Abstract

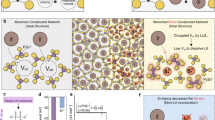

There are two types of solid electrolytes which has been recently expected to be applied to all-solid-state batteries. One is the glasses characterized by an amorphous state. The other is the glass ceramics containing crystalline in an amorphous matrix. However, the non-crystalline state of glasses and glass ceramics is still an open question. It has been anticipated that sea-island and core-shell structures including crystalline nanoparticles have been proposed as candidate models for glass ceramics. Nevertheless, no direct observation has been conducted so far. Here we report the non-crystalline state of Li2S–P2S5 glasses and glass ceramics, and the crystallization behavior of the glasses during heating via direct transmission electron microscopy (TEM) observation. High resolution TEM images clearly revealed the presence of crystalline nanoparticles in an amorphous region. Eventually we suggest that the precipitation and connection of crystalline nanoparticles in an amorphous matrix are key to achieving high ionic conductivity.

Similar content being viewed by others

Introduction

Lithium-ion secondary batteries have received a lot of attention in recent years due to their excellent charge-discharge cycle characteristics and high energy density. However, safety concerns exist because they require the use of a flammable organic solvent. To resolve the safety problem, we focused on a sulfide-type all-solid-state battery using a non-flammable inorganic solid electrolyte. Sulfide-based inorganic solid electrolytes are known to be electrochemically stable in a wide potential window and exhibit high lithium ion conductivities due to the high polarizability of sulfide ions1,2,3,4,5,6. Therefore, sulfide solid electrolytes are promising candidates for developing all-solid-state batteries.

Li2S–P2S5 glasses prepared by a mechanical milling technique exhibit high conductivities of over 10−4 S cm−1 at room temperature7. Notably, Li2S–P2S5 glass crystallizes by heat treatment, and its lithium ion conductivities highly depend on the type of precipitated crystalline phases and the composition of Li2S8, 9. F. Mizuno. et al. showed that conductivity was enhanced by crystallization with compositions from 70 to 85 mol% Li2S; the obtained glass-ceramics exhibited high conductivity of about 10−3 S cm−1 at room temperature. With compositions of 70 and 80 mol% Li2S, the conductivity enhancement was due to the precipitation of metastable Li7P3S11 and LGPS analog (Li3.25P0.95S4) crystal phases, respectively10,11,12. Therefore, the high conductivities of Li2S–P2S5 glass-ceramics were directly associated with the percent composition of Li2S and the type of precipitated crystalline phase.

A glass ceramic is generally defined as a material obtained by crystallizing glasses. Sea-island and core-shell structures including crystalline nanoparticles have been proposed as possible models of glass ceramics. However, the size and morphology of crystals in an amorphous matrix have not been clarified yet. Although various experiments have been conducted so far to reveal the structure of Li2S–P2S5 solid electrolytes13,14,15,16, there have been no direct observations of the microstructure of the corresponding glasses and glass ceramics. In this study, we carried out direct observation and structural analysis for the 75Li2S·25P2S5 and 80Li2S·20P2S5 solid electrolytes using transmission electron microscopy (TEM). Notably, Li2S–P2S5 glasses composed of approximately compositions 75 mol% Li2S exhibited great chemical stability. H. Muramatsu. et al. showed that in the Li2S–P2S5 system, 75Li2S·25P2S5 glasses generated the least amount of H2S when exposed to air17. This excellent chemical stability provide the best experimental condition for in-situ TEM observation of Li2S–P2S5 solid electrolytes because the sulfide-based solid electrolyte is highly sensitive to electron beam irradiation.

Results and Discussion

We first examined the microstructure of the 80Li2S·20P2S5 glass ceramics obtained by heat-treatment at 240 °C. Fig. 1(a) and (b) shows the XRD pattern and high resolution (HR) TEM image of the 80Li2S·20P2S5 glass ceramics. The inset of Fig. 1(b) shows a bright field (BF) image indicating the morphology of 80Li2S·20P2S5 glass ceramics. Characteristic speckled contrasts could be observed, as indicated by small arrows in the BF image. These contrasts are attributed to the aggregation of crystalline nanoparticles. The HR-TEM image (b) was obtained from the area indicated by the circle in the BF image. In the XRD pattern (a), the profiles due to a Li10GeP2S12 (LGPS) analog crystal (Li3.25P0.95S4) phase were detected. In the HR-TEM image (b), lattice fringes were observed in the sample. Notably, crystalline nanoparticles with an average size of about 5 nm were present in an amorphous matrix and connected to each other, as indicated by dotted circles. These nanoparticles appear to be LGPS analog crystals. This indicates that precipitation and connection of LGPS analog crystalline nanoparticles in an amorphous matrix contributes to a high ionic conductivity of more than 10−3 S cm−1 in the 80Li2S·20P2S5 glass-ceramics10.

