Abstract

An advanced organic photodetector (OPD) with a butter layer of Si-rich silicon oxynitride (SiOxNy) was fabricated. The detector structure is as follows: Indium tin oxide (ITO) coated glass substrate/SiOxNy(10 nm)/naphthalene-based donor:C60(1:1)/ITO. Values of x and y in SiOxNy were carefully controlled and the detector performances such as dark current and thermal stability were investigated. When the values of x and y are 0.16 and 0.66, the detector illustrates low dark current as well as excellent thermal stability. In the OPD, silicon oxynitride layer works as electron barrier under reverse bias, leading to the decrease of dark current and increase of detectivity. Since the band gap of silicon oxynitride unlike conventional buffer layers can also be controlled by adjusting x and y values, it can be adapted into various photodiode applications.

Similar content being viewed by others

Introduction

Organic photodetectors (OPDs) have been widely used in practical applications such as photo-sensors, chemical sensors1,2,3,4,5,6, X-ray detectors7, and image sensors8,9,10,11. Among the applications, image sensors, which have been considered of replacing conventional silicon-based image sensors4, 10, have attracted research interest from industries and there has been considerable effort to improve the device performances of them such as the spectral response, external quantum efficiency (EQE), dark current (DC), and sensitivity. Among these, the External quantum efficiency (EQE), DC, and thermal stability are the key factors to evaluate the performance of OPDs. EQE is coupled to the efficiency and signal-to-noise ratio (SNR) of the devices. Low DC stabilizes the signal of the devices, leading to high SNR. Because organic materials in OPDs are exposed to high temperature process such as post-annealing at 180 °C, passivation step, top layer planarization, and microlens forming process, they should be thermally stable without performance degradation.

Decreasing DC and enhancing thermal stability have been generally improved by introducing new buffer layers12 such as MoOx 13, WOx 14, and VOx 15. However, MoOx is susceptible to the loss of oxygen during evaporation which can result in the change of stoichiometry and electronic energy levels16. Since various active materials are also used in fabricating OPDs, the band structure of a buffer layer should be aligned to HOMO and LUMO levels of bulk heterojuction (BHJ) films. Conventional buffer layers such as MoOx are very difficult to change their band structure, i.e. their HOMO and LUMO levels do not change without regard to neighboring active materials. Therefore, new buffer layers with thermal stability and easily adjustable band structure have been required.

As one of good candidates for new buffer layers, silicon oxynitride (SiOxNy) film has been well received because its band structure is able to be freely controlled by adjusting the x and y. Moreover, it is thermally stable at high temperature process and is also chemically inert enough to be used in electronic devices17 such as thin-film transistors18, and buffer layer for Flash memory19 because of their excellent passivation characteristics. Here, we report that introduction of SiOxNy film as buffer layer into OPDs decreased DC, leading to high detectivity and photo-responsivity. In addition, the OPDs become thermally stable at high temperature process.

Materials and Methods

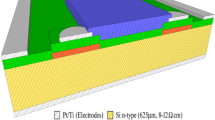

Two kinds of samples were fabricated on indium tin oxide (ITO)-coated glasses. Si-rich SiOxNy films were sequentially deposited on ITO glass by Plasma-Enhanced Chemical Vapor Deposition (PECVD) using various SiH4:NH3:NO2 gas mixtures with carrier N2 gas; 670 W of RF power was applied and the deposition temperature was 180 °C. The S1 sample does not have a SiOxNy buffer layer, while the S2 sample has 10 nm thickness of SiOxNy buffer layer, where the ratios of x (O/Si) and y (N/Si) are 0.16 and 0.66, respectively. After depositing SiOxNy buffer layer, a 160-nm-thick 1:1 organic blend layer of ‘naphthalen based donor’, C60, and a 7-nm-thick ITO capping layer were deposited, as depicted in Fig. 1(a). The ‘naphthalen based donor’ is novel push-pull-structured organic semiconducting materials, which is 5- (naphthalen-1-yl (phenyl) amino) selenophen-2-yl) methylene) -1H-indene-1,3 (2 H) -dione, with the absorption properties selective to green-light to be produced from Samsung advanced institute of technology (SAIT) as shown in Fig. 1(b) and it have a LUMO and HOMO values as a 3.6 eV and 5.5 eV as shown in Fig. 1(c) 20 respectively.

