Abstract

Methods and mechanisms for improvement of photocatalytic activity, are important and popular research topics for renewable energy production and waste water treatment. Here, we demonstrate a facile laser drilling method for engineering well-aligned pore arrays on magnetron-sputtered WS2 nanofilms with increased active edge sites; the proposed method promotes partial oxidation to fabricate WS2/WO3 heterojunctions that enhance the separation of photogenerated electron-hole pairs. The WS2 film after one, two, and three treatments exhibited photocurrent density of 3.9, 6.2, and 8 μA/cm2, respectively, reaching up to 31 times larger than that of pristine WS2 film along with greatly improved charge recombination kinetics. The unprecedented combinational roles of laser drilling revealed in this study in regards to geometric tailoring, chemical transformation, and heterojunction positioning for WS2-based composite nanomaterials create a foundation for further enhancing the performance of other 2D transition metal dichalcogenides in photocatalysis via laser treatment.

Similar content being viewed by others

Introduction

Since the successful development of graphene, 2D layered materials have attracted tremendous research interests. The material is limited in terms of practical application, however, due to its zero-bandgap properties caused by valence and conduction bands meeting at the K points of the Brillouin zone1. In recent years, 2D layered transition metal dichalcogenides (TMDs) have become a popular research topic by virtue of their tunable bandgaps2, strong light-matter interactions3, extreme strain sustainability4, valley-selective optical stark effect5, and enhanced catalytic properties6. Tungsten disulfide (WS2), a typical layered TMD, consists of many layers of trigonal prismatic coordinated S-W-S planes connected to each other by van der Waals-type interactions. They offer novel functionalities over photodetectors7, lithium ion batteries8, solar cells9, optical limiters10, and hydrogen evolution reaction (HER) catalysts11. Compared to Pt-group metals, WS2 with modest Gibbs’ free energy is non-precious and earth-abundant, representing a remarkable potential alternative in electrochemical energy applications. The bandgap of semi-conductive WS2 is closely related to its layer numbers, ranging from 1.3 to 2.1 eV as it changes from bulk to fewer layers and exhibiting strong quantum confinement effect12, direct band gap transition13 and large spin-orbit coupling14, all of which make it a very promising photocatalyst.

Heterojunction design is an efficient strategy to extend photocurrent responses and facilitate rapid charge transfer via matched energy levels to inhibit electron-hole pair recombination15. Visible-light responding WO3/WS2 heterojunctions have been developed by hydrothermal/gas phase reaction16, in-situ anodic oxidation17, spray pyrolysis/sulfurization18, sputtering/plasma sulfurization19, and have exhibited both high optical absorption coefficients and catalytic activity. Compared against bulk WS2, the lateral heterostructure of WS2/WO3 is capable of much greater degradation of methyl orange and higher photocurrent response20. The slow decrease in photocurrent observed on the WS2/WO3 composite when the light was switched off reflects the favorable recombination properties of electron/hole pairs in the heterojunction21. Although several synthesis routes have been proposed to fabricate heterostructure, the effects of laser treatment on the formation of WS2/WO3 heterostructure remain unclear.

Thermodynamically, the formation of basal plane sites is more preferential than the formation of catalytically active edge sites22. The surface energy of the edge site was almost two orders of magnitude higher than that of the basal plane23. Structural design to expose active edge sites has been extensively investigated in recent years. Structures including highly ordered double-gyroid MoS2 bicontinous network24, defect-rich MoS2 ultrathin nanosheets25, and vertically aligned layered MoS2 films26, have been successfully developed to produce abundant active edge sites. Despite the notable progress made in the synthesis of two-dimensional metal chalcogenides, the geometric tailoring of porous WS2/WO3 heterostructure by laser treatment remains unexplored. Laser technique has been demonstrated as an attractive method to easily improve the photocatalytic properties of nanomaterials27, 28. The enhanced photocatalytic water splitting activity by laser treated TiO2 has been reported due to the structure modification under the laser irradiation29. Laser treatment of TMDs such as laser-thinning of bulk MoS2 into single layer and defect engineering of WSe2 films30, 31, represents a controllable strategy to increase material properties. In this study, magnetron sputtering and a facile, nanosecond pulse laser treatment was used to prepare porous WS2/WO3 heterojunctions to explore a new laser drilling technique for the geometric tailoring, chemical transformation, and heterojunction positioning of the material. The laser facilitated selective oxidation and increased number of active edge sites, in effect significantly enhancing the photoelectrocatalytic performance as well as the fast transportation of photogenerated electrons in the heterogeneous composite catalyst.

