Abstract

Solid-state milling has emerged as an alternative, sustainable approach for preparing virtually all classes of compounds and materials. In situ reaction monitoring is essential to understanding the kinetics and mechanisms of these reactions, but it has proved difficult to use standard analytical techniques to analyze the contents of the closed, rapidly moving reaction chamber (jar). Monitoring by Raman spectroscopy is an attractive choice, because it allows uninterrupted data collection from the outside of a translucent milling jar. It complements the already established in situ monitoring based on powder X-ray diffraction, which has limited accessibility to the wider research community, because it requires a synchrotron X-ray source. The Raman spectroscopy monitoring setup used in this protocol consists of an affordable, small portable spectrometer, a laser source and a Raman probe. Translucent reaction jars, most commonly made from a plastic material, enable interaction of the laser beam with the solid sample residing inside the closed reaction jar and collection of Raman-scattered photons while the ball mill is in operation. Acquired Raman spectra are analyzed using commercial or open-source software for data analysis (e.g., MATLAB, Octave, Python, R). Plotting the Raman spectra versus time enables qualitative analysis of reaction paths. This is demonstrated for an example reaction: the formation in the solid state of a cocrystal between nicotinamide and salicylic acid. A more rigorous data analysis can be achieved using multivariate analysis.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The dataset generated during the current study is available in the Supplementary Information and at the GitHub repository (https://github.com/stipe-lukin/Nat_Prot).

Code availability

All the in-house written scripts used for analysis are available in the Supplementary Information and at the GitHub repository (https://github.com/stipe-lukin/Nat_Prot).

References

Do, J–L. & Friščić, T. Mechanochemistry: a force of synthesis. ACS Cent. Sci. 3, 13–19 (2017).

Frišcic, T., Mottillo, C. & Titi, H. M. Mechanochemistry for synthesis. Angew. Chem. Int. Ed. 59, 1018–1029 (2020).

Wiggins, K. M., Brantely, J. N. & Bielawski, C. W. Methods for activating and characterizing mechanically responsive polymers. Chem. Soc. Rev. 42, 7130–7147 (2013).

Beyer, M. K. & Clausen-Schaumann, H. Mechanochemistry: the mechanical activation of covalent bonds. Chem. Rev. 105, 2921–2948 (2005).

Takacs, L. The historical development of mechanochemistry. Chem. Soc. Rev. 42, 7649–7659 (2013).

Do, J–L. & Friščić, T. Chemistry 2.0: developing a new, solvent-free system of chemical synthesis based on mechanochemistry. Synlett 28, 2066–2092 (2017).

Andersen, J. & Mack, J. Mechanochemistry and organic synthesis: from mystical to practical. Green. Chem. 20, 1435–1443 (2018).

Wang, G. –W. Mechanochemical organic synthesis. Chem. Soc. Rev. 42, 7668–7700 (2013).

Boldyreva, E. Mechanochemistry of inorganic and organic systems: what is similar, what is different? Chem. Soc. Rev. 42, 7719–7738 (2013).

Šepelák, V., Düvel, A., Wilkening, M., Becker, K.-D. & Heitjans, P. Mechanochemical reactions and syntheses of oxides. Chem. Soc. Rev. 42, 7507–7520 (2013).

Beillard, A., Bantreil, X., Mètro, T.-X., Martinez, J. & Lamaty, F. Alternative technologies that facilitate access to discrete metal complexes. Chem. Rev. 119, 7529–7609 (2019).

Rightmire, N. R. & Hanusa, T. P. Advances in organometallic synthesis with mechanochemical methods. Dalton Trans. 45, 2352–2362 (2016).

Friščić, T. Supramolecular concepts and new techniques in mechanochemistry: cocrystals, cages, rotaxanes, open metal-organic frameworks. Chem. Soc. Rev. 41, 3493–3510 (2012).