Results and Discussion

After fabricating OPD samples, the thickness of SiOxNy film in the S1 sample was characterized by Transmission Electron Microscopy (TEM). As shown Fig. 2(a), the Si-rich SiOxNy layer on the ITO has been uniformly deposited to about 10 nm thickness. In addition, it was confirmed that Si-rich SiOxNy layer is formed from the EDS spectrum (not shown here). The region of the active layer denoted with the red rectangle in Fig. 2(a) was enlarged in Fig. 2(b) and the layer looks partially crystalline. However, the XRD scan in Fig. 2(c) does not show any peak from the active layer but peaks from ITO. As a result, the active layer is generally amorphous phase and appears to be locally crystallized in short-range order.

Figure 2(d) shows the XPS spectrum of the Si-rich SiOxNy film. The compositions of Si, N, and O as well as x(=O/Si) and y(=N/Si) ratios obtained from the XPS measurements are summarized in Table 1. The x and y values for the SiOxNy sample were 0.16 and 0.66, respectively. Si 2p peak has lower peak area of Si3N4 chemical state (397.8 eV in N 1 s and 101.8 eV in Si 2p) due to the existence of Si-Si chemical state (99.6 eV in Si 2p). In general, Si 2p in SiO2 films is located at 103.3 eV. This shows a distinct evolution of Si 2p spectra with the incorporation of N into the dielectric film. The Si 2p peak in SiOxNy shifts toward a low binding energy because the incorporation of N into dielectric film.

Figure 3(a) shows REELS acquired for the Si-rich SiOxNy thin film (Fig. 2a), and the band gap of thin film was determined from the onset value of its energy loss signal21. The band gaps of the SiOx=0.16Ny=0.66 film was 3.1 ± 0.1 eV as shown in Fig. 3(a) although Gurava et al. reported22 that the band gap of Si-rich SiNx film ranges from 2.11 eV to 2.56 eV when x varies from 0.48 to 0.87. The band gap of 3.1 eV for Si-rich SiOxNy is much higher than that of SiNx film. This discrepancy originates from the fact that the top of the valence band for a SiNx film consists primarily of N 2p lone pairs while the bottom of the conduction band is dominated by the Si 3 s state23, 24. However, the top of the valence band of the SiO2 thin film is formed by a non-bonding O 2p state, and the lowest conduction band is dominated by extended Si 3 s states25, 26. For SiOxNy dielectrics, the increase of O composition into the SiNx modifies the valence-band density of state profile. The N 2p, O 2p nonbonding peak and Si 3 s peak lead to little change. And then, the band gap value of SiOxNy is enlarger than that of SiNx.

Figure 3(b) illustrates valence band spectra acquired from the Si-rich SiOxNy films and ITO substrate, and the valence band maximum (VBM) for each sample was determined as the intersection between the baseline and the linear fit of the leading edge of the valence band27. The valence band offset ΔEv was obtained as the difference between the VBMs of SiOxNy and the Fermi energy (EF) of ITO substrate. There exists significant difference in the ΔEv at SiOxNy/ITO interface depending on the chemical states of SiOxNy film. The conduction band offsets (ΔEc) were determined from the band gap (Eg) and ΔEv according to the relation ΔEc = Eg(SiOxNy) − ΔEv(SiOxNy/ITO)28. The energy band diagram of S2 in the SiOx=0.16Ny=0.66 thin films are shown in Fig. 3(c).

