Abstract

Carbon dioxide (CO2) emissions from China’s cement production process have increased rapidly in recent decades, comprising the second-largest source of CO2 emissions in the country, next only to fossil fuel combustion. However, there used to lack high-quality data to estimate provincial process-related CO2 emissions from the cement industry of China. It has been recognised that many previous publications have adopted cement-based accounting methods or national average emission factors to estimate them. This study assembles fundamental provincial clinker production data and provincial clinker emission factors from multiple official statistics sources, following the Intergovernmental Panel on Climate Change (IPCC) methodology (A clinker-based estimation methodology), to develop a high-quality panel dataset of China’s provincial process-related cement emissions during 1993–2019. In 2019, the gross cement process emissions of China amounted to 818.2 Mt CO2, and the cumulative emissions between 1993–2019 were estimated to be approximately 12.5 Gt CO2. There are significant differences in provincial process-related CO2 emissions. The dataset is crucial to provincial cement process emission characterisation and emissions reduction policy-making in China.

Measurement(s) | carbon dioxide emission process |

Technology Type(s) | computational modeling technique |

Factor Type(s) | cement production • clinker production • the emission factor of clinker |

Sample Characteristic - Organism | cement • clinker • Nonmetallic Minerals |

Sample Characteristic - Environment | manufacturing process |

Sample Characteristic - Location | Province (China) |

Similar content being viewed by others

Background & Summary

As a common building material, cement is widely used in housing and road construction. In general, the global cement industry accounts for about 5–7% of the world’s CO2 emissions1. Since 1990, global cement production has increased nearly fourfold, the growth rate of which is substantially faster than energy production over the same time period2. Global cement production in 2019 is estimated at approximately 4.1 Gt3. According to China National Bureau of Statistics, in 2019, China produced 2.3 Gt cement4, accounting for 56.8% of the world’s total cement production, and in recent years its process-related emissions from cement production accounted for more than 50% of the global process emissions from cement production2. Hence, China’s cement industry is a crucial sector for reducing industrial process CO2 emissions in the world. In May 2021, seven ministries of China, including the State Administration for Market Regulation, the Ministry of Industry and Information Technology, the National Development and Reform Commission, and the Ministry of Ecology and Environment, jointly issued the Opinions on Improving the Quality of Cement Products and Regulating the Cement Market, which stated that the carbon emissions of the cement industry must reach its peak before 20305. Although it is very important to reduce CO2 emissions from the direct combustion of fossil fuels and the use of fossil energy-based electricity in the cement industry, reducing process-related emissions from cement production is also a crucial part of achieving the carbon peaking and neutrality goal of China’s cement industry.

To quantify CO2 emissions from the cement production process is the basis of managing process-related CO2 emissions from China’s cement production plants. Currently, there lacks of consistency in the reported CO2 emissions from China’s cement production process. There are also no official cement process emissions data in consecutive years’ order, with only national-level data for a few years 19946, 20057, 20108, 20129, 201410 being publicly available. Although some studies have estimated process CO2 emissions from China’s cement industry, these works rely on the national-level data, such as Emissions Database for Global Atmospheric Research (EDGAR), Carbon Dioxide Information Analysis Center (CDIAC) and Global Carbon Budget (GCB)11,12,13,14 (Table 1). The more precise provincial-level emission data were seldomly counted. On the other hand, many of these studies calculated the cement-related process emissions based on the cement output12,15,16,17 (that is, using an average cement emission factor to directly multiply with cement output). With the average cement emission factor (0.2906 tonne CO2 per tonne cement), Carbon Emission Accounts and Datasets (CEADs) calculated provincial process cement emissions with provincial cement production data during 1997–201916,18,19. However, according to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories20, the cement-based method doesn’t reflect the actual process of emission occurrence in the cement production. Those calculations are generally of low accuracy since it does not consider regional differences in cement manufacturing process and cement–clinker ratios across China21. The clinker production provides the best activity data for the process emissions calculation of cement industry20,22. Only a few studies have recently used the clinker production method to estimate China’s provincial carbon emissions of the cement production process21. For example, CEADs used a national average emission factor of 0.4964 tonne CO2 per tonne clinker to calculate provincial process cement emissions during 1996–201621. However, in terms of emission factors, those studies use a single average clinker emission factor to calculate the cement emissions of different provinces, which fail to conform to the best practices recommended by the IPCC guidelines20. This is because the emission factors of cement industries in different provinces in China are quite different23.

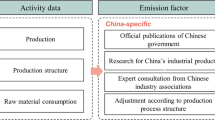

To provide high-quality data to estimate China’s process-related emissions from cement production, this study developed a panel dataset for the cement industries of China’s 31 provinces during the time interval of 1993–2019. A clinker-based estimation methodology was adopted. The dataset was assembled from provincial-level data of cement production, clinker production and cement–clinker ratios, as well as other basic data and the official provincial emission factors. The dataset provides a robust scientific support for further analyses of China’s greenhouse gas emission issues and emission management strategies. Figure 1 shows the overall structural design of the cement emission estimation methodology in this study, and the dataset is available online at https://doi.org/10.11922/sciencedb.00024.

Methods

The process-related CO2 emissions from cement production in the dataset were estimated according to the IPCC territorial-based accounting scope. It means that these emissions ‘taking place within national (including administered) territories and offshore areas over which the country has jurisdiction’24. The administrative territorial accounting method can be used to estimate the human-induced emissions directly within one region’s boundaries25.