Hasa, D., Schneider Rauber, G., Voinovich, D. & Jones, W. Cocrystal formation through mechanochemistry: from neat and liquid-assisted grinding to polymer-assisted grinding. Angew. Chem. Int. Ed. 54, 7371–7375 (2015).

Stolar, T. & Užarević, K. Mechanochemistry: an efficient and versatile toolbox for synthesis, transformation, and functionalization of porous metal-organic frameworks. CrystEngComm 22, 4511–4525 (2020).

Porcheddu, A., Colacino, E., De Luca, L. & Delogu, F. Metal-mediated and metal-catalyzed reactions under mechanochemical conditions. ACS Catal. 10, 8344–8394 (2020).

Hernández, J. G., Ardila-Fierro, K. J., Crawford, D., James, S. L. & Bolm, C. Mechanoenzymatic peptide and amide bond formation. Green. Chem. 19, 2620–2625 (2017).

Tan, D., Loots, L. & Friščić, T. Towards medicinal mechanochemistry: evolution of milling from pharmaceutical solid form screening to the synthesis of active pharmaceutical ingredients (APIs). Chem. Comunn 52, 7760–7781 (2016).

Colacino, E., Porcheddu, A., Charnay, C. & Delogu, F. From enabling technologies to medicinal mechanochemistry: an eco-friendly access to hydantoin-based active pharmaceutical ingredients. React. Chem. Eng. 4, 1179–1188 (2019).

Anastas, P. & Eghbali, N. Green chemistry: principles and practice. Chem. Soc. Rev. 39, 301–312 (2010).

Gomolón-Bel, F. Ten chemical innovations that will change our world: IUPAC identifies emerging technologies in chemistry with potential to make our planet more sustainable. Chem. Int. 41, 12–17 (2019).

Baláž, P. et al. Hallmarks of mechanochemistry: from nanoparticles to technology. Chem. Soc. Rev. 42, 7571–7637 (2013).

Mulas, G., Loiselle, S., Schiffini, L. & Cocco, G. The mechanochemical self-propagating reaction between hexachlorobenzene and calcium hydride. J. Solid State Chem. 129, 263–270 (1997).

Doppiu, S., Schultz, L. & Gutfleisch, O. In situ pressure and temperature monitoring during the conversion of Mg into MgH2 by high-pressure reactive ball milling. J. Alloy. Compd. 427, 204–208 (2007).

Troschke, E., Grätz, S., Lübken, T. & Borchardt, L. Mechanochemical Friedel–Crafts alkylation – a sustainable pathway towards porous organic. Polym. Angew. Chem. Int. Ed. 56, 6859–6863 (2017).

Friščić, T., Childs, S. L., Rizvi, S. A. A. & Jones, W. The role of solvent in mechanochemical and sonochemical cocrystal formation: a solubility-based approach for predicting cocrystallisation outcome. CrystEngComm 11, 418–426 (2009).

Bowmaker, G. A. Solvent-assisted mechanochemistry. Chem. Commun. 49, 334–348 (2013).

Friščić, T. et al. Ion- and liquid-assisted grinding: improved mechanochemical synthesis of metal–organic frameworks reveals salt inclusion and anion templating. Angew. Chem. Int. Ed. 49, 712–715 (2010).

Hasa, D., Carlino, E. & Jones, W. Polymer-assisted grinding, a versatile method for polymorph control of cocrystallization. Crys. Growth Des. 16, 1772–1779 (2016).

Mukherjee, A., Rogers, R. D. & Myerson, A. S. Cocrystal formation by ionic liquid-assisted grinding: case study with cocrystals of caffeine. CrystEngComm 20, 3817–3821 (2018).

Mørup, S., Jiang, J. Z., Bødker, F. & Horsewell, A. Crystal growth and the steady-state grain size during high-energy ball-milling. Europhys. Lett. 56, 441–446 (2001).

Delogu, F. & Takacs, L. Information on the mechanism of mechanochemical reaction from detailed studies of the reaction kinetics. J. Mater. Sci. 53, 13331–13342 (2018).