Figure 4(a,b) show the results from EQE and DC for the OPD devices. In Fig. 4(a), the S2 sample exhibits equally (or slight improved) a normal EQE characteristic with a maximum value of ~67% at a wavelength of 550 nm, compared with the S1 sample (without SiOxNy sample). The DC characteristics (0.18 nA/cm2 at −3 V) of the S2 sample were improved, compared with the S1 sample (4.28 nA/cm2 at −3 V) as shown in Fig. 4(b). For clear comparison, the units of the DC were converted to the number of electrons flowing through a unit area of 1 μm2 at a bias voltage of −3 V for 1 s. The calculated values are displayed near the corresponding DC curves in Fig. 4(b). The DC value for the OPD device with S2, which is 11 e/(s · μm2), is less than reference device (S1 sample), which is 267 e/(s · μm2).

(a) EQE curves of S1 (without SiOxNy) and S2 (i.e with SiOxNy film) measured for the OPDs, respectively. (b) Current density-voltage characteristics in the dark for the OPDs in (a). (c) Detectivities of S1 and S2. (d) Photo-responsivities of S1 and S2. (e) Thermal stability for DC with a various temperature from 150 °C to 180 °C.

According to Leem et al.29, the dark current of the OPD with MoOx buffer layer was 6.41 nA/cm2 at −3 V. Compared with this value, the dark current of the reference sample (S1) (4.28 nA/cm2 at −3 V) was improved so much and the dark current of the S2 sample (0.18 nA/cm2 at −3 V) was enhanced enormously.

The detectivity and photo-responsivity of the OPDs are displayed in Fig. 4(c,d). The detectivity of the S1 sample (without SiOxNy) is on the order of 1013 in the green region, while the detectivity of the S2 sample is much higher, on the order of 1014 in the green region. In Fig. 4(d), the two samples show similar photo-response. The thermal stabilities of the OPDs are illustrated in Fig. 4(e). The analysis of the thermal stability of the OPD was performed by annealing the device at increasing temperatures of up to 180 °C for 30 min at each temperature. The S2 sample shows remarkably good dark current characteristic (38 e/(s · μm2) at −3 V, 180 °C), compared with the S1 sample (without SiOxNy film, which has poor dark current (2,060,000 e/(s · μm2) at −3 V, 180 °C), as shown in Fig. 4(e). These results suggest that using SiOxNy as a buffer layer makes OPDs thermally stable and the DC can be decreased further.

In order to unveil the possible origins of the reduced DC in the S2 sample, compared to reference (S1) sample, the full band diagrams of the samples are plotted in Fig. 5(a and b), based on the bandgaps and valence band offsets (Fig. 3) of the OPD without SiOxNy (S1 sample, ITO/naphthalen based donor:C60(1:1)/ITO structure) and the sample with SiOxNy (S2 sample, ITO/SiOx=0.16Ny=0.66/naphthalen based donor:C60(1:1)/ITO structure). Both electrons and holes can transport from the ITO anode and cathode to the acceptor and donor under reverse bias condition29, 30 for the S1 sample (without SiOxNy film), as shown in Fig. 5(a). The current leakage under reverse bias is primarily dominated by electrons rather than holes since the electron barrier (0.6 eV) between the work function of ITO (4.7 eV) and LUMO level (4.1 eV) of C60(1:1) in the blend system is much smaller than the hole barrier (0.8 eV) between the HOMO level (5.5 eV) of naphthalene based donor and the work function of ITO (4.7 eV).

(a) and (b) Re-plots the full band diagram of without SiOxNy (S1 sample, ITO/naphthalen based donor:C60(1:1)/ITO structure) and with SiOxNy (S2 sample, ITO/SiOx=0.16Ny=0.66/naphthalen based donor: C60(1:1)/ITO structure) using the bandgap and valance band offset of SiOxNy films as previously measured in Fig. 3.