Research scope

Carbon dioxide emissions in the cement production process mainly occur in the clinker production process. Clinker is an intermediate product in the production of cement. In the production of clinker, limestone containing calcium carbonate and magnesium carbonate is heated over 1000 °C to calcine the limestone, and carbon dioxide is released as a by-product. In general, there are two primary sources of CO2 emission in the cement manufacturing process. The first source of the CO2 emission is from the chemical reaction of limestone calcination process (largely CaCO3 in limestone)26, i.e. the process depicted by Eq. (1). The second source is from the direct usage of fossil fuels and electricity that power the cement manufacturing process. In this study, we only focus on CO2 emissions from the limestone calcination process. This is because, in CO2 emission inventories, fossil fuel and electricity emissions consumed by cement production are normally attributed to the emissions of the energy sector27.

Calculate process-related CO2 emissions of cement manufacture

According to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories, there are three primary methods to measure CO2 emissions from cement production process20.The first method is to multiply the estimated clinker production by the emission factor. Clinker production estimates are inferred from the output and clinker content ratio of cement by types; exports and imports of clinker are also considered. The second method is to multiply the actual clinker output by the emission factor and the cement kiln dust correction factor. Compared with the first method, the emission accounting method that directly uses clinker production data has lower uncertainty. The third method is to calculate CO2 emissions from the cement production process based on the weight and composition of carbonates in raw materials and fuel sources, the emission factor of carbonate, and the proportion of calcination achieved. The third method generally covers a wide range of data and is more accurate. But in fact, it is often difficult to collect plant-level supporting data.

Based on the collected and estimated data of clinker production by province, this paper uses the second method in order to obtain the provincial cement production process emission data from 1993 to 2019. Clinker or cement production data are used, depending on data availability, to estimate the CO2 emissions. Following the 2006 IPCC Guidelines for National Greenhouse Gas Inventories(vol.3 ch.2 p.2.10) and the 2005 China Greenhouse Gas Emissions Inventory Study (p.103)20,28, the calculation process of the second method follows Eq. (2).

Where CO2 Emissions refer to the emissions of CO2 from cement production process, Mcl the weight (mass) of clinker produced, EFcl the emission factor of clinker, CFckd the emission correction factor of cement kiln dust (CKD).

According to chemical reaction formula as in Eq. (1), the emission factor for clinker is determined by Eq. (3):

Where CCaO is the content of CaO in clinker, CMgO the content of MgO in clinker. We directly used the calculated outcome of clinker emission factors from the books about the 1994 and 2005 China Greenhouse Gas Emissions Inventory Study28,29.

If there are clinker production data of 31 provinces in the corresponding year, we calculate the CO2 emissions of cement production process directly. However, if the clinker production data of year t is missing, then the annual clinker data can be estimated with the cement production data by Eq. (4) as below.

Where Mcl,t represents the estimated cement clinker output of the missing year t, Mc,t the cement production of year t without cement clinker data, t1 and t2 are the latest years with data before and after the data-missing year respectively.

Emission coefficient

Various organisations have suggested default emission factors for clinker. IPCC Tier 2 and Cement Sustainability Initiative (CSI), respectively, provided emission factors of 0.510 tonne CO2 per tonne clinker (not including a correction for CKD) and 0.525 tonne CO2 per tonne clinker (including a correction for MgCO3)20,30. Using the cement-based method, EDGAR, CDIAC and CEADs suggested emission factors of 0.390 tonne CO2 per tonne cement, 0.499 tonne CO2 per tonne cement and 0.2906 tonne CO2 per tonne cement, respectively31.

1994 China Greenhouse Gas Emissions Inventory Study29 suggests that the average clinker emission factors of China in 1994 is 0.5277 tonne CO2 per tonne clinker. The book also provided the clinker emission factors of various provinces in China in 1994. According to the data, with the exception of a few provinces, the numerical deviations of the clinker emission factors in most of Chinese provinces were relatively small. Shanxi, Liaoning and Hunan have higher clinker emission factors due to higher content of MgO in the produced clinker; Ningxia has a low content of CaO and moderate content of MgO in the clinker; therefore, its clinker emission factor is the lowest. For the calculation of emissions from the cement production process in various provinces from 1993 to 1999, this study uses the clinker emission factors of each province in 1994.

From 2000 to 2019, we adopted the clinker emission factors of each province in 2005 to calculate the provincial process emissions. The 2005 clinker emission factors of provinces and regions in China were given in page 160–161 of the 2005 China Greenhouse Gas Emissions Inventory Study28. However, there are a few provinces where the emission factors are missing in 2005. We assume that the content of \(CaO\) and \(MgO\) in the clinker of a province is close to the average of the region. Therefore, the missing emission factor per unit of cement clinker can be replaced by the average level of the regions where it is located. The 2005 clinker emission factors of Tianjin, Shanxi and Inner Mongolia were set to the average emission factor of the North China, i.e. 0.5270. The 2005 clinker emission factors of Jilin and Heilongjiang were set to the average emission factor of the Northeastern China, i.e. 0.5458. The 2005 clinker emission factors of Shanghai, Jiangsu, Anhui and Jiangxi were set to the average emission factor of the Eastern China, i.e. 0.5381. The 2005 clinker emission factors of Henan, Hunan and Guangxi were set to the average emission factor of the Central-southern China, i.e. 0.5456. The 2005 clinker emission factors of Chongqing, Guizhou and Tibet were set to the average emission factor of the Southwestern China, i.e. 0.5283. The 2005 clinker emission factors of Qinghai and Shaanxi were set to the average emission factor of the Northwestern China, i.e. 0.5393. The final provincial clinker emission factors are illustrated in Table 2.