Ma, X., Yuan, W., Bell, S. E. J. & James, S. L. Better understanding of mechanochemical reactions: Raman monitoring reveals surprisingly simple pseudo-fluid model for a ball milling reaction. Chem. Commun. 50, 1585–1587 (2014).

Tröbs, L. & Emmerling, F. Mechanochemical synthesis and characterisation of cocrystals and metal organic compounds. Faraday Discuss. 170, 109–119 (2014).

Rehder, S. et al. Investigation of the formation process of two piracetam cocrystals during grinding. Pharmaceutics 3, 706–722 (2011).

Hutchings, B. P., Crawford, D. E., Gao, L., Hu, P. & James, S. L. Feedback kinetics in mechanochemistry: the importance of cohesive states. Angew. Chem. Int. Ed. 56, 15252–15256 (2017).

Belenguer, A. M., Lampronti, G. I., Cruz-Cabeza, A. J., Hunter, C. A. & Sanders, J. K. M. Solvation and surface effects on polymorph stabilities at the nanoscale. Chem. Sci. 7, 6617–6627 (2016).

Belenguer, A. M., Lampronti, G. I., Wales, D. J. & Sanders, J. K. M. Direct observation of intermediates in a thermodynamically controlled solid-state dynamic covalent reaction. J. Am. Chem. Soc. 136, 16156–16166 (2014).

Štrukil, V. et al. Towards an environmentally-friendly laboratory: dimensionality and reactivity in the mechanosynthesis of metal–organic compounds. Chem. Commun. 46, 9191–9193 (2010).

Cliffe, M. J., Mottillo, C., Stein, R. S., Bucar, D.-K. & Frišcic, T. Accelerated aging: a low energy, solvent-free alternative to solvothermal and mechanochemical synthesis of metal-organic materials. Chem. Sci. 3, 2495–2500 (2012).

Hammerer, F. et al. Solvent-free enzyme activity: quick, high-yielding mechanoenzymatic hydrolysis of cellulose into glucose. Angew. Chem. Int. Ed. 57, 2621–2624 (2018).

Belenguer, A. M., Michalchuk, A. A. L., Lampronti, G. I. & Sanders, J. K. M. Understanding the unexpected effect of frequency on the kinetics of a covalent reaction under ball-milling conditions. Beilstein J. Org. Chem. 15, 1226–1235 (2019).

Katsenis, A. D. et al. In situ X-ray diffraction monitoring of a mechanochemical reaction reveals a unique topology metal-organic framework. Nat. Commun. 6, 6662 (2015).

Krusenbaum, A., Grätz, S., Bimmermann, S., Hutscha, S. & Borchardt, L. The mechanochemical Scholl reaction as a versatile synthesis tool for the solvent-free generation of microporous polymers. RSC Adv. 10, 25509–25516 (2020).

Brekalo, I. et al. Manometric real-time studies of the mechanochemical synthesis of zeolitic imidazolate frameworks. Chem. Sci. 11, 2141–2147 (2020).

Grätz, S. et al. The mechanochemical Scholl reaction—a solvent-free and versatile graphitization tool. Chem. Commun. 54, 5307–5310 (2018).

Friščić, T. et al. Real-time and in situ monitoring of mechanochemical milling reactions. Nat. Chem. 5, 66–73 (2013).

Halasz, I. et al. In situ and real-time monitoring of mechanochemical milling reactions using synchrotron X-ray diffraction. Nat. Protoc. 8, 1718–1729 (2013).

Halasz, I. et al. Quantitative in situ and real-time monitoring of mechanochemical reactions. Faraday Discuss. 170, 203–221 (2014).

Gracin, D., Štrukil, V., Frišcic, T., Halasz, I. & Užarevic, K. Laboratory real-time and in situ monitoring of mechanochemical milling reactions by Raman spectroscopy. Angew. Chem. Int. Ed. 53, 6193–6197 (2014).

