Abstract

The development of lentiviral-based therapeutics is challenged by the high cost of current Good Manufacturing Practices (cGMP) production. Lentiviruses are enveloped viruses that capture a portion of the host cell membrane during budding, which then constitutes part of the virus particle. This process might lead to lipid and protein depletion in the cell membrane and affect cell viability. Furthermore, growth in suspension also causes stresses that can affect virus production yields. To assess the impact of these issues, selected supplements (Cholesterol Lipid Concentrate, Chemically Defined Lipid Concentrate, Lipid Mixture 1, Gelatin Peptone N3, N-Acetyl-L-Cysteine and Pluronic F-68) were assayed in order to improve production yields in a transient transfection production of a Sendai virus F/HN-pseudotyped HIV-1-based third generation lentiviral vector in FreeStyle 293 (serum-free media) in suspension. None of the supplements tested had a significant positive impact on lentiviral vector yields, but small non-significant improvements could be combined to increase vector production in a cell line where other conditions have been optimised.

Similar content being viewed by others

Introduction

The use of viral vectors for therapeutic gene delivery capitalises on the co-evolution of viruses and mammalian host cells1 that naturally makes them efficient gene transfer agents. A number of naturally-occurring viruses have been adapted as viral vectors for gene therapy2. Lentiviruses are particularly suited for this purpose because they can integrate into the host genome, have a large transgene capacity and can transduce both dividing and non-dividing cells3. Therapeutic lentiviral vectors have encountered pre-clinical success in ex vivo clinical trials for treatment of leukaemia4,5,6 and using haematopoietic stem cells7,8,9,10 and are being assayed in early in vivo clinical trials for Parkinson’s disease11 and age-related macular degeneration12.

The United Kingdom Cystic Fibrosis Gene Therapy Consortium is currently developing a lentiviral vector platform which is pseudotyped with the Sendai virus (murine parainfluenza virus type 1) fusion and haemagglutinin-neuraminidase (F/HN) envelope proteins13, to facilitate delivery to lung cells14, 15. In Sendai virus, the HN protein is responsible for haemagglutination and receptor binding and has neuraminidase activity16. The glycoprotein F is required for virus-induced haemolysis, cell fusion and the initiation of infection17. This lentiviral vector product is now being considered for current Good Manufacturing Practice (cGMP) vector production and clinical evaluation.

The development of lentiviral-based therapeutics is hindered by the high cost of cGMP production. This is particularly relevant for in vivo applications where large quantities of viral vector may be required, as opposed to the smaller quantities sufficient for ex vivo transduction. Furthermore, production titres for lentiviral vectors appear several log-orders lower than those typically obtained for recombinant Adenoviral and Adeno-Associated Viral vectors, which have benefited from improvements in vector production in recent years18, 19.

Production of viral gene therapy products often involves the use of bovine serum in cell culture. This supplementation is performed in order to provide a source of essential nutrients to the cells and increase virus production yields. The use of serum in cell culture poses ethical considerations20 as well as a potential risk of transfer of viruses or prions into the final product21. While extensive contaminant testing could address the safety issue, it can be mitigated by careful tracking of the reagents’ sources (i.e. country of origin, batch number, etc.). It does, however, remain a risk, which must be assessed and reported22. Furthermore, immune responses caused by the use of bovine serum have been observed in bone marrow transplant23, cell therapy24, 25 and gene therapy26 clinical trials. As a result, there is regulatory pressure to reduce or remove animal serum from production processes21. Moreover, if serum continues to be used, supply limitation of certified material is another issue which could arise, with demand rising as more products reach the stage of large-scale manufacture27. While human serum in cell culture28 could be used as an alternative for small-scale manufacturing, it is unlikely to be a viable option, in terms of both the supply and cost, for long-term, large-scale manufacturing.

Lentiviral vectors have been produced in the absence of serum, reducing the immunogenicity of the final product without affecting final transduction efficiency29. In turn, efforts to reduce the reliance on serum, and to provide more completely defined mammalian cell growth conditions, have led to the development of specialised media that are both serum-free and protein-free. One popular growth medium for lentivirus production is the FreeStyle™ 293 Expression Medium (FreeStyle 293)30. It is a chemically defined, animal origin-free, protein-free medium developed to support growth and transfection of FreeStyle™ 293-F cells, a fast-growing clonal isolate of HEK 293 that has been adapted to suspension culture in serum-free media. FreeStyle 293 is manufactured at a cGMP-compliant facility and is marketed as suitable for cGMP production of vectors. It contains the GlutaMAX™ supplement, marketed as minimising toxic ammonia build-up and improving cell viability; however, the rest of its formulation is proprietary. It is therefore not obvious to assess if constituents usually present in serum added as a supplement might be lacking for optimised lentiviral vector production.

Serum deprivation during vector production was shown to affect producer cells. Depending on the cell type, it can lead to reduction in total lipid content and, therefore, reduction in infectious vector titres, while in other cell types it will lead to a rise in de novo lipid biosynthesis, particularly for cholesterol, reducing the impact on titres31. In addition, lentiviruses being enveloped viruses, when newly developed virions bud from producer cells they capture a portion of the cell membrane, which then constitutes a key component of the viral particle. Viral and host cell membranes are of different composition; the HIV-1 envelope is, for example, more ordered than the host cell membrane from which it originated32. HIV-1 buds from areas of the plasma membrane with high levels of lipid rafts33 which are organised areas enriched in cholesterol, sphingolipids, and glycosylphosphatidylinositol-linked proteins34. It has been hypothesised that these components are preferentially incorporated in the viral envelope as a result of preferential sorting of HIV-1 Gag to lipid rafts33. More specifically, the molar ratio of cholesterol to phospholipid is about 2.5 times higher in virion envelopes compared to the host cell membrane32 and the levels of several other raft lipids and proteins are elevated in virions compared with their progenitor cells. We hypothesise, therefore, that the exodus of proteins and lipids that occurs during virus budding could deplete the producer cells’ reserves, and ultimately reduce viability, leading to a lower rate of virus production. Furthermore, growth in suspension culture is associated with stresses due to shear forces and bubble-bursting which can also affect production yield35. To begin to address these issues, the addition of different media supplements to the producer cell growth medium was explored for the potential to increase lentiviral vector production titres in the specific context of the Sendai virus F/HN-pseudotyped lentiviral vectors.

Results

Standardisation of lentiviral vector production

The production of a third generation HIV-1-based lentiviral vector, expressing an Enhanced Green Fluorescence Protein (EGFP) and Firefly Luciferase (Lux) fusion protein (EGFPLux) was evaluated in the presence of a variety of supplements. This vector was pseudotyped with the Sendai virus F/HN envelope proteins13 to generate rHIV.F/HN CMV- EGFPLux. The first step to accomplish this was to develop an experimental method that could result in reproducible lentivirus yields.

Preliminary studies indicated that the transient transfection step was a large source of the variability between vector production experiments. Hence, the impact on production variability of two alternate transfection strategies was evaluated: a multiple independent transfections strategy, where 12 flasks of cells were transfected independently (Fig. 1A), and a single-flask transfection strategy, where cells in a single, larger seed flask were collectively transfected and then subsequently split into 12 smaller flasks (Fig. 1B).