According to the 2005 China national greenhouse gas inventory Study28, the clinker emission factors of 31 provinces in China ranged between 0.5232–0.5556 tonne CO2 per tonne clinker, which is higher than 0.4964 tonne CO2 per tonne clinker production used by Shan et al.21. Moreover, provincial differences of clinker emission factors were ignored by these studies, which simply use a national average emission factor to calculate emissions from the cement production process in different provinces. It would cause inaccurate accounting of cement process CO2 emissions at the provincial level.

If assuming that the calcined CKD in the system is not lost, then the CKD correction factor will be 1 (Vol.3 ch.2 p.2.12)20. According to the 2005 China National Greenhouse Gas Inventory research group’s field survey and expert experience, Chinese companies directly screen raw material ores, maximise the use of low-grade ores and rocks, and install dust removal devices, so that the amount of unrecovered clinker dust is close to zero (p. 105)28. As a result, the correction factor for cement kiln dust would be 128. The uncertainty caused by this way will be considered in the uncertainty analysis later.

Data source

Up-to-date statistics and analyses of raw materials inputs and clinker production and country-specific emission factors are preferred for estimating the process CO2 emissions from cement production32. Following this suggestion, our dataset mainly includes two groups of raw data: provincial clinker production data and provincial cement production data. The China National Bureau of Statistics had provided national and provincial cement production data from 1993 to 20194. The provincial clinker production data have different sources in various years. The provincial cement clinker output data in 1993, 1994, and 1997 are respectively from the 1994 China Industry Economy Statistical Yearbook, the 1994 China Greenhouse Gas Emissions Inventory Study, and the 1998 China Industry Economy Statistical Yearbook29,33,34. The statistical database of the National Research Network released the provincial cement clinker data for 2002, 2015 and 201635,36. The 2015 provincial clinker output data only includes the first 10 months. This study multiplies the numbers by 1.2 to estimate the entire year’s provincial clinker output. The provincial clinker production data from 2005 to 2007 are from the cement yearbooks by the China Cement Association37,38,39.The provincial cement clinker output data from 2008 to 2014 are respectively from the 2009 China Industry Economy Statistical Yearbook, the 2010 China Industry Economy Statistical Yearbook, the 2011 China Industry Economy Statistical Yearbook, the 2012 China Industry Economy Statistical Yearbook, the 2013 China Industry Statistical Yearbook, the 2014 China Industry Statistical Yearbook and the 2015 China Industry Statistical Yearbook40,41,42,43,44,45,46. The provincial clinker output in 2017 is mainly based on the 2017 and 2018 economic operation report of China’s cement industry by China Cement Association47,48, except the Jiangsu and Zhejiang Province. The provincial cement clinker output data of year 2018 was collected from the Secondary Industry Volume of the 2018 China Economic Census Yearbook49. The provincial clinker production data of year 2019 is given by the China Cement Association. Most of the provincial clinker data for the remaining years (i.e. years 1995, 1996, 1998–2001, 2003, 2004.) are estimated based on the cement–clinker ratio values of the previous and subsequent years and the current year’s cement production. However, the clinker data of a few provinces in these remaining years are from public sources. For example, the 2004 clinker production of 17 provinces, i.e. Beijing, Shanxi, Inner Mongolia, Liaoning, Shanghai, Zhejiang, Fujian, Jiangxi, Shandong, Hubei, Hainan, Chongqing, Guizhou, Yunnan, Shaanxi, Gansu and Xinjiang, are from the their own 2004 Economic Census Yearbook50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66. The 2004 clinker production of Anhui Province is from the 2005 Anhui Industry Economy Statistical Yearbook67. The 1998 clinker production of Qinghai is from the 1999 Qinghai Statistical Yearbook68. The 1996 clinker production of Anhui is from the 1998 Anhui Statistical Yearbook69. The 1995 and 1996 clinker production of Xinjiang are from the 1997 Xinjiang Statistical Yearbook70. The 1995 clinker production of Beijing, Shanxi, Liaoning, Jiangsu, Zhejiang, and Fujian is from the their own third national industrial census of China in 199571,72,73,74,75,76.

Data Records

Our dataset is an Excel file containing six sheets. The six sheets involve the raw cement production, the raw clinker production, the calculated clinker-cement ratio, the clinker emission factor, the final cement process emission inventory data and the uncertainty analysis. The China’s provincial cement production process emissions dataset includes 833 data records (31 × 27 − 4 = 833). The Chongqing city was separated from the Sichuan Province in 1997 and became a municipality directly under the Central Government. Therefore, there is no data for Chongqing during 1993–1996. The annual cement production data for all other provinces of China have been provided in the dataset. Our dataset is stored on the website of Science Data Bank website77. It is accessible through a doi link https://doi.org/10.11922/sciencedb.00024.

Based on the level of economic development, the Mainland China can be classified into three geographic areas, i.e. the eastern, central and western regions. Figure 2 is an illustration of the cement-related emissions of the three major economic regions across China. The figure shows that, in general, China’s cement production process emissions increased steadily during 1993–2000, and began to grow rapidly after 2000. After reaching 757.0 Mt CO2 in 2014, it decreased to 716.4 Mt CO2 in 2015, and then turned over to reach 818.2 Mt CO2 in 2019. The cement emissions in central and western regions have increased substantially since 2006, while the eastern region has basically maintained CO2 emissions around 230 Mt CO2. The data reflect the large-scale on-going industrialization and construction process in middle and western China.

