).

Marzban, R. & Salehi, J. G. H. R. Isolation of native Bacillus thuringiensis Berliner isolates from the agricultural soils of Iran (2006).

Marzban, R., He, Q., Liu, X. & Zhang, Q. Effects of Bacillus thuringiensis toxin Cry1Ac and cytoplasmic polyhedrosis virus of Helicoverpa armigera (Hübner)(HaCPV) on cotton bollworm (Lepidoptera: Noctuidae). J. Invertebr. Pathol. 101, 71–76 (2009).

Stankovich, S. et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon N. Y. 45, 1558–1565 (2007).

Kang, X. J., Zhang, J. M., Sun, X. W., Zhang, F. R. & Zhang, Y. X. One-pot synthesis of vanadium dioxide nanoflowers on graphene oxide. Ceram. Int. 42, 7883–7887 (2016).

Ghribi, D., Elleuch, M., Abdelkefi, L. & Ellouze-Chaabouni, S. Evaluation of larvicidal potency of Bacillus subtilis SPB1 biosurfactant against Ephestia kuehniella (Lepidoptera: Pyralidae) larvae and influence of abiotic factors on its insecticidal activity. J. Stored Prod. Res. 48, 68–72 (2012).

Author information

Authors and Affiliations

Contributions

All authors conceived the experiments, E.J. performed the experiment, analyzed the data and result with support from Sh.M. and All authors wrote the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Maghsoudi, S., Jalali, E. Noble UV protective agent for Bacillus thuringiensis based on a combination of graphene oxide and olive oil. Sci Rep 7, 11019 (2017). https://doi.org/10.1038/s41598-017-11080-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-11080-9

This article is cited by

-

Impacts of UV radiation on Bacillus biocontrol agents and their resistance mechanisms

World Journal of Microbiology and Biotechnology (2024)

-

Enhancing insecticidal efficacy of Bacillus thuringiensis Cry1Ab through pH-sensitive encapsulation

Applied Microbiology and Biotechnology (2023)

-

Harnessing Phyllosphere Microbiome for Improving Soil Fertility, Crop Production, and Environmental Sustainability

Journal of Soil Science and Plant Nutrition (2023)

-

Effect of High Temperature and UV Radiation on the Insecticidal Capacity of a Spodoptera frugiperda Nucleopolyhedrovirus Microencapsulated in a Matrix Based on Oxidized Corn Starch

Neotropical Entomology (2023)

-

Determination, distribution, and environmental fate of Bacillus thuringiensis spores in various honeybee matrices after field application as plant protection product

Environmental Science and Pollution Research (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.