Schematic representation of the different transient transfection, production and titration protocols for lentiviral vectors produced in flasks. In both cases, Human Embryonic Kidney 293T cells (HEK 293T) were transiently transfected with a ‘transfection mix’ of the five plasmids required for virus production complexed with polyethylenimine (PEI). (A) In the multiple independent transfections strategy, cells were split into the required number of replicates prior to transfection and the ‘transfection mixes’ were prepared independently for each flask. Media change was performed after 24 hours including the addition of sodium butyrate. (B) In the single-flask transfection strategy, the cells were split after transient transfection into the required number of replicates. Media change and sodium butyrate addition were performed after 24 hours and, if appropriate, the assayed supplement added at this point. (A and B) After an additional 48 hours of incubation, the production was harvested by centrifugation and the supernatant filtered. A sample of the filtrate was used for transduction in a 12 well plate seeded with HEK 293T in media containing hexadimethrine bromide (polybrene) After a 72-hour incubation, the titre was determined by flow cytometry.

For the multiple independent transfections strategy, 20 mL of HEK 293T cells at 1 × 106 cells/mL were seeded in 12 separate 125 mL flasks. Twelve independently prepared transfection mixtures (each comprising 30 μg of plasmid DNA) were used to transfect the flasks. The media was changed after 24 hours and the rHIV.F/HN CMV- EGFPLux virus generated was harvested after a further 48 hours’ incubation. The viral titre for each of the 12 independent cultures, as determined by flow cytometry, is shown in Fig. 2A.

Lentiviral vector production yields for the multiple independent transfections strategy flask and the single-flask transfection strategy. Individual rHIV.F/HN CMV- EGFPLux yields from flasks containing non-supplemented medium from (A) multiple independent transfections strategy (12 independent 125 mL flasks at 1 × 106 HEK 293T cells/mL in 20 mL) where cells were transfected with independently prepared ‘transfection mixes’ necessary to produce rHIV.F/HN CMV- EGFPLux, or (B) single-flask transfection strategy where HEK 293T cells (1 × 106 cells/mL in a 1000 mL flask) were transfected with the five plasmids necessary to produce rHIV.F/HN CMV- EGFPLux and subsequently divided into 12 separate 20 mL cultures in 125 mL flasks. Titres were measured by flow cytometry (flow cytometry transducing units: FTU/mL). The dashed lines show the average titre for all flasks for each strategy.

For the single-flask transfection strategy, a single ‘transfection mix’ was prepared for transfection of 240 mL of HEK 293T cells at 1 × 106 cells/mL seeded into one 1000 mL flask with 360 µg of the vector plasmid DNA mixture. Twenty-four hours after transfection, the media was changed by centrifugation and the culture divided between 12 separate 125 mL flasks, 20 mL per flask. The rHIV.F/HN CMV- EGFPLux virus generated was harvested after a further 48 hours’ incubation. The virus titre for each flask was determined using flow cytometry and results are shown in Fig. 2B.

As shown in Fig. 2A and B, the absolute titres of rHIV.F/HN CMV- EGFPLux generated by these two approaches vary largely between replicates. To be able to compare the performance of different supplements, titres were normalised to the average titre of the non-supplemented flasks in each experiment. Comparing the normalised titration results from the multiple independent transfections strategy (mean of twelve flasks: 100, standard deviation: 93.5) with those from the single-flask transfection strategy (mean of twelve flasks: 100, standard deviation: 51.4) indicated that there was less variation observed using the single-flask transfection strategy. Using these data, to model future studies incorporating three replicates, statistical power analysis demonstrated the superiority of the single-flask transfection strategy. Using the multiple independent transfections approach a minimum of a 3.33-fold increase in titre would be necessary to observe a statistical difference with 80% power using triplicates, whereas the single flask approach could readily distinguish a 2.28-fold increase in titre with the same power. Given the reduced variability, and the anticipated lower threshold for reaching statistical differences when comparing experimental groups, the single-flask transfection strategy was selected for all subsequent experiments.

Cholesterol Lipid Concentrate supplementation does not improve yields

To address the possibility of lipid depletion in cells producing lentiviral vectors, several lipid supplements have been investigated with the aim of increasing lentiviral vector productivity and/or infectivity. Of these, cholesterol-based supplements have been shown previously to significantly improve production titres of Vesicular Stomatitis Virus G glycoprotein (VSV-g)-pseudotyped lentiviral vectors in the presence of serum36, 37 and to restore infectivity in serum-deprived retroviral vector production to levels seen when serum was used38. The timing of lipid supplementation is crucial as addition prior to transfection can profoundly decrease viral yields (Figure S1). One potential explanation for this unexpected adverse effect of lipid supplementation was that it had an adverse effect on HEK 293T cell transfection with the producer plasmid mixture. To mitigate the impact of this potential effect, a study was performed where Cholesterol Lipid Concentrate (CLC), a commercial, animal-free, cholesterol-based proprietary formulation sold as a 250x concentrate suitable for cGMP manufacturing supplementation was carried out during rHIV.F/HN CMV- EGFPLux production 24 hours post-transfection.

Post-transfection CLC supplementation was investigated using the single-flask transfection strategy described above. The steps for supplementation studies are presented in Fig. 1B. A single 1000 mL flask containing 1 × 106 cells/mL in 240 mL media was transfected with 360 µg of the plasmid mixture required to produce rHIV.F/HN CMV- EGFPLux. Twenty-four hours after transfection, the flasks were centrifuged for media change and the pelleted cells resuspended in 225 mL FreeStyle 293 with sodium butyrate. The culture was then divided between 12 separate 125 mL flasks (18 mL per flask). Triplicate flasks were supplemented with 2 mL of CLC diluted in FreeStyle 293 for final concentrations of 0.5X, 1X or 2X CLC in a final volume of 20 mL. Three flasks, where 2 mL of FreeStyle 293 without CLC were added, served as a triplicate negative control. Virus produced under these conditions was harvested 48 hours after supplementation and titrated. It is relevant to note that some of the supplement in the production media is carried over to the titration plates. It is not, however, expected to have a significant effect as the volume of production supernatant used for titration represents only about 0.5% of the volume in the titration wells. Contrary to lipid supplementation before transfection, here, there was no significant change in titre with any of the CLC concentrations evaluated post-transfection (Fig. 3A), although a trend for inhibition of virus production was noted with 2x CLC.

Lentiviral vector titres following lipid medium supplementation. Yields of rHIV.F/HN CMV- EGFPLux in non-supplemented medium (dark green) or medium supplemented (yellow) with (A) Cholesterol Lipid Concentrate, (B) Chemically Defined Lipid Concentrate or (C) Lipid Mixture 1, (D) Gelatin Peptone N3, (E) N-acetyl-cysteine, or (F) Pluronic F-68. Titres were measured by flow cytometry and are shown relative to non-supplemented values. Bars represent the mean of triplicate production studies ± standard error of the mean. There were no statistically significant differences between group means as determined by one-way ANOVA, except in (E): (A) F(3,8) = 3.798, p = 0.0582, (B) F(3,8) = 1.025, p = 0.4315, (C) F(3,8) = 1.230, p = 0.3606), (D) F(3,8) = 1.113, p = 0.3993, (E) F(3,8) = 11.04, p = 0.0032 and (F) F(3,8) = 1.621, p = 0.2598, followed, if appropriate, by Dunnett’s post-test. A calculated p value of > 0.05 was deemed non-significant as indicated with ns on charts. A calculated p value of < 0.05 was deemed a significant difference as indicated with one star (*) on charts.

Methyl-beta-cyclodextrin (mβCD) is used as a complexing agent in the CLC formulation to enhance solubility in water-based tissue culture media39. Interestingly, mβCD can selectively extract cholesterol from the plasma membrane40, 41, which can affect cellular processes such as endocytosis42 as well as cell sensitivity to HIV-1 infection43, 44. A number of studies have explored the inhibitory impact of mβCD on HIV-1 yields45 and infectivity46, 47. This impact appears less when pseudotyping vectors with VSV-g47, although the effect, if any, on a Sendai virus F/HN pseudotype (as used here) is unknown. A possible solution to this problem would be to exclude mβCD from the cholesterol supplement, however, the CLC manufacturer was unable to produce either a mβCD-free CLC or CLC-supplemented medium, (Life Technologies, personal communication). It was, therefore, determined that CLC could not be used as a possible supplement at this stage.