Results and Discussion

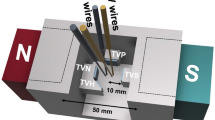

Laser materials processing is a popular technology employed in industry and the laser system used in this study is a low-cost widely and commercially available Q-switched Yb doped fiber laser with operational wavelength at near infrared, providing a cost effective way to modify materials for large area. Figure 1a shows a schematic diagram of the proposed laser treatment on the WS2 surface via a laser drilling setup with nanosecond pulse beam. When the laser radiation focuses on the surface of WS2, the laser heat flux, qin, at a distance ‘R’ from the center of the laser beam on the surface of the sample with Gaussian distribution as-expressed by Eqs (1) and (2)32. The consistent irradiation can result in the melting, ionization, bond breakage, gasification and phase explosion of the selected area.

where α is the material absorption coefficient, P p is the instantaneous laser power, r is the effective laser beam radius (which varies with the depth of hole), δ(t) is a pulse function, d is the laser beam diameter, M is the beam quality parameter, λ is to the laser wavelength, Z m is the melt depth and f c is the focal length of the focusing lens. These equations indicate that the heat flux on the materials surface is depending laser beam diameter, laser power and material absorption coefficient with respect to the input wavelength. Generally, the heat-affected zone and depth, which is characterized by structural changes of the laser irradiated sheet due to penetration of thermal wave, increases with the laser pulse energy delivery to the sheet. This proportional relationship allows for the control of the depth and affected zone of drilled WS2 film by altering the laser process parameters. Figure 1b shows the zoom-in structural model of orderly aligned, porous WS2 arrays after laser treatment containing many small particles around the holes. In order to form an applicable porous structure, the experimental parameters were selected as laser power of 0.92 W, λ = 1064 nm, pulse duration of 47 ns, repetition frequency of 50 kHz, scanning speed of ~1800 mm s−1 (See Supplementary Figs S1 and S2 for laser characterization details).

Hexagonal (2H) and octahedral (1T) lattice structures are the main stable crystal phases of synthesized WS2 thin films. They facilitate controllable optical and electronic properties by allowing the designer to fine-tune the atomic distribution. Figure 2a shows the 2H semi-conductive phase of WS2 where strong, W-S covalent bonding within the single molecular layer combined with van der Waals interactions with a standard stack spacing of 0.618 nm create strong anisotropy. Figure 2b shows the Raman spectra of sputter-deposited WS2 film before and after annealing. The crystallinity of the treated WS2 film was greatly enhanced compared to the pristine sputtered film as revealed by a stronger peak intensity post-annealing at 800 °C. In addition to the peak at 521.0 cm−1 for the underlying substrate, two typical peaks at 356.7 cm−1 and 421.5 cm−1 appeared corresponding to the in-plane E1 2g and out-of-plane A1g vibration from the WS2 crystalline film. The difference in shift excitation of the Raman spectra between E1 2g and A1g modes (Δ = A1g − E1 2g) was 64.8 cm−1, indicating that the synthesized nanofilms consisted of several WS2 layers33, 34. Figure 2c shows the topography of WS2 film as-measured by AFM. We observed a cluster effect-dependent, small hill at the edge of the film where the coverage of WS2 was continuous. Generally, film thickness is dependent on sputtering parameters such as radio frequency power, gas pressure, and deposition time35; under the optimized conditions, the films were deposited at a rate of approximately 5 nm min−1. Figure 2d shows the corresponding height information along the white line marked in Fig. 2c, where the thickness of both sputtered and annealed WS2 films was ~51.8 nm.

