Abstract

In this study, the resistive switching scheme using TiO2 nanorod arrays synthesized by a large-scale and low-cost hydrothermal process was reported. Especially, the nonlinear I–V characteristics of TiO2 nanorod arrays with a nonlinearity of up to ~10, which suppress the leakage current less than 10−4 Acm−2, were demonstrated, exhibiting a self-selecting resistive switching behavior. It provides a simple pathway for integration of RRAM crossbar arrays without additional stacking of active devices. The mechanisms of the nonlinear resistive switching behaviors were discussed in detail. In addition, the maximum array numbers of 79 for self-selecting RRAM cells were estimated. The results demonstrate an opportunity of using the concept of self-selecting resistive switching characteristics in a single material, which offers a new strategy to tackle the sneak path issue of RRAM in the crossbar arrays structure.

Similar content being viewed by others

Introduction

Among the emerging nonvolatile memory (NVM) technologies, resistive switching random access memory (RRAM) utilizing resistive switching (RS) phenomena is one of the most promising candidates for next-generation nonvolatile memory due to the simplest device structure, the fastest switching speed, the highest stacking density, the lowest power consumption, the largest scalability, the lowest fabrication process cost and the strongest potential for fabricating multistate memories1,2,3,4. The resistive switching phenomena in the transition metal oxide, such as NiO5, TiO2 6, 7, ZnO8, and Cu2O9 through two-dimension (2D) metal-insulator-metal (MIM) thin film structures with excellent memory performances has been intensively investigated and demonstrated, previously.

An effective method to increase memory integration density can be realized via three-dimensional crossbar architecture arrays (Fig. S1a), with which the smallest possible cell size of 4F2 (F = minimum feature size) for high-density nonvolatile memory applications can be achieved10. However, an inherent problem, namely a sneak path issue, for which the leakage current flows through neighboring RRAM devices of the crossbar arrays, occurs11. The designated cell with high resistance state (HRS), while the undesignated neighboring cells are in the low resistance state (LRS), may generate parasitic paths in the crossbar array with applied external voltage between the word-line (top) and the bit-line (bottom) (Fig. S1b). Consequently, the total read current is much higher than the accessed current due to the sneak current through the neighboring cells, leading to not only unnecessary power consumption but also a misreading problem. Note that the readout margin is significantly decreased as the crossbar array size increases, which eliminates the scalability of memory in the crossbar arrays11, 12. Therefore, it is necessary to find the method to overcome the sneak current issue and achieve the excellent scalability. In order to access any device randomly without reading interference between neighboring cells, each memory element must be connected with a selecting element to prevent sneak path current problem (Fig. S1c). Using a transistor, which occupies a 6–8F2 size as the selecting device to overcome the sneak current in a crossbar array, normally limits stacking capability of achieving 4F2 integration densities13. Alternatively, passive crossbar arrays utilizing one diode-one resistor (1D1R)12, 14, 15, one selector-one resistor (1S1R)16, 17 or complementary resistive switches (CRS)11, 18,19,20 with the I–V nonlinearity characteristics provide effective ways to overcome the sneak path issue. Either the combination of the selecting device or the concept of CRS makes the fabrication of the memristor more complicated with high manufacture cost and low stacking density.

To reduce the dimension of devices and achieve a high packing density with the improved device performance, finding out suitable device configuration through nanostructures associated with unique electrical properties is a useful way to explore the underlying resistive switching mechanisms in nanoscale. The resistive switching characteristics of nanostructured materials, such as ZnO NW21,22,23, NiO NW24,25,26, CuOx NW27, 28, Co3O4 NW29, Zn2SnO4 NW30 and gold-Ga2O3 NW31, have attracted great attention because of a simple fabrication process with the low power consumption and high density storage. In addition, integration of two oxide layers into bilayer oxide configuration as an insulating layer exhibits a selective functionality with an engineered nonlinearity32,33,34. Moreover, the promising material, such as VOx, with self-selecting resistive switching performance for crossbar memory arrays was demonstrated35. Such unique property offers a simple way for practical application without additional device steak.

Although various TiO2 thin film devices have been widely evaluated as a resistive switching material for RRAM6, 7, 36, the resistive switching characteristics of TiO2 nanorod arrays (NRs) structure have seldom been discussed. In this regard, the self-selecting resistive switching characteristics of TiO2 nanorod grown on a fluorine-doped tin oxide (FTO) by a hydrothermal method are investigated for the first time37. Using Pt/TiO2 NRs/Pt to fabricate RRAM device, the I–V characteristics with nonlinearity up to ~10 were successfully demonstrated. The characteristics of Pt/TiO2 NRs/Pt were measured to suppress the leakage current <3.7 V, showing that the leakage current in the TiO2 NRs device was significantly limited within 10−4 Acm−2. The mechanisms of the switching behavior and nonlinear electrical properties were investigated and discussed in detail. The concept of nonlinear I–V characteristics in single material offers the new strategy to overcome the sneak path problem in the crossbar arrays structure.