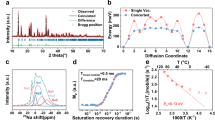

Next, the microstructure of the 75Li2S·25P2S5 glasses and glass ceramics were investigated. First, we confirmed the crystal structures of the 75Li2S·25P2S5 glasses and glass-ceramics by powder XRD experiments. The glass-ceramic sample was prepared by heating precursor 75Li2S·25P2S5 glasses at 210 °C. Figure 2 shows the XRD patterns of the 75Li2S·25P2S5 glasses and glass-ceramics at room temperature. The as-prepared glass sample after mechanical milling was intrinsically amorphous. On the other hand, the glass-ceramic sample exhibited XRD patterns that are attributable to the \(\beta \)-Li3PS4 crystal6. To further understand the microstructure and crystallization behavior in the 75Li2S·25P2S5 glasses, in-situ TEM observation were carried out. Figure 3(a) and (b) show DF and HR images of the microstructure of the 75Li2S·25P2S5 glasses. The corresponding electron diffraction (ED) pattern is shown in the inset of Fig. 3(a). Typical halo rings were observed in the ED pattern. This indicates that the spatially-averaged structure of 75Li2S·25P2S5 glasses are characterized by an amorphous state. In the DF image (a), however, crystallized regions exhibiting bright contrasts were visualized, as indicated by arrows. The average size of crystalline nanoparticles was approximately 5 to 20 nm. In addition, crystalline nanoparticles were likely to scatter over the sample without connecting. This image is entirely different from the 75Li2S·25P2S5 glass ceramics, which will be discussed later. In the HR-TEM image (b), furthermore, crystalline nanoparticles with an average size of approximately 5 nm are randomly distributed in an amorphous matrix, as indicated by yellow dotted circles. That is, in spite of a spatially-averaged amorphous structure, crystalline nanoparticles were present in the 75Li2S·25P2S5 glasses.

To understand the crystallization behavior of the 75Li2S·25P2S5 glasses, we conducted in-situ TEM observations of the heating process. Figure 4 shows variations of ED patterns as a function of temperature, together with the corresponding BF image, DSC curve and integral intensity profiles of the ED patterns at 280 °C. A series of ED patterns in Fig. 4(a1) and (b1) were respectively obtained from regions 1 and 2, as indicated by yellow circles in the BF image (d). The integral intensity profiles of the ED pattern at 280 °C in regions 1 and 2 are shown in Fig. 4 (a2) and (b2), respectively. In the initial state at 20 °C, the ED patterns in regions 1 and 2 exhibited halo rings, which indicate an amorphous state. At region 1, crystallization was detected at approximately 180 °C and, remarkably, proceeded above 200 °C with increasing temperature, as seen in Fig. 4 (a1). To identify the precipitated crystalline phase, we analyzed the integral intensity profiles of the ED pattern at 280 °C. As seen in Fig. 4 (a2), the peak positions of the intensity profile almost correspond to the XRD profiles for orthorhombic \(\beta \)-Li3PS4 with the space group Pnma6. When we investigated the crystallization behavior of many other particles, we found that a polycrystalline state similar to region 1 frequently appeared. At region 2, on the other hand, crystallization could be observed at approximately 220 °C, as seen in Fig. 4 (b1). The intensity profiles shown in Fig. 4 (b2) approximately correspond to the XRD profiles of the \(\beta \)-Li3PS4 crystal. The ED pattern at 280 °C indicates the precipitation of a single crystalline particle having the same crystal orientation. This crystallization behavior was relatively minor. Based on the analysis of the ED pattern at 280 °C, the crystal orientation was parallel to the \([\bar{1}10]\) direction in the orthorhombic Pnma structure. Thus, the crystallization behavior of the 75Li2S·25P2S5 glasses can be characterized by the precipitation of a \(\beta \)-Li3PS4 crystalline phase. This is compatible with the XRD pattern in Fig. 2. These crystallization behaviors are compared with the DSC curve in Fig. 4(c). The exothermal peak observed at around 220 °C is attributable to the transition from glass to the \(\beta \)-Li3PS4 crystal.