We exposed the same WS2 sample under successive laser treatment once, twice and three times; the resulting optical images are shown in Fig. 3a–c, respectively. Several microscale pores were in orderly alignment over the sample surface, and the pores density increased with the number of laser treatments. Figure 3d and e show SEM images of the WS2 film before and after laser drilling at low magnification, respectively. The WS2 film fabricated by sputtering and annealing was relatively smooth at low magnification. As shown in Fig. 3e, the average distance between the adjacent pores was ~80 μm. The average diameter of a single hole was ~17 μm, as shown in Fig. 3f. There was an abundance of small particles surrounding the hole, the smallest diameter of which reached ~62 nm. The unique formation of small particles observed was likely influenced by the fast transition from the overheated liquid to a mixture of vapor and drops during the vaporization of the laser-focused area36. The TEM image shown in Fig. 3g reveals that vertically oriented and horizontally aligned WS2 nanosheets coexisted in the samples. Further TEM characterization of the layers spacing within WS2 sample can be found in Supplementary Fig. S3. The layer-to-layer spacing was measured to be 0.63 nm (See Supplementary Fig. S3a), which is close to the standard 2H-WS2. Furthermore, based on horizontally aligned WS2 layers the interplanar spacing was 0.27 nm (See Supplementary Fig. S3b), which is consistent with the (100) plane of hexagonal WS2 nanosheets37. Figure 3h shows a HRTEM cross-section image of the laser treated WS2 film deposited on the silicon substrate. There was about ~10 nm silicon oxidation layer observed due to the natural oxidization. From the zoom-in HRTEM image shown in Fig. 3i, which is magnified picture of the part indicated by a red dot circle shown in Fig. 3h, the exposed active edge sites inside the hole can be clearly identified, which are highly catalytically active compared to the basal planes38. It is expected the overall photo-catalytic activity of this sample can be significantly enhanced by these exposed active edge sites.

Optical images of WS2 film with laser treatment (a) once; (b) twice; (c) three times. SEM images of WS2 film (d) before laser treatment; (e,f) after one laser treatment. (g) TEM image of transferred WS2 film with laser-drilled hole. (h) HRTEM cross-section image of laser treated WS2 film. (i) Zoom-in HRTEM image of the hole area as indicated in (h) by red dot circular.

To further investigate the influence of laser treatment on photoelectrical activity of the samples, I-t measurements were taken to examine the photocurrent density of the WS2 film within 120 s light on/off cycles (Fig. 4a). The photocurrent densities of the silicon substrate with WS2 film was 0.25 μA cm−2 at 0 V versus Ag/AgCl. After the WS2 samples were subjected to laser treatment once, twice, and three times, the obtained photocurrent densities were 3.9, 6.2, and 8 μA cm−2, respectively. In other words, the photocurrent density of the sample laser-treated three times improved up to 31 times higher than that of the pristine sample. The photocurrent densities of pure silicon substrate were measured as reference, being 0.03 μA cm−2 at 0 V versus Ag/AgCl (See Supplementary Fig. S4), of which the photoelectrical activity is relatively poor. The photocurrent reproduced by these samples under light ON/OFF repeatedly is very consistent. There was a substantial current spike when the light was turned on due to the rapid recombination of excessive holes with electrons in quick succession39 after the separation of photoexcited electron-hole pairs. As the depth of laser drilled hole is about 156 nm under the average laser power of 0.92 W (See Supplementary Fig. S5), the hole has located on the substrate across the WS2 thin film. To exclude the influence of silicon substrate on the photocatalytic activity, the photocurrents of silicon wafer before and after laser treatment three times were conducted and compared with the performance of Si/WS2 after laser treatment three times. Relatively the photocurrent of silicon substrate with three times laser treatment is ignorable compared to silicon wafer with WS2 film deposition treated under the same conditions (See Supplementary Fig. S6 for details). Over the course of subsequent experiments, we found that the photocurrent density continually increased as the number of laser treatments increased; this further confirmed that laser drilling is an efficient way to enhance photocurrent. After repeating the laser scanning of nearly 20 times, the sample showed maximum photocurrent density achieved up to ~20 μA cm−2. Overlapping holes became more frequent as the treatment repetition number increased due to limitations in our laser setup, so the optimized value appeared within 15–25 treatments.

(a) Photocurrent as a function of time under solar simulated illumination (420 nm cut-off) without bias of the corresponding WS2 before and after one, two, and three laser treatments. (b) Electron lifetime measurements obtained based on decay of open circuit potential in a dark environment. XPS spectra of W 4f core level peak region for WS2 (c) before and (d) after laser treatment. (e) Raman spectra of WS2 before and after laser treatment. Inset shows two magnified peaks from 240 to 290 cm−1, and 750 to 900 cm−1. (f) Schematic diagram of band structure and charge transfer in WS2/WO3 heterostructure under visible light irradiation. (LT represents to laser treatment).