Chemically Defined Lipid Concentrate supplementation does not significantly improve yields

Due to the possible issues of mβCD-containing supplements, an alternative mβCD-free supplement containing cholesterol, Chemically Defined Lipid Concentrate (CDLC), was evaluated. CDLC is a concentrated lipid emulsion of saturated and unsaturated fatty acids and surfactants, designed to reduce or replace foetal bovine serum in cell culture media. It has been shown to improved titres of VSV-g-pseudotyped lentiviral vectors in the presence of serum36 and restore infectious particle productivity of retroviral vectors to the levels seen when using serum in HEK 293-derived cells38. The impact of CDLC addition to rHIV.F/HN CMV- EGFPLux production using the single-flask strategy was evaluated. A single 1000 mL flask containing 1 × 106 cells/mL in 240 mL media was transfected with 360 µg of the plasmid mixture required to produce rHIV.F/HN CMV- EGFPLux. Twenty-four hours after transfection, the flasks were centrifuged for media change and the cells resuspended in 225 mL FreeStyle 293 with sodium butyrate. The culture was then divided between 12 separate 125 mL flasks (18 mL per flask). CDLC is supplied as a concentrate and the manufacturer’s guidelines recommended evaluating dilutions ranging from 1:100 to 1:1000. Triplicate flasks were supplemented with 2 mL of CDLC diluted in FreeStyle 293 for final dilutions of 1:1000, 1:333 or 1:100 of CDLC in a final volume of 20 mL. Three flasks, where 2 mL of FreeStyle were added without CDLC, served as a triplicate negative control. Virus produced under these conditions was harvested 48 hours after supplementation and titrated. Although a trend for increased virus production in the presence of CDLC was observed, there was no significant change in titres with any of the CDLC concentrations evaluated (Fig. 3B).

Lipid Mixture 1 supplementation does not improve yields

It has been reported that Lipid Mixture 1 can be used as a supplement in a VSV-g pseudotyped lentiviral vector producer cell line grown in a low-calcium, serum-free media48. According to the manufacturer, Lipid Mixture 1 contains non-animal derived fatty acids (2 μg/mL arachidonic and 10 μg/mL each linoleic, linolenic, myristic, oleic, palmitic and stearic), 0.22 mg/mL cholesterol from New Zealand sheep’s wool, 2.2 mg/mL Tween-80, 70 μg/mL tocopherol acetate and 100 mg/mL Pluronic F-68 solubilised in cell culture water. Lipid Mixture 1 has been shown to increase 25 kDa linear polyethylenimine (PEI) transient transfection efficiency and, when used at 0.1% v/v, to not affect cell growth in HEK 293 derived cells49. The impact of Lipid Mixture 1 on lentiviral vector production yields was therefore assessed here. As described above, a single, large flask of transfected cells was prepared and, 24 hours later, split into 12 flasks after the media change, at which point sodium butyrate was added. Triplicate flasks were supplemented with 0.5X (0.05%), 1X (0.1%) or 2X (0.2%) the reported beneficial concentration of Lipid Mixture 1, or with FreeStyle 293 only, as a negative control. Virus produced under these conditions was harvested 48 hours after supplementation and titrated. Figure 3C shows that none of the concentrations had a significant impact on virus titre.

Gelatin Peptone N3 supplementation does not improve yields

Gelatin Peptone N3 is also used as a supplement in a VSV-g pseudotyped lentiviral vector producer cell line grown in a low-calcium serum-free media48. Gelatin Peptone N3 is manufactured by a controlled enzymatic hydrolysis of gelatine and has been shown to have a positive effect on cell growth and transfection efficiency in HEK 293 derived cells at a concentration of 0.5% v/v49. The impact of Gelatin Peptone N3 on production yields was therefore assessed. A single large flask of transfected cells was prepared and, 24 hours later, split into 12 flasks after the media change, at which point sodium butyrate was added. Triplicate flasks were supplemented with half (0.25%), once (0.5%) or twice (1%) the optimal reported concentration, or with FreeStyle 293 only, as a negative control. Virus produced under these conditions was harvested 48 hours after supplementation and titrated. Figure 3D shows that none of the concentrations of Gelatin Peptone N3 tested had a significant impact on virus titre, although a trend for inhibition of virus production was noted with 1% supplementation.

N-Acetyl-L-Cysteine supplementation does not improve yields

Medium supplements that are not membrane components, but that can still affect cell viability, were also assayed. N-Acetyl-L-Cysteine (NAC) is a widely used mucolytic agent and paracetamol overdose management medication with a general anti-apoptotic effect50 and is also known to have effects on HIV. Cell treatment with NAC can inhibit HIV-1 Long Terminal Repeat (LTR)-directed gene expression51, suggesting an inhibitory effect on HIV-1 transcription. NAC was therefore assayed as an anti-HIV drug, showing no benefit in asymptomatic patients52, but possible benefit if taken before initiating anti-retroviral therapy53. In cell culture HIV-1 replication studies, however, a dose-dependent effect of NAC has been observed on HIV-1 yields54. NAC doses of 0.12 and 0.25 mM decreased the infectious HIV-1 yield up to two-fold and cell viability to 75% of the level of non-supplemented controls. By contrast, NAC doses of 0.5–2 mM increased HIV-1 yield up to two-fold, while increasing cell viability to 120% of the level of non-supplemented controls, demonstrating a correlation with NAC’s modulation of cell growth. Finally, in chronically infected T lymphocytes, high NAC concentrations (4–16 mM) increased the cell proliferative rate increasing virus multiplication 4- to 6-fold, although, at such concentrations NAC also had an inhibitory effect in acutely infected cells, interfering with early events in the life cycle and reducing titres up to 4-fold54.

The impact of NAC on lentiviral vector production yields was therefore assessed. As described above, a single large flask of transfected cells was prepared and, 24 hours later, split into 12 flasks after the media change for supplementation. In an attempt to cover the reported range of concentrations affecting HIV-1 yields and cell proliferation54 three doses were assayed: 0.25 mM (reported to decrease HIV-1 yields), 1 mM (reported to increase HIV-1 yields) and 4 mM (reported to increase cell proliferation, but to decrease titres in acutely infected cells) as well as a FreeStyle 293 only control. Virus produced under these conditions was harvested 48 hours later and titrated. The results showed that, under the conditions used here, the two lower concentrations did not have a significant impact on virus production yield, contrary to previous reports using different conditions. However, the higher NAC dose had a significant (p < 0.05) two-fold adverse impact on virus titre (Fig. 3E) and consistent with NAC’s reported HIV-1 interference capacity at high doses in acutely infected cells54.

Pluronic F-68 supplementation does not significantly improve yields

Polaxamers, such as Pluronic F-68, are non-ionic surfactants, comprising triblock copolymers made of hydrophilic polyethyleneoxyde and hydrophobic polypropylene oxide. Pluronic F-68, is widely used to protect cells from injury due to agitation and/or gas bubble sparging in bioreactors35. The cell protective effect of Pluronic F-68 has been attributed to two possible mechanisms: (i) it could reduce the cell-to-bubble attachment55 and damage caused by bubble bursting56, (ii) it could also increase the resistance of the cells to shear stress by decreasing the plasma membrane fluidity in cells57. Pluronic F-68 is known to be a component of FreeStyle 293, and the manufacturer’s recommendations suggest supplementation with an additional 2.5–5 mL/L of 10% Pluronic F-68 (0.025–0.05%) in large-scale bioreactor suspension cultures to reduce shear stress in the culture. While it was not assumed that additional Pluronic F-68 would necessarily increase viral titres in flask conditions, it was critical to rule out a deleterious effect on titres in bioreactors. An experiment was therefore designed to assay vector production yields using medium supplemented with additional Pluronic F-68.