Results and Discussion

Fig. 1(a) shows schematics of rutile TiO2 nanorod arrays grown on a FTO glass substrate by a previously reported hydrothermal method37. TiO2 NR arrays were hydrothermally grown on the fluorine-doped tin oxide (FTO) substrate in 50 mL of aqueous hydrochloric acid (the ratio of DI water to 37% HCl is 1:1) and 1 mL of titanium (IV) test-n-butoxide (TnBT) in a Teflon-lined stainless steel autoclave (125 ml volume) at 150 °C for 3 hours, followed by heat treatment in air at 350 °C for 3 hours to increase the crystallinity of TiO2 nanorods and improve their contact to the substrate. Fig. 1(b) and inset show a corresponding field-emission scanning electron microscopy (FESEM) image of one-dimensional, high-density and well-aligned TiO2 nanorod arrays on the FTO substrate. The corresponding cross-sectional SEM image as shown in Fig. 1(c) clearly confirms the diameters of TiO2 nanorods are in the ranges of 30~200 nm and the typical nanorod lengths of ~700 nm. The tetragonal rutile structure of TiO2 nanorods was confirmed by X-ray diffractometer (XRD)with ICDD-PDF No.01-088-1175 where two major peaks at planes of (101) and (002) can be indexed as shown in Fig. S2. Furthermore, Fig. 1(d) shows a low magnified transmission electron microscopy (TEM) image of a TiO2 nanorod. The corresponding high-resolution TEM (HRTEM) image as shown in Fig. 1(e) reveals a single crystalline nature. Inset in Fig. 1(e) shows a selected area diffraction (SAED) pattern, also confirming the single crystalline nature of the TiO2 nanorod with the rutile phase. Two internal spacings of 0.32 and 0.28 nm, which are consistent with the d-spacings of (110) and (001) planes of the rutile TiO2, were indexed. As a result, the growth direction along [001] can be confirmed. Moreover, peaks at 265, 429 and 606 cm−1, corresponding to the multi-photon process, Eg and A1g 38 were observed in the Raman spectra as shown in Figure S3, providing another solid evidence of rutile TiO2 nanorods grown on the FTO substrate.

(a) Schematics of the fabrication processes of TiO2 NR arrays and Pt/TiO2 NRs/FTO device. (b) Tilted SEM image of TiO2 nanorod arrays. The inset shows a top-view SEM image of TiO2 nanorod arrays. (c) Cross-sectional SEM image of vertically aligned TiO2 nanorod arrays with a length of ~700 nm grown on FTO substrate. (d) A low-magnification TEM image of TiO2 nanorod. (e) HRTEM image of the TiO2 nanorod. The inset shows the diffraction pattern extracted by fast Fourier transform (FFT), confirming a single crystalline structure of the TiO2 nanorod.