China process cement emissions by regions, 1993–2019. The stack area chart represents CO2 emissions from three major economic regions. The Eastern China includes Beijing, Tianjin, Hebei, Liaoning, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong, Guangdong, and Hainan. The Middle China includes Shanxi, Jilin, Heilongjiang, Anhui, Jiangxi, Henan, Hubei, and Hunan. The Western China includes Inner Mongolia, Guangxi, Chongqing, Sichuan, Guizhou, Yunnan, Tibet, Shaanxi, Gansu, Qinghai, Ningxia, and Xinjiang.

Figure 3 is an illustration for the proportion of emissions from different regions in 1993, 2000, 2005, 2010, 2015 and 2019. The proportion of emissions in the eastern region decreased from 54.6% in 1993 to 31.9% in 2019; while the central and western regions increased from 25.9% and 19.5% in 1993, to 30.2% and 37.9% in 2019, respectively. At present, each of the eastern, central and western regions accounts for about one-third of the CO2 emissions, with the western region being the highest.

Figure 4 shows the current status of CO2 emissions from the cement production process of various provinces in China in 2019. It shows that Anhui and Guangdong provinces have the highest process cement emissions, at 72.5 Mt CO2 and 59.8 Mt CO2 respectively, while Sichuan, Yunnan, Guizhou, Shandong, Guangxi, and Hunan are in the second echelon, with emissions varying from 39.3 to 50.8 Mt CO2. The provinces around Anhui, including Jiangsu, Zhejiang, Fujian, Jiangxi, Hubei, Chongqing, Henan and Hebei, are in the third echelon, with emissions ranging from 28.6 to 36.2 Mt CO2. The fourth echelon includes Liaoning, Shanxi, Shaanxi, Gansu, Xinjiang and Inner Mongolia, which have emissions between 16.3 and 22.8 Mt CO2. Jilin, Heilongjiang, Qinghai, Tibet, Ningxia, Shanghai, Beijing, and Hainan have the lowest emissions levels, which are below 9.4 Mt CO2. Table 3 lists provincial emission data for some specific years, including 1993, 2000, 2005, 2010, 2015, and 2019. Shanghai’s cement process carbon emissions have dropped to zero from 2016, and Beijing’s cement process carbon emissions in 2019 have become lower than 1993. The period of the fastest increase in carbon emissions from China’s cement process is mainly between 2000 and 2010.

Figure 5 shows the differences in the ratio of process CO2 emissions to cement production between provinces in 1993, 2000, 2005, 2010, 2015, and 2019. Cement process carbon emissions per unit of cement production vary significantly among different provinces. It also varies significantly each year from 1993 to 2019. Domestic clinker trade between provinces and international trade between provinces and other countries are important reasons for this difference.

Notably, the ratios of clinker production to cement production in the data set vary by province. For example, it is relatively high (0.9614 in 2019) in Anhui, while the clinker-cement ratio in Jiangsu is relatively low (0.3522 in 2019). Anhui has a large clinker and cement production capacity, and lots of clinker are produced in the cities of Anhui province, such as Wuhu, Tongling, Fanchang, Zongyang and other places along the Yangtze River. Hence, a large part of Anhui’s clinker production is transported to coastal areas downstream the Yangtze River, such as in Jiangsu and Zhejiang, for grinding and processing to produce cement. Clinker trade is one of the important reasons for the difference in the ratio of clinker production to cement production in various provinces.

Technical Validation

Uncertainty analysis

In general, there are two primary sources of uncertainty for cement-related emissions. One comes from the uncertainty of activity data; the other one pertains to the uncertainty of emission factors78. The uncertainty of the activity data is further comprised of uncertainties from the clinker output data of the cement industry, the clinker output data of enterprises, and the under-counted amount of kiln dust. The clinker output may be under-reported by local cement industry authorities. The clinker output provided by enterprises may contain technical errors of clinker weighing. The under-counted amount of kiln dust refers to the kiln ash lost during limestone burning, which contains calcium oxide after the decomposition of calcium carbonate. The uncertainty of emission factors comes from the sampling error of MgO and CaO contents in clinker and the error of chemical analysis of clinker conducted by enterprises. It may also come from the error of MgO and CaO contents in raw materials brought into the final calculation20,28.

The IPCC Good Practice Guide suggests that the uncertainty of plant-level clinker data is typically around 1–2%79.This study uses the median value of 1.5%. The industry statistics of clinker output are generally completed by the China Building Materials Quantitative Economic Supervision Committee, whose uncertainties are unclear. In the 2005 China Greenhouse Gas Emissions Inventory Study, the level of uncertainty was set at 5%, and the uncertainty caused by the correction coefficient of the kiln dust is 0.3%28. Based on this, the combined uncertainty of raw clinker production data is 6.8%. For those estimated clinker production data, this study temporarily set a higher uncertainty at 10%. The uncertainty in our clinker production data for all years are determined in this way.

The IPCC Good Practice Guide sets the uncertainty of chemical analysis at 1–2%79. This study uses the upper limit value of the range as the 2005 uncertainty of chemical analysis, i.e. 2%. The sampling error is about 0.2%29. Hence, the combined uncertainty of actual clinker emission factor of Chinese provinces is 2.2% in 2005 and 1994. The estimated clinker emission factor of the province by the regional average value is likely to have a higher uncertainty, and we set the uncertainty level at 4% in 2005. The 2005 clinker emission factors, which were derived from the 2005 China Greenhouse Gas Emission Inventory study, are used in the calculation of process-related emissions during 2000–2019. The 1994 clinker emission factors, derived from the 1994 China Greenhouse Gas Emission Inventory study, are used in the calculation of process-related emission during 1993–1999. The clinker emission factors are likely to vary with years, so that the uncertainty of the clinker emission factor in other years will be higher than the values in 2005 and 1994. Taking the period 2000–2019 as an example, the content of calcium carbonate and magnesium carbonate in the limestone for the production of clinker in various provinces are likely different with the value in 2005. We assume that it change gradually. This means that the closer the year to 2005, the smaller the changes in the clinker emission factor and hence the uncertainty; as the year interval increases, the corresponding uncertainty grows. Therefore, for the uncertainties of clinker emission factors in other years of period 2000–2019, we assume that they are based on the uncertainties in 2005 and increase every five years according to the rule: increase by 0.1 for each year in the first five years, 0.2 for each year in the second five years and 0.3 for each year in the third five years.