As described above, a single, large flask of transfected cells was prepared and, 24 hours later, split into 12 flasks after the media change for supplementation, at which point sodium butyrate was added. The manufacturer’s recommended concentration of Pluronic F-68 supplementation is 0.05%, therefore, after the media change, triplicate flasks were supplemented with 0.5X (0.025%), 1X (0.05%) or 2X (0.1%) of the upper limit of the recommended concentration of additional Pluronic F-68, or with FreeStyle 293 only, as a negative control. Virus produced under these conditions was harvested 48 hours after supplementation and the virus titrated. Vector titres were not affected by any concentration of Pluronic F-68 added in the culture medium of the transfected cells (Fig. 3F), although a trend for enhanced virus production was noted with 0.1% Pluronic F-68.

Discussion

A critical parameter affecting the cost of viral vector manufacturing is the final production titre, therefore, improvements to lentiviral vector production processes should ultimately increase efficiency and reduce overall costs. To this effect, serum-free media reduces the complexity, duration and cost of downstream processing as well as risks of transfer of viruses or prions into the final product. Furthermore, suspension production increases yields58 and allows the use of controlled bioreactors enhancing reproducibility. The experiments described here aimed to address issues arising during lentiviral vector production in serum-free suspension culture, specifically, the potential for depletion of cell membrane lipid and protein components that could occur due to high levels of virus production, as well as mitigating stresses due to bubble-bursting and shear forces generated during cell culture.

A simple protocol for a well-controlled, small-scale (20 mL) lentiviral vector production was developed based on transient transfection of HEK 293T cells in suspension. Several steps were taken to reduce potential variability, including the use of a master mix to bulk transfect cells in a single, large flask, which was then split to prepare 12 identical flasks of transfected cells for experimentation. This approach more closely resembles that adopted when using a stable producer cell line where all cultures are derived from a single, typically clonal, source. This allowed the experiments described here to be powered at 80%, sufficient to detect a 2.28-fold increase in titre.

Using this protocol, several media supplements were evaluated for their effect on lentiviral vector titre. All supplements tested were added 24-hour after transient transfection with the component lentiviral vector plasmids to minimise interaction of the supplement with the transfection mixture/process. Disappointingly, none of the media supplements tested significantly increased vector titre in these studies. CDLC supplementation led to the largest increase in titre (2.13-fold), but the observed trend did not reach significance, both because it did not reach the 2.28-fold threshold determined by power calculations and because of great inter-replicate variability (±0.81-fold). A follow-on study incorporating a greater number of replicates might confirm a modest increase in virus productivity with this approach. Another possibility would be to aggregate marginal gains by combining supplements with multiple non-significant (but positive) trends such as a combination of 1:333 CDLC and 0.1% Pluronic F-68.

To prevent any interference with the transfection process, supplements were always added at the media change step. It is possible, however, that a longer exposure of the cells to the supplements might be necessary to observe detectable effects in virus yield. Alternatively, it is also possible that the transfection step itself could be enhanced by the supplement as it has been reported for Lipid Mixture 1 and Gelatin Peptone N349.

In the case of lipid supplements, the issue of the presence of mβCD in the supplements was noted above. It is also relevant to note the reactivity of mβCD with polyethylene which lines bioreactors used for large-scale production such as the WAVE Bioreactor (GE Healthcare)30. This issue was previously described59 following the unsuccessful growth of cholesterol-dependent cell lines in this type of bioreactor60. This would prevent the use of CLC in such bioreactors as it might cause leaching of cholesterol from the cell membrane. A possible solution would be to use an alternative bioreactor coating.

It is also possible that the increase in infectivity observed in VSV-g pseudotyped lentiviral vectors following cholesterol supplementation could not be reproduced here because of the different pseudotype. While mβCD-induced cholesterol depletion was shown not to influence VSV-g transport from the Golgi to the plasma membrane61, cholesterol depletion using statins has been shown to impair the transport of VSV-g from the endoplasmic reticulum to the Golgi and that cholesterol supplementation can reverse this impairment62. The effects of cholesterol depletion on Sendai virus F/HN migration to the cell surface have not been studied. Another solution to cholesterol depletion has recently been presented in which, instead of using a media supplement, a plasmid is transfected which leads to the overexpression of 3-hydroxy-3-methylglutaryl-coenzyme A reductase, a crucial cholesterogenic enzyme, in the producer cells63. This was reported to increase de novo cholesterol biosynthesis and to enhance by 2- to 3-fold both the physical and infectious titres.

In the case of polaxamers, Pluronic F-68 is reported to protect cells from sparging and injury due to agitation in bioreactors35. It is listed by the manufacturer as a component of FreeStyle 293 media, but at an undisclosed concentration. It is further recommended to supplement with an additional 2.5–5 mL/L of 10% Pluronic F-68 in agitating bioreactors. As no adverse effect was observed on titres in the experiment described above, it was decided to implement 5 mL/L 10% Pluronic F-68 (0.05%) supplementation in the ongoing large-scale production of lentiviral vectors)30. Each large-scale (1 L and 5 L) production run being unique, expensive and with multiple changing parameters, it has not been possible to determine the significance of any beneficial effect observed following this supplementation. However, cell counts and viability did appear to have increased and, importantly, no dramatic deleterious effects have been observed following implementation in bioreactors (data not shown).

Another supplement, chloroquine, has been extensively studied in the literature in this context. Chloroquine is a lysosomotropic amine used as an effective and safe anti-malarial and anti-rheumatoid agent. Its accumulation inhibits enzymes present in lysosomes and therefore proteolytic processes64. The inhibition of lysosomal enzymatic activity has also been shown to inhibit the degradation of DNA transfected with calcium phosphate65. This effect was observed in a calcium phosphate transient transfection production of retroviral vectors where titres where doubled with chloroquine addition66. However, the enhanced gene expression and transfection efficiency is counterbalanced by extensive cell toxicity after relatively brief (>4 hours)67 exposure. In large-scale production, quickly removing a toxic reagent is difficult and having to perform such a step would preferably be avoided.

While chloroquine has also been used in lentiviral vector production36, 68,69,70,71,72, a study of its effects on lentiviral yields detected no change in titres in a calcium phosphate transient transfection production73. Furthermore, the transfection reagent might be critical in chloroquine’s effect. Chloroquine addition was observed to reduce lentiviral vector titres when used in combination with PEI in DMEM without serum74. It has been suggested that PEI has a similar ‘DNA protection effect’ as chloroquine in lysosomes75, which might explain this discrepancy. For these reasons, chloroquine was not tested as a supplement here.

Several protein, lipid and other supplements are commercially available that could ultimately benefit lentiviral vector production, but to thoroughly evaluate these would probably require a protocol with a higher practical throughput. Moreover, the supplements tested in this study could have a benefit in an alternate experimental production setup. This is exemplified by the discordant results found with NAC supplementation in the present experimental setup compared to those obtained in HIV-1 infection of lymphocytes. It is therefore possible that third generation lentiviral vector production and the native HIV-1 life cycle have different requirements. Some supplements, such as caffeine, have been shown to increase lentiviral titres76, but have not been shown to be efficacious in the production system used in this study (data not shown). The use of the Sendai virus F/HN pseudotype might also result in different requirements compared with the more widely used VSV-g pseudotype. Both pseudotypes comprise proteins that are integrated into the cell membrane, but the exact effect of their presence on membrane composition is unknown.