Series of ED patterns (a1) and (b1) as a function of temperature in the milled 75Li2S·25P2S5 glasses, which were obtained from regions 1 and 2, respectively, as indicated by yellow circles in the BF image (d). The integrated intensity profiles (a2) and (b2) were constructed from the ED pattern at 280 °C in regions 1 and 2, respectively. The DSC curve of the 75Li2S·25P2S5 glasses is shown in (c).

To reveal the microstructure of the 75Li2S·25P2S5 glass ceramics, we carried out in-situ TEM observation at 210 °C. Figure 5(a) and (b) show DF and HR-TEM images, together with the corresponding ED pattern in the inset of Fig. 5(a). In the DF image (a), numerous crystallized regions can be observed as bright contrasts compared to the glasses. On average, the sizes of crystalline nanoparticles were approximately 30 to 60 nm. Crystalline nanoparticles were likely to connect to each other. In the ED pattern, Debye-Scherrer rings consisting of spots were observed, together with weak halo rings. Based on the analysis of the integral intensity profile, the crystal structure was confirmed to be \(\beta \)-Li3PS4. In the HR-TEM image (b), lattice fringes can be clearly observed and crystalline particles with an average size of approximately 30 nm are adjacent to each other, as indicated by yellow dotted circles. To understand the crystal structure of the crystalline particles, we carried out Fast Fourier transform (FFT) calculations for the nanoscale local regions with an area of approximately 10 × 10 nm2. The FFT pattern obtained from the region indicated by a dotted white square is shown in the inset of Fig. 5(b). In the FFT pattern, the ED pattern with the [131] incidence from the orthorhombic Pnma structure was reproduced. Based on these patterns, the 75Li2S·25P2S5 glass ceramics were characterized by the aggregation of \(\beta \)-Li3PS4 crystalline particles in an amorphous matrix.

In the present study, we examined microstructures of Li2S–P2S5 glasses and glass ceramics via in-situ TEM observation. HR-TEM and DF images revealed that 75Li2S·25P2S5 glasses were characterized by an amorphous state, in which nano-sized crystals were randomly distributed. These nano-sized crystals are shown in Fig. 3(b) and may play an essential role as a nucleus for crystallization. On the other hand, 75Li2S·25P2S5 and 80Li2S·20P2S5 glass ceramics were characterized by an aggregation of crystalline nanoparticles. Notably,\(\beta \)-Li3PS4 and LGPS analog crystalline nanoparticles, which are responsible for high ionic conductivity, connected to each other in an amorphous matrix. This implies that ionic conduction in Li2S–P2S5 glass ceramics is due to the connection between precipitated crystalline nanoparticles. In addition, in-situ TEM observation during heating revealed that the crystallization started at around 200 °C and the \(\beta \)-Li3PS4 crystalline phase precipitated. This suggests that the exothermal reaction in the 75Li2S·25P2S5 glasses is due to crystallization.

Conclusion

We examined the microstructures of Li2S–P2S5 glasses and glass ceramics via TEM. In-situ TEM observation at room temperature revealed that the glasses could be identified as an amorphous state studded with crystalline nanoparticles; whereas, the glass ceramics were characterized by the aggregation of \(\beta \)-Li3PS4 and LGPS analog crystalline particles exhibiting high ionic conductivity. To reveal the crystallization behavior of the glasses, we investigated the crystallization process in 75Li2S·25P2S5 glasses. We found that \(\beta \)-Li3PS4 crystals started to precipitate at approximately 200 °C in an exothermal reaction. Based on these data, the precipitation and connection of \(\beta \)-Li3PS4 and LGPS analog crystalline nanoparticles contribute to high ionic conductivity.