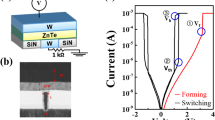

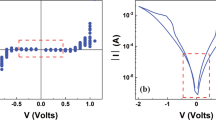

For resistive switching characteristics measurements, a Pt thin film with a thickness of 100 nm as the top electrode was deposited on TiO2 nanorod arrays with ~700 nm in length by the rf-magnetron sputtering at room temperature while the FTO substrate was used as the bottom electrode (BE) as shown in inset of Fig. 2(a). Note that the diameter of the Pt electrode is fixed at 200 nm by a metal shadow mask. I–V characteristics of the Pt/TiO2 NRs/FTO memory device were studied by DC voltage sweep measurements where the bias voltages were applied to the top electrode (TE) with the bottom electrode (BE) grounded, and the pristine device with a resistance of ~167 Ω from I–V curve was measured. Before resistive switching phenomena are achieved, an irreversible “Forming process” has to be applied. A gradual decrease of the resistance was observed as shown in Fig. 2(a) after applying a continuous DC voltage sweep to ~9.8 V on the top electrode. The resistive switching of from low resistance state (LRS) to high resistance state (HRS) instead of from HRS to LRS in the forming process was found, which is different from the general forming process in RRAM device39. (Forming process of another device, Fig. S4) Fig. 2(b,c) represent typical I–V characteristics of a Pt/TiO2 NRs/FTO device with linear and semi-log plots, respectively. By applying a positive bias from 0 V to 12 V with a compliance current (CC) of 1 mA, an abrupt increase of current could be observed at 9.6 V, which is called a SET voltage (Vset). The resistance of the device was changed from the HRS to LRS during this operation, namely the “SET process”, as shown in Fig. 2(b,c). On the other hand, with a decrease in applied voltage from 12 to 0 V, the suddenly decreased current at 3.7 V can be found, which is called a hold voltage (Vhold) as the electrical property of TiO2 returns back to the insulating state. It could be observed that there was a significantly increased resistance, leading to current suppressed at a low voltages region. When we sweep to the negative bias, the resistance of the device switching to HRS at ∼−6.65 V (RESET voltage, Vreset) was observed, which is called the “RESET process”. At voltages below the Vhold, the limited current can be reached, namely nonlinearity resistive switching, which can be accessed by applying an appropriate reading voltage (Vread) from Vholdto Vset. Write operation can be performed at voltages >3.7 V while erase operations can be performed at voltages <−6.7 V. (I-V curve of another device are shown in Figure S5.) The selecting operation of the nonlinearity resistive switching found in Pt/TiO2 NRs/FTO device can be used to all of the unselected cells, which can be considered as the worst case with the N × N cross-point arrays in the LRS as shown in Fig. S1 40. At this half-biased scheme, Vread was effectively applied to the selected cell, whereas Vread/2 and −Vread/2 were imposed to unselected cells (N + N − 2) connected the applied word line and bit line, mainly contributing to the sneak path current40. In our device, Vread and Vread/2 at 6 and 3 V were assumed. The LRS current or the leakage current of the unselected cells (unselected cells are biased at Vread/2) was suppressed while keeping Vread/2 below 3.7 V (Vhold), showing that the leakage current was significantly limited within 10−4 Acm−2. The nonlinearity is about 10 as an important factor for improving the readout margin in cross-point arrays, which is defined as I(Vread)/I(Vread/2), where Vread is the full-read voltage and Vread/2 is the half-read voltage. The nonlinearity resistive switching in the TiO2 NRs device offers the selecting function, which could decrease reading interference between neighboring cells, thus improving the crossbar arrays size. In addition, the length difference will also affect resistivity of the nanorod. If the resistivity of the NRs layer is too high, the forming process needs a larger bias to the following operation, even no resistive switching behavior. If the NRs layer resistivity is too low, the NRs layer may act as a simple metallic contact. Therefore, TiO2 NRs with the length of ~700 nm in the current study can be a suitable length with the good performance memory operation.

(a) Typical I-V characteristics of a forming process for Pt/TiO2 NRs/FTO device. The inset shows a schematic of a Pt/TiO2 NRs/FTO device. (b) Typical resistive switching behavior of Pt/TiO2 NRs/FTO device in linear scale. (c) Typical resistive switching behavior of Pt/TiO2 NRs/FTO device in semi-log scale.

Endurance and retention tests were conducted in order to investigate the reliability of the Pt/TiO2 NRs/FTO device. Obtained by repetitive ON/OFF sweeping operation, the endurance cycling test results are shown in Fig. 3(a). The typical resistances of the ON-state (LRS) and the OFF-state (HRS) on the order magnitudes of 104 and 105~106 are obtained using the read voltage at 6 V. With a ROFF/RON ratio of approximately 10~102, the memory device has a sufficient window for efficient memory applications. The resistive switching in TiO2 NRs devices is reproducible with cyclic tests of ~25 cycles. Until now, the cycle performance is still limited by lack of enough vacancy migration to switch device from HRS to LRS under the high bias operation, which can be expected to be improved by decreasing the length of nanorods with optimized crystallinity. The retention property of memory was conducted to evaluate the data storage ability at room temperature, and the obtained results using the read voltage at −0.1 V are shown in Fig. 3(b). Distinctly, the memory shows good retention characteristics up to 103 sec without obvious degradation in both the HRS and LRS. The cumulative probability distributions of current in LRS at Vread and Vread/2 in the TiO2 NRs device were measured as shown in Fig. 3(c). The device maintains the nonlinear performance during the switching cycle, namely self-selecting resistive switching property. Figure 3(d) shows cumulative probability distributions of Vset and Vhold obtained from I-V curves of TiO2 NRs device. For Vhold < 3.7 V, the total current of the device is ensured being limited, suppressing the leakage current of the device. Note that the device can be programmed, and the stored information can be read by applying an appropriate reading voltage between Vset and Vhold. The experimental results from Fig. 3(c,d) indicate that the switching performances are reproducible from cycle to cycle.

