Abstract

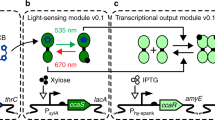

Control of the lac operon with isopropyl β-d-1-thiogalactopyranoside (IPTG) has been used to regulate gene expression in Escherichia coli for countless applications, including metabolic engineering and recombinant protein production. However, optogenetics offers unique capabilities, such as easy tunability, reversibility, dynamic induction strength and spatial control, that are difficult to obtain with chemical inducers. We have developed a series of circuits for optogenetic regulation of the lac operon, which we call OptoLAC, to control gene expression from various IPTG-inducible promoters using only blue light. Applying them to metabolic engineering improves mevalonate and isobutanol production by 24% and 27% respectively, compared to IPTG induction, in light-controlled fermentations scalable to at least two-litre bioreactors. Furthermore, OptoLAC circuits enable control of recombinant protein production, reaching yields comparable to IPTG induction but with easier tunability of expression. OptoLAC circuits are potentially useful to confer light control over other cell functions originally designed to be IPTG-inducible.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the findings of this study are available within the paper and Supplementary Information. Source data are provided with this paper.

References

Pontrelli, S. et al. Escherichia coli as a host for metabolic engineering. Metab. Eng. 50, 16–46 (2018).

Sanford, K., Chotani, G., Danielson, N. & Zahn, J. A. Scaling up of renewable chemicals. Curr. Opin. Biotechnol. 38, 112–122 (2016).

Burgard, A., Burk, M. J., Osterhout, R., Van Dien, S. & Yim, H. Development of a commercial scale process for production of 1,4-butanediol from sugar. Curr. Opin. Biotechnol. 42, 118–125 (2016).

Lalwani, M. A., Zhao, E. M. & Avalos, J. L. Current and future modalities of dynamic control in metabolic engineering. Curr. Opin. Biotechnol. 52, 56–65 (2018).

Zhao, E. M. et al. Optogenetic regulation of engineered cellular metabolism for microbial chemical production. Nature 555, 683–687 (2018).

Jacob, F. & Monod, J. Genetic regulatory mechanisms in the synthesis of proteins. J. Mol. Biol. 3, 318–356 (1961).

Donovan, R. S., Robinson, C. W. & Click, B. R. Review: optimizing inducer and culture conditions for expression of foreign proteins under the control of the lac promoter. J. Ind. Microbiol. 16, 145–154 (1996).

Levskaya, A. Engineering Escherichia coli to see light. Nature 438, 441–442 (2005).

Tabor, J. J., Levskaya, A. & Voigt, C. A. Multichromatic control of gene expression in Escherichia coli. J. Mol. Biol. 405, 315–324 (2011).

Ohlendorf, R., Vidavski, R. R., Eldar, A., Moffat, K. & Möglich, A. From dusk till dawn: one-plasmid systems for light-regulated gene expression. J. Mol. Biol. 416, 534–542 (2012).

Möglich, A. et al. Design and signaling mechanism of light-regulated histidine kinases. J. Mol. Biol. 385, 1433–1444 (2009).

Orman, M. A. & Brynildsen, M. P. Dormancy is not necessary or sufficient for bacterial persistence. Antimicrob. Agents Chemother. 57, 3230–3239 (2013).

Tu, G.-F., Reid, G. E., Zhang, J.-G., Moritz, R. L. & Simpson, R. J. C-terminal extension of truncated recombinant proteins in Escherichia coli with a 10Sa RNA decapeptide. J. Biol. Chem. 270, 9322–9326 (1995).

Hentschel, E. et al. Destabilized eYFP variants for dynamic gene expression studies in Corynebacterium glutamicum. Microb. Biotechnol. 6, 196–201 (2013).

Studier, F. W. & Moffatt, B. A. Use of bacteriophage T7 RNA polymerase to direct selective high-level expression of cloned genes. J. Mol. Biol. 189, 113–130 (1986).

Brosius, J., Erfle, M. & Storella, J. Spacing of the -10 and -35 regions in the tac promoter. Effect on its in vivo activity. J. Biol. Chem. 260, 3539–3541 (1985).

Zhao, E. M. et al. Light-based control of metabolic flux through assembly of synthetic organelles. Nat. Chem. Biol. 15, 589–597 (2019).

Martin, V. J. J., Pitera, D. J., Withers, S. T., Newman, J. D. & Keasling, J. D. Engineering a mevalonate pathway in Escherichia coli for production of terpenoids. Nat. Biotechnol. 21, 796–802 (2003).

Atsumi, S., Hanai, T. & Liao, J. C. Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 451, 86–89 (2008).