The FreeStyle 293 media, used for the experiments described here, is a specialised medium developed for the optimal growth of HEK 293 derived cells in suspension and it is possible that only marginal benefit can be obtained by any additional media supplementation in this context. This could explain why supplements observed to improve production yields in other media have not been successful here. It may, therefore, be helpful to reassess the potential of these supplements to benefit production if alternative (perhaps non-optimal) media were used.

Finally, while variability was minimised using a single transfection rather than 12 independent transfections for each experiment, the variability of the experimental setup did not allow determination of small variations in titres (below 2.28-fold) as being significant. As described earlier in the case of CDLC, a larger number of replicates could have addressed this problem. An alternative setup involving a producer cell line could also be employed to minimise variation, removing the variability introduced by the transfection step.

Another factor that might explain the lack of effect of supplementation in the experimental setup, compared with an observed impact in other studies, might be sub-optimal production yields in the present setup. Even with a producer cell line, if the maximal production of lentiviral vector particles is not reached, then depletion of membrane components may not yet be rate-limiting. Thus it may be useful to reassess the possible benefit of such supplementation during late-stage production optimisation.

In summary, this study evaluated the addition of a variety of supplements to the producer cell growth medium, for the potential to increase lentiviral vector production titres. In the particular context of rHIV.F/HN CMV- EGFPLux production in FreeStyle 293 media, none of the supplements evaluated successfully enhanced vector production.

Methods

Cells

The HEK 293T/17 (HEK 293T)66 (ATCC, Manassas, VA, USA, CRL-11268) cell line was used in all experiments. It was adapted to growth in suspension using sequential serum reduction, accomplished by transitioning to an increasing proportion of new media by 25% per passage, with agitation starting when the transition was complete. The cells were maintained on a rotating platform with an orbital diameter of 1.9 cm (Thermo Scientific, Loughborough, UK) at 185 revolutions per minute (rpm) in a humidified incubator (Thermo Scientific) at 8% CO2 and 37 °C in FreeStyle 293 (Life Technologies, Paisley, UK) without serum or antibiotics. Cell growth was monitored by determining live cell density using 0.2% trypan blue dye exclusion and a Neubauer improved hemacytometer (Sigma, Gillingham, UK). Cells were passaged twice a week by diluting to 3.5 × 105 live cells per mL.

Lentiviral vector production

A third generation HIV-1-based lentiviral vector, expressing an EGFPLux fusion protein under the control of a human cytomegalovirus immediate early enhancer and promoter without intron (CMV-) and pseudotyped with Sendai virus F/HN proteins (rHIV.F/HN CMV- EGFPLux), was produced by transient transfection of HEK 293T cells)30. This vector was generated using the HIV-1 vector genome plasmid pGM290 (a derivative of pRRLSIN.cPPT.PGK-GFP.WPRE (Addgene #12252) where the PGK, GFP and WPRE sequences were replaced with the CMV enhancer/promoter from pCIKCFTR77, EGFPLux from pEGFP-Luc (Promega), and the mut6 form of the WPRE sequence lacking an intact X protein coding sequence)78. Additional HIV-1 and Sendai virus F/HN proteins were supplied by plasmids pGM281 (a monomeric form of pMDLg/pRRE (Addgene #12251), pRSV-Rev (Addgene #12253) as well as pGM301 and pGM303, derivatives of pCAGGS-Fct4 and pCAGGS-SIVct + HN)13 respectively, where the ampicillin resistance gene has been substituted for a kanamycin resistance gene. For virus production the plasmids pGM290, pGM281, pRSV-Rev, pGM301 and pGM303 were used in a mass ratio of 20:10:5:7:7 respectively.

A 1000 mL polycarbonate flask (Corning, Flintshire, UK) was seeded with 240 mL of HEK 293T cells at 1 × 106 ± 10% cells/mL. These were transiently transfected with a “transfection mix” of 1.5 µg plasmid DNA per 106 cells using 25 kDa branched polyethylenimine (PEI) (Sigma) at an N:P ratio (ratio of moles of amine groups of cationic polymers to moles of phosphate groups of DNA) of 15:179. Twenty-four hours after transfection, the cells were centrifuged and the supernatant replaced by 225 mL fresh FreeStyle 293 to reduce PEI toxicity. At this point, sodium butyrate (Sigma), a known enhancer of transfection efficiency and transgene expression80, as well as of lentiviral vector production81, 82, was added at a concentration of 5 mM. The cells were then split into the required number of 125 mL polycarbonate flasks (Corning) containing 18 mL volume in each to evaluate the different supplements. The supplements tested were: Cholesterol Lipid Concentrate (CLC), Chemically Defined Lipid Concentrate (CDLC) (Life Technologies), Lipid Mixture 1 (Sigma), Gelatin Peptone N3, (Organotechnie, La Courneuve, France), N-Acetyl-L-Cysteine (NAC) (Sigma) and Pluronic F-68 (Life Technologies). Each was diluted to the desired concentration in FreeStyle 293, filtered using a 0.2 μm surfactant-free cellulose acetate filter (Thermo Scientific), and 2 mL was added to three replicate flasks. For each experiment, three flasks were not supplemented and had only 2 mL of FreeStyle 293 added to act as the non-supplemented control. After a total incubation of 72 hours, cells were harvested and pelleted by centrifugation, 6 minutes at 500 rcf. The supernatant was filtered using a 0.45 µm filter with a Supor membrane (Pall, Portsmouth, UK) and either used immediately for titration or stored at −80 °C.

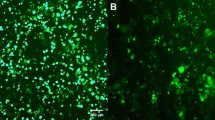

Lentiviral vector titration

HEK 293T cells were seeded at 5 × 105 ± 10% cells per well in a 12-well plate (Corning) in FreeStyle 293 containing 8 µg/mL hexadimethrine bromide (polybrene) (Sigma), a known enhancer of retrovirus transduction efficiency83. The cells were subsequently transduced by the addition of diluted virus stocks – typically 1:5 diluted virus in FreeStyle 293, though other dilutions were used as necessary to ensure the proportion of transduced cells did not exceed ~20%. After 72 hours’ incubation, EGFP production was confirmed by fluorescence microscopy and the cells were harvested in 5 mL polystyrene round-bottom tubes (Corning) and centrifuged 6 minutes at 500 rcf. Pellets were resuspended in 350 μL of flow cytometry buffer containing 10% (v/v) Bovine Serum Albumin (BSA), 10 mM EDTA and 2% (v/v) paraformaldehyde (PFA) in Dulbecco’s phosphate-buffered saline (Sigma). The number of EGFP positive cells was determined using a FACSCalibur (BD, Oxford, UK) cell sorter and associated CellQuest Pro 6.0 (BD) software. Titres were obtained by gating for EGFP positive cells compared to triplicate untreated samples average set at ≤0.05% EGFP positive cells, and converting the obtained percentage into flow cytometry transducing units (FTU/mL), a measure of functional titre, by multiplying by the number of cells per well and the sample dilution. For each experiment, titres were normalised with the control condition of each experiment set at 100%.