(a) Endurance test of the Pt/TiO2 NRs/FTO device under DC switching sweep mode at a read voltage of 6 V. (b) Retention tests of the Pt/TiO2 NRs/FTO device under a continuous read voltage stress of −0.1 V. (c) Cumulative distribution of current in LRS at VREAD and VREAD/2 for the Pt/TiO2 NRs/FTO device. (d) Cumulative distribution of VSET and Vhold for the Pt/TiO2 NRs/FTO device.

The possible model to explain the observed nonlinear resistive switching phenomenon were proposed as shown in Fig. 4. In the “Forming process”, an amount of heat generated by the Joule heating flowing into TiO2 NRs can easily trigger an oxidation reaction, making oxygen-deficient TiO2 NRs more oxidized after applying a large bias with a high current density (Fig. 4a). The energy dispersive spectrum (EDS) results of pristine TiO2 NR show that atomic compositions of Ti and O are of 37.2 and 62.8 at %, respectively, confirming the oxygen-deficient in TiO2 NR with the O/Ti ratio of ~1.67 as shown in Fig. S6. The geometry of nanorod arrays provides a large area surface to adsorb O2 molecules to accelerate the oxidation process, leading to an increase in resistance of TiO2 NRs. Otherwise, the O2 molecules adsorbed on the defective area of TiO2 NRs surface serve as the traps for charged carriers to form chemisorbed oxygen adatoms and increase the surface potential, leading to the decrease in the conductivity of TiO2 NRs surface41. The diameter of TiO2 NRs becomes larger, resulting in the bottom of nanorods being wider than the top region when the nanorods grow taller from bottom to top and ultimately touch each other to form a continuous film at the bottom (see the Fig. 1c)37. In this way, the porosity of TiO2 NRs film near top electrode is higher than that near bottom electrode. The different porosities (the different sizes of the surface area) to adsorb O2 and the migration of oxygen ions under the positive bias result in the formation of the TiO2-x suboxide region (TiO2 layer with oxygen-deficient region) layer near the bottom FTO electrode (cathode, grounded electrode) and TiO2 fully-oxide region (TiO2 layer with oxygen-rich region) near the top Pt electrode (anode, the electrode on which the voltage was applied) (Fig. 4b). During the SET process as shown in Fig. 4(c), oxygen vacancies diffuse from the anode (the electrode on which the voltage was applied) to cathode (grounded electrode) along with nanorod surface and form metallic filaments to connect the top electrode and the suboxide region, and switch device from HRS to LRS. Additionally, the oxygen-deficient TiO2-x suboxide region serves as a supplementary reservoir of oxygen vacancies to connect conducting filaments. Simultaneously, electrons can be injected from cathode to anode. The Joule heating effect by electron injection should provide a thermal energy to drive ionic migration42, 43. Note that the filaments usually have larger size near the bottom electrode and small size near the grounded electrode42, 44. The oxygen-deficient TiO2-x suboxide region plays an important role, resulting in non-linearity I-V phenomena. Numbers of non-stoichiometric Ti suboxides (TinO2n-1, so-called Magne´li phase), including Ti2O3, Ti3O5, Ti4O7, Ti5O9 45, have been known to demonstrate the gradual transition from metal to insulator33. In our case, non-linearity I-V characteristics in the device may be attributed to a gradual transition of suboxide phase in TiO2-x suboxide region after the formation of filaments during the SET process. In addition, the deposition of Pt electrode is also deposited on the surface of NRs due to the porosity of TiO2 NRs film, which would form a metal patch on the nanorod surface and this patch distribution is the difference from top and bottom of NRs. Top of nanorods has more metal patch to increase the conductivity by assisting connection of the filaments in LRS while the bottom of nanorods seldom has metal patch owing to lower porosity of TiO2 NRs film. Metal patch distribution and oxidation difference from top and bottom of NRs would result in the Schottky barrier height, suppressing the current in LRS. Therefore, the current of LRS would be suppressed in the low bias. In the RESET process, a significant amount of heat generated by the Joule heating interrupts the local filaments when the high current density flows into the metallic filaments (Fig. 4d)42, 43. Simultaneously, Joule heating also provides energy to the thermochemical reaction, causing the migration of oxygen vacancies (oxygen ions). The positions for the rupture of the filaments would normally form near the top electrode owing to much thinner filament sizes. To corroborate the existence of the non-stoichiometric Ti suboxides region nearby the bottom FTO electrode, X-Ray photoelectron spectroscopy (XPS) at the O 1 s core-level was used to identify the oxygen distribution of TiO2 NRs from top to bottom regions after the resistive switching operation as shown in Fig. 4(e). From the peak fitting deconvolution analysis, a distinct peak at 531.1 eV46 owing to non-lattice oxygen in oxygen deficient TiOx indicates the presence of unbonded oxygen molecules (oxygen interstitials) and oxygen vacancies, while a peak at 529.7 eV46 related to the lattice oxygen in stoichiometric TiO2 was found. The higher percentage of non-lattice oxygen near the TiO2 NRs bottom side distinctly confirms the existence non-stoichiometric Ti suboxides region nearby the bottom FTO electrode.