This study uses the error propagation method (Approach 1) recommended by the IPCC to determine uncertainties of provincial process-related CO2 emissions of cement production. According to the multiplication relationship of clinker production data and clinker emission factor, the combined uncertainty of each province’s carbon dioxide emissions is 7.1–7.9% in 2005. During 1993–2019, the combined uncertainties of provincial carbon dioxide emissions range from 7.1% to 11.7%. The max and min of them by years are shown in Fig. 6.

For the combined uncertainty of the process carbon dioxide emissions from China’s total cement production over the years, this study use two methods, including the error propagation method and the Monte Carlo method. First, the combined uncertainty of the national clinker production is calculated with the average uncertainty of provincial clinker production with the weight of provincial clinker production. The combined uncertainty of national average clinker emission factor is calculated with the uncertainty of provincial clinker emission factor with the weight of provincial clinker production. Then the combined uncertainty of national process-related cement emission is around 7.1–11.0% with the error propagation method during 1993–2019, as shown in Fig. 6. Second, under the normal distribution for the national clinker production and clinker emission factor, we employ the Monte Carlo method to calculate the combined uncertainty for the national process emission of cement industry. Based on determining the combined uncertainty of the national clinker production and the average clinker factor, we respectively calculated the standard deviation of the normal distribution patterns. Then we conduct random sampling on both the activity data and emission factors for 200,000 times and get 200,000 estimations on the national process-related CO2 emissions in the cement industry. The uncertainty range, therefore, was 95% confidential intervals of the estimations. The Monte Carlo simulation was conducted in Python3.8. The uncertainties of national process-related cement emission through the Monte Carlo simulations range from 7.131% to 11.018% during 1993–2019. As introduced above in the Emission coefficient subsection, there are some variations of average national clinker emission factor in the several clinker-based sources: IPCC, 1994 China National Greenhouse Gas Inventory Study (NGGI1994), 2005 China National Greenhouse Gas Inventory Study (NGGI2005), CSI and Shan et al.21. The Coefficient of Variation (CV, the standard deviation divided by the mean) by these institutions is 3.2%. In the 1994 China Greenhouse Gas Emission Inventory study, the combined uncertainty of national process-related CO2 emission in cement industry is about 6.6–8.3%. The calculated uncertainties of this study by the two methods are 7.1%, which are close to the calculated uncertainty of the 1994 China Greenhouse Gas Emission Inventory study. In addition to the above uncertainties of clinker emission factors and activity data, some other uncertainties should also be considered when using the datasets. For example, the carbon absorption effect in the use of cement has been neglected in the calculation, which also creates a certain degree of uncertainty. There may be differences between the China Cement Association and the National Bureau of Statistics in the statistical methods of cement production and clinker production. This difference in data sources may also increase the uncertainty of the calculation results.

Comparison with previous cement emission estimates

To verify the cement emissions data given in this study, we compared our results with estimates of other professional institutes or research groups, as shown in Fig. 7. It illustrates that our estimates for cement-related emissions of China are lying in the middle range, close to the official estimates, with less than 1% difference.

Process emissions from China’s cement production, 1993–2019. Also shown are estimates from CDIAC (Gilfillan et al.12,80), EDGAR v5.0 (Crippa et al.13), EDGAR v6.0 (Crippa et al.14), GCB (Andrew11, data version 210723), CEADs with the cement-based method (Shan et al.16,18; Guan et al.19) and clinker-based method (Shan et al.21).

According to the first and second national communications submitted by Chinese officials to the United Nations Framework Convention on Climate Change (UNFCCC)2, process emissions from the cement production process in Mainland China in 1994 and 2005 were 157.8 Mt CO26 and 411.7 Mt CO27, respectively. In the third national communication, the first and the second Biennial Update Report, the process emissions of non-metallic mineral products and the clinker production were reported, but the process emissions of cement production were not directly reported. In 2010, 2012 and 2014, China’s cement clinker production was 1.18875 Gt clinker10, 1.3392 Gt clinker9 and 1.4865 Gt clinker8, respectively. The 2005 National Greenhouse Gas Inventory reported that the national average carbon emission factor for clinker was 0.5383. Like Andrew (2019), we use this clinker emission coefficient to estimate the total cement process carbon emissions in Mainland China2. In 2010, 2012 and 2014, its process emission were be roughly 639.9 Mt CO2, 701.9 Mt CO2 and 758.3 Mt CO2, respectively.

Our estimation results suggest that China process-related cement CO2 emissions have been likely overestimated by the old version data of CDIAC and EDGAR. For example, in the year 2012, the old version of CDIAC overestimated 55% of the emissions and EDGAR overestimated by 22%. However, due to the lower emission factors of cement and clinker, the cement-based results and clinker-based results of CEADs have underestimated China’s cement-related CO2 emissions by 10% and 7%, respectively. The new version data of CDIAC by Gilfillan et al.12 show much lower cement process emission in China than its old version data of CDIAC by Gilfillan et al.12,80. In 2010, 2012 and 2014, the gap between CDIAC’s new version of China’s cement process data and the results of China’s greenhouse gas inventory was −8.5%, 1.6%, and 2.5%, respectively. Since 2013, EDGAR 6.014 has shown much lower values than EDGAR v5.013 for China’s process-related cement CO2 emissions because of an adjustment acknowledging the lower clinker ratio. Based on the comparisons (Fig. 7), only the estimated values of GCB11 and the new version data of CDIAC (Gilfillan et al.)12 are close to the results of this study, and the differences between GCB and this study are generally within 2.5% in the last ten years.