Juribašić, M., Užarević, K., Gracin, D. & Ćurić, M. Mechanochemical C–H bond activation: rapid and regioselective double cyclopalladation monitored by in situ Raman spectroscopy. Chem. Commun. 50, 10287–10290 (2014).

Simon, L. L. et al. Assessment of recent process analytical technology (PAT) trends: a multiauthor review. Org. Process Res. Dev. 19, 3–62 (2015).

Esmonde-White, K. A., Cuellar, M., Uerpmann, C., Lenain, B. & Lewis, I. R. Raman spectroscopy as a process analytical technology for pharmaceutical manufacturing and bioprocessing. Anal. Bioanal. Chem. 409, 637–649 (2017).

Pataki, H. et al. Implementation of Raman signal feedback to perform controlled crystallization of carvedilol. Org. Process Res. Dev. 17, 493–499 (2012).

Csontos, I. et al. Feedback control of oximation reaction by inline Raman spectroscopy. Org. Process Res. Dev. 19, 189–195 (2015).

De Beer, T. et al. Near infrared and Raman spectroscopy for the in-process monitoring of pharmaceutical production processes. Int. J. Pharm. 417, 32–47 (2011).

Pelletier, M. J. Quantitative analysis using Raman spectrometry. Appl. Spectrosc. 57, 20A–42A (2003).

Lisac, K. et al. Halogen-bonded cocrystallization with phosphorus, arsenic and antimony acceptors. Nat. Commun. 10, 61 (2019).

Batzdorf, L., Fischer, F., Wilke, M., Wenzel, K.-J. & Emmerling, F. Direct in situ investigation of milling reactions using combined x-ray diffraction and Raman spectroscopy. Angew. Chem. Int. Ed. 54, 1799–1802 (2015).

Lukin, S. et al. Tandem in situ monitoring for quantitative assessment of mechanochemical reactions involving structurally unknown phases. Chem. Eur. J. 23, 13941–13949 (2017).

Lukin, S. et al. Isotope labeling reveals fast atomic and molecular exchange in mechanochemical milling reactions. J. Am. Chem. Soc. 141, 1212–1216 (2019).

Lukin, S. et al. Mechanochemical metathesis between AgNO3 and NaX (X = Cl, Br, I) and Ag2XNO3 double-salt formation. Inorg. Chem. 59, 12200–12208 (2020).

Kulla, H. et al. Warming up for mechanosynthesis—temperature development in ball mills during synthesis. Chem. Commun. 53, 1664–1667 (2017).

Ali, S. J., Maierhofer, N. Z. & Christiane, E. F. Ettringite via mechanochemistry: a green and rapid approach for industrial application. ACS Omega 4, 7734–7737 (2019).

Fischer, F., Wenzel, K.-J., Rademann, K. & Emmerling, F. Quantitative determination of activation energies in mechanochemical reactions. Phys. Chem. Chem. Phys. 18, 23320–23325 (2016).

Kulla, H. et al. In situ investigations of mechanochemical one‐pot syntheses. Angew. Chem. Int. Ed. 57, 5930–5933 (2018).

Sović, I. et al. Mechanochemical preparation of active pharmaceutical ingredients monitored by in situ raman spectroscopy. ACS Omega 5, 28663–28672 (2020).

De Oliveira, P. F. M. et al. Tandem X-ray absorption spectroscopy and scattering for in situ time-resolved monitoring of gold nanoparticle mechanosynthesis. Chem. Commun. 56, 10329–10332 (2020).

Schiffmann, J. G., Emmerling, F., Martins, I. C. B. & Van Wüllen, L. In-situ reaction monitoring of a mechanochemical ball mill reaction with solid state NMR. Solid State Nucl. Magn. Reson. 109, 101687 (2020).

Kulla, H. et al. Tuning the apparent stability of polymorphic cocrystals through mechanochemistry. Cryst. Growth Des. 19, 7271–7279 (2019).

Surov, A. O. et al. Solid forms of ciprofloxacin salicylate: polymorphism, formation pathways, and thermodynamic stability. Cryst. Growth Des. 19, 2979–2990 (2019).