Statistical analysis

Where possible, statistically significant differences between group means were determined by one-way ANOVA using Prism 7 (GraphPad, La Jolla, CA, USA) and reported as F(k-1, N-k) = F value, p = p value, where k is the number of groups and N the number of data points. This was followed, if appropriate, by Dunnett’s post-test, to compare each of a number of treatments with a single control. A calculated p value of >0.05 was deemed non-significant (indicated with “ns” on figures). Calculated p values of <0.05 were deemed a significant difference and indicated with one star (*) on figures. Error bars in figures represent the standard error of the mean (SEM). Statistical power was evaluated using G*Power 3.184 (University of Düsseldorf, Düsseldorf, Germany).

Data Availability

All primary data can be made available upon request.

Change history

25 April 2018

A correction to this article has been published and is linked from the HTML and PDF versions of this paper. The error has not been fixed in the paper.

References

Villarreal, L. P. Viruses and the Evolution of Life. (American Society of Microbiology, 2005).

Giacca, M. & Zacchigna, S. Virus-mediated gene delivery for human gene therapy. J Control Release 161, 377–388, doi:10.1016/j.jconrel.2012.04.008 (2012).

Weinberg, J. B., Matthews, T. J., Cullen, B. R. & Malim, M. H. Productive human immunodeficiency virus type 1 (HIV-1) infection of nonproliferating human monocytes. J Exp Med 174, 1477–1482, doi:10.1084/jem.174.6.1477 (1991).

Kalos, M. et al. T cells with chimeric antigen receptors have potent antitumor effects and can establish memory in patients with advanced leukemia. Sci Transl Med 3, 95ra73, doi:10.1126/scitranslmed.3002842 (2011).

Porter, D. L., Levine, B. L., Kalos, M., Bagg, A. & June, C. H. Chimeric antigen receptor-modified T cells in chronic lymphoid leukemia. The New England journal of medicine 365, 725–733, doi:10.1056/NEJMoa1103849 (2011).

Grupp, S. A. et al. Chimeric antigen receptor-modified T cells for acute lymphoid leukemia. The New England journal of medicine 368, 1509–1518, doi:10.1056/NEJMoa1215134 (2013).

Cartier, N. et al. Hematopoietic stem cell gene therapy with a lentiviral vector in X-linked adrenoleukodystrophy. Science 326, 818–823, doi:10.1126/science.1171242 (2009).

Biffi, A. et al. Lentiviral hematopoietic stem cell gene therapy benefits metachromatic leukodystrophy. Science 341, 1233158, doi:10.1126/science.1233158 (2013).

Aiuti, A. et al. Lentiviral hematopoietic stem cell gene therapy in patients with Wiskott-Aldrich syndrome. Science 341, 1233151, doi:10.1126/science.1233151 (2013).

De Ravin, S. S. et al. Lentiviral hematopoietic stem cell gene therapy for X-linked severe combined immunodeficiency. Sci Transl Med 8, 335ra357, doi:10.1126/scitranslmed.aad8856 (2016).

Palfi, S. et al. Long-term safety and tolerability of ProSavin, a lentiviral vector-based gene therapy for Parkinson’s disease: a dose escalation, open-label, phase 1/2 trial. Lancet 383, 1138–1146, doi:10.1016/S0140-6736(13)61939-X (2014).

Pecen, P. E. & Kaiser, P. K. Current phase 1/2 research for neovascular age-related macular degeneration. Curr Opin Ophthalmol 26, 188–193, doi:10.1097/ICU.0000000000000147 (2015).

Kobayashi, M., Iida, A., Ueda, Y. & Hasegawa, M. Pseudotyped lentivirus vectors derived from simian immunodeficiency virus SIVagm with envelope glycoproteins from paramyxovirus. J Virol 77, 2607–2614, doi:10.1128/JVI.77.4.2607-2614.2003 (2003).

Alton, E. W. et al. Preparation for a first-in-man lentivirus trial in patients with cystic fibrosis. Thorax 72, 137–147, doi:10.1136/thoraxjnl-2016-208406 (2017).

Mitomo, K. et al. Toward gene therapy for cystic fibrosis using a lentivirus pseudotyped with Sendai virus envelopes. Mol Ther 18, 1173–1182, doi:10.1038/mt.2010.13 (2010).

Scheid, A., Caliguiri, L. A., Compans, R. W. & Choppin, P. W. Isolation of paramyxovirus glycoproteins. Association of both hemagglutinating and neuraminidase activities with the larger SV5 glycoprotein. Virology 50, 640–652 (1972).

Homma, M. Trypsin action on the growth of Sendai virus in tissue culture cells. I. Restoration of the infectivity for L cells by direct action of tyrpsin on L cell-borne Sendai virus. J Virol 8, 619–629 (1971).

Clement, N. & Grieger, J. C. Manufacturing of recombinant adeno-associated viral vectors for clinical trials. Mol Ther Methods Clin Dev 3, 16002, doi:10.1038/mtm.2016.2 (2016).

Kallel, H. & Kamen, A. A. Large-scale adenovirus and poxvirus-vectored vaccine manufacturing to enable clinical trials. Biotechnol J 10, 741–747, doi:10.1002/biot.201400390 (2015).

Even, M. S., Sandusky, C. B. & Barnard, N. D. Serum-free hybridoma culture: ethical, scientific and safety considerations. Trends Biotechnol 24, 105–108, doi:10.1016/j.tibtech.2006.01.001 (2006).

World Health Organisation. Medicinal and other products and human and animal transmissible spongiform encephalopathies: memorandum from a WHO meeting. Bull World Health Organ 75, 505–513 (1997).

Food and Drug Administration. Guidance for FDA Reviewers and Sponsors: Content and Review of Chemistry, Manufacturing, and Control (CMC) Information for Human Gene Therapy Investigational New Drug Applications (INDs) (2008).

Macy, E., Bulpitt, K., Champlin, R. E. & Saxon, A. Anaphylaxis to infusion of autologous bone marrow: an apparent reaction to self, mediated by IgE antibody to bovine serum albumin. J Allergy Clin Immunol 83, 871–875, doi:10.1016/0091-6749(89)90099-7 (1989).

Mackensen, A., Drager, R., Schlesier, M., Mertelsmann, R. & Lindemann, A. Presence of IgE antibodies to bovine serum albumin in a patient developing anaphylaxis after vaccination with human peptide-pulsed dendritic cells. Cancer Immunol Immunother 49, 152–156, doi:10.1007/s002620050614 (2000).

Selvaggi, T. A., Walker, R. E. & Fleisher, T. A. Development of antibodies to fetal calf serum with arthus-like reactions in human immunodeficiency virus-infected patients given syngeneic lymphocyte infusions. Blood 89, 776–779 (1997).

Tuschong, L., Soenen, S. L., Blaese, R. M., Candotti, F. & Muul, L. M. Immune response to fetal calf serum by two adenosine deaminase-deficient patients after T cell gene therapy. Human gene therapy 13, 1605–1610, doi:10.1089/10430340260201699 (2002).

Brindley, D. A. et al. Peak serum: implications of serum supply for cell therapy manufacturing. Regen Med 7, 7–13, doi:10.2217/rme.11.112 (2012).

Kurita, M. et al. Differential effects of three preparations of human serum on expansion of various types of human cells. Plast Reconstr Surg 122, 438–448, doi:10.1097/PRS.0b013e31817d618d (2008).

Baekelandt, V., Eggermont, K., Michiels, M., Nuttin, B. & Debyser, Z. Optimized lentiviral vector production and purification procedure prevents immune response after transduction of mouse brain. Gene Ther 10, 1933–1940, doi:10.1038/sj.gt.3302094 (2003).

Hyde, S. C. et al. 82. Scalable, Animal-Free, Suspension-Based Production of Siv Lentiviral Vectors. Molecular Therapy 23, S35–S36, doi:10.1016/s1525-0016(16)33687-5 (2015).