The major advantage of the self-selecting resistive switching behavior of TiO2 NRs compared with general RRAM elements is the suppression of sneak paths to achieve large passive crossbar arrays. To estimate the maximum crossbar array density of the resistive switching behaviors of TiO2 NRs, two passive crossbar arrays (N rows × N columns) using general RRAM cells (1R)12 and self-selecting RRAM cells based on TiO2 NRs with the worst read scheme were evaluated where the crossbar array can be simplified as the equivalent circuit in Fig. 5(a) 40. The read margin (ΔVout) normalized to pull-up voltage (Vpu) as an important parameter of estimating the cross array density can be calculated by the Kirchhoff equation given by refs 40 and 47 (Detail calculation, please read the supporting information)

Where Vout, Rselect, Rsneak and Rpu represent the voltage across the pull-up resistor, parameters of selected cell resistance, sneak path resistance and connective resistance in the measured system, respectively. Note that the sneak resistances can be given by \({{\rm{R}}}_{{\rm{sneak}}}=\frac{2{{\rm{R}}}_{{\rm{LRS}}}^{{\rm{sneak}}}}{{\rm{N}}-1}+\frac{{{\rm{R}}}_{{\rm{LRS}}}^{{\rm{sneak}}}}{{({\rm{N}}-1)}^{2}}\). As a result, the dependence of ΔVout/Vpu on the crossbar number (N) in 1R and self-selecting RRAM can be shown in Fig. 5(b). Notably, the read margin decreases as the crossbar numbers increase for both the general RRAM cells and the self-selecting RRAM cells. Therefore, the maximum N numbers of 4 and 79 for the general RRAM cells and the self-selecting RRAM cells could be achieved by taking ΔV/Vpu of 0.1 (10%) into account, respectively. Clearly, the improved readout margin in the cross-point array of the self-selecting RRAM cells compared to the general RRAM device due to the nonlinearity of Pt/TiO2 NRs/FTO configuration can be confirmed. In the future, more works will be clearly needed to improve the self-selecting memory performance, and to increase the ratio of Rsneak/RLRS 24 for enlarging the crossbar array numbers (Fig. S7).

(a) A schematic of N × N crossbar arrays and the corresponding equivalent circuit of crossbar arrays using one bit-line and pull-up read scheme, with which the red dotted line denotes the sneak path. The misreading current path (sneak path) in N × N crossbar arrays occurs where all bits are at LRS except the red cell is selected. The green regions are parallel resistor networks, namely bits on selected BLs and bits on selected WLs. The blue regions are bits on unselected WLs and BLs. (b) The dependence of normalized read voltage margin ΔV/Vpu with the crossbar line number (N) at read voltages of 0.1 and 6 V for the general RRAM device and the self-selecting resistive switching Pt/TiO2 NRs/FTO device.

Conclusions

To summarize, the resistive switching characteristics of TiO2 nanorod system synthesized by a large-scale and low-cost hydrothermal method has investigated. As a proof of concept, the nonlinear I–V characteristics of TiO2 nanorod arrays was measured to suppress the leakage current less than 10−4 Acm−2, demonstrating the self-selecting resistive switching with nonlinearity up to ~10 for crossbar memory arrays application. The unique property offers a simple way for practical crossbar arrays application without additional device steak. The mechanism of the nonlinear resistive switching behavior was discussed in detail. The concept of self-selecting resistive switching in single material offers the new strategy to overcome the sneak path issue for RRAM in the crossbar arrays structure.

Methods

Synthesis of Rutile TiO2 NR arrays

Rutile TiO2 NR arrays were hydrothermally grown on the fluorine-doped tin oxide (FTO) substrate in 50 mL of aqueous hydrochloric acid (the ratio of DI water to 37% HCl is 1:1) and 1 mL of titanium(IV) test-n-butoxide (TnBT) in a Teflon-lined stainless steel autoclave (125 ml volume) at 150 °C for 3 hours. After the reaction, the sealed autoclave was cooled down to room temperature slowly. After the NR are grown, the substrate was rinsed with deionized water and baked at 80 °C. Finally, the sample was annealed in air at 350 °C for 3 hours to increase the crystallinity of TiO2 nanorods and improve their contact to the substrate.

Device Fabrications

After the synthesis of TiO2 NR arrays, the Pt as the top electrode with a thickness of 100 nm was deposited on the TiO2 NR arrays via rf-magnetron sputtering at room temperature. The Pt electrodes of diameters 200 were fabricated via a metal shadow mask.