However, the SiOx=0.16Ny=0.66 film in the S2 sample acts as electron blocking role since the LUMO level of SiOx=0.16Ny=0.66 has higher than that of naphthalen based donor: C60(1:1) layer. Thus, the insertion of the SiOx=0.16Ny=0.66 (S2 sample) layer between the anode and acceptor layer in Fig. 5(b) increased the effective electron barrier due to its low-lying LUMO level of 2.0 eV and the barrier prevents electrons from flowing to the acceptor layer. Thus, the leakage current under reverse bias decreases.

Lastly, it is also worthwhile to mention the tunability of the bandgap of SiOxNy. According to Park, et al. and Wong, et al.31, 32, the energy bandgap of SiNy increases from 1.1 eV to 5.5 eV as the N/Si (y) value rises in the SiNy thin film. When the value of y is ~1, the valance band and the conduction band sharply decrease. However, the valance band offset (VBO) is not greatly reduced if the value is less than 1, although the conduction band offset is continuously decreased. In our previous study33, we reported that if y = 0.92 or less, there is a decrease in the band gap while VBO does not decrease significantly. As more oxygen atoms are added to SiNy, the energy bandgap of SiOxNy increases and the valance band increases more than the conduction band. Therefore, the bandgap tunability and band structure of the SiOxNy layer reduces the dark current and improves the device performance.

In summary, we demonstrated the device performance applied to Si-rich SiOxNy film as a buffer layer in an OPDs. Then, external quantum efficiency (EQE) was slightly improved, and the DC and thermal stability were significantly improved, compared with that obtained without the Si-rich SiOxNy buffer layer. These results showed that a Si-rich SiOxNy could be a promising buffer layer for the practical OPD applications.

Characterization

The surface roughness of SiOxNy film was about 3 nm by using Atomic Force Microscopy (AFM, Dimension ICON, Bruker, not shown here). All organic layers were thermally evaporated (<10−7 Torr) at a rate of 1 nm/s. The overlapping area of the two electrodes was 0.04 cm2 (0.2 cm × 0.2 cm). The device was finally encapsulated with glass. The current-voltage characteristics of the devices were measured by a Keithley K4200 parameter analyzer. The EQE was measured using a setup illuminated by monochromatic light generated by an ozone-free xenon lamp with a chopper frequency of 30 Hz. The monochromatic light intensity was calibrated using a silicon photodiode (Hamamatsu, S1337).

Band gap and composition measurements were performed by means of reflection electron energy loss spectroscopy (REELS) using auger electron spectroscopy (AES, PHI-4700, Concentric hemispherical analyzer) and X-ray photoelectron spectroscopy (XPS, PHI Quantera II Scanning XPS Microprobe), respectively. REELS spectra were measured using the primary electron energy of 1,500 eV for excitation and constant analyzer pass energy of 10 eV. The full width at half maximum (FWHM) of the elastic peak was 0.8 eV. Before REELS analysis, samples were subjected to an Ar+ ion gun cleaning to eliminate surface contamination.

References

Clark, J. & Lanzani, G. Organic photonics for communications. Nature Photonics. 4, 438–446, doi:10.1038/nphoton.2010.160 (2010).

Baeg, K.-J., Binda, M., Natali, D., Caironi, M. & Noh, Y.-Y. Organic Light Detectors: Photodiodes and Phototransistors. Adv. Mater. 25, 4267–95, doi:10.1002/adma.v25.31 (2013).

Gong, X. et al. High-detectivity polymer photodetectors with spectral response from 300 nm to 1450 nm. Science 325, 1665–7, doi:10.1126/science.1176706 (2009).

Tong, X. & Forrest, S. R. An integrated organic passive pixel sensor. Org. Electron. 12, 1822–1825, doi:10.1016/j.orgel.2011.07.012 (2011).