Method

Sample preparation

The Li2S–P2S5 glass solid electrolytes were prepared by mechanical milling technique. Li2S (Idemitsu Kosan Co., >99.9%) and P2S5 (Aldrich, 99%) initial crystalline powders was used to prepare the 75Li2S·25P2S5 and 80Li2S·20P2S5 (mol %) glass sample. The mechanical milling process was conducted at room temperature by a planetary ball mill apparatus (Fritsch Pulverisette 7) consisting of an Al2O3 pot (volume 45 ml) and Al2O3 balls (10 mm in diameter)11. The milling time was 20 h and the rotation speed was 370 rpm. All the processes were conducted in a glove box filled with dry argon gas (less than 1 ppm water). The 80Li2S·20P2S5 glass-ceramic sample was obtained by crystallizing the mechanically milled 80Li2S·20P2S5 glass via heat-treatment at 240 °C for 2 h. To identify the precipitated crystal phase, X-ray diffraction (XRD) measurements were performed using a diffractometer (Rigaku Ultima IV) with CuKα radiation. Thermal behavior of the glass solid electrolytes was examined with a differential scanning calorimeter (DSC, Rigaku Co., model DSC 8231). The Li2S–P2S5 glass sample for the DSC measurements was put into the stainless-steel pan, which was then crimp-sealed. The DSC measurements were carried out at the heating rate of 5 °C min−1 from room temperature to 400 °C.

TEM observation

In-situ TEM observations were carried out using JEM-2100F field-emission-type TEM systems with acceleration voltages of 200 kV in the temperature range from 20 to 300 °C. Samples were mounted on an amorphous carbon film supported by a Cu grid for TEM observation, which was then attached to a TEM holder in a dry Ar-filled glove box. During observation, we used a double-tilt vacuum transfer TEM holder (Gatan model 648) to prevent the sample from being exposed to air. The vacuum degree in TEM was approximately 1.0 × 10−5 Pa. Since the Li2S–P2S5 solid electrolytes are very sensitive to the electron beam irradiation, the electron beam was not converged on the Li2S–P2S5 sample as much as possible to avoid destroying it. In addition, to realize the optimum intensity of the electron beam for observations of the Li2S–P2S5 solid electrolytes, the size of the condenser aperture was set to be 40 μm in diameter. Features of the microstructure and crystallization behavior of Li2S–P2S5 solid electrolytes were examined by taking high resolution (HR) TEM images, dark field (DF) images, and corresponding electron diffraction (ED) patterns with a 14-bits CCD camera. To prevent damage to the sample by the electron beam, the exposure time was within 2 seconds. For identification of the precipitated crystalline phase from ED patterns, we utilized a computer program called “Process Diffraction”. In Process Diffraction, digital ED patterns can be transformed into integral intensities as a function of scattering angle, producing the intensity profile such as a usual XRD pattern18,19,20,21. By comparing the obtained ED patterns with XRD profiles, it was possible to identify the precipitated crystalline phase.

References

Mercier, R., Malugani, J. P., Fahys, B. & Robert, G. Superionic conduction in Li2S - P2S5 - LiI – glasses. Solid State Ionics 5, 663–666 (1981).

Pradel, A. & Ribes, M. Electrical properties of lithium conductive silicon sulfide glasses prepared by twin roller quenching. Solid State Ionics 18, 351–355 (1986).

Kondo, S., Takada, K. & Yamamura, Y. New lithium ion conductors based on Li2S-SiS2 system. Solid State Ionics 53, 1183–1186 (1992).

Tatsumisago, M., Hirai, K., Hirata, T., Takahashi, M. & Minami, T. Structure and properties of lithium ion conducting oxysulfide glasses prepared by rapid quenching. Solid State Ionics 86, 487–490 (1996).

Kanno, R. & Murayama, M. Lithium Ionic Conductor Thio-LISICON: The Li2S-GeS2-P2S5 System. J. Electrochem. Soc. 148, A742–A746 (2001).

Hori, S. et al. Phase Diagram of the Li4GeS4-Li3PS4 Quasi-Binary System Containing the Superionic Conductor Li10GeP2S12. J. Am. Ceram. Soc. 98, 3352–3360 (2015).

Hayashi, A., Hama, S., Morimoto, H., Tatsumisago, M. & Minami, T. Preparation of Li2S-P2S5 Amorphous Solid Electrolytes by Mechanical Milling. J. Am. Ceram. Soc 84, 477–479 (2001).