Characterizations

A field emission scanning electron microscope (FE-SEM, JSM-6500F, JEOL), operating at 15 kV and a field emission transmission electron microscope (FE-TEM, JEM-3000F, JEOL) equipped with an energy dispersion spectrometer (EDS), operating at 300 kV were used to study surface morphologies and microstructures. X-ray diffraction spectrometer (Shimadzu XRD 6000, Cu Kα radiation with a wavelength of 0.154 nm) and Raman microscope (Horiba Jobin Yvon LabRam HR800 with an excitation wavelength of 632.8 nm) was performed to characterize crystal structure. The resistive switching characteristics of the fabricated devices were investigated using a Keithley 4200 semiconductor parameter analyzer in voltage sweeping mode at room temperature. All of the operation voltages were applied on the top Pt electrode, and the FTO as the bottom electrode was grounded. The chemical bonding states were characterized by X-ray photoelectron spectroscopy (XPS, ULVAC-PHI, PHI Quantera SXM).

References

Waser, R. & Aono, M. Nanoionics-based resistive switching memories. Nat Mater 6, 833–840, doi:10.1038/nmat2023 (2007).

Sawa, A. Resistive switching in transition metal oxides. Materials Today 11, 28–36, doi:10.1016/S1369-7021(08)70119-6 (2008).

Waser, R., Dittmann, R., Staikov, G. & Szot, K. Redox-Based Resistive Switching Memories – Nanoionic Mechanisms, Prospects, and Challenges. Advanced Materials 21, 2632–2663, doi:10.1002/adma.200900375 (2009).

Yang, J. J., Strukov, D. B. & Stewart, D. R. Memristive devices for computing. Nat Nano 8, 13–24, doi:10.1038/nnano.2012.240 (2013).

Baek, I. G et al. Highly scalable nonvolatile resistive memory using simple binary oxide driven by asymmetric unipolar voltage pulses. In: Electron Devices Meeting, 2004. IEDM Technical Digest. IEEE International ed^(eds) (2004).

Choi, B. J. et al. Resistive switching mechanism of TiO2 thin films grown by atomic-layer deposition. Journal of Applied Physics 98, 033715–033710, doi:10.1063/1.2001146 (2005).

Tsunoda, K., Fukuzumi, Y., Jameson, J. R., Wang, Z., Griffin, P. B. & Nishi, Y. Bipolar resistive switching in polycrystalline TiO2 films. Applied Physics Letters 90, 113501, doi:10.1063/1.2712777 (2007).

Chang, W.-Y., Lai, Y.-C., Wu, T.-B., Wang, S.-F., Chen, F. & Tsai, M.-J. Unipolar resistive switching characteristics of ZnO thin films for nonvolatile memory applications. Applied Physics Letters 92, 022110, doi:10.1063/1.2834852 (2008).

Tzu-Ning, F. et al. Erase mechanism for copper oxide resistive switching memory cells with nickel electrode. In: Electron Devices Meeting, 2006. IEDM ‘06. International ed^(eds) (2006).

Kügeler, C., Meier, M., Rosezin, R., Gilles, S. & Waser, R. High density 3D memory architecture based on the resistive switching effect. Solid-State Electronics 53, 1287–1292, doi:10.1016/j.sse.2009.09.034 (2009).

Linn, E., Rosezin, R., Kugeler, C. & Waser, R. Complementary resistive switches for passive nanocrossbar memories. Nat Mater 9, 403–406, doi:10.1038/nmat2748 (2010).

Huang, C.-H., Huang, J.-S., Lin, S.-M., Chang, W.-Y., He, J.-H. & Chueh, Y.-L. ZnO1–x Nanorod Arrays/ZnO Thin Film Bilayer Structure: From Homojunction Diode and High-Performance Memristor to Complementary 1D1R Application. Acs Nano 6, 8407–8414, doi:10.1021/nn303233r (2012).

Shyh-Shyuan, S. et al. A 5 ns fast write multi-level non-volatile 1 K bits RRAM memory with advance write scheme. In: VLSI Circuits, 2009 Symposium on (ed^(eds) (2009).

Lee, M.-J. et al. Low-Temperature-Grown Transition Metal Oxide Based Storage Materials and Oxide Transistors for High-Density Non-volatile Memory. Advanced Functional Materials 19, 1587–1593, doi:10.1002/adfm.v19:10 (2009).

Liu, Z.-J., Gan, J.-Y. & Yew, T.-R. ZnO-based one diode-one resistor device structure for crossbar memory applications. Applied Physics Letters 100, 153503, doi:10.1063/1.3701722 (2012).