Rodrigues, A. F., Amaral, A. I., Verissimo, V., Alves, P. M. & Coroadinha, A. S. Adaptation of retrovirus producer cells to serum deprivation: Implications in lipid biosynthesis and vector production. Biotechnol Bioeng 109, 1269–1279, doi:10.1002/bit.24410 (2012).

Aloia, R. C., Tian, H. & Jensen, F. C. Lipid composition and fluidity of the human immunodeficiency virus envelope and host cell plasma membranes. Proc Natl Acad Sci USA 90, 5181–5185, doi:10.1073/pnas.90.11.5181 (1993).

Nguyen, D. H. & Hildreth, J. E. Evidence for budding of human immunodeficiency virus type 1 selectively from glycolipid-enriched membrane lipid rafts. J Virol 74, 3264–3272, doi:10.1128/JVI.74.7.3264-3272.2000 (2000).

Simons, K. & Ikonen, E. Functional rafts in cell membranes. Nature 387, 569–572, doi:10.1038/42408 (1997).

Kilburn, D. G. & Webb, F. C. The cultivation of animal cells at controlled dissolved oxygen partial pressure. Biotechnology and Bioengineering 10, 801–814, doi:10.1002/bit.260100607 (1968).

Mitta, B., Rimann, M. & Fussenegger, M. Detailed design and comparative analysis of protocols for optimized production of high-performance HIV-1-derived lentiviral particles. Metab Eng 7, 426–436, doi:10.1016/j.ymben.2005.06.006 (2005).

Chen, Y. et al. Cholesterol Supplementation During Production Increases the Infectivity of Retroviral and Lentiviral Vectors Pseudotyped with the Vesicular Stomatitis Virus Glycoprotein (VSV-G). Biochemical engineering journal 44, 199–207, doi:10.1016/j.bej.2008.12.004 (2009).

Rodrigues, A. F., Carmo, M., Alves, P. M. & Coroadinha, A. S. Retroviral vector production under serum deprivation: The role of lipids. Biotechnol Bioeng 104, 1171–1181, doi:10.1002/bit.22499 (2009).

Christian, A. E., Haynes, M. P., Phillips, M. C. & Rothblat, G. H. Use of cyclodextrins for manipulating cellular cholesterol content. J Lipid Res 38, 2264–2272 (1997).

Klein, U., Gimpl, G. & Fahrenholz, F. Alteration of the myometrial plasma membrane cholesterol content with beta-cyclodextrin modulates the binding affinity of the oxytocin receptor. Biochemistry 34, 13784–13793, doi:10.1021/bi00042a009 (1995).

Kilsdonk, E. P. et al. Cellular cholesterol efflux mediated by cyclodextrins. J Biol Chem 270, 17250–17256, doi:10.1074/jbc.270.29.17250 (1995).

Rodal, S. K. et al. Extraction of cholesterol with methyl-beta-cyclodextrin perturbs formation of clathrin-coated endocytic vesicles. Mol Biol Cell 10, 961–974, doi:10.1091/mbc.10.4.961 (1999).

Liao, Z., Cimakasky, L. M., Hampton, R., Nguyen, D. H. & Hildreth, J. E. Lipid rafts and HIV pathogenesis: host membrane cholesterol is required for infection by HIV type 1. AIDS Res Hum Retroviruses 17, 1009–1019, doi:10.1089/088922201300343690 (2001).

Viard, M. et al. Role of cholesterol in human immunodeficiency virus type 1 envelope protein-mediated fusion with host cells. J Virol 76, 11584–11595, doi:10.1128/JVI.76.22.11584-11595.2002 (2002).

Ono, A. & Freed, E. O. Plasma membrane rafts play a critical role in HIV-1 assembly and release. Proc Natl Acad Sci USA 98, 13925–13930, doi:10.1073/pnas.241320298 (2001).

Campbell, S. M., Crowe, S. M. & Mak, J. Virion-associated cholesterol is critical for the maintenance of HIV-1 structure and infectivity. AIDS 16, 2253–2261, doi:10.1097/00002030-200211220-00004 (2002).

Guyader, M., Kiyokawa, E., Abrami, L., Turelli, P. & Trono, D. Role for human immunodeficiency virus type 1 membrane cholesterol in viral internalization. J Virol 76, 10356–10364, doi:10.1128/JVI.76.20.10356-10364.2002 (2002).

Broussau, S. et al. Inducible packaging cells for large-scale production of lentiviral vectors in serum-free suspension culture. Mol Ther 16, 500–507, doi:10.1038/sj.mt.6300383 (2008).

Pham, P. L. et al. Large-scale transient transfection of serum-free suspension-growing HEK293 EBNA1 cells: peptone additives improve cell growth and transfection efficiency. Biotechnol Bioeng 84, 332–342, doi:10.1002/bit.10774 (2003).

Mayer, M. & Noble, M. N-acetyl-L-cysteine is a pluripotent protector against cell death and enhancer of trophic factor-mediated cell survival in vitro. Proc Natl Acad Sci USA 91, 7496–7500, doi:10.1073/pnas.91.16.7496 (1994).

Roederer, M. et al. Cytokine-stimulated human immunodeficiency virus replication is inhibited by N-acetyl-L-cysteine. Proc Natl Acad Sci U S A 87, 4884–4888, doi:10.1073/pnas.87.12.4884 (1990).

Akerlund, B. et al. Effect of N-acetylcysteine(NAC) treatment on HIV-1 infection: a double-blind placebo-controlled trial. Eur J Clin Pharmacol 50, 457–461, doi:10.1007/s002280050140 (1996).

Spada, C. et al. The effect of N-acetylcysteine supplementation upon viral load, CD4, CD8, total lymphocyte count and hematocrit in individuals undergoing antiretroviral treatment. Clin Chem Lab Med 40, 452–455, doi:10.1515/CCLM.2002.077 (2002).

Pani, A., Marongiu, M. E. & La Colla, P. Modulatory effect of N-acetyl-L-cysteine on the HIV-1 multiplication in chronically and acutely infected cell lines. Antiviral Res 22, 31–43, doi:10.1016/0166-3542(93)90084-V (1993).

Jordan, M., Eppenberger, H. M., Sucker, H., Widmer, F. & Einsele, A. Interactions between animal cells and gas bubbles: The influence of serum and pluronic F68 on the physical properties of the bubble surface. Biotechnol Bioeng 43, 446–454, doi:10.1002/bit.260430603 (1994).

Dey, D., BoultonStone, J. M., Emery, A. N. & Blake, J. R. Experimental comparisons with a numerical model of surfactant effects on the burst of a single bubble. Chem Eng Sci 52, 2769–2783, doi:10.1016/S0009-2509(97)00083-3 (1997).

Ramirez, O. T. & Mutharasan, R. The role of the plasma membrane fluidity on the shear sensitivity of hybridomas grown under hydrodynamic stress. Biotechnol Bioeng 36, 911–920, doi:10.1002/bit.260360906 (1990).

Lesch, H. P. et al. Production and purification of lentiviral vectors generated in 293T suspension cells with baculoviral vectors. Gene Ther 18, 531–538, doi:10.1038/gt.2010.162 (2011).

Okonkowski, J. et al. Cholesterol delivery to NS0 cells: challenges and solutions in disposable linear low-density polyethylene-based bioreactors. J Biosci Bioeng 103, 50–59, doi:10.1263/jbb.103.50 (2007).

Kadarusman, J., Bhatia, R., McLaughlin, J. & Lin, W. R. Growing cholesterol-dependent NS0 myeloma cell line in the wave bioreactor system: overcoming cholesterol-polymer interaction by using pretreated polymer or inert fluorinated ethylene propylene. Biotechnol Prog 21, 1341–1346, doi:10.1021/bp050091+ (2005).