In previous studies, only CEADs have provided provincial-level CO2 emission estimates for the cement industry with both the cement-based method and clinker-based method. The process emission difference between this study and CEADs by provinces in 2014 are shown in Fig. 8. The difference between the results of this article and the two methods of CEADs varies from province to province. In Jiangsu, the cement-based and clinker-based estimates by CEADs is 26.9 Mt CO2 and 6.3 Mt CO2 higher than this study’s estimates, respectively. In Anhui, the cement-based and clinker-based estimates by CEADs are 33.4 Mt CO2 and 9.4 Mt CO2 lower than this study’s estimates, respectively. In Henan, the cement-based estimate is 6.2 Mt CO2 higher than this study’s estimates, but the clinker-based estimate is 3.8 Mt CO2 lower than this study’s estimates. Our provincial-level clinker emission factor estimation provides the latest and longest-term emission inventory of China and its provinces, and is an important supplement to existing emission estimates and official emission inventories. Also, the two methods of CEADs adopted the national average emission factor, which cannot reflect provincial differences in the cement manufacturing process and cement–clinker ratios across China.

Limitations

Our dataset has the following limitations: first, despite we applied the clinker emission factors of various provinces in China, the emission factor of the year 1994 and 2005 was assumed to be representative for the time interval of 1993–1999 and 2000–2019 respectively. Considering the differences in clinker production technology in different years, variations in annual emission factors are expected. In future studies, the provincial clinker emission factors of different years, if possible, should be applied to achieve a more accurate emission inventory estimation of the cement production process. Second, due to the lack of clinker data for the years 1995–1996, 1998–2001 and 2003–2004, we assumed that the clinker-to-cement ratio is constant, so that we used the averages of the clinker-cement ratio of the previous and next years, and the annual cement data of the previous years to estimate the clinker data. Third, this study uses the standard territorial principle in estimating the emissions of each province. We use the perspective of administrative boundaries to calculate the CO2 emissions of the cement production process, without considering the impact of the transfer of cement and cement clinker between different provinces from the perspective of final consumption.

Code availability

The data file with XLSX format are accessible on ScienceDB. No additional code is used during the calculation of provincial process CO2 emissions from China cement production. The installation of Microsoft Office or WPS Office is recommended to manage the data and reproduce the study results.

References

Benhelal, E., Zahedi, G., Shamsaei, E. & Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. Journal of Cleaner Production 51, 142–161, https://doi.org/10.1016/j.jclepro.2012.10.049 (2013).

Andrew, R. M. Global CO2 emissions from cement production, 1928–2018. Earth System Science Data 11, 1675–1710, https://doi.org/10.5194/essd-11-1675-2019 (2019).

United States Geological Survey. Mineral industry surveys. https://www.usgs.gov/centers/nmic/cement-statistics-and-information (2021).

The People’s Republic of China National Bureau of Statistic. National data. https://data.stats.gov.cn/easyquery.htm?cn=E0103 (2021).

General Administration of Market Supervision et al. Opinions on improving the quality of cement products and standardizing the cement market order. http://www.gov.cn/zhengce/zhengceku/2021-05/26/content_5612468.htm (2021).

National Development and Reform Commission (NDRC). The People’s Republic of China: Initial National Communication on Climate Change (China Planning Press, Beijing, 2004).

National Development and Reform Commission (NDRC). The People’s Republic of China: Second National Communication on Climate Change (China Economic Press, 2013).

National Development and Reform Commission (NDRC). The People’s Republic of China: Third National Communication on Climate Change. https://www.mee.gov.cn/ywgz/ydqhbh/wsqtkz/201907/P020190701762678052438.pdf (2018).

National Development and Reform Commission (NDRC). The People’s Republic of China: First Biennial Update Report on Climate Change. https://www.mee.gov.cn/ywgz/ydqhbh/wsqtkz/201904/P020190419522735276116.pdf (2016).

National Development and Reform Commission (NDRC). The People’s Republic of China: Second Biennial Update Report on Climate Change. https://www.mee.gov.cn/ywgz/ydqhbh/wsqtkz/201907/P020190701765971866571.pdf (2018).

Andrew, R. M. Global CO2 emissions from cement production. Zenodo https://doi.org/10.5281/zenodo.5126601 (2021).

Gilfillan, D., Marland, G., Boden, T. & Andres, R. Global, regional, and national fossil-fuel CO2 emissions: 1751–2017. ESSDIVE https://doi.org/10.15485/1712447 (2020).

Crippa, M. et al. Fossil CO2 and GHG emissions of all world countries 2019 report (Publications Office of the European Union, Luxembourg, 2019).

Crippa, M. et al. Edgar v6.0 greenhouse gas emissions. European Commission, Joint Research Centre (JRC) http://data.europa.eu/89h/97a67d67-c62e-4826-b873-9d972c4f670b (2021).

Liu, Z. et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 524, 335–338, https://doi.org/10.1038/nature14677 (2015).

Shan, Y. et al. China CO2 emission accounts 1997–2015. Scientific Data 5, 170201, https://doi.org/10.1038/sdata.2017.201 (2018).