Nalwa, K. S. et al. Polythiophene-Fullerene Based Photodetectors: Tuning of Spectral Response and Application in Photoluminescence Based (Bio)Chemical Sensors. Adv. Mater. 22, 4157–61, doi:10.1002/adma.v22:37 (2010).

Wojciechowski, J. R. et al. Organic photodiodes for biosensor miniaturization. Anal. Chem. 81, 3455–61, doi:10.1021/ac8027323 (2009).

Agostinelli, T. et al. A polymer/fullerene based photodetector with extremely low dark current for x-ray medical imaging applications. Appl. Phys. Lett. 93, 203305, doi:10.1063/1.3028640 (2008).

Yu, G., Wang, J., McElvain, J. & Heeger, A. J. Large-Area, Full-Color Image Sensors Made with Semiconducting Polymers. Adv. Mater. 10, 1431–1434, doi:10.1002/(ISSN)1521-4095 (1998).

Someya, T. et al. Integration of organic FETs with organic photodiodes for a large area, flexible, and lightweight sheet image scanners. IEEE Trans. Electron Devices 52, 2502–2511, doi:10.1109/TED.2005.857935 (2005).

Tedd, S., Zaus, E. S., Frust, J., Henseler, D. & Lugli, P. Active Pixel Concept Combined With Organic Photodiode for Imaging Devices. IEEE Electron Device Lett 28, 893–895, doi:10.1109/LED.2007.905425 (2007).

Ng, T. N., Wong, W. S., Chabinyc, M. L., Sambandan, S. & Street, R. A. Flexible image sensor array with bulk heterojunction organic photodiode. Appl. Phys. Lett. 92, 213303, doi:10.1063/1.2937018 (2008).

Nam, C.-Y., Su, D. & Black, C. T. High-Performance Air-Processed Polymer–Fullerene Bulk Heterojunction Solar Cells. Adv. Funct. Mater. 19, 3552–5, doi:10.1021/nl502208u (2009).

Gwinner, M. C. et al. Doping of Organic Semiconductors Using Molybdenum Trioxide: a Quantitative Time-Dependent Electrical and Spectroscopic Study. Adv. Funct. Mater. 21, 1432–1441, doi:10.1002/adfm.v21.8 (2011).

Vasilopoulou, M. et al. Tungsten oxides as interfacial layers for improved performance in hybrid optoelectronic devices. Thin Solid Films 519, 5748–5753, doi:10.1016/j.tsf.2010.12.207 (2011).

Li, G., Chu, C.-W., Shrotriya, V., Huang, J. & Yang, Y. Efficient inverted polymer solar cells. Appl. Phys. Lett. 88, 253503, doi:10.1063/1.2212270 (2006).

Irfan et al. Energy level evolution of air and oxygen exposed molybdenum trioxide films. Appl. Phys. Lett. 96, 243307, doi:10.1063/1.3454779 (2010).

Lipiński, M. et al. Investigation of graded index SiOxNy antireflection coating for silicon solar cell manufacturing. Phys. Status Solidi C 4, 1566–1569, doi:10.1002/(ISSN)1610-1642 (2007).

Hiranaka, K. & Yamaguchi, T. Amorphous Silicon Thin-Film Transistors with SiOxNy/SiNx Gate Insulators. Jpn. J. Appl Phys 29, 229–235, doi:10.1143/JJAP.29.229 (1990).

Jung, S. et al. Fabrication and characterization of metal-oxide-nitride-oxynitride-polysilicon nonvolatile semiconductor memory device with silicon oxynitride (SiOxNy) as tunneling layer on glass. J. Appl. Phys. 102, 094502, doi:10.1063/1.2802201 (2007).

Xavier, B. et al. Dipolar donor–acceptor molecules in the cyanine limit for high efficiency green-light-selective organic photodiodes. J. Mater. Chem. C 4, 1117–1125, doi:10.1039/C5TC03567H (2016).