Keller, P. & Simons, K. Cholesterol is required for surface transport of influenza virus hemagglutinin. J Cell Biol 140, 1357–1367 (1998).

Ridsdale, A. et al. Cholesterol is required for efficient endoplasmic reticulum-to-Golgi transport of secretory membrane proteins. Mol Biol Cell 17, 1593–1605, doi:10.1091/mbc.E05-02-0100 (2006).

Holic, N., Frin, S., Seye, A. K., Galy, A. & Fenard, D. Improvement of De Novo Cholesterol Biosynthesis Efficiently Promotes the Production of Human Immunodeficiency Virus Type 1-Derived Lentiviral Vectors. Hum Gene Ther Methods. doi:10.1089/hgtb.2016.150 (2016).

Solomon, V. R. & Lee, H. Chloroquine and its analogs: a new promise of an old drug for effective and safe cancer therapies. Eur J Pharmacol 625, 220–233, doi:10.1016/j.ejphar.2009.06.063 (2009).

Luthman, H. & Magnusson, G. High efficiency polyoma DNA transfection of chloroquine treated cells. Nucleic Acids Res 11, 1295–1308, doi:10.1093/nar/11.5.1295 (1983).

Pear, W. S., Nolan, G. P., Scott, M. L. & Baltimore, D. Production of high-titer helper-free retroviruses by transient transfection. Proc Natl Acad Sci U S A 90, 8392–8396, doi:10.1073/pnas.90.18.8392 (1993).

Ciftci, K. & Levy, R. J. Enhanced plasmid DNA transfection with lysosomotropic agents in cultured fibroblasts. Int J Pharm 218, 81–92, doi:10.1016/S0378-5173(01)00623-8 (2001).

Beyer, W. R., Westphal, M., Ostertag, W. & von Laer, D. Oncoretrovirus and lentivirus vectors pseudotyped with lymphocytic choriomeningitis virus glycoprotein: generation, concentration, and broad host range. J Virol 76, 1488–1495, doi:10.1128/JVI.76.3.1488-1495.2002 (2002).

Park, F., Ohashi, K., Chiu, W., Naldini, L. & Kay, M. A. Efficient lentiviral transduction of liver requires cell cycling in vivo. Nat Genet 24, 49–52, doi:10.1038/71673 (2000).

Mochizuki, H., Schwartz, J. P., Tanaka, K., Brady, R. O. & Reiser, J. High-titer human immunodeficiency virus type 1-based vector systems for gene delivery into nondividing cells. J Virol 72, 8873–8883 (1998).

Reiser, J. et al. Transduction of nondividing cells using pseudotyped defective high-titer HIV type 1 particles. Proc Natl Acad Sci USA 93, 15266–15271, doi:10.1073/pnas.93.26.15266 (1996).

al Yacoub, N., Romanowska, M., Haritonova, N. & Foerster, J. Optimized production and concentration of lentiviral vectors containing large inserts. The journal of gene medicine 9, 579–584, doi:10.1002/jgm.1052 (2007).

Karolewski, B. A., Watson, D. J., Parente, M. K. & Wolfe, J. H. Comparison of transfection conditions for a lentivirus vector produced in large volumes. Human gene therapy 14, 1287–1296, doi:10.1089/104303403322319372 (2003).

Kuroda, H., Kutner, R. H., Bazan, N. G. & Reiser, J. Simplified lentivirus vector production in protein-free media using polyethylenimine-mediated transfection. J Virol Methods 157, 113–121, doi:10.1016/j.jviromet.2008.11.021 (2009).

Boussif, O. et al. A versatile vector for gene and oligonucleotide transfer into cells in culture and in vivo: polyethylenimine. Proc Natl Acad Sci USA 92, 7297–7301, doi:10.1073/pnas.92.16.7297 (1995).

Ellis, B. L., Potts, P. R. & Porteus, M. H. Creating higher titer lentivirus with caffeine. Human gene therapy 22, 93–100, doi:10.1089/hum.2010.068 (2011).

Rose, A. C. et al. Optimisation of real-time quantitative RT-PCR for the evaluation of non-viral mediated gene transfer to the airways. Gene Ther 9, 1312–1320, doi:10.1038/sj.gt.3301792 (2002).

Zanta-Boussif, M. A. et al. Validation of a mutated PRE sequence allowing high and sustained transgene expression while abrogating WHV-X protein synthesis: application to the gene therapy of WAS. Gene Ther 16, 605–619, doi:10.1038/gt.2009.3 (2009).

Davies, L. A. et al. The use of CpG-free plasmids to mediate persistent gene expression following repeated aerosol delivery of pDNA/PEI complexes. Biomaterials 33, 5618–5627, doi:10.1016/j.biomaterials.2012.04.019 (2012).

Gorman, C. M., Howard, B. H. & Reeves, R. Expression of recombinant plasmids in mammalian cells is enhanced by sodium butyrate. Nucleic Acids Res 11, 7631–7648, doi:10.1093/nar/11.21.7631 (1983).

Sakoda, T., Kasahara, N., Hamamori, Y. & Kedes, L. A high-titer lentiviral production system mediates efficient transduction of differentiated cells including beating cardiac myocytes. J Mol Cell Cardiol 31, 2037–2047, doi:10.1006/jmcc.1999.1035 (1999).

Gasmi, M. et al. Requirements for efficient production and transduction of human immunodeficiency virus type 1-based vectors. J Virol 73, 1828–1834 (1999).

Toyoshima, K. & Vogt, P. K. Enhancement and inhibition of avian sarcoma viruses by polycations and polyanions. Virology 38, 414–426, doi:10.1016/0042-6822(69)90154-8 (1969).

Faul, F., Erdfelder, E., Lang, A. G. & Buchner, A. G*Power 3: a flexible statistical power analysis program for the social, behavioral, and biomedical sciences. Behav Res Methods 39, 175–191, doi:10.3758/BF03193146 (2007).

Acknowledgements

We thank ID Pharma Co., Ltd for providing original vector components. JFG was supported by the Clarendon Fund of the University of Oxford, the de Breyne Scholarship from Keble College and a Doctoral Foreign Study Award from the Canadian Institutes of Health Research. L.R.D., D.R.G. and S.C.H. were supported by the Cystic Fibrosis Trust, Just Gene Therapy and the Medicor Foundation.

Author information

Authors and Affiliations

Contributions

All authors contributed to the design of the experiments and reviewed the manuscript. JFG performed the experiments. J.F.G., D.R.G. and S.C.H. prepared the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gélinas, JF., Davies, L.A., Gill, D.R. et al. Assessment of selected media supplements to improve F/HN lentiviral vector production yields. Sci Rep 7, 10198 (2017). https://doi.org/10.1038/s41598-017-07893-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-07893-3

This article is cited by

-

Viral vector platforms within the gene therapy landscape

Signal Transduction and Targeted Therapy (2021)

-

Development of a laboratory scalable process for enhancing lentivirus production by transient transfection of HEK293 adherent cultures

Gene Therapy (2020)

-

LentiPro26: novel stable cell lines for constitutive lentiviral vector production

Scientific Reports (2018)

-

Norisoboldine, a natural AhR agonist, promotes Treg differentiation and attenuates colitis via targeting glycolysis and subsequent NAD+/SIRT1/SUV39H1/H3K9me3 signaling pathway

Cell Death & Disease (2018)

-

The murine lung as a factory to produce secreted intrapulmonary and circulatory proteins

Gene Therapy (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.