To better understand the improved photoelectrocatalytic performance observed, open-circuit photovoltage decay (OCPVD) was conducted to characterize the inherent electronic properties of the samples. OCPVD is an efficient method for assessing the recombination rate of photogenerated electrons and holes by monitoring the decay of photovoltage V oc over time after illumination termination. The lifetime of the photoelectrons is directly related to the voltage decay, as described by the following equation40, 41:

where τ is the potential-dependent lifetime, k B is the Boltzmann constant, T is the temperature (K), e is the electronic charge, and dV oc/dt is the open-circuit voltage decay over time. Figure 4b shows a comparison of the voltage decay rate of WS2 samples without laser treatment and after one, two, or three laser treatments. Laser-treated samples showed lower voltage decay rates, indicating prolonged electron lifetime.

XPS characterization was performed to investigate the chemical composition and band states of the samples. Figure 4c shows the XPS spectrum of WS2 film without laser treatment, which contained peaks located at 33.18 and 35.28 eV corresponding to W 4f 7/2 and W 4f 5/2 lines of the W atoms in +4 form, respectively42, 43. The peak located at 38.38 eV can be ascribed to W 5p 3/2 44, 45. The XPS spectrum of a laser-treated sample is shown in Fig. 4d, where peaks located at 32.16 and 34.37 eV belong to W 4f 7/2 and W 4f 5/2 peaks of the atoms in +4 form, and relatively high energies of 35.74 and 37.75 eV originate from W 4f 5/2 and W 4f 7/2 peaks of the W atoms in +6 oxidation state, all of which are in agreement with previously reported WO3 values20, 46. These results altogether reveal that the laser-treated sample contained two compositions of chemical compounds (WS2 with W4+ and WO3 with W6+). Because the laser-drilling process was conducted in ambient air, partial oxidation of WS2 into WO3 naturally occurred during localized bond breakage and new bond formation47.

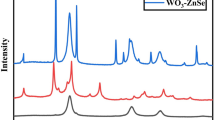

Raman images obtained from the samples before (black) and after (red) laser drilling are shown in Fig. 4e. To characterize the impact of laser modification, the Raman spectrum after laser treatment shown in Fig. 4e is from the edge of the laser-drilled hole; the modified sample spectrum (red) showed peaks at 262.5 cm−1, 710.2 cm−1, and 809.4 cm−1. The figure inset shows the magnified spectrum of two peaks: One from 240 to 290 cm−1 and the other from 750 to 900 cm−1 for a clear comparison. The two peaks between 600 to 900 cm−1 can be ascribed to the stretching ν(O-W-O) mode, and the peak at 262.5 cm−1 corresponds to the bending δ(O-W-O) mode48, 49, indicating partial oxidation of WS2 into WO3 at the laser-drilled hole edge. These characteristic Raman peaks observed agree well with previous studies of WO3 50, 51. The structural analysis and phase change in the pristine WS2 film and laser treated WS2 film was examined by X-ray diffractometer (XRD, See Supplementary Fig. S7). Both XRD pattern exhibits the characteristic diffraction peaks corresponding to (002), (004), (101), (103) planes, which match well with standard JCPDS for the 2H-WS2 (JCPDS Card No. 08-0237). After laser treatment there are new peaks appear which match the orthorhombic WO3 (JCPDS Card No. 32-1394). The low intensity of the WO3 peaks, we believe, is due to the small portion of WO3 in the sample. Furthermore, it is well known that the WO3 can react with KOH and dissolved in KOH aqueous solution52, so experiments were conducted to compare the TEM results for investigation of the laser drilled samples influenced by KOH etching (See detailed experiment and TEM results in Fig. S8). The result shows a clearer surface of laser drilled WS2 film with cavities after the KOH etching, which also confirms the formation of WO3 in WS2 film by laser treatment.