Baez, A., Cho, K. M. & Liao, J. C. High-flux isobutanol production using engineered Escherichia coli: a bioreactor study with in situ product removal. Appl. Microbiol. Biotechnol. 90, 1681–1690 (2011).

Goulas, T. et al. The pCri system: a vector collection for recombinant protein expression and purification. PLoS ONE 9, e112643 (2014).

Chang, A. C. Y. & Cohen, S. N. Construction and characterization of amplifiable multicopy DNA cloning vehicles derived from the P15A cryptic miniplasmid. J. Bacteriol. 134, 1141–1156 (1978).

Marin, A. M. et al. Naringenin degradation by the endophytic diazotroph Herbaspirillum seropedicae SmR1. Microbiology 159, 167–175 (2013).

Baumschlager, A., Aoki, S. K. & Khammash, M. Dynamic blue light-inducible T7 RNA polymerases (Opto-T7RNAPs) for precise spatiotemporal gene expression control. ACS Synth. Biol. 6, 2157–2167 (2017).

Chou, C., Young, D. D. & Deiters, A. Photocaged T7 RNA polymerase for the light activation of transcription and gene function in pro- and eukaryotic cells. ChemBioChem 11, 972–977 (2010).

Binder, D. et al. Light-responsive control of bacterial gene expression: precise triggering of the lac promoter activity using photocaged IPTG. Integr. Biol. 6, 755–765 (2014).

Wu, G. et al. Metabolic burden: cornerstones in synthetic biology and metabolic engineering applications. Trends Biotechnol. 34, 652–664 (2016).

Hillson, N. et al. Building a global alliance of biofoundries. Nat. Commun. 10, 1038–1041 (2019).

Awan, A. R. et al. Biosynthesis of the antibiotic nonribosomal peptide penicillin in baker’s yeast. Nat. Commun. 8, 15202 (2017).

Latimer, L. N. & Dueber, J. E. Iterative optimization of xylose catabolism in Saccharomyces cerevisiae using combinatorial expression tuning. Biotechnol. Bioeng. 114, 1301–1309 (2017).

Hennemann, J. et al. Optogenetic control by pulsed illumination. ChemBioChem 19, 1296–1304 (2018).

Diensthuber, R. P., Bommer, M., Gleichmann, T. & Möglich, A. Full-length structure of a sensor histidine kinase pinpoints coaxial coiled coils as signal transducers and modulators. Structure 21, 1127–1136 (2013).

Ajikumar, P. K. et al. Isoprenoid pathway optimization for taxol precursor overproduction in Escherichia coli. Science 330, 70–74 (2010).

Melis, A. et al. Chromatic regulation in Chlamydomonas reinhardtii alters photosystem stoichiometry and improves the quantum efficiency of photosynthesis. Photosynth. Res. 47, 253–265 (1996).

Ort, D. R., Zhu, X. & Melis, A. Optimizing antenna size to maximize photosynthetic efficiency. Plant Physiol. 155, 79–85 (2011).

Nilsson, G., Belasco, J. G., Cohen, S. N. & Von Gabain, A. Growth-rate dependent regulation of mRNA stability in Escherichia coli. Nature 312, 75–77 (1984).

Gottesman, S. Proteases and their targets in Escherichia coli. Annu. Rev. Genet. 30, 465–506 (1996).

Doong, S. J., Gupta, A. & Prather, K. L. J. Layered dynamic regulation for improving metabolic pathway productivity in Escherichia coli. Proc. Natl Acad. Sci. USA 115, 2964–2969 (2018).

Valiyaveetil, F. I., MacKinnon, R. & Muir, T. W. Semisynthesis and folding of the potassium channel KcsA. J. Am. Chem. Soc. 124, 9113–9120 (2002).

San-Miguel, T., Pérez-Bermúdez, P. & Gavidia, I. Production of soluble eukaryotic recombinant proteins in E. coli is favoured in early log-phase cultures induced at low temperature. Springerplus 2, 1–4 (2013).

Studier, F. W. Protein production by auto-induction in high density shaking cultures. Protein Expr. Purif. 41, 207–234 (2005).

Mok, W. W. K. & Brynildsen, M. P. Timing of DNA damage responses impacts persistence to fluoroquinolones. Proc. Natl Acad. Sci. USA 115, E6301–E6309 (2018).

Partridge, J. D., Nhu, N. T. Q., Dufour, Y. S. & Harshey, R. M. Escherichia coli remodels the chemotaxis pathway for swarming. mBio 10, 1–16 (2019).

McGinness, K. E., Baker, T. A. & Sauer, R. T. Engineering controllable protein degradation. Mol. Cell 22, 701–707 (2006).