Jiun-Jia, H., Yi-Ming, T., Wun-Cheng, L., Chung-Wei, H. & Hou, T.-H. One selector-one resistor (1S1R) crossbar array for high-density flexible memory applications. In: Electron Devices Meeting (IEDM), 2011 IEEE International ed^(eds) (2011).

Lee, W. et al. High Current Density and Nonlinearity Combination of Selection Device Based on TaOx/TiO2/TaOx Structure for One Selector–One Resistor Arrays. Acs Nano 6, 8166–8172, doi:10.1021/nn3028776 (2012).

Lee, M.-J. et al. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5−x/TaO2−x bilayer structures. Nat Mater 10, 625–630, doi:10.1038/nmat3070 (2011).

Lin, S.-M. et al. Single-Step Formation of ZnO/ZnWOx Bilayer Structure via Interfacial Engineering for High Performance and Low Energy Consumption Resistive Memory with Controllable High Resistance States. ACS Applied Materials & Interfaces 5, 7831–7837, doi:10.1021/am4016928 (2013).

Lin, S.-M. et al. Tunable Multilevel Storage of Complementary Resistive Switching on Single-Step Formation of ZnO/ZnWOx Bilayer Structure via Interfacial Engineering. ACS Applied Materials & Interfaces 6, 17686–17693, doi:10.1021/am504004v (2014).

Chang, W.-Y., Lin, C.-A., He, J.-H. & Wu, T.-B. Resistive switching behaviors of ZnO nanorod layers. Applied Physics Letters 96, 242109, doi:10.1063/1.3453450 (2010).

Yen-De, C. et al. Single-ZnO-Nanowire Memory. Electron Devices, IEEE Transactions on 58, 1735–1740, doi:10.1109/TED.2011.2121914 (2011).

Yang, Y. C. et al. Nonvolatile resistive switching in single crystalline ZnO nanowires. Nanoscale 3, 1917–1921, doi:10.1039/c1nr10096c (2011).

Kim, S. I., Lee, J. H., Chang, Y. W., Hwang, S. S. & Yoo, K.-H. Reversible resistive switching behaviors in NiO nanowires. Applied Physics Letters 93, 033503, doi:10.1063/1.2958234 (2008).

Oka, K., Yanagida, T., Nagashima, K., Tanaka, H. & Kawai, T. Nonvolatile Bipolar Resistive Memory Switching in Single Crystalline NiO Heterostructured Nanowires. Journal of the American Chemical Society 131, 3434–3435, doi:10.1021/ja8089922 (2009).

Oka, K., Yanagida, T., Nagashima, K., Kawai, T., Kim, J.-S. & Park, B. H. Resistive-Switching Memory Effects of NiO Nanowire/Metal Junctions. Journal of the American Chemical Society 132, 6634–6635, doi:10.1021/ja101742f (2010).

Deng, X. L. et al. Confining grains of textured Cu2O films to single-crystal nanowires and resultant change in resistive switching characteristics. Nanoscale 4, 2029–2033, doi:10.1039/c2nr12100j (2012).

Liang, K.-D. et al. Single CuOx Nanowire Memristor: Forming-Free Resistive Switching Behavior. ACS Applied Materials & Interfaces 6, 16537–16544, doi:10.1021/am502741m (2014).

Nagashima, K. et al. Resistive Switching Multistate Nonvolatile Memory Effects in a Single Cobalt Oxide Nanowire. Nano Letters 10, 1359–1363, doi:10.1021/nl9042906 (2010).

Dong, H. et al. High performance bipolar resistive switching memory devices based on Zn2SnO4 nanowires. Nanoscale 4, 2571–2574, doi:10.1039/c2nr30133d (2012).

Hsu, C. W. & Chou, L. J. Bipolar resistive switching of single gold-in-Ga2O3 nanowire. Nano Lett 12, 4247–4253, doi:10.1021/nl301855u (2012).

Joshua Yang, J. et al. Engineering nonlinearity into memristors for passive crossbar applications. Applied Physics Letters 100, 113501, doi:10.1063/1.3693392 (2012).

Woo, J. et al. Selector-less RRAM with non-linearity of device for cross-point array applications. Microelectronic Engineering 109, 360–363, doi:10.1016/j.mee.2013.03.130 (2013).

Lee, S. et al. Tunnel barrier engineering of titanium oxide for high non-linearity of selector-less resistive random access memory. Applied Physics Letters 104, 052108, doi:10.1063/1.4864471 (2014).

Myungwoo, S. et al. Self-Selective Characteristics of Nanoscale VOx Devices for High-Density ReRAM Applications. Electron Device Letters, IEEE 33, 718–720, doi:10.1109/LED.2012.2188989 (2012).