The formation of a WS2/WO3 heterojunction also contributed to the significant enhancement in photocurrent density in the laser-drilled samples. The UV-Vis transmittance spectra of WS2 film before and after laser treatment were measured. The band gap energy (Eg) was evaluated to be 1.4 eV from the plot of (αhν)1/2 vs. hν (see Fig. S9 and detailed calculation in Supplementary), which is consisted with previous works53, 54. Compared with pristine WS2, a slight increase in the band gap of the WS2 film after laser treatment indicates the occurrence of oxidation. The approximate valence band position was evaluated based on the flat-band potential from the Mott-Schottky plot (see Fig. S10 and details in Supplementary). The valence band after laser treatment increased, which is probably due to the partial oxidation of WS2 into WO3 created by laser treatment. WO3 has a band gap of 2.5–2.8 eV, of which the potential at the valence band maximum versus the reversible hydrogen electrode (RHE) is larger than that of WS2 20, 55. The approximate band structure and charge transfer of WS2/WO3 heterostructure is presented in Fig. 4f according to the obtained bandgaps and flat-band potential. The photogenerated electrons were transferred from WS2 to WO3 through the CB gradient. The valence band (VB) maximum of WS2 is lower than that of WO3, so holes were able to transfer through the opposite direction and accumulate on the WS2. The conveying and separation of visible-light excited charge carriers between different energy levels improved the photocurrent density of laser-drilled samples and slowed the recombination of photogenerated charge pairs; our OCPVD results further support for this observation.

Raman mapping was further conducted to probe heterojunction locations, which would in practice create a foundation for the controllable and precise positioning of the WS2/WO3 heterojunction. Figure 5a and b show the intensity distribution of the Raman peak at ~356 cm−1 representing the existence of WS2 over a selected area of 20 × 20 μm for the samples before and after laser treatment. The shaded area represents the intensity level, where darker shading indicates greater intensity. There was practically no WS2 left within the laser-drilled hole area. Figure 5c and d show the corresponding Raman mappings of the typical peak of WO3 at ~710 cm−1 before and after laser treatment. The darker color distributed around the hole area in Fig. 5d compared to Fig. 5c marks the existence of WO3 on the laser treated surface, which further confirms the enhanced partial oxidation induced by laser treatment.

In this study, we utilized laser treatment to create and fine-tune a porous surface structure with increased active edge sites and partial oxidation for the facile formation of WS2/WO3 heterojunctions. The density of laser-drilled holes increased alongside repeated laser treatments, which enhanced the oxidation and thus the photoelectrocatalytic performance of the sample. After three laser treatments, enhanced photoelectrical activity was observed in regards to the photocurrent density of the WS2/WO3 heterojunction which improved up to 31 times alongside prolonged electron lifetime. The optimal photocurrent density was ~2 × 10−5 Acm−2 under visible-light illumination – about 80 times higher than that of pristine sputter-deposited WS2 film. This laser-drilling-based heterojunction tailoring process may provide a new and highly effective approach to enhancing the photoelectrocatalytic performance of 2D TMDs materials for electrochemical energy applications.

Methods

Preparation of WS2 films and laser treatment

WS2 thin films were deposited onto a silicon wafer by magnetron sputtering (KYKY, FD-600K) with a 99.99% WS2 disk target (Ø*0.125 inch, China New Metal Materials Technology Co, Ltd). The radio frequency power, argon gas pressure, substrate temperature, and deposition time were set as 60 W, 50 Pa, 200 °C, and 10 min, respectively. The sputtered WS2 thin films were placed at the center of a tubular furnace with constant temperature of 800 °C to crystallize for 2 h with flowing sulfer/argon ambience in the chamber, then cooled naturally to room temperature. The laser treatment process was conducted with a home-made, nanosecond pulse laser drilling setup equipped with an infrared light laser (power = 0.92 W, λ = 1064 nm, pulse duration = 47 ns, frequency = 50 kHz, laser mode: TEM00). A computer was connected to the laser setup to control the laser drill position and area.

Characterization of laser-dilled porous WS2/WO3 heterojunction

Optical images were recorded by an optical microscope equipped with a CCD camera (Lecia, DM1750M). The morphology of the WS2 film before and after laser treatment was characterized by scanning electron microscope (JEOL, JSM-6490). Field-emission transmission electron microscope (JEOL, JEM-2100F) were used to observe the nanoscale morphology and crystal structure of thin solid film samples before and after laser treatment. The surface topography and roughness of the thin films were examined under an atomic force microscope (Bruker, Nanoscope Multimode 8), and the crystalline compositions and heterojunction locations of the samples were evaluated via Raman spectroscopy (Horiba Jobin Yvon, HR800) with an excitation laser source of 488 nm. X-ray photoelectron spectroscopy (Thermo Scientific, ESCALAB 250Xi) was carried out with a monochromatic Al Kα source to investigate the chemical states of the thin film samples. Mott-Schottcky analysis was conducted using an electrochemical workstation (Zahner, Zennium) with a frequency of 1kHz in dark condition. The structural analysis and phase change of sample was examined by X-ray diffraction (XRD, Rigaku SmartLab) using Cu Kα radiation.