Zuo, R., Hashimoto, Y., Yang, L., Bentley, W. E. & Wood, T. K. Autoinducer 2 controls biofilm formation in Escherichia coli through a novel motility quorum-sensing regulator (MqsR, B3022). J. Bacteriol. 188, 305–316 (2006).

Ronchel, M. C. et al. Characterization of cell lysis in Pseudomonas putida induced upon expression of heterologous killing genes. Appl. Environ. Microbiol. 64, 4904–4911 (1998).

Rittmann, D., Lindner, S. N. & Wendisch, V. F. Engineering of a glycerol utilization pathway for amino acid production by Corynebacterium glutamicum. Appl. Environ. Microbiol. 74, 6216–6222 (2008).

Nguyen, H. D., Phan, T. T. P. & Schumann, W. Expression vectors for the rapid purification of recombinant proteins in Bacillus subtilis. Curr. Microbiol. 55, 89–93 (2007).

Inoue, H., Nojima, H. & Okayma, H. High efficiency transformation of Escherichia coli with plasmids. Gene 96, 23–28 (1990).

Gibson, D. G. et al. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nat. Methods 6, 343–345 (2009).

Atsumi, S. et al. Engineering the isobutanol biosynthetic pathway in Escherichia coli by comparison of three aldehyde reductase/alcohol dehydrogenase genes. Appl. Microbiol. Biotechnol. 85, 651–657 (2010).

Zhou, K., Qiao, K., Edgar, S. & Stephanopoulos, G. Distributing a metabolic pathway among a microbial consortium enhances production of natural products. Nat. Biotechnol. 33, 377–383 (2015).

Pédelacq, J. D., Cabantous, S., Tran, T., Terwilliger, T. C. & Waldo, G. S. Engineering and characterization of a superfolder green fluorescent protein. Nat. Biotechnol. 24, 79–88 (2006).

Towbin, H., Staehellin, T. & Gordon, J. Electrophoretic transfer of proteins from polyacrylamide gels to nitrocellulose sheets: procedure and some applications. Proc. Natl Acad. Sci. USA 76, 4350–4354 (1979).

Datsenko, K. A. & Wanner, B. L. One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc. Natl Acad. Sci. USA 97, 6640–6645 (2000).

Lee, M. E., DeLoache, W. C., Cervantes, B. & Dueber, J. E. A highly characterized yeast toolkit for modular, multipart assembly. ACS Synth. Biol. 4, 975–986 (2015).

Dower, W. J., Miller, J. F. & Ragsdale, C. W. High efficiency transformation of E. coli by high voltage electroporation. Nucleic Acids Res. 16, 6127–6145 (1988).

Cherepanov, P. P. & Wackernagel, W. Gene disruption in Escherichia coli: TcR and KmR cassettes with the option of Flp-catalyzed excision of the antibiotic-resistance determinant. Gene 158, 9–14 (1995).

Acknowledgements

We thank M. Brynildsen for strain MG1655 ΔlacI::FRT-KanR-FRT, A. Möglich for plasmids pDusk and pDawn, J. Keasling for plasmid pMevT and J. Liao for plasmids pSA65 and pSA69. We are very grateful to W. Mok and M. Brynildsen for advice and troubleshooting regarding E. coli protocols. We thank C. DeCoste, K. Rittenbach and the Princeton Molecular Biology Flow Cytometry Resource Center for assistance with flow cytometry experiments. J.L.A. is supported by the US Department of Energy, Office of Science, Office of Biological and Environmental Research award no. DE-SC0019363, the NSF CAREER Award CBET-1751840, The Pew Charitable Trusts, The Eric and Wendy Schmidt Transformative Technology Fund Award and the Camille Dreyfus Teacher-Scholar Award.

Author information

Authors and Affiliations

Contributions

M.A.L. and J.L.A. conceived this project and designed the experiments. M.A.L., S.S.I. and C.C.-L. constructed the strains and plasmids. M.A.L. and S.S.I. performed the experiments shown in Figs. 1 and 2. M.A.L., E.M.Z. and H.K. performed the experiments shown in Figs. 3 and 4. M.A.L., C.C.-L. and C.D. performed the experiments shown in Fig. 5. M.A.L. performed experiments shown in Extended Data Figs. 1–10. C.C.-L. and C.D. performed experiments shown in Extended Data Figs. 2 and 9. M.A.L., C.C.-L. and J.L.A. analyzed the data and wrote the manuscript. J.L.A. supervised and funded the project.