Lukin, S. et al. Experimental and theoretical study of selectivity in mechanochemical cocrystallization of nicotinamide with anthranilic and salicylic acid. Cryst. Growth Des. 18, 1539–1547 (2018).

Kulla, H., Michalchuk, A. A. L. & Emmerling, F. Manipulating the dynamics of mechanochemical ternary cocrystal formation. Chem. Commun. 55, 9793–9796 (2019).

Fischer, F., Lubjuhn, D., Greiser, S., Rademann, K. & Emmerling, F. Supply and demand in the ball mill: competitive cocrystal reactions. Cryst. Growth Des. 16, 5843–5851 (2016).

Lukin, S. et al. Mechanochemical carbon–carbon bond formation that proceeds via a cocrystal intermediate. Chem. Commun. 54, 13216–13219 (2018).

Kulla, H., Greiser, S., Benemann, S., Rademann, K. & Emmerling, F. Knowing when to stop–trapping metastable polymorphs in mechanochemical reactions. Cryst. Growth Des. 17, 1190–1196 (2017).

Stolar, T. et al. In situ monitoring of the mechanosynthesis of the archetypal metal-organic framework HKUST-1: effect of liquid additives on the milling reactivity. Inorg. Chem. 56, 6599–6608 (2017).

Fischer, F. et al. Polymorphism of mechanochemically synthesized cocrystals: a case study. Cryst. Growth Des. 16, 1701–1707 (2016).

Tireli, M. et al. Mechanochemical reactions studied by in situ Raman spectroscopy: base catalysis in liquid-assisted grinding. Chem. Commun. 51, 8058–8061 (2015).

Belenguer, A. M. et al. Understanding the influence of surface solvation and structure on polymorph stability: a combined mechanochemical and theoretical approach. J. Am. Chem. Soc. 140, 17051–17059 (2018).

Andersen, J. M. & Mack, J. Decoupling the Arrhenius equation via mechanochemistry. Chem. Sci. 8, 5447–5453 (2017).

Julien, P. A., Malvestiti, I. & Friščić, T. The effect of milling frequency on a mechanochemical organic reaction monitored by in situ Raman spectroscopy. Beilstein J. Org. Chem. 13, 2160–2168 (2017).

Michalchuk, A. A. L., Tumanov, I. A. & Boldyreva, E. V. Ball size or ball mass—what matters in organic mechanochemical synthesis? CrystEngComm 21, 2174–2179 (2019).

Fischer, F., Fendel, N., Greiser, S., Rademann, K. & Emmerling, F. Impact Is important—systematic investigation of the influence of milling balls in mechanochemical reactions. Org. Process Res. Dev. 21, 655–659 (2017).

Kulla, H., Fischer, F., Benemann, S., Rademann, K. & Emmerling, F. The effect of the ball to reactant ratio on mechanochemical reaction times studied by in situ PXRD. CrystEngComm 19, 3902–3907 (2017).

Julien, P. A. et al. In situ monitoring and mechanism of the mechanochemical formation of a microporous MOF-74 framework. J. Am. Chem. Soc. 138, 2929–2932 (2016).

Wilke, M., Batzdorf, L., Fischer, F., Rademann, K. & Emmerling, F. Cadmium phenylphosphonates: preparation, characterisation and in situ investigation. RSC Adv. 6, 36011–36019 (2016).

Lukin, S. et al. Solid-state supramolecular assembly of salicylic acid and 2-pyridone, 3-hydroxypyridine or 4-pyridone. Croat. Chem. Acta 90, 707–710 (2017).

Bjelopetrović, A. et al. Mechanism of mechanochemical C–H bond activation in an azobenzene substrate by Pd(II) catalysts. Chem. Eur. J. 24, 10672–10682 (2018).

Ardila‐Fierro, K. J. et al. Direct visualization of a mechanochemically induced molecular rearrangement. Angew. Chem. Int. Ed. 59, 13458–13462 (2020).