Photoelectrocatalytic measurements of laser-dilled porous WS2/WO3 heterojunction

Photoelectrocatalytic measurements were taken in a 5 cm × 5 cm × 5 cm quartz reactor applying the conventional three-electrode system with a Pt-wire as the counter eletrode, Ag/AgCl as the reference electrode, and fabricated samples as the working electrode. A 300 W Xe lamp equipped with a 420 nm cut-off filter (PLS-SXE300, Beijing Perfect Light Technology Co., Ltd.) served as the irradiation source, and the intensity of visible light was measured with an illumination meter (THORLABS, S314C). An electrochemical analyzer (CHI600C, Shanghai Chenhua Instruments Company) was used to record the transient current in 0.1 s intervals as a Xe lamp alternatively switched on/off. Photovoltage decay profiles were measured to determine the recombination rate of photogenerated electrons and holes. Owing to the chemical stability of WS2/WO3 in acidic electrolyte, 0.5 mol L−1 H2SO4 aqueous solution was used as a supporting electrolyte.

Chemical reagents including sulfer powder (99.5%), potassium hydroxide, sulphuric acid, acetone, and ethanol were purchased from Sigma and used as-received. Throughout the entirety of the experiment, deionized water with a resistivity of 18.2 MΩ cm was used to prepare aqueous solutions and for rinsing.

References

Zhou, S. et al. Substrate-induced bandgap opening in epitaxial graphene. Nat. Mater. 6, 770–775 (2007).

Ramasubramaniam, A., Naveh, D. & Towe, E. Tunable band gaps in bilayer transition-metal dichalcogenides. Phys. Rev. B 84, 205325 (2011).

Britnell, L. et al. Strong light-matter interactions in heterostructures of atomically thin films. Science 340, 1311–1314 (2013).

McCreary, A. et al. Effects of uniaxial and biaxial strain on few-layered terrace structures of MoS2 grown by vapor transport. ACS Nano 10, 3186–3197 (2016).

Sie, E. J. et al. Valley-selective optical stark effect in monolayer WS2. Nat. Mater. 14, 290–294 (2015).

Ji, Q. et al. Morphological engineering of CVD-grown transition metal dichalcogenides for efficient electrochemical hydrogen evolution. Adv. Mater. 28, 6019–6061 (2016).

Pawbake, A. S., Waykar, R. G., Late, D. J. & Jadkar, S. R. Highly transparent wafer-scale synthesis of crystalline WS2 nanoparticle thin film for photodetector and humidity-sensing applications. ACS Appl. Mater. Inter. 8, 3359–3365 (2016).

Bhandavat, R., David, L. & Singh, G. Synthesis of surface-functionalized WS2 nanosheets and performance as li-ion battery anodes. J. Phys. Chem. Lett. 3, 1523–1530 (2012).

Shanmugam, M., Durcan, C. A., Jacobs-Gedrim, R. & Yu, B. Layered semiconductor tungsten disulfide: Photoactive material in bulk heterojunction solar cells. Nano Energy 2, 419–424 (2013).

Long, H. et al. Tuning nonlinear optical absorption properties of WS2 nanosheets. Nanoscale 7, 17771–17777 (2015).

Sun, C. et al. N-doped WS2 nanosheets: A high-performance electrocatalyst for the hydrogen evolution reaction. J. Mater. Chem. A 4, 11234–11238 (2016).

Thripuranthaka, M., Kashid, R. V., Rout, C. S. & Late, D. J. Temperature dependent raman spectroscopy of chemically derived few layer MoS2 and WS2 nanosheets. Appl. Phys. Lett. 104, 081911 (2014).

Li, W. et al. Bandgap engineering of different stacking WS2 bilayer under an external electric field. Solid State Commun 225, 32–37 (2016).

Latzke, D. W. et al. Electronic structure, spin-orbit coupling, and interlayer interaction in bulk MoS2 and WS2. Phys. Rev. B 91, 235202 (2015).

Voiry, D., Yang, J. & Chhowalla, M. Recent strategies for improving the catalytic activity of 2D TMD nanosheets toward the hydrogen evolution reaction. Adv. Mater. 28, 6019–6261 (2016).

Cao, S., Zhao, C., Han, T. & Peng, L. The WO3/WS2 nanostructures: Preparation, characterization and optical absorption properties. Physica E 81, 235–239 (2016).