Mizuno, F., Hayashi, A., Tadanaga, K. & Tatsumisago, M. New, highly ion-conductive crystals precipitated from Li2S-P2S5 glasses. Adv. Mater. 17, 918–921 (2005).

Hayashi, A., Minami, K., Ujiie, S. & Tatsumisago, M. Preparation and ionic conductivity of Li7P3S11−z glass-ceramic electrolytes. J. Non-Cryst. Solids 356, 2670–2673 (2010).

Hayashi, A., Hama, S., Minami, T. & Tatsumisago, M. Formation of superionic crystals from mechanically milled Li2S-P2S5 glasses. Electrochem. Commun. 5, 111–114 (2003).

Mizuno, F., Hayashi, A., Tadanaga, K. & Tatsumisago, M. High Lithium Ion Conducting Glass-Ceramics in the System Li2S-P2S5. Solid State Ionics 177, 2721–2725 (2006).

Kamaya, N. et al. A Lithium Superionic Conductor. Nat. Mater. 10, 682–686 (2011).

Onodera, Y. et al. Crystal Structure of Li7P3S11 Studied by Neutron and Synchrotron X-ray Powder Diffraction. J. Phys. Soc. Jpn. 79, 87–89 (2010).

Ohara, K. et al. Structural and electronic features of binary Li2S-P2S5 glasses. Sci. Rep 6, 21302 (2016).

Mori, K. et al. Visualization of conduction pathways in lithium superionic conductors: Li2S-P2S5 glasses and Li7P3S11 glass-ceramic. Chem. Phys. Lett. 584, 113–118 (2013).

Onodera, Y. et al. Structural origin of ionic conductivity for Li7P3S11 metastable crystal by neutron and X-ray diffraction. J. Phys. Conf. Ser. 502, 012021 (2014).

Muramatsu, H., Hayashi, A., Ohtomo, T., Hama, S. & Tatsumisago, M. Structural change of Li2S-P2S5 sulfide solid electrolytes in the atmosphere. Solid State Ionics 182, 116–119 (2011).

Lábár, J. L. Consistent indexing of a (set of) single crystal SAED pattern(s) with the ProcessDiffraction program. Ultramicroscopy 103, 237–249 (2005).

Lábár, J. L. Electron diffraction based analysis of phase fractions and texture in nanocrystalline thin films, part I: Principles, Microsc. Microanal. 14, 287–295 (2008).

Lábár, J. L. Electron diffraction based analysis of phase fractions and texture in nanocrystalline thin films, Part II: Implementation. Microsc. Microanal. 15, 20–29 (2009).

Lábár, J. L. et al. Electron diffraction based analysis of phase fractions and texture in nanocrystalline thin films, part III: Application examples, Microsc. Microanal. 18, 406–420 (2012).

Acknowledgements

This work is supported by Advanced Low Carbon Technology Research and Development Program of Specially Promoted Research for Innovative Next Generation Batteries (ALCA-SPRING).

Author information

Authors and Affiliations

Contributions

H.T. and S.M. conceived and designed the study. A.H. and M.T. prepared the samples and conducted XRD experiments. H.M conducted the DSC experiments. H.T. and S.M. performed TEM experiments and all authors contributed to the discussion of the results. H.T. wrote the paper with help from all authors. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tsukasaki, H., Mori, S., Morimoto, H. et al. Direct observation of a non-crystalline state of Li2S–P2S5 solid electrolytes. Sci Rep 7, 4142 (2017). https://doi.org/10.1038/s41598-017-04030-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-04030-y

This article is cited by

-

Self-organized hetero-nanodomains actuating super Li+ conduction in glass ceramics

Nature Communications (2023)

-

3D observation using TEM tomography of solid electrolyte–electrode interface in all-solid-state Li-ion batteries

Journal of Solid State Electrochemistry (2023)

-

An electrochemically stable homogeneous glassy electrolyte formed at room temperature for all-solid-state sodium batteries

Nature Communications (2022)

-

A glance at the influence of different dopant elements on Li7La3Zr2O12 garnets

Ionics (2021)

-

Fundamentals of inorganic solid-state electrolytes for batteries

Nature Materials (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.