Biliškov, N. et al. In‐situ and real‐time monitoring of mechanochemical preparation of Li2Mg(NH2BH3)4 and Na2Mg(NH2BH3)4 and their thermal dehydrogenation. Chem. Eur. J. 23, 16274–16282 (2017).

Berry, D. J. et al. Applying hot-stage microscopy to co-crystal screening: a study of nicotinamide with seven active pharmaceutical ingredients. Cryst. Growth Des. 8, 1697–1712 (2008).

André, V. et al. Mechanosynthesis of the metallodrug bismuth subsalicylate from Bi2O3 and structure of bismuth salicylate without auxiliary organic ligands. Angew. Chem. Int. Ed. 50, 7858–7861 (2011).

Trask, A. V., Motherwell, W. D. S. & Jones, W. Physical stability enhancement of theophylline via cocrystallization. Int. J. Pharm. 320, 114–123 (2006).

Good, D. J. & Rodríguez-Hornedo, N. Solubility advantage of pharmaceutical cocrystals. Cryst. Growth Des. 9, 2252–2264 (2009).

Stolar, T. et al. Control of pharmaceutical cocrystal polymorphism on various scales by mechanochemistry: transfer from the laboratory batch to the large-scale extrusion processing. ACS Sustain. Chem. Eng. 7, 7102–7110 (2019).

de Juan, A., Jaumot, J. & Tauler, R. Multivariate curve resolution (MCR). Solving the mixture analysis problem. Anal. Methods 6, 4964–4976 (2014).

Haferkamp, S., Paul, A., Michalchuk, A. A. L. & Emmerling, F. Unexpected polymorphism during a catalyzed mechanochemical Knoevenagel condensation. Beilstein J. Org. Chem. 15, 1141–1148 (2019).

Leistenschneider, D. et al. Tailoring the porosity of a mesoporous carbon by a solvent-free mechanochemical approach. Carbon 147, 43–50 (2019).

Šepelák, V., Bégin-Colin, S. & Le Caër, G. Transformations in oxides induced by high-energy ball-milling. Dalton Trans. 41, 11927–11948 (2012).

Vogt, C. G. et al. Direct mechanocatalysis: palladium as milling media and catalyst in the mechanochemical suzuki polymerization. Angew. Chem. Int. Ed. 58, 18942–18947 (2019).

Métro, T. –X., Gervais, C., Martinez, A., Bonhomme, C. & Laurencin, D. Unleashing the potential of 17ONMR spectroscopy using mechanochemistry. Angew. Chem. Int. Ed. 56, 6803–6807 (2017).

Užarević, K. et al. Enthalpy vs. friction: heat flow modelling of unexpected temperature profiles in mechanochemistry of metal-organic frameworks. Chem. Sci. 9, 2525–2532 (2018).

Belenguer, A. M., Lampronti, G. I. & Sanders, J. K. M. Reliable mechanochemistry: protocols for reproducible outcomes of neat and liquid assisted ball-mill grinding experiments. J. Vis. Exp. 131, (2018).

Eilers, P. H. C. & Boelens, H. F. M. Baseline correction with asymmetric least squares smoothing. Leiden University Medical Center Report, Leiden (2005).

Eilers, P. H. C. A perfect smoother. Anal. Chem. 75, 3631–3636 (2003).

Acknowledgements

We thank the Ruđer Bošković Institute for financial support and our colleagues at the fine-mechanics workshop for their continuous help. The Croatian Science Foundation supports S.L. We thank the reviewers for their constructive critiques and suggestions to improve our manuscript. Part of this work was supported by the COST Action CA18112—Mechanochemistry for Sustainable Industry and by the Croatian Science Foundation (IP-2020-02-1419).

Author information

Authors and Affiliations

Contributions

The methodology was originally designed and adapted by I.H. and K.U. and further developed by S.L. S.L. performed experiments and script preparation. S.L. wrote and prepared the manuscript with input from I.H. and K.U.