Yang, L. et al. Synergistic WO3·2H2O nanoplates/WS2 hybrid catalysts for high-efficiency hydrogen evolution. ACS Appl. Mater. Interfaces 8, 13966–13972 (2016).

Adelifard, M., Salamatizadeh, R. & Ketabi, S. Fabrication and characterization of nanostructural WS2/WO3 binary compound semiconductors prepared by the sulfurization of sprayed thin films. J. Mater. Sci.: Mater. Electron 27, 5243–5250 (2016).

Morrish, R., Haak, T. & Wolden, C. A. Low-temperature synthesis of n-type WS2 thin films via H2S plasma sulfurization of WO3. Chem. Mater. 26, 3986–3992 (2014).

Zhou, P. et al. Fabrication of two-dimensional lateral heterostructures of WS2/WO3⋅ H2O through selective oxidation of monolayer WS2. Angew. Chem. Int. Ed. 54, 15226–15230 (2015).

Huo, N., Yue, Q., Yang, J., Yang, S. & Li, J. Abnormal photocurrent response and enhanced photocatalytic activity induced by charge transfer between WS2 nanosheets and WO3 nanoparticles. ChemPhysChem 14, 4069–4073 (2013).

Albu‐Yaron, A. et al. MoS2 hybrid nanostructures: From octahedral to quasi-spherical shells within individual nanoparticles. Angew. Chem. Int. Ed. 50, 1810–1814 (2011).

Verble, J., Wietling, T. & Reed, P. Rigid-layer lattice vibrations and van der waals bonding in hexagonal MoS2. Solid State Commun 11, 941–944 (1972).

Kibsgaard, J., Chen, Z., Reinecke, B. N. & Jaramillo, T. F. Engineering the surface structure of MoS2 to preferentially expose active edge sites for electrocatalysis. Nat. Mater. 11, 963–969 (2012).

Xie, J. et al. Defect-rich MoS2 ultrathin nanosheets with additional active edge sites for enhanced electrocatalytic hydrogen evolution. Adv. Mater. 25, 5807–5813 (2013).

Kong, D. et al. Synthesis of MoS2 and MoSe2 films with vertically aligned layers. Nano Lett. 13, 1341–1347 (2013).

Russo, P., D’Urso, L., Hu, A., Zhou, N. & Compagnini, G. In liquid laser treated graphene oxide for dye removal. Appl. Surf. Sci. 348, 85–91 (2015).

Buccheri, M. A. et al. Modification of graphene oxide by laser irradiation: a new route to enhance antibacterial activity. Nanotechnology 27, 245704 (2016).

Filice, S. et al. Laser processing of TiO2 colloids for an enhanced photocatalytic water splitting activity. J. Colloid Interf. Sci 489, 131–137 (2017).

Castellanos-Gomez, A. et al. Laser-thinning of MoS2: on demand generation of a single-layer semiconductor. Nano Lett. 12, 3187–3192 (2012).

Lu, J. et al. Atomic healing of defects in transition metal dichalcogenides. Nano Lett. 15, 3524–3532 (2015).

Mishra, S. & Yadava, V. Modeling and optimization of laser beam percussion drilling of nickel-based superalloy sheet using Nd: Yag laser. Opt. Laser Eng. 51, 681–695 (2013).

Berkdemir, A. et al. Identification of individual and few layers of WS2 using raman spectroscopy. Sci. Rep 3, 1755 (2013).

Zhao, W. et al. Lattice dynamics in mono-and few-layer sheets of WS2 and WSe2. Nanoscale 5, 9677–9683 (2013).

Zeng, L. et al. High-responsivity uv-vis photodetector based on transferable WS2 film deposited by magnetron sputtering. Sci. Rep 6, 20343 (2016).

Costil, S., Lamraoui, A., Langlade, C., Heintz, O. & Oltra, R. Surface modifications induced by pulsed-laser texturing-influence of laser impact on the surface properties. Appl. Surf. Sci. 288, 542–549 (2014).

Du, Y. et al. Improving the anode performance of WS2 through a self-assembled double carbon coating. J. Phys. Chem. C 119, 15874–15881 (2015).

Karunadasa, H. I. et al. A molecular MoS2 edge site mimic for catalytic hydrogen generation. Science 335, 698–702 (2012).