Shan, Y. et al. New provincial CO2 emission inventories in China based on apparent energy consumption data and updated emission factors. Applied Energy 184, 742–750, https://doi.org/10.1016/j.apenergy.2016.03.073 (2016).

Shan, Y., Huang, Q., Guan, D. & Hubacek, K. China CO2 emission accounts 2016–2017. Scientific Data 7, 1–9, https://doi.org/10.1038/s41597-020-0393-y (2020).

Guan, Y. et al. Assessment to China’s recent emission pattern shifts. Earth’s Future 9, e2021EF002241, https://doi.org/10.1029/2021EF002241 (2021).

IPCC 2006. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Institute for Global Environmental Strategies (IGES), Japan, (2006).

Shan, Y. et al. Peak cement-related CO2 emissions and the changes in drivers in China. Journal of Industrial Ecology 23, 959–971, https://doi.org/10.1111/jiec.12839 (2019).

National Development and Reform Commission (NDRC). CO2 accounting and reporting guideline for the cement enterprises of China. http://www.gov.cn/gzdt/att/att/site1/20131104/001e3741a2cc13e13f2f08.pdf. Accessed April 22, 2021 (2013).

Cai, B., Wang, J., He, J. & Geng, Y. Evaluating CO2 emission performance in china’s cement industry: An enterprise perspective. Applied Energy 166, 191–200, https://doi.org/10.1016/j.apenergy.2015.11.006 (2016).

Intergovernmental Panel on Climate Change (IPCC). Revised 1996 IPCC guidelines for national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/gl/invs1.html. Accessed April 22, 2021 (1997).

Kennedy, C. et al. Methodology for inventorying greenhouse gas emissions from global cities. Energy Policy 38, 4828–4837, https://doi.org/10.1016/j.enpol.2009.08.050 (2010).

Worrell, E., Price, L., Martin, N., Hendriks, C. & Meida, L. O. Carbon dioxide emissions from the global cement industry. Annual Review of Energy and the Environment 26, 303–329, https://doi.org/10.1146/annurev.energy.26.1.303 (2001).

Friedlingstein, P. et al. Global carbon budget 2019. Earth System Science Data 11, 1783–1838, https://doi.org/10.5194/essd-11-1783-2019 (2019).

Climate Change Department of National Development and Reform Commission. The People’s Republic of China National Greenhouse Gas Inventory in 2005 (China Environmental Press, Beijing, 2014).

Office of the National Coordination Group Coping with Climate Change & Energy Research Institute of National Development and Reform Commission. The People’s Republic of China National Greenhouse Gas Inventory (China Environmental Science Press, Beijing, 2007).

Cement Sustainability Initiative (CSI). CO2 and energy accounting and reporting standard for the cement industry, version 3.0. http://wbcsdservers.org/wbcsdpublications/cd_files/datas/business-solutions/cement/pdf/CSI-CO2%20Protocol.pdf (2011).

Shen, L. et al. Factory-level measurements on CO2 emission factors of cement production in china. Renewable and Sustainable Energy Reviews 34, 337–349, https://doi.org/10.1016/j.rser.2014.03.025 (2014).

Ke, J., McNeil, M., Price, L., Khanna, N. Z. & Zhou, N. Estimation of CO2 emissions from china’s cement production: Methodologies and uncertainties. Energy Policy 57, 172–181, https://doi.org/10.1016/j.enpol.2013.01.028 (2013).

National Statistics Department of Industrial Transportation Statistics. China Industrial Economic Statistical Yearbook 1994 (China Statistics Press, Beijing, 1995).

National Statistics Department of Industrial Transportation Statistics. China Industry Economy Statistical Yearbook 1998 (China Statistics Press, Beijing, 1999).

Development Research Center of the State Council. Key industry database. http://data.drcnet.com.cn/home (2021).

Industry Information Network. National portland cement clinker production statistics by province from January to October in 2015. https://www.chyxx.com/data/201511/360526.html (2015).

China Cement Association (CCA). China Cement Almanac 2001–2005 (JiLin Education Publishing House, Jilin, 2007).

China Cement Association (CCA). China Cement Almanac 2007 (China Building Materials Press, Beijing, 2008).

China Cement Association (CCA). China Cement Almanac 2008 (Jiangsu People’s Publishing House, Nanjing, 2009).

Industry Statistics Department of National Statistics Bureau of China. China Industry Economy Statistical Yearbook 2009 (China Statistics Press, Beijing, 2010).

Industry Statistics Department of National Statistics Bureau of China. China Industry Economy Statistical Yearbook 2010 (China Statistics Press, Beijing, 2011).

Industry Statistics Department of National Statistics Bureau of China. China Industry Economy Statistical Yearbook 2011 (China Statistics Press, Beijing, 2011).

Industry Statistics Department of National Statistics Bureau of China. China Industry Economy Statistical Yearbook 2012 (China Statistics Press, Beijing, 2012).

Industry Statistics Department of National Statistics Bureau of China. China Industry Statistical Yearbook 2013 (volume 2) (China Statistics Press, Beijing, 2013).

Industry Statistics Department of National Statistics Bureau of China. China Industry Statistical Yearbook 2014 (volume 2) (China Statistics Press, Beijing, 2014).

Industry Statistics Department of National Statistics Bureau of China. China Industry Statistical Yearbook 2015 (volume 2) (China Statistics Press, Beijing, 2015).

Chen, B. Economic operation of the cement industry in 2017 and outlook for 2018. http://www.dcement.com/article/201802/161169.html (2018).