Corresponding author

Ethics declarations

Competing interests

I.H. and K.U. are shareholders in InSolido Technologies (Croatia).

Additional information

Peer review information Nature Protocols thanks Ana Belenguer, Nicholas Leadbeater and Adam Michalchuk for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Key references using this protocol

Lukin, S. et al. Chem. Eur. J. 23, 13941–13949 (2017): https://chemistry-europe.onlinelibrary.wiley.com/doi/abs/10.1002/chem.201702489

Lukin, S. et al. J. Am. Chem. Soc. 141, 1212–1216 (2019): https://pubs.acs.org/doi/10.1021/jacs.8b12149

Gracin, D., Štrukil, V., Friščić, T., Halasz, I. & Užarević, K. Angew. Chem. Int. Ed. 53, 6193-6197 (2014): https://onlinelibrary.wiley.com/doi/abs/10.1002/anie.201402334

Lukin, S. et al. Chem. Commun. 54, 13216–13219 (2018): https://pubs.rsc.org/en/content/articlelanding/2018/cc/c8cc07853j#!divAbstract

Bjelopetrović, A. et al. Chem. Eur. J. 24, 10672–10682 (2018): https://chemistry-europe.onlinelibrary.wiley.com/doi/abs/10.1002/chem.201802403

Extended data

Extended Data Fig. 1

ATR-IR of reactants na, sal and resulting na:sal cocrystal.

Extended Data Fig. 2 Rietveld refinement of PXRD pattern (X-ray source: CuKα) of the resulting na:sal cocrystal after 60 min milling.

CSD code of the used structural model: SODDOF. Color scheme: blue—experimental PXRD pattern, red—refinement, gray—difference.

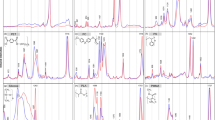

Extended Data Fig. 3 Selected Raman spectra from the monitoring experiment.

Lines indicate the Raman bands of interest for qualitative monitoring of the reaction progress.

Extended Data Fig. 4

The plot of in situ collected Raman spectra stored in variable SpectraAll before spike corrections.

Extended Data Fig. 5

The plot of in situ collected Raman spectra stored in variable SpectraAll after spike corrections.

Extended Data Fig. 6

The plot of in situ collected Raman spectra stored in variable Spectra after the subtraction of the PMMA contribution.

Extended Data Fig. 7 The plot of in situ collected Raman spectra stored in variable sp after defining spectral and temporal range.

Note that spectral range is now in the range from first_wnmb up to last_wnmb.

Extended Data Fig. 8

a,b, Examples of the baseline correction of selected in situ Raman spectra at 1 min (a) and 50 min (b) into milling experiment. Color code: blue—experimental Raman spectrum, orange—baseline estimation.

Extended Data Fig. 9

The plot of in situ collected Raman spectra stored in variable Nsp after the baseline correction.

Extended Data Fig. 10 The plot of in situ collected Raman spectra stored in variable N1sp after normalization.

Note the different scale on y-axis when compared with the nonnormalized spectra in Extended Data Fig. 9.

Supplementary information

Supplementary Information

Supplementary Figs. 1–3.

Supplementary Data 1

Experimental Raman spectra and GNU Octave scripts.

Rights and permissions

About this article

Cite this article

Lukin, S., Užarević, K. & Halasz, I. Raman spectroscopy for real-time and in situ monitoring of mechanochemical milling reactions. Nat Protoc 16, 3492–3521 (2021). https://doi.org/10.1038/s41596-021-00545-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41596-021-00545-x

This article is cited by

-

Leveraging mechanochemistry for sustainable polymer degradation

Polymer Journal (2024)

-

Growth of α-Sn on silicon by a reversed β-Sn to α-Sn phase transformation for quantum material integration

Communications Materials (2022)

-

Advancing mechanochemical synthesis by combining milling with different energy sources

Nature Reviews Chemistry (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.