Wang, L. & Daoud, W. A. BiOi/TiO2-nanorod array heterojunction solar cell: Growth, charge transport kinetics and photoelectrochemical properties. Appl. Surf. Sci. 324, 532–537 (2015).

Halder, G. & Bhattacharyya, S. Plight of mn doping in colloidal CdS quantum dots to boost the efficiency of solar cells. J. Phys. Chem. C 119, 13404–13412 (2015).

Zhang, Z. & Wang, P. Optimization of photoelectrochemical water splitting performance on hierarchical TiO2 nanotube arrays. Energy Environ. Sci. 5, 6506–6512 (2012).

Wang, L. et al. Hydrogen-treated mesoporous WO3 as a reducing agent of CO2 to fuels (CH4 and CH3OH) with enhanced photothermal catalytic performance. J. Mater. Chem. A 4, 5314–5322 (2016).

Sang, Y. et al. From UV to near-infrared, WS2 nanosheet: A novel photocatalyst for full solar light spectrum photodegradation. Adv. Mater. 27, 363–369 (2015).

Yuwen, L. et al. Rapid preparation of single-layer transition metal dichalcogenide nanosheets via ultrasonication enhanced lithium intercalation. Chem. Commun. 52, 529–532 (2016).

Voiry, D. et al. Enhanced catalytic activity in strained chemically exfoliated WS2 nanosheets for hydrogen evolution. Nat. Mater. 12, 850–855 (2013).

Zhao, Z. G. & Miyauchi, M. A novel visible-light-driven photochromic material with high-reversibility: Tungsten oxide-based organic-inorganic hybrid microflowers. Chem. Commun. 2204–2206 (2009).

Lu, J. et al. Improved photoelectrical properties of MoS2 films after laser micromachining. ACS Nano 8, 6334–6343 (2014).

Daniel, M., Desbat, B., Lassegues, J., Gerand, B. & Figlarz, M. Infrared and raman study of WO3 tungsten trioxides and WO3, xH2O tungsten trioxide tydrates. J. Solid State Chem. 67, 235–247 (1987).

Rajagopal, S. et al. Controlled growth of WO3 nanostructures with three different morphologies and their structural, optical, and photodecomposition studies. Nanoscale Res. Lett. 4, 1335 (2009).

Manciu, F. S. et al. Spectroscopic analysis of tungsten oxide thin films. J. Mater. Res. 25, 2401–2406 (2010).

Enriquez-Carrejo, J. L., Ramos, M. A., Mireles-Jr-Garcia, J. & Hurtado-Macias, A. Nano-mechanical and structural study of WO3 thin films. Thin Solid Films 606, 148–154 (2016).

Qi, H., Wang, C. & Liu, J. A Simple method for the synthesis of highly oriented potassium‐doped tungsten oxide nanowires. Adv. Mater. 15, 411–414 (2003).

Kuc, A., Zibouche, N. & Heine, T. Influence of quantum confinement on the electronic structure of the transition metal sulfide TS2. Phys. Rev. B 83, 245213 (2011).

Wang, Q. H., Kalantar-Zadeh, K., Kis, A., Coleman, J. N. & Strano, M. S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol 7, 699–712 (2012).

Liu, X., Wang, F. & Wang, Q. Nanostructure-based WO3 photoanodes for photoelectrochemical water splitting. Phys. Chem. Chem. Phys. 14, 7894–7911 (2012).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Grant No. 61575167) and the Hong Kong Polytechnic university (Project Number: 1-ZVGH, G-UA7N).

Author information

Authors and Affiliations

Contributions

S.M., L.T. and Y.H.T. developed the concept. S.M. and L.H.Z. conducted the experiments. S.M. and Y.H.T. wrote the paper. S.M., C.Y.T. and P.K.C. performed the laser characterization and treatment. S.M., H.L., H.Y. and C.C. conducted the XPS and Mott-Schottky analysis. S.M., Y.C., K.H.F., X.Z., S.P.L. and Y.H.T. reviewed and edited the manuscript. Y.H.T. directed the overall research. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, S., Zeng, L., Tao, L. et al. Enhanced Photocatalytic Activity of WS2 Film by Laser Drilling to Produce Porous WS2/WO3 Heterostructure. Sci Rep 7, 3125 (2017). https://doi.org/10.1038/s41598-017-03254-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-03254-2

This article is cited by

-

Laser printed two-dimensional transition metal dichalcogenides

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.