Abstract

Dynamic shape-morphing soft materials systems are ubiquitous in living organisms; they are also of rapidly increasing relevance to emerging technologies in soft machines1,2,3, flexible electronics4,5 and smart medicines6. Soft matter equipped with responsive components can switch between designed shapes or structures, but cannot support the types of dynamic morphing capabilities needed to reproduce natural, continuous processes of interest for many applications7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24. Challenges lie in the development of schemes to reprogram target shapes after fabrication, especially when complexities associated with the operating physics and disturbances from the environment can stop the use of deterministic theoretical models to guide inverse design and control strategies25,26,27,28,29,30. Here we present a mechanical metasurface constructed from a matrix of filamentary metal traces, driven by reprogrammable, distributed Lorentz forces that follow from the passage of electrical currents in the presence of a static magnetic field. The resulting system demonstrates complex, dynamic morphing capabilities with response times within 0.1 second. Implementing an in situ stereo-imaging feedback strategy with a digitally controlled actuation scheme guided by an optimization algorithm yields surfaces that can follow a self-evolving inverse design to morph into a wide range of three-dimensional target shapes with high precision, including an ability to morph against extrinsic or intrinsic perturbations. These concepts support a data-driven approach to the design of dynamic soft matter, with many unique characteristics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are contained within the manuscript. Raw data are available from the corresponding authors upon reasonable request.

Code availability

The codes that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Rafsanjani, A., Bertoldi, K. & Studart, A. R. Programming soft robots with flexible mechanical metamaterials. Sci. Robot. 4, eaav7874 (2019).

McEvoy, M. A. & Correll, N. Materials that couple sensing, actuation, computation, and communication. Science 347, 1261689 (2015).

Morin, S. A. et al. Camouflage and display for soft machines. Science 337, 828–832 (2012).

Wang, C., Wang, C., Huang, Z. & Xu, S. Materials and structures toward soft electronics. Adv. Mater. 30, 1801368 (2018).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Cianchetti, M., Laschi, C., Menciassi, A. & Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 3, 143–153 (2018).

Boley, J. W., Rees, W., Lissandrello, C., Horenstein, M. N. & Mahadevan, L. Shape-shifting structured lattices via multimaterial 4D printing. Proc. Natl Acad. Sci. USA 116, 201908806 (2019).

Liu, K., Hacker, F. & Daraio, C. Robotic surfaces with reversible, spatiotemporal control for shape morphing and object manipulation. Sci. Robot. 6, eabf5116 (2021).

Guo, Y., Zhang, J., Hu, W., Khan, M. T. A. & Sitti, M. Shape-programmable liquid crystal elastomer structures with arbitrary three-dimensional director fields and geometries. Nat. Commun. 12, 5936 (2021).

Hajiesmaili, E. & Clarke, D. R. Reconfigurable shape-morphing dielectric elastomers using spatially varying electric fields. Nat. Commun. 10, 183 (2019).

Gladman, A. S., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Yu, C. et al. Electronically programmable, reversible shape change in two‐and three‐dimensional hydrogel structures. Adv. Mater. 25, 1541–1546 (2013).

Zhang, H., Guo, X., Wu, J., Fang, D. & Zhang, Y. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 4, eaar8535 (2018).

Li, S. et al. Liquid-induced topological transformations of cellular microstructures. Nature 592, 386–391 (2021).

Pikul, J. et al. Stretchable surfaces with programmable 3D texture morphing for synthetic camouflaging skins. Science 358, 210–214 (2017).

Barnes, M. et al. Reactive 3D printing of shape-programmable liquid crystal elastomer actuators. ACS Appl. Mater. Interfaces 12, 28692–28699 (2020).

Ford, M. J. et al. A multifunctional shape-morphing elastomer with liquid metal inclusions. Proc. Natl Acad. Sci. USA 116, 21438–21444 (2019).

Alapan, Y., Karacakol, A. C., Guzelhan, S. N., Isik, I. & Sitti, M. Reprogrammable shape morphing of magnetic soft machines. Sci. Adv. 6, eabc6414 (2020).

Kim, Y., Yuk, H., Zhao, R., Chester, S. A. & Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 558, 274–279 (2018).

Cui, J. et al. Nanomagnetic encoding of shape-morphing micromachines. Nature 575, 164–168 (2019).

Ze, Q. et al. Magnetic shape memory polymers with integrated multifunctional shape manipulation. Adv. Mater. 32, 1906657 (2020).

Mao, G. et al. Soft electromagnetic actuators. Sci. Adv. 6, eabc0251 (2020).