Chen, B. 2018 China Cement Industry Economic Operation Report. http://lwzb.stats.gov.cn/pub/lwzb/gzdt/201905/t20190521_5117.html (2019).

Office of the Leading Group of the Fourth National Economic Census of the State Council. China Economic Census Yearbook 2018 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2020).

Beijing Municipal Bureau Statistics & Beijing First National Economic Census Leading Group Office. Beijing Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Shanxi First National Economic Census Leading Group Office. Shanxi Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

InnerMongolia First National Economic Census Leading Group Office. InnerMongolia Economic Census Yearbook 2004 (Volume 1 of the Secondary Industry) (Chinese Statistics Press, Beijing, 2006).

Liaoning First National Economic Census Leading Group Office. Liaoning Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Shanghai First National Economic Census Leading Group Office. Shanghai Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Zhejiang First National Economic Census Leading Group Office. Zhejiang Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Fujian First National Economic Census Leading Group Office. Fujian Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Jiangxi First National Economic Census Leading Group Office. Jiangxi Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Shandong First National Economic Census Leading Group Office. Shandong Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Hubei First National Economic Census Leading Group Office & Hubei Bureau Statistics. Hubei Economic Census Yearbook 2004 (Chinese Statistics Press, Beijing, 2006).

Hainan First National Economic Census Leading Group Office. Hainan Economic Census Yearbook 2004 (the Secondary Industry Volume) (Hainan Publishing House, Hainan, 2005).

Chongqing Economic Census Leading Group Office. Chongqing Economic Census Yearbook 2004 (2 Volumes in total) (Chinese Statistics Press, Beijing, 2006).

Guizhou First National Economic Census Leading Group Office. Guizhou Economic Census Yearbook 2004 (the Secondary Industry Volume) (China City Press, Beijing, 2006).

Yunnan First National Economic Census Leading Group Office. Yunnan Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2007).

Shaanxi First National Economic Census Leading Group Office. Shaanxi Economic Census Yearbook 2004 (the Secondary Industry Volume) (Chinese Statistics Press, Beijing, 2006).

Gansu First National Economic Census Leading Group Office. Gansu Economic Census Yearbook 2004 (Volume 1 of the Secondary Industry) (Chinese Statistics Press, Beijing, 2006).

Economic Census Leading Group Office of Xinjiang Uygur Autonomous Region. Xinjiang Economic Census Yearbook 2004 (Volume 2) (Chinese Statistics Press, Beijing, 2006).

State-owned Assets Management Committee of Anhui Province, Anhui Province Development and Reform Commission & Anhui Statistics Bureau. Anhui Statistical Yearbook of Industrial Economy 2005 (China Statistics Press, Beijing, 2005).

Qinghai Statistics Bureau. Qinghai Statistical Yearbook 1999 (China Statistics Press, Beijing, 2000).

Anhui Statistical Bureau. Anhui Statistical Yearbook 1998 (Chinese Statistics Press, Beijing, 1998).

Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 1997 (Chinese Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Beijing. The data of Third National Industrial Census of China in 1995 (Beijing Volume) (China Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Shanxi Province. The data of Third National Industrial Census of China in 1995 (Shanxi Volume of Comprehensive fascicle) (China Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Liaoning. Data of Third National Industrial Census of China in 1995 (The Second Liaoning Volume) (China Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Jiangsu. Data of Third National Industrial Census of China in 1995 (Jiangsu Volume) (China Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Zhejiang. Data of Third National Industrial Census of China in 1995 (Zhejiang Volume) (China Statistics Press, Beijing, 1997).

The Third Industrial Census Office of Fujian. Data of Third National Industrial Census of China in 1995 (Fujian Volume) (China Statistics Press, Beijing, 1997).

Liao, S., Wang, D., Xia, C. & Tang, J. Data from:China’s provincial CO2 emissions from cement production, 1993–2019 https://doi.org/10.11922/sciencedb.00024 (2021).

Wei, J., Geng, Y. & Wang, S. Identification of factors influencing CO2 emission estimation from chinese cement industry and determination of their uncertainty. Acta Scientiae Circumstantiae 36, 4234–4244, https://doi.org/10.13671/j.hjkxxb.2016.0117 (2016).

Intergovernmental Panel on Climate Change (IPCC). Good practice guidance and uncertainty management in national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/gp/english/gpgaum_en.html (2000).

Gilfillan, D., Marland, G., Boden, T. & Andres, R. Global, regional, and national fossil-fuel CO2 emissions: 1751–2016. ESSDIVE https://doi.org/10.15485/1712447 (2019).

Acknowledgements

This work was supported by Shenzhen Low-Carbon City Big Data Engineering Laboratory (Grant No. ShenzhenDRC[2017]1089); Discipline Construction Program on Combating Climate Change and Low-Carbon Economics of the Harbin Institute of Techonlogy, Shenzhen, China (Grant No. ShenzhenDRC[2018]725).

Author information

Authors and Affiliations

Contributions

Shiming Liao led the project, collected and assembled the raw data, and prepared the manuscript. Dong Wang and Jie Tang designed the research. Changyou Xia and Shiming Liao revised the manuscript and participated in constructing the database.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liao, S., Wang, D., Xia, C. et al. China’s provincial process CO2 emissions from cement production during 1993–2019. Sci Data 9, 165 (2022). https://doi.org/10.1038/s41597-022-01270-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-022-01270-0

This article is cited by

-

Projecting future carbon emissions from cement production in developing countries

Nature Communications (2023)

-

China’s process-related greenhouse gas emission dataset 1990–2020

Scientific Data (2023)

-

Near-real-time daily estimates of fossil fuel CO2 emissions from major high-emission cities in China

Scientific Data (2022)