Corresponding author

Ethics declarations

Competing interests

J.L.A., M.A.L. and C.C.-L. have filed a patent application (‘Optogenetic circuits for controlling chemical and protein production in Escherichia coli’, US patent application 62,935,267) describing the OptoLAC circuit design and application for chemical and recombinant protein production.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Development of OptoLAC circuits.

a, GFP expression in blue light or darkness from the constitutive PBBA promoter (EMAL231) or from PT5-lacO in a strain in which lacI expression is controlled by pDawn (EMAL57). P = 0.07118. b, GFP expression in blue light or darkness from PBBA (EMAL231) or from PT5-lacO in strains containing the pDawn system controlling LacI fused to SsrA tags terminating in LAA (EMAL68, which gave rise to OptoLAC1), AAV (EMAL69, which gave rise to OptoLAC2), or ASV (EMAL71). From left to right: P < 0.00001, P < 0.00001, P = 0.00536. c, GFP expression in blue light or darkness driven by the PFixK2 (pMAL441) or PFixK2-lacO (pMAL442) promoter using pDusk (EMAL152 and EMAL153, respectively). P = 0.000037. **P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as median values of 10,000 single-cell flow cytometry events; error bars represent one standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 3 independent experiments.

Extended Data Fig. 2 Quantification of LacI protein levels for OptoLAC circuits.

Integrated peak volumes of LacI protein levels quantified via Western blot. From left to right: P = 0.00102, P = 0.000041. Loading controls and uncropped blots used for quantification (samples derived from the same experiment and processed in parallel) are provided as source data. ** P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as mean values; error bars represent the standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 2 independent experiments.

Extended Data Fig. 3 Response of OptoLAC circuits to IPTG.

GFP expression from PT5-lacO controlled by OptoLAC1 (orange, EMAL68), OptoLAC2 (purple, EMAL69), or OptoLAC3 (gray, EMAL230) under blue light with different concentrations of IPTG added at the time of inoculation. From left to right: P < 0.00001, P = 0.000076, P = 0.00692, P = 0.000025. **P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as median values of 10,000 single-cell flow cytometry events; error bars represent one standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 3 independent experiments.

Extended Data Fig. 4 Response of OptoLAC circuits to low temperatures.

GFP expression at 18 °C from PBBA (EMAL231) or PT5-lacO controlled by OptoLAC1 (EMAL68), OptoLAC2 (EMAL69), or OptoLAC3 (EMAL230) under blue light or darkness. From left to right: P < 0.00001, P = 0.000014, P = 0.0222. *P < 0.05, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as median values of 10,000 single-cell flow cytometry events; error bars represent one standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 3 independent experiments.

Extended Data Fig. 5 Tunability of OptoLAC circuits with light intensity.

GFP expression from the constitutive PBBA promoter (EMAL231) or from PT5-lacO controlled by OptoLAC1 (EMAL68) or OptoLAC3 (EMAL230) under continuous blue light of differing intensities or darkness. From left to right: P = 0.0189, P = 0.00314, P < 0.00001, P < 0.00001. *P < 0.05, **P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as median values of 10,000 single-cell flow cytometry events; error bars represent one standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 3 independent experiments.

Extended Data Fig. 6 Spatial control of GFP expression on an LB agar plate.

LB agar plate containing a lawn of EMAL68 (OptoLAC1 driving GFP) illuminated with a projection of a tiger image. Scale bar: 1 cm. Data are representative of n = 2 independent experiments.

Extended Data Fig. 7 Growth curves of K strains containing OptoLAC circuits under different induction conditions.

a–c, OD600 measurements for strains containing OptoLAC1 (EMAL68; orange circle), OptoLAC2 (EMAL69; purple triangle), OptoLAC3 (EMAL230; gray square), or an IPTG-induced control (EMAL77; green diamond) using different induction conditions, shown on top of each graph as uninduced (blue) or induced (gray). a, Cultures of each strain grown under continuous blue light for 4 hours before switching them to darkness (OptoLAC circuits) or adding 1 mM IPTG (IPTG control). From left to right: P = 0.00827, P = 0.1472. b, Cultures grown entirely uninduced under continuous blue light (OptoLAC circuits) or without IPTG (IPTG control). From left to right: P = 0.00275, P = 0.0508. c, Cultures grown constitutively induced in darkness (OptoLAC circuits) or with 1 mM IPTG (IPTG control). From left to right: P = 0.000393, P = 0.00145, P = 0.33. **P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as mean values; error bars represent the standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 2 independent experiments.