Zhang, F. et al. Rapidly deployable and morphable 3D mesostructures with applications in multimodal biomedical devices. Proc. Natl Acad. Sci. USA 118, e2026414118 (2021).

Xia, X. et al. Electrochemically reconfigurable architected materials. Nature 573, 205–213 (2019).

Fan, Z. et al. Inverse design strategies for 3D surfaces formed by mechanically guided assembly. Adv. Mater. 32, 1908424 (2020).

Choi, G. P., Dudte, L. H. & Mahadevan, L. Programming shape using kirigami tessellations. Nat. Mater. 18, 999–1004 (2019).

Bossart, A., Dykstra, D. M., van der Laan, J. & Coulais, C. Oligomodal metamaterials with multifunctional mechanics. Proc. Natl Acad. Sci. USA 118, e2018610118 (2021).

Baek, C., Martin, A. G., Poincloux, S., Chen, T. & Reis, P. M. Smooth triaxial weaving with naturally curved ribbons. Phys. Rev. Lett. 127, 104301 (2021).

Coulais, C., Sabbadini, A., Vink, F. & van Hecke, M. Multi-step self-guided pathways for shape-changing metamaterials. Nature 561, 512–515 (2018).

Guseinov, R., McMahan, C., Pérez, J., Daraio, C. & Bickel, B. Programming temporal morphing of self-actuated shells. Nat. Commun. 11, 237 (2020).

Kaspar, C., Ravoo, B. J., van der Wiel, W. G., Wegner, S. V. & Pernice, W. H. P. The rise of intelligent matter. Nature 594, 345–355 (2021).

Hu, W., Lum, G. Z., Mastrangeli, M. & Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 554, 81–85 (2018).

Overvelde, J. T., Weaver, J. C., Hoberman, C. & Bertoldi, K. Rational design of reconfigurable prismatic architected materials. Nature 541, 347–352 (2017).

Waters, J. T. et al. Twist again: dynamically and reversibly controllable chirality in liquid crystalline elastomer microposts. Sci. Adv. 6, eaay5349 (2020).

Wang, Y. et al. Repeatable and reprogrammable shape morphing from photoresponsive gold nanorod/liquid crystal elastomers. Adv. Mater. 32, 2004270 (2020).

Xu, C., Yang, Z. & Lum, G. Z. Small-scale magnetic actuators with optimal six degrees-of-freedom programming temporal morphing of self-actuated shells. Adv. Mater. 33, 2100170 (2021).

Phelan, M. F. III, Tiryaki, M. E., Lazovic, J., Gilbert, H. & Sitti, M. Heat‐mitigated design and lorentz force‐based steering of an MRI‐driven microcatheter toward minimally invasive surgery. Adv. Sci. 9, 2105352 (2022).

Kotikian, A. et al. Innervated, self‐sensing liquid crystal elastomer actuators with closed loop control. Adv. Mater. 33, 2101814 (2021).

Wang, X. et al. Freestanding 3D mesostructures, functional devices, and shape-programmable systems based on mechanically induced assembly with shape memory polymers. Adv. Mater. 31, 1805615 (2019).

Wang, Y., Li, L., Hofmann, D., Andrade, J. E. & Daraio, C. Structured fabrics with tunable mechanical properties. Nature 596, 238–243 (2021).

Zhang, B. et al. Short-term oscillation and falling dynamics for a water drop dripping in quiescent air. Phys. Rev. Fluids 4, 123604 (2019).

Tang, C. et al. Dynamics of droplet impact on solid surface with different roughness. Int. J. Multiph. Flow 96, 56–69 (2017).

Acknowledgements

Y.B., Y.P. and Xiaoyue Ni acknowledge funding support from the Pratt School of Engineering and School of Medicine at Duke University. Y.H. acknowledges support from the NSF (grant no. CMMI 16-35443). This work was performed in part at the Duke University Shared Materials Instrumentation Facility, a member of the North Carolina Research Triangle Nanotechnology Network, which is supported by the National Science Foundation (award no. ECCS-2025064) as part of the National Nanotechnology Coordinated Infrastructure. Xiaoyue Ni thanks L. Bridgeman, J. Lu and Z. Wang for helpful discussions.