Yun, J., Cho, K., Park, B., Park, B. H. & Kim, S. Resistance switching memory devices constructed on plastic with solution-processed titanium oxide. Journal of Materials Chemistry 19, 2082–2085, doi:10.1039/b817062b (2009).

Liu, B. & Aydil, E. S. Growth of Oriented Single-Crystalline Rutile TiO2 Nanorods on Transparent Conducting Substrates for Dye-Sensitized Solar Cells. Journal of the American Chemical Society 131, 3985–3990, doi:10.1021/ja8078972 (2009).

Mazza, T. et al. Raman spectroscopy characterization of TiO2 rutile nanocrystals. Physical Review B 75, 045416, doi:10.1103/PhysRevB.75.045416 (2007).

Yang, J. J., Inoue, I. H., Mikolajick, T. & Hwang, C. S. Metal oxide memories based on thermochemical and valence change mechanisms. Mrs Bull 37, 131–137, doi:10.1557/mrs.2011.356 (2012).

Flocke, A. & Noll, T. G. Fundamental analysis of resistive nano-crossbars for the use in hybrid Nano/CMOS-memory. In: Solid State Circuits Conference, 2007. ESSCIRC 2007. 33rd European (ed^(eds) (2007).

Huang, T.-H. et al. Resistive Memory for Harsh Electronics: Immunity to Surface Effect and High Corrosion Resistance via Surface Modification. Scientific Reports 4, 4402, doi:10.1038/srep04402 (2014).

Chang, S. H. et al. Occurrence of Both Unipolar Memory and Threshold Resistance Switching in a NiO Film. Physical Review Letters 102, 026801, doi:10.1103/PhysRevLett.102.026801 (2009).

Kyung Min, K., Doo Seok, J. & Cheol Seong, H. Nanofilamentary resistive switching in binary oxide system; a review on the present status and outlook. Nanotechnology 22, 254002, doi:10.1088/0957-4484/22/25/254002 (2011).

Huang, C.-H., Huang, J.-S., Lai, C.-C., Huang, H.-W., Lin, S.-J. & Chueh, Y.-L. Manipulated Transformation of Filamentary and Homogeneous Resistive Switching on ZnO Thin Film Memristor with Controllable Multistate. ACS Applied Materials & Interfaces 5, 6017–6023, doi:10.1021/am4007287 (2013).

Bursill, L. A. & Hyde, B. G. Crystallographic shear in the higher titanium oxides: Structure, texture, mechanisms and thermodynamics. Progress in Solid State Chemistry 7, 177–253, doi:10.1016/0079-6786(72)90008-8 (1972).

Sang-Joon, P. et al. In situ control of oxygen vacancies in TiO2 by atomic layer deposition for resistive switching devices. Nanotechnology 24, 295202, doi:10.1088/0957-4484/24/29/295202 (2013).

Jiun-Jia, H., Yi-Ming, T., Wun-Cheng, L., Chung-Wei, H. & Tuo-Hung, H. One selector-one resistor (1S1R) crossbar array for high-density flexible memory applications. In: Electron Devices Meeting (IEDM), 2011 IEEE International ed^(eds) (2011).

Acknowledgements

The research is supported by Ministry of Science and Technology through Grant through grants no, 104-2628-M-007-004-MY3, 104-2221-E-007-048-MY3, 104-2633-M-007-001, 105-2119-M-009-009 and the National Tsing Hua University through Grant no. 104N2022E1. Y.L. Chueh greatly appreciates the use of facility at CNMM, National Tsing Hua University through Grant No. 104N2744E1.

Author information

Authors and Affiliations

Contributions

C.-H. Huang and Y.-L. Chueh planned and designed the experiments. C.-H. Huang and T.-S. Chou conducted the material synthesis, C.-H. Huang fabricated device and analyzed electrical measurement and Y.-L. Chueh supervised the project. T.-S. Chou, J.-S. Huang performed the TEM observation. S.-M. Lin conducted the XPS analysis. C.-H. Huang and Y.-L. Chueh prepared the manuscript. All of the authors contributed to the discussion.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, CH., Chou, TS., Huang, JS. et al. Self-Selecting Resistive Switching Scheme Using TiO2 Nanorod Arrays. Sci Rep 7, 2066 (2017). https://doi.org/10.1038/s41598-017-01354-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-01354-7

This article is cited by

-

Simultaneous emulation of synaptic and intrinsic plasticity using a memristive synapse

Nature Communications (2022)

-

Investigation of morphological and electrical properties of RTA-processed TiO2 for memristor application

Journal of Sol-Gel Science and Technology (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.