Extended Data Fig. 8 Optimization of the cell density of induction with IPTG for chemical production.

a, Isobutanol production from pMAL534 by EMAL201 when induced with 1 mM IPTG at different cell densities. P = 0.819. b, Mevalonate production from pMAL487 by EMAL135 when induced with 1 mM IPTG at different cell densities. P = 0.02185. *P < 0.01. Statistics are derived using a two-sided t-test. All data shown as mean values; error bars represent the standard deviation of n = 4 biologically independent samples; open circles represent individual data points. Data are representative of n = 2 independent experiments.

Extended Data Fig. 9 Optimization of YFP and FdeR production using OptoLAC circuits.

a, YFP production when inducing at different cell densities (ρs) by switching cultures from blue light to darkness using OptoLAC1B (EMAL284, top panel) or adding IPTG (EMAL283, bottom panel). NI = Not induced: kept under blue light or no IPTG added. b, Comparison of FdeR production between OptoLAC1B (EMAL335) and OptoLAC2B (EMAL336) cultured under continuous blue light for 12 hours. c, FdeR production when inducing at different cell densities (ρs) by adding IPTG (EMAL329, top panel) or switching cultures from blue light to darkness using OptoLAC2B (EMAL336, bottom panel). NI = Not induced: kept under blue light or no IPTG added. All samples were resolved via SDS-PAGE (12% polyacrylamide). d, Tunability of YFP production using different doses of light or concentrations of IPTG, resolved and quantified via Western blot. From left to right: P = 0.0201, P = 0.000383, P = 0.000206. Loading controls and uncropped gels and blots, including those used for quantification in d (samples derived from the same experiment and processed in parallel) are provided as source data. *P < 0.05, ***P < 0.001. Statistics are derived using a two-sided t-test. All data shown as mean values; error bars represent the standard deviation of three biologically independent samples; open circles represent individual data points. Data are representative of n = 2 independent experiments.

Extended Data Fig. 10 Growth curves of B strains containing OptoLAC circuits under different induction conditions.

a, b, Time course of OD600 readings for BL21 DE3 (EMAL283; orange square), Rosetta 2 (EMAL276; green diamond), and OptoBL containing OptoLAC1B (EMAL284; black circle without IPTG, yellow circle with IPTG), containing plasmids for YFP production, grown under different induction conditions, which are shown on top of each graph as uninduced (blue) or induced (gray). a, Cultures from each strain grown under blue light before switching to the dark (OptoLAC1B) or adding IPTG. From left to right: P < 0.0122, P = 0.0946. b, Cultures grown entirely uninduced under blue light (OptoLAC1B), without IPTG, or OptoLAC1B with blue light and IPTG. From left to right: P = 0.00342, P = 0.0017. *P < 0.05, **P < 0.01. Statistics are derived using a two-sided t-test. All data shown as mean values; error bars represent the standard deviation of n = 3 biologically independent samples; open circles represent individual data points. Data are representative of n = 2 independent experiments.

Supplementary information

Supplementary Information

Supplementary Tables 1–2, Figs. 1–4 and Notes 1–9.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Source Data Fig. 5

Unprocessed western blots and gels.

Source Data Extended Data Fig. 1

Statistical source data.

Source Data Extended Data Fig. 2

Statistical source data.

Source Data Extended Data Fig. 2

Unprocessed western blots and gels.

Source Data Extended Data Fig. 3

Statistical source data.

Source Data Extended Data Fig. 4

Statistical source data.

Source Data Extended Data Fig. 5

Statistical source data.

Source Data Extended Data Fig. 7

Statistical source data.

Source Data Extended Data Fig. 8

Statistical source data.

Source Data Extended Data Fig. 9

Statistical source data.

Source Data Extended Data Fig. 9

Unprocessed western blots and gels.

Source Data Extended Data Fig. 10

Statistical source data.

Rights and permissions

About this article

Cite this article

Lalwani, M.A., Ip, S.S., Carrasco-López, C. et al. Optogenetic control of the lac operon for bacterial chemical and protein production. Nat Chem Biol 17, 71–79 (2021). https://doi.org/10.1038/s41589-020-0639-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41589-020-0639-1

This article is cited by

-

Engineered autonomous dynamic regulation of metabolic flux

Nature Reviews Bioengineering (2023)

-

An optogenetic toolkit for light-inducible antibiotic resistance

Nature Communications (2023)

-

Optimal control of bioproduction in the presence of population heterogeneity

Journal of Mathematical Biology (2023)

-

Bifunctional optogenetic switch for improving shikimic acid production in E. coli

Biotechnology for Biofuels and Bioproducts (2022)

-

Light-induced production of isobutanol and 3-methyl-1-butanol by metabolically engineered cyanobacteria

Microbial Cell Factories (2022)