Author information

Authors and Affiliations

Contributions

Y.B., H.W., Y.H., J.A.R. and Xiaoyue Ni conceived the idea and designed the research. Y.B. and Y.Y. fabricated the samples. Y.B., Y.X., Y.P., J.-T.K., Xinchen Ni, T.-L.L., M.H. and Xiaoyue Ni performed the experiments. H.W. and Y.H. performed the finite-element modelling and theoretical study. Y.B. and Xiaoyue Ni analysed the experimental data. Y.B., H.W., Y.H., J.A.R. and Xiaoyue Ni wrote the manuscript, with input from all co-authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Guo Zhan Lum and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 The analytical model of the electromagnetic response of a serpentine beam corroborated by FEA study and experimental characterizations.

a, Schematic illustration (top and cross-sectional views) of the initial state of a serpentine beam (beam width H = 1.20 mm, serpentine period λ = 0.18 mm). b, Analytical model and FEA prediction of the maximum out-of-plane displacement u dependent on the combination of electric current I, magnetic field B, and material and geometry parameters. c, Schematic illustration of a single beam, placed in a magnetic field B and carrying a current density J with an out-of-plane displacement u, under an electromagnetic force FEM = J × B. d, Optical images of a representative serpentine beam (side view) driven to the maximum displacement u. If exceeding the elastic limit, an irreversible deformation u’ will remain after unloading. e–g, Experimental characterizations of mechanical (e, f) and thermal (g) behaviors of a single beam under current-controlled electromagnetic actuation (B = 224 mT) in comparison with the theoretical predictions. Scale bar, 1 mm.

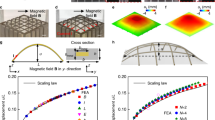

Extended Data Fig. 2 Experimental validation of the scaling law using a single serpentine beam.

a, Top-view optical images of serpentine beams with the same beam length (L = 11 mm) but different beam widths (H = 0.84 mm, 1.20 mm, 1.56 mm). In a magnetic field of 224 mT, current-controlled experiments show that the electromagnetic responses of the beams with various PI thicknesses (hPI = 5.0 μm, 7.5 μm, 12.0 μm) agree with the analytical solutions. b, Experimentally measured electromagnetic responses follow the scaling law predicted by the analytical model. c, Side-view optical images of a serpentine beam of the design presented in the main text (H = 1.20 mm, hPI = 7.5 μm) actuated in a magnetic field of 224 mT (left) and a tailored serpentine beam (H = 1.56 mm, hPI = 5.0 μm) actuated in a reduced magnetic field of 25 mT (right). Applying the same current (15 mA) deforms the two beams to the same height (around 2.25 mm). d, The two beams in (c) exhibit approximately the same current-controlled mechanical behavior. Scale bars, 1 mm.

Extended Data Fig. 3 Shape morphing in time-varying, non-uniform magnetic fields.

a, Schematic illustration of a single serpentine beam in a non-uniform magnetic field generated by a small disk magnet (diameter D = 11.0 mm, thickness h = 5.0 mm, surface field B = 481.6 mT) moving 3-mm below the beam (ΔZ = −3 mm). b, c, Optical images of the beam (applied current I = 20 mA) changing shapes as the position of the magnet changes along X-axis (b, ΔY = 0) and Y-axis (c, ΔX = 0). Scale bars, 1 mm. d, Schematic illustration of a 4 × 4 sample in a non-uniform magnetic field generated by a pair of large magnets (D = 76.2 mm, h = 12.7 mm, surface field B = 245.1 mT) and a small magnet (D = 11.0 mm, h = 5.0 mm, surface field B = 481.6 mT) in the middle, 3.0 mm below the center of the sample. e, Magnetic flux density in X-direction (BX) of the approximately uniform/non-uniform field measured by a gaussmeter (GMHT201, Apex Magnets) with/without the presence of the small magnet across the center (O) along X-axis (left) and Y-axis (right). f, Experimental results (optical images and 3D reconstructed surfaces) of a 4×4 sample morphing into the same donut-like target shape via the experiment-driven self-evolving process in the uniform and the non-uniform magnetic field. Scale bars, 5 mm.

Extended Data Fig. 4 Typical descent of loss function over function evaluations.

a–c, For a 4×4 sample morphing into Shape I (a), III (b), IV (c) (Supplementary Note 8) through the experiment-driven approach using the gradient-based algorithm (see Methods section ‘Optimization algorithm’), the experimentally-measured loss function f(V) (with an initial value f(V = 0) in the range of 0.05-0.35) descends by ~99.5% to a steady state in 170–510 function evaluations (5-15 iterations). The 3D imaging noise is δu = 0.016 mm (Supplementary Note 14). d–f, Comparison of a global solver (pattern search algorithm) with the gradient-based algorithm for a 4×4 sample morphing into Shape IV using model-driven simulation. Subjecting the objective function to typical experimental noise (δu = 0.016 mm, Supplementary Note 14) and targeting a final loss of 0.005f(V = 0), the gradient-based algorithm finds the solution faster than the global solver (d). Both algorithms settle to a minimum loss of 0.0006f(V = 0) within 20,000 function evaluations (e). With pronounced noise (δu = 0.16 mm), the gradient descent method ends up with a local solution (0.08f(V = 0)), while the pattern search method finds the same minimum (0.0006f(V = 0)) as the case with low noise (f).

Extended Data Fig. 5 Experiment-driven self-evolving process in comparison with the model-driven approach.

a, Target explicit shapes and optical images of the experiment-driven morphing results of a 4×4 sample. b, 3D reconstructed surfaces overlaid with contour plots of the minimized errors. c, Histogram plots of the minimized errors for model-driven and experiment-driven outputs. Scale bars, 5 mm.

Extended Data Fig. 6 Simulation of the impact of experimental noise on the optimization process.

a, Comparison between the distribution of final loss f0 after 15 iterations from model-driven simulations (1,000 trials, given 3D imaging noise δu = 0.016 mm, 12-bit PWM output, and maximum current Imax = 27 mA) versus that from the experiments (97 trials), for a 4×4 sample morphing into the target shape in Fig. 3b. b, Simulation results of the final loss f0 (without imaging noise and iteration constraint) given n-bit PWM voltage control, compared with the case without actuation noise (continuous, analog voltage control). c–f, Histogram plots of the final loss f0 (1,000 simulation trials) with a decreasing 3D imaging noise δu = 0.024 mm (c), 0.016 mm (d), 0.008 mm (e) and 0.004 mm (f).

Extended Data Fig. 7 The optical images of a 2 × 2 sample with modified serpentine design for amplified nonlinear mechanical behavior in response to a range of actuation voltages.

a–d, Side-view images of the sample deforming out-of-plane given an increasing voltage to port 1 (Fig. 4a) given V1 = 0 V (a), 0.25 V (b), 2.75 V (c), and 3 V (d), respectively. The rate of change of u1 decreases as the actuation voltage increases. Scale bar, 5 mm.

Extended Data Fig. 8 Self-evolving shape morphing toward semi-real-time shape learning.

a, Schematic illustration of a duplicated stereo-imaging setup enabling a semi-real-time control of a 4×4 sample simulating the dynamic shape-shifting of a palm surface with 4×4 markers (with inter-spacing a0 = 15 mm). b, Experimental results of the continuous semi-real-time shape learning of the palm surface with the thumb moving up. c, Morphing results of representative frames from a recording of hand making eight gestures. Scale bars, 5 mm.

Extended Data Fig. 9 A 3×3 reflective sample self-evolving to achieve an optical and a structural function simultaneously.

a, Representative optical images of the laser spots on the receiving screen. The target optical function is to overlap two laser spots on the receiving screen. A customized image analysis method detects the centroid coordinates of the red/green laser spots to monitor their current locations on the screen ([xr/g, yr/g]). b, The typical evolution of loss functions (Supplementary Note 16) over number of functional evaluations. The optimized loss function (fmulti(V)) is a linear combination of two parts: I) an optical loss function fopt(V) that evaluates the distance between the center of the two laser spots; II) a structural loss function fstruct(V) that evaluates the central nodal displacement error. Scale bar, 5 mm.

Extended Data Fig. 10 Allowed shape (structural function) configurations of a 3×3 sample enforcing only the optical function (Fig. 5c, d).

a, Allowed values of the central nodal displacement (u5) when the sample overlaps the beams (when the distance between the centroids of the laser spots is less than 0.1 mm) with three distinctive incident angles. b, Model predictions, and the ex-situ 3D imaging results of the sample (cross-sectional view) when overlapping the laser spots in the configurations with the highest, lowest, and target central displacement.

Supplementary information

Supplementary Information

Supplementary notes, figures, table, video legends and references.

41586_2022_5061_MOESM4_ESM.mp4

Supplementary Video 2. The target shapes and slow-motion video in Supplementary Video 2 were reconstructed and reproduced with permission from supplementary video 1 (00:00:15–00:04:23, 0.6× playback) in ref. 42 (Elsevier).

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bai, Y., Wang, H., Xue, Y. et al. A dynamically reprogrammable surface with self-evolving shape morphing. Nature 609, 701–708 (2022). https://doi.org/10.1038/s41586-022-05061-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-05061-w

This article is cited by

-

Embedded shape morphing for morphologically adaptive robots

Nature Communications (2023)

-

A multifunctional soft robotic shape display with high-speed actuation, sensing, and control

Nature Communications (2023)

-

Coaxially printed magnetic mechanical electrical hybrid structures with actuation and sensing functionalities

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.