Jin, H., Oh, S. K., Kang, H. J. & Cho, M. H. Band gap and band offsets for ultrathin (HfO2)x(SiO2)1− x dielectric films on Si(100). Appl.Phys.Lett. 89, 122901, doi:10.1063/1.2355453 (2006).

Guraya, M. M. et al. Bond densities and electronic structure of amorphous SiNx:H. Phys. Review B 49, 13446–13451, doi:10.1103/PhysRevB.49.13446 (1994).

Miyazaki, S., Narasaki, M., Suyama, A., Yamaoka, M. & Murakami, H. The role of hydrogen migration in negative-bias temperature instability. Appl. Surf. Sci. 216, 252 (2003).

McGuinness, C. et al. Electronic Structure of Thin Film Silicon Oxynitrides Measured Using Soft X-Ray Emission and Absorption Spectroscopies. J. Appl. Phys. 94, 3919–3922, doi:10.1063/1.1599629 (2003).

Lucovsky, G. & Phillips, J. C. Limitations for aggressively scaled CMOS Si devices due to bond coordination constraints and reduced band offset energies at Si-high-k dielectric interfaces. Appl. Surf. Sci. 166, 497–503, doi:10.1016/S0169-4332(00)00482-7 (2000).

Lucovsky, G. & Phillips, J. C. The effects of chemical bonding and band offset constraints at Si-dielectric interfaces on the integration of alternative high-K dielectrics into aggressively-scaled CMOS Si devices. Microelectron. Eng. 48, 291–294, doi:10.1016/S0167-9317(99)00391-3 (1999).

Reiche, R., Yubero, F., Espinos, J. P. & Gonzalez-Elipe, A. R. Structure, microstructure and electronic characterisation of the Al2O3/SiO2 interface by electron spectroscopies. Surf. Sci. 457, 199–210, doi:10.1016/S0039-6028(00)00375-7 (2000).

Tahir, D. et al. Band alignment of atomic layer deposited (ZrO2)x(SiO2)1− x gate dielectrics on Si(100). Appl. Phys. Lett. 94, 212902, doi:10.1063/1.3143223 (2009).

Leem, D.-S. et al. Low dark current small molecule organic photodetectors with selective response to green light. Appl. Phys. Lett. 103, 043305, doi:10.1063/1.4816502 (2013).

Binda, M. et al. High detectivity squaraine-based near infrared photodetector with nA/cm2 dark current. Appl. Phys. Lett. 98, 073303, doi:10.1063/1.3553767 (2011).

Park, J. et al. Bandgap measurement of thin dielectric films using monochromated STEM-EELS. Ultramicroscopy 109, 1183–8, doi:10.1016/j.ultramic.2009.04.005 (2009).

Wong, H. & Gritsenko, V. A. Defects in silicon oxynitride gate dielectric films. Microelectron Reliab. 42, 597–605, doi:10.1016/S0026-2714(02)00005-7 (2002).

Heo, S. et al. Defect states in amorphous SiNx:H compounds using thermally stimulated exo-electron emission. Thin Solid Films 616, 850–855, doi:10.1016/j.tsf.2016.10.001 (2016).

Author information

Authors and Affiliations

Contributions

Sung Heo, Jooho lee, Seong Heon Kim, Dong-Jin Yun, Jong-Bong Park, Kihong Kim characterized and analyzed the organic photo-detector (OPD) device. NamJeong Kim, Yongsung Kim, Dongwook Lee, Kyu-Sik Kim prepared and characterized the OPD device performance. Sung Heo, Kyu-Sik Kim, Hee Jae Kang organized the study and wrote the manuscript. All authors commented on the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Heo, S., lee, J., Kim, S.H. et al. Device performance enhancement via a Si-rich silicon oxynitride buffer layer for the organic photodetecting device. Sci Rep 7, 1516 (2017). https://doi.org/10.1038/s41598-017-01653-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-01653-z

This article is cited by

-

The role of defects in organic image sensors for